A kind of water-emulsified polydimethylsiloxane functional sponge and its preparation method and application

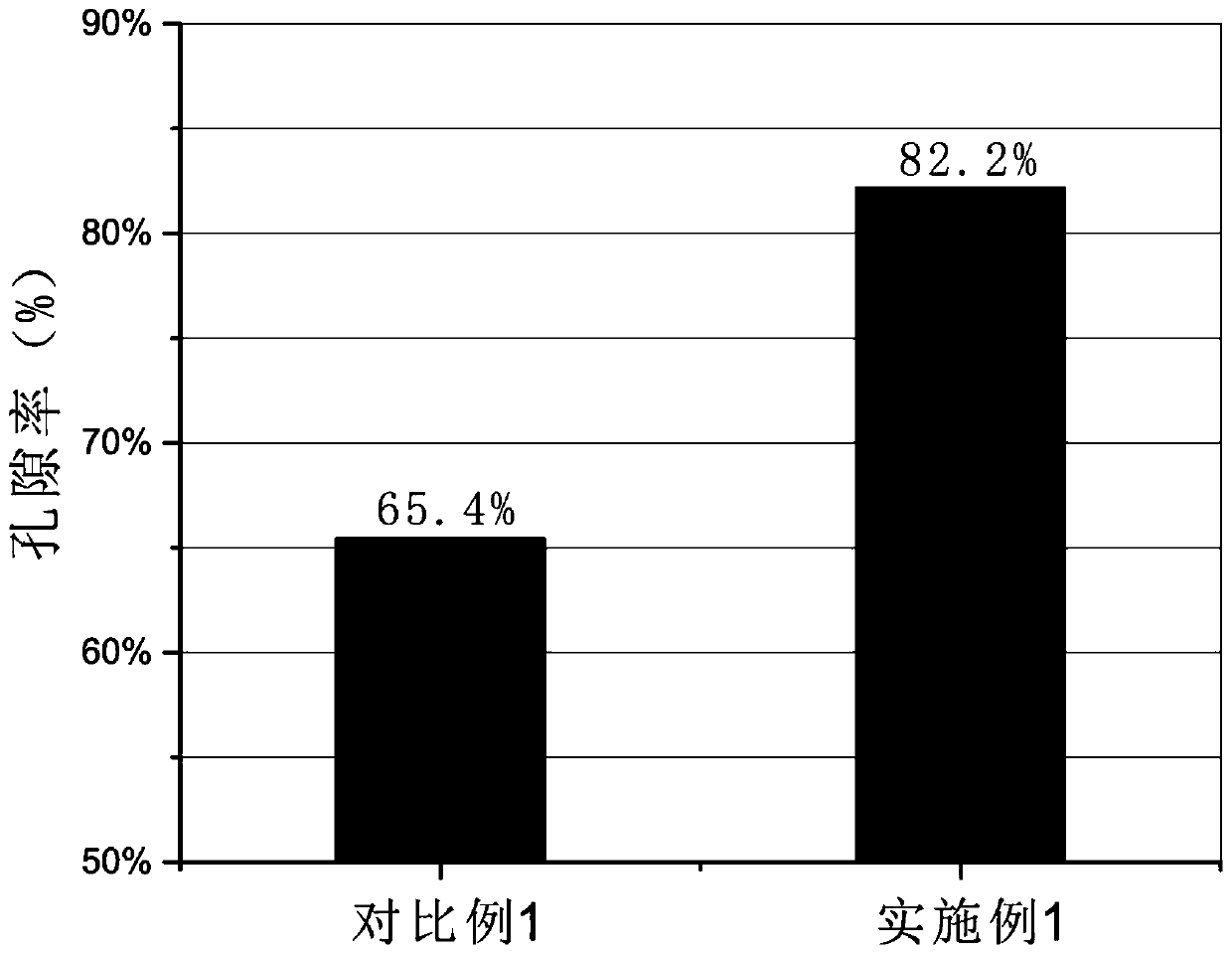

A dimethylsiloxane, water emulsification technology, applied in chemical instruments and methods, separation methods, liquid separation and other directions, can solve the problems of uneven pores, small modules, and easy particle aggregation of functional sponges, and achieve adsorption. The effect of fast speed, high adsorption capacity and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

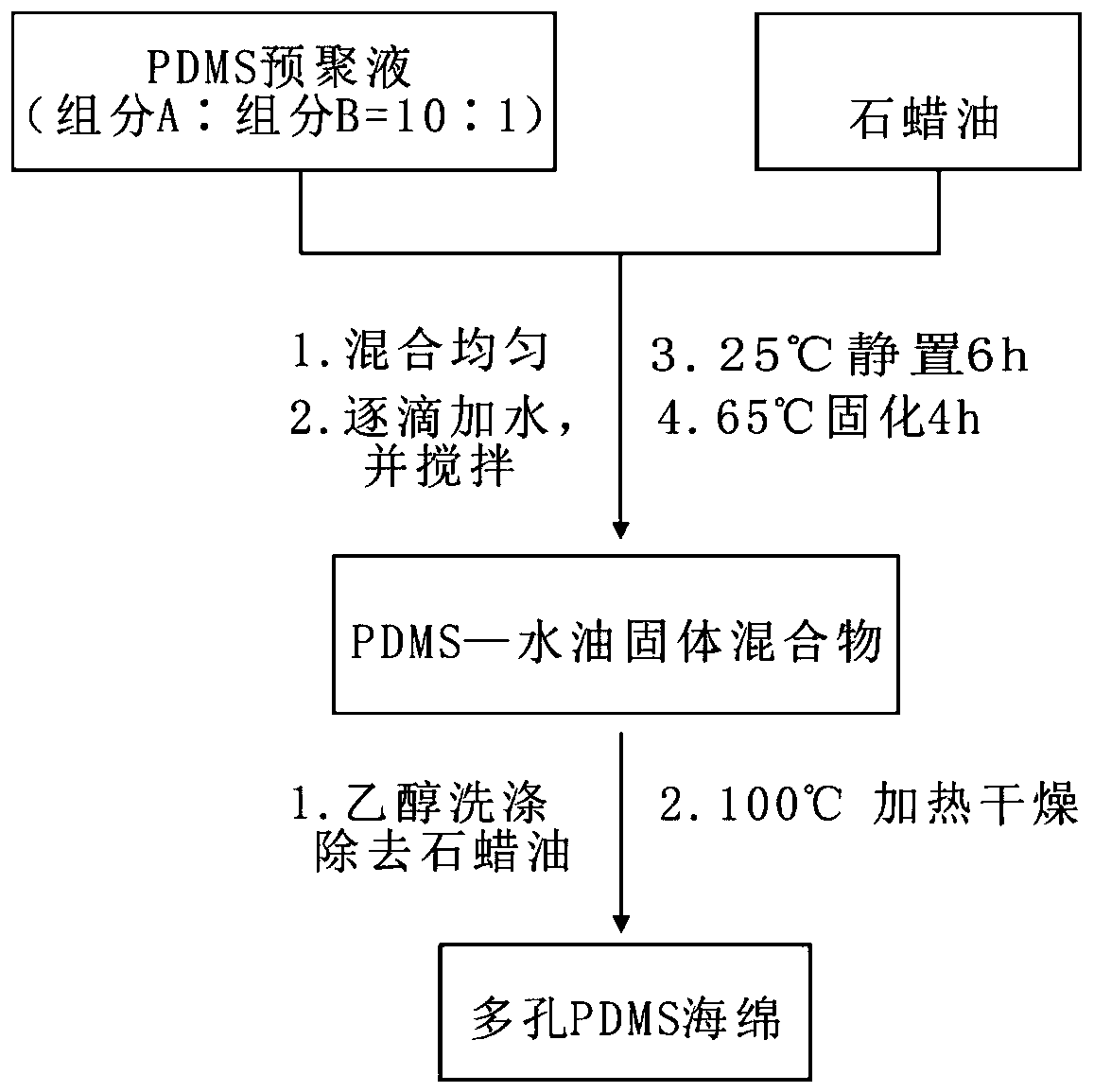

[0040] The preparation of embodiment 1 sample is carried out as follows:

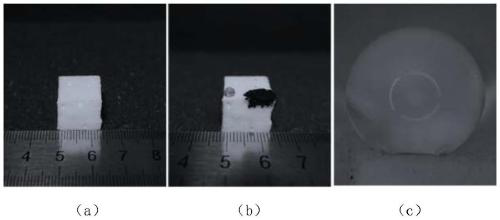

[0041] First, clean the mold and dry it for later use. The preparation process is as figure 1 As shown, first weigh 5 g of PDMSSylgard component A and component B according to the mass ratio of 10:1 and pour it into a beaker, and then weigh 7.5 g of paraffin oil and add it, and stir it with a glass rod for about 2 minutes to ensure uniform mixing; then Add 40g of water drop by drop, stir with a glass rod while adding water until it is completely emulsified, and then pour it into the mold. After standing at room temperature for 6 hours, it was placed in a drying oven at 65° C. for 4 hours to cure. After demoulding, the obtained product was ultrasonically cleaned several times with absolute ethanol and ultrapure water to remove residual paraffin oil. Finally, place it in a drying oven at 100°C to dry and remove water for 6 hours to obtain a three-dimensional porous PDMS sponge. In the present inventio...

Embodiment 2

[0043] The preparation of embodiment 2 samples is carried out as follows:

[0044] First, clean the mold and dry it for later use. Weigh 5 g of PDMS Sylgard component A and component B according to the mass ratio of 10:1 and pour it into a beaker, and add 1 g of paraffin oil into it, and stir it with a glass rod for about 2 minutes to ensure uniform mixing; then add 19 g of water drop by drop , stir with a glass rod while adding water until fully emulsified, then pour it into molds. After standing at room temperature for 6 hours, it was placed in a drying oven at 65° C. for 4 hours to cure. After demoulding, the obtained product was ultrasonically cleaned several times with absolute ethanol and ultrapure water to remove residual paraffin oil. Finally, place it in a drying oven at 100°C to dry and remove water for 6 hours to obtain a three-dimensional porous PDMS sponge.

Embodiment 3

[0046] The preparation of embodiment 3 sample is carried out as follows:

[0047] First, clean the mold and dry it for later use. According to the mass ratio of 10:1, weigh 5g of PDMS Sylgard component A and component B into a beaker, and add 2g of paraffin oil into the beaker, stir well with a glass rod for about 2min to ensure uniform mixing; then add 22g of water drop by drop , stir with a glass rod while adding water until fully emulsified, then pour it into molds. After standing at room temperature for 6 hours, it was placed in a drying oven at 65° C. for 4 hours to cure. After demoulding, the obtained product was ultrasonically cleaned several times with absolute ethanol and ultrapure water to remove residual paraffin oil. Finally, place it in a drying oven at 100°C to dry and remove water for 6 hours to obtain a three-dimensional porous PDMS sponge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com