A 7a09 aluminum alloy long-wall deep-rib box-shaped ball-head rocker arm isothermal forging forming mold and method

A technology of isothermal forging and forming die, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of coarse grains, disordered flow lines, unqualified shape and size of aluminum alloy forgings, etc. The effect of good internal organization performance, improved mold design and high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

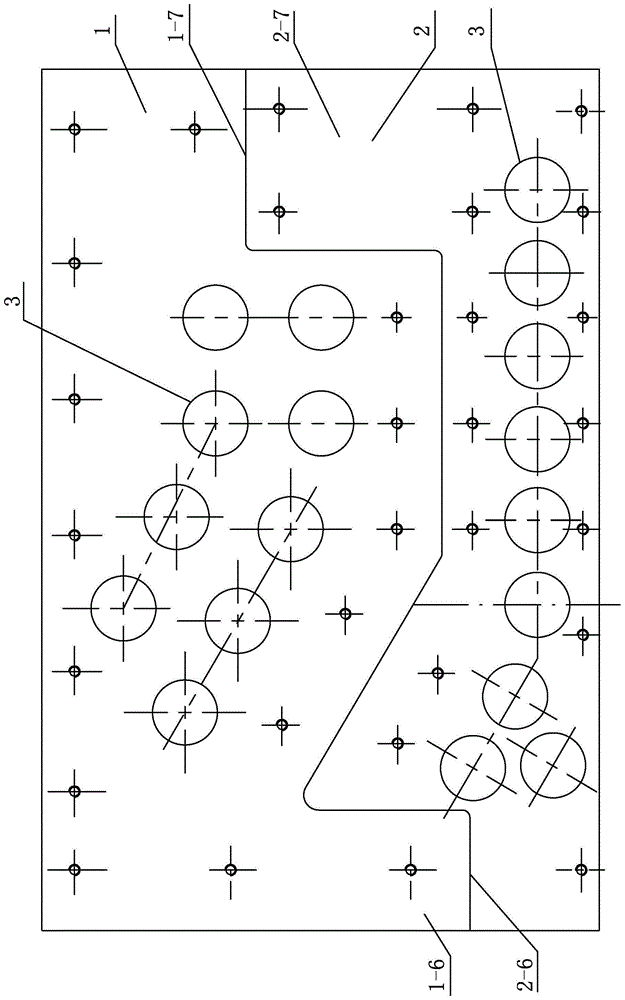

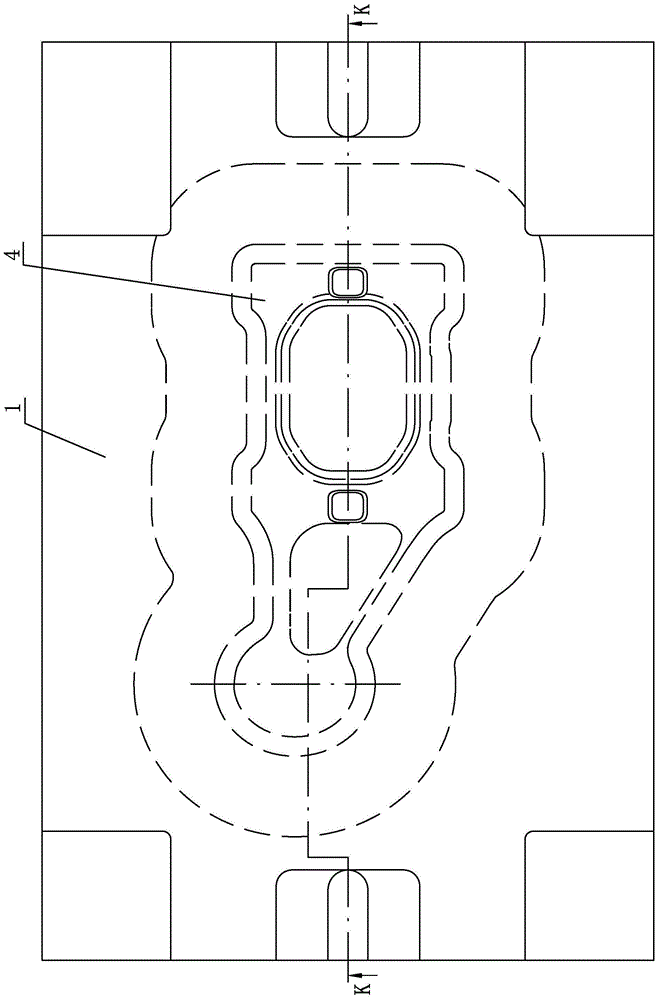

[0031] Specific implementation mode one: combine Figure 1-Figure 17 Explain, a kind of 7A09 aluminum alloy long-walled deep-rib box-shaped ball-head rocker arm isothermal die forging forming mold of the present embodiment, it comprises upper die 1, lower die 2 and a plurality of electric heating coils 3;

[0032] The lower surface of the upper mold 1 has an upper mold horizontal plane 1-1 and an upper mold inclined plane 1-2, the upper mold inclined plane 1-2 is inclined upwardly, and the upper mold horizontal plane 1-1 and the upper mold inclined plane 1-2 are provided with integrally formed The upper half cavity 1-3, the cavity on the horizontal plane 1-1 of the upper die is processed with an upper half protrusion 1-4 extending downward;

[0033] The upper surface of the lower mold 2 has a lower mold horizontal plane and a lower mold slope, the lower mold slope is in the same direction as the upper mold slope 1-2, and the lower mold horizontal plane and the lower mold slope...

specific Embodiment approach 2

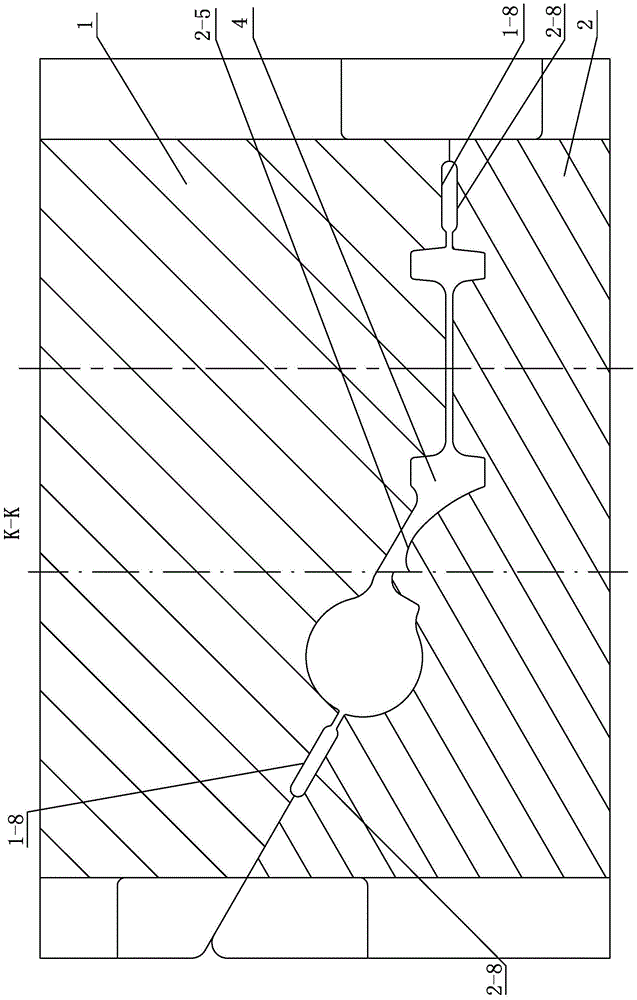

[0035] Specific implementation mode two: combination image 3 and Figure 11-Figure 12 Explain that the rib 2-5 in this embodiment is a rib that gradually protrudes outward from the horizontal surface of the lower die in the direction of the inclined surface of the lower die, and the curve from the low end to the top end of the cross section of the rib 2-5 is an arc curve with a smooth transition . Such setting meets the design requirements and the actual need for forming a long-wall deep-rib box-shaped ball rocker arm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific implementation mode three: combination figure 1 , image 3 , Image 6 with Figure 12 Description, the two corners of the upper mold slope 1-2 in this embodiment are provided with downwardly extending upper mold positioning columns 1-6, and the two corners of the upper mold horizontal plane 1-1 are provided with upwardly recessed upper mold steps 1- 7. The two corners of the horizontal plane of the lower mold are provided with upwardly extending lower mold positioning columns 2-7, and the two corners of the inclined surface of the lower mold are provided with downwardly recessed lower mold steps 2-6, and the lower surface of the upper mold 1 There is a circle of upper mold sealing grooves 1-8 on the upper surface, and a circle of lower mold sealing grooves 2-8 is processed on the upper surface of the lower mold 2. The upper mold sealing grooves 1-8 and the lower mold sealing grooves 2-8 are formed Sealing cavity, the upper mold 1 is sealed and closed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com