A non-modulated steel using tellurium to control the morphology of sulfide inclusions and its manufacturing method

A sulfide, non-modulated technology, applied in the field of non-modulated steel and its manufacturing, can solve the problems of difficult operation, low yield, high tellurium element, etc., and achieve the effect of reducing deformation, improving cutting performance and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: A non-modulated steel using tellurium to control the sulfide inclusion form, using a 100-ton EAF electric arc furnace to smelt → LF refining → VD furnace vacuum treatment, after vacuum degassing in the VD furnace, add a core coating to the molten steel A 0.3-0.5mm iron sheet-wrapped tellurium-manganese alloy cored wire is used to adjust the form of MnS inclusions, and the content of tellurium in the cored wire is 30% by mass percentage. .

[0049] Specifically, in this embodiment, the elemental composition of the non-modulated steel contains C: 0.38%, Si: 0.50%, Mn: 1.20%, S: 0.041%, Cr: 0.15%, Ni: 0.02%, Mo : 0.03%, Te: 0.0050%, and the balance is iron and unavoidable impurities. Te / S=0.12, ω[Mn] / ω[S]=29.

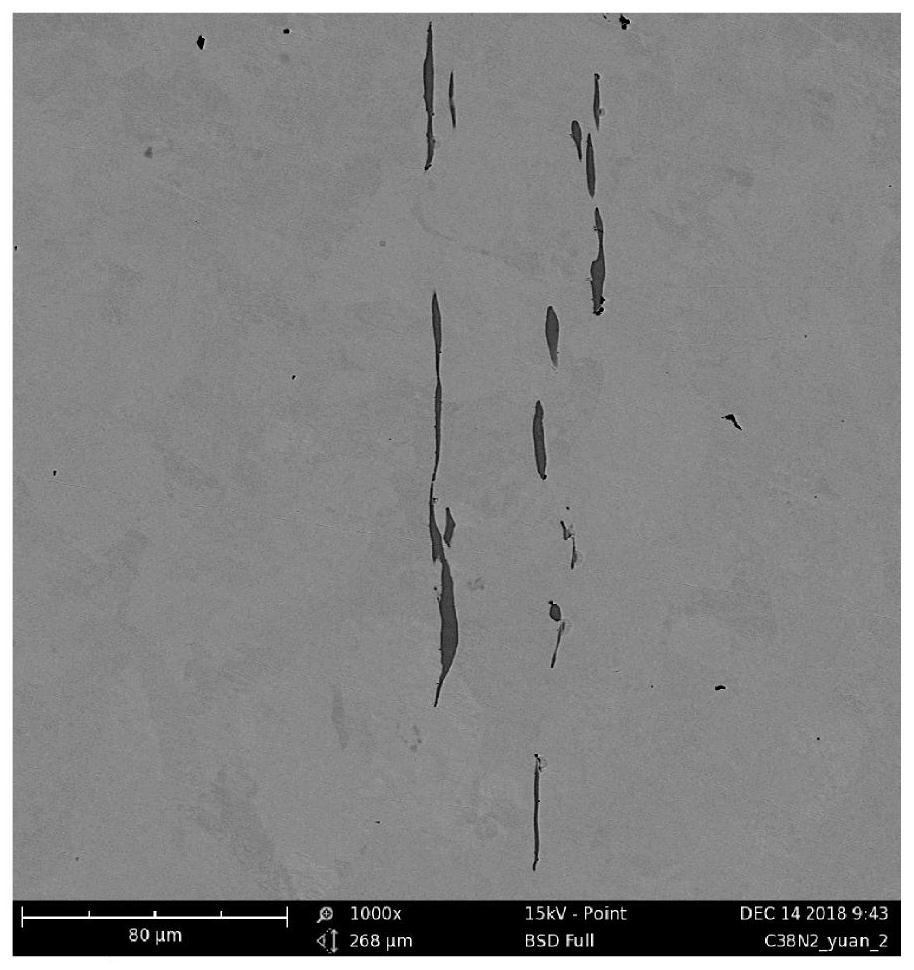

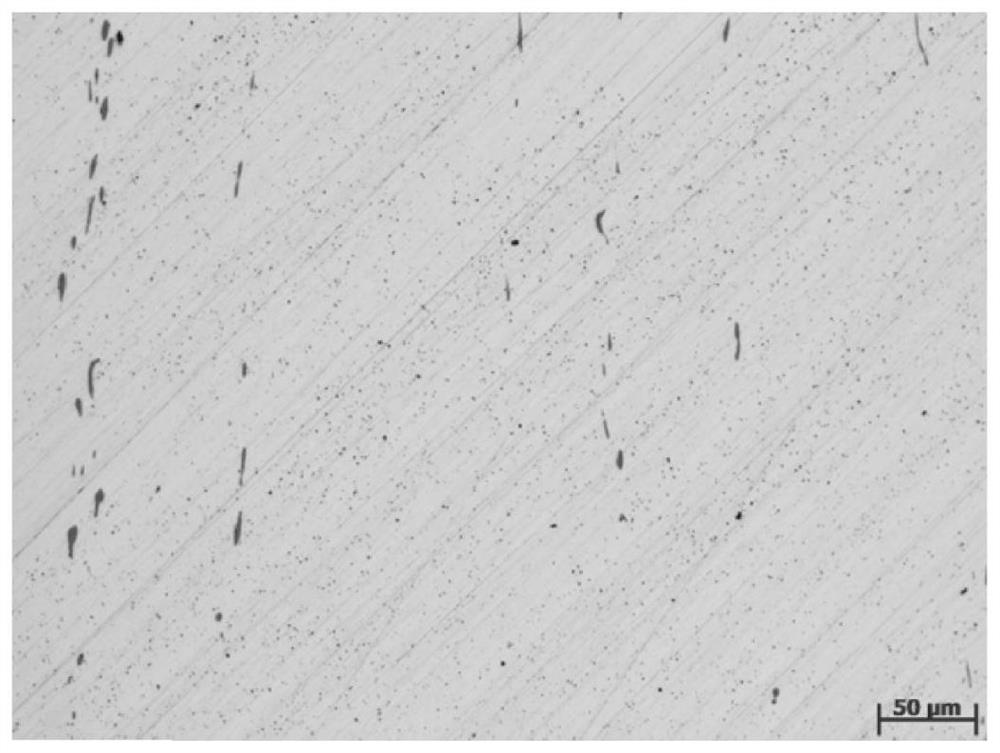

[0050] The obtained non-tempered steel was analyzed, the MnS morphology after rolling was detected, and compared with the MnS inclusions in the traditional Te-free rolling material. The macroscopic distribution of MnS in the metallography of traditiona...

Embodiment 2

[0052] Example 2: A non-modulated steel using tellurium to control the sulfide inclusion form, using a 100-ton EAF electric arc furnace for smelting→LF refining→VD furnace vacuum treatment, after vacuum degassing in the VD furnace, add a core coating to the molten steel A 0.3-0.5 mm iron-wrapped tellurium-manganese alloy cored wire is used to adjust the form of MnS inclusions, and the content of tellurium in the cored wire is 60% by mass percentage. .

[0053] Specifically, in this embodiment, the element composition of the non-modulated steel contains C: 0.37%, Si: 0.48%, Mn: 1.35%, S: 0.041%, Cr: 0.17%, Ni: 0.01%, Mo : 0.02%, Te: 0.012%, and the balance is iron and unavoidable impurities. Te / S=0.29, ω[Mn] / ω[S]=33.

[0054] The obtained non-tempered steel was analyzed, the MnS morphology after rolling was detected, and compared with the MnS inclusions in the traditional Te-free rolling material. In this example, the macro distribution of MnS inclusions in the metallographi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com