Patents

Literature

418results about How to "Shape adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

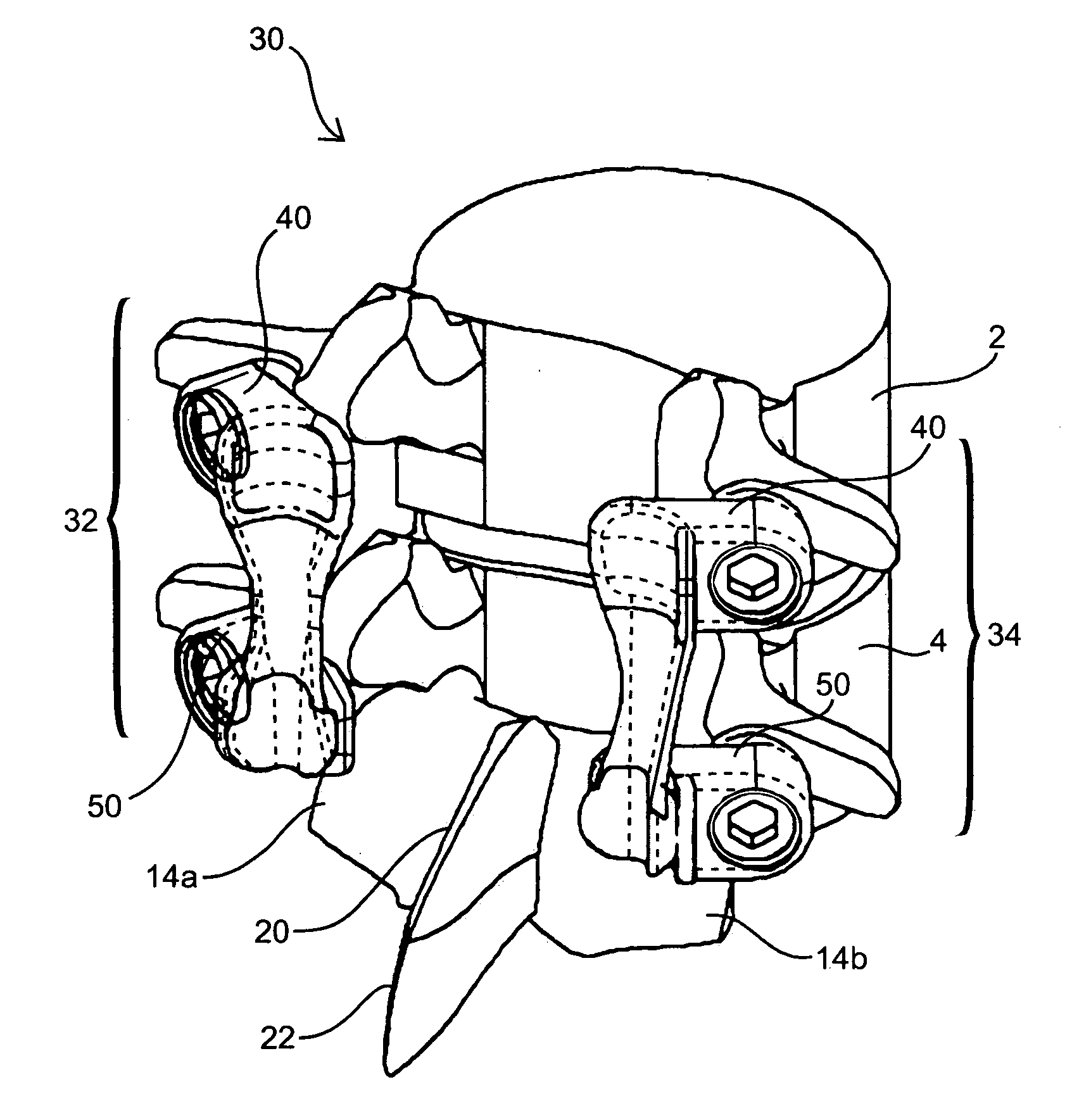

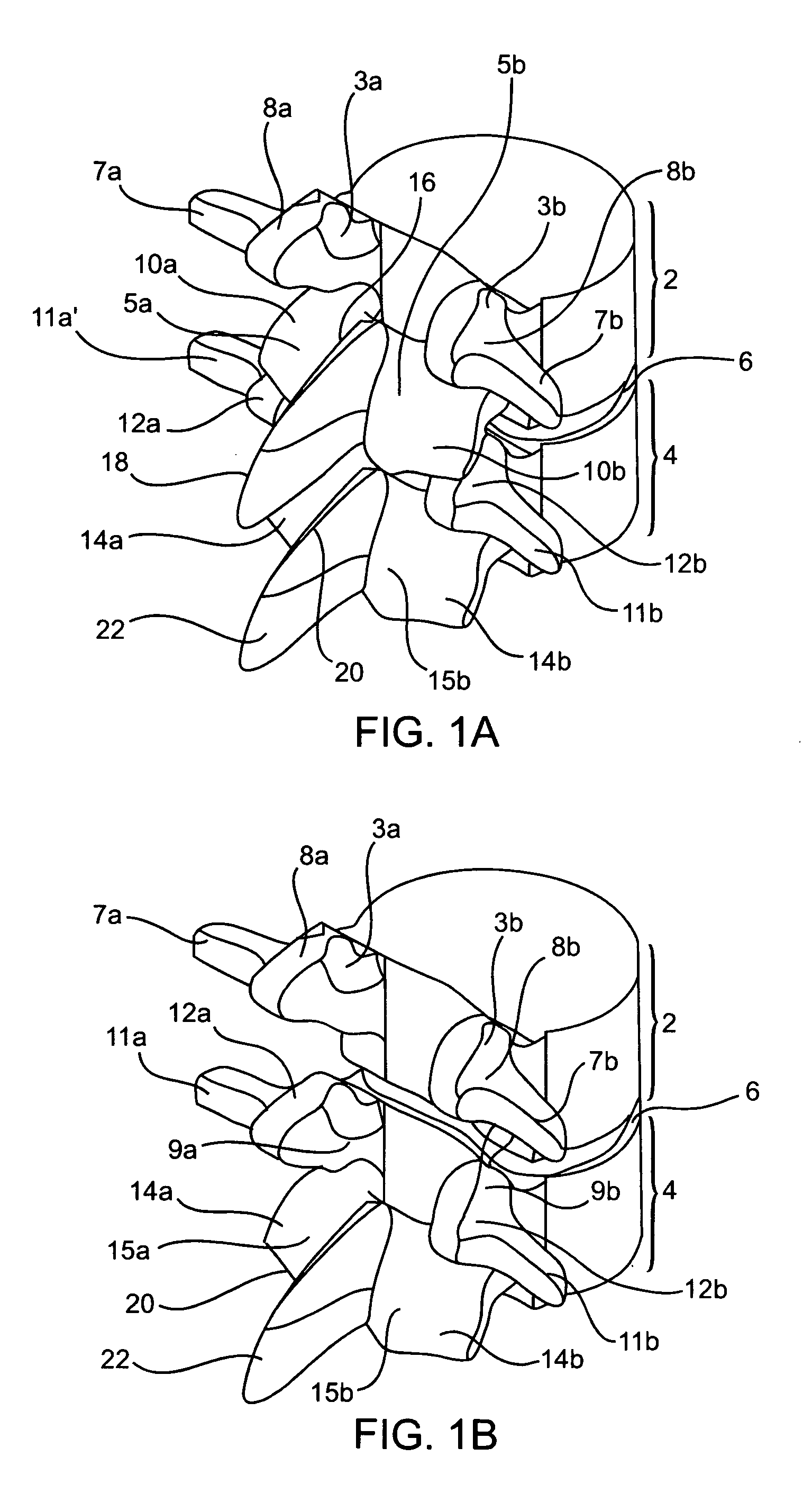

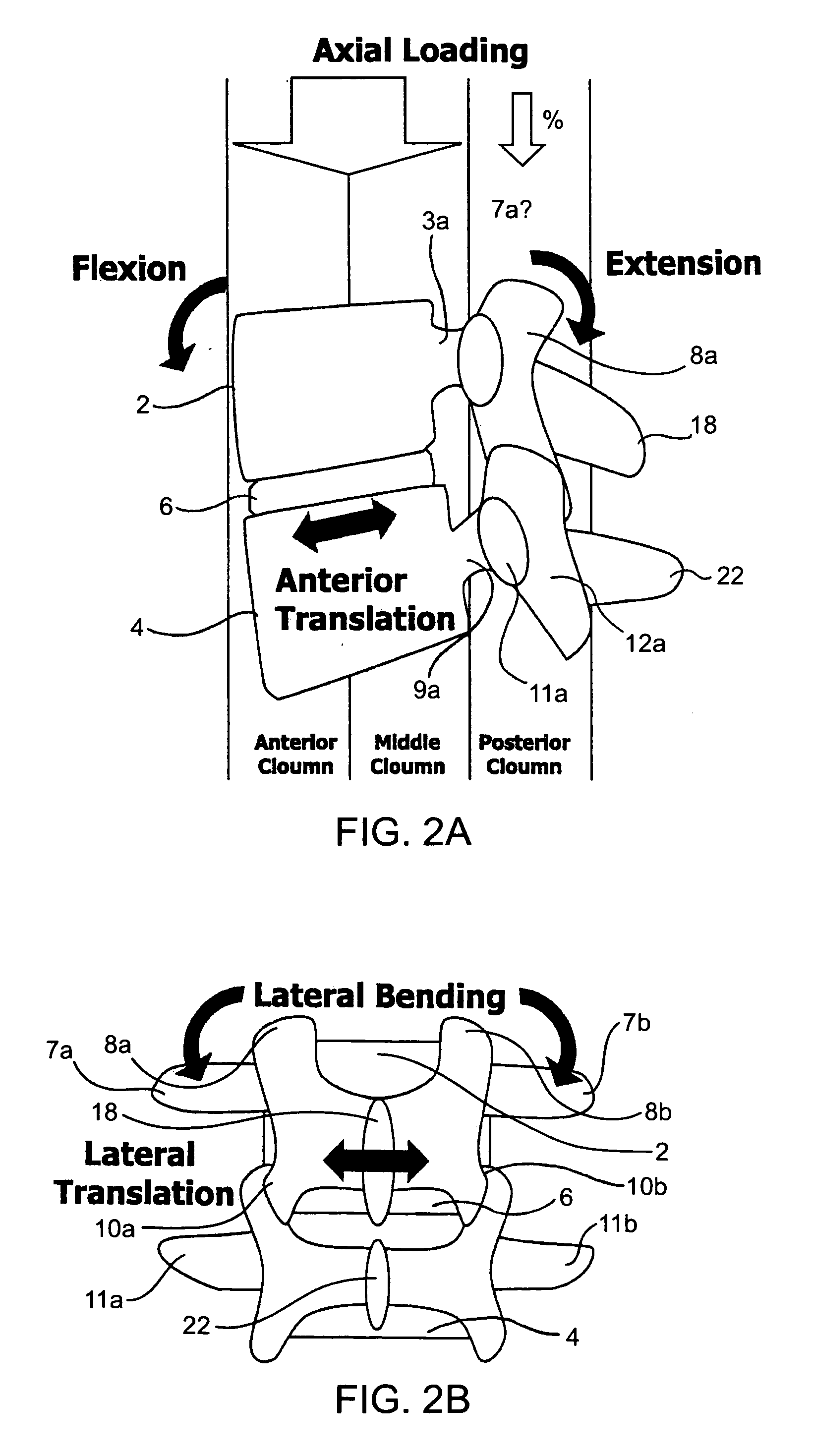

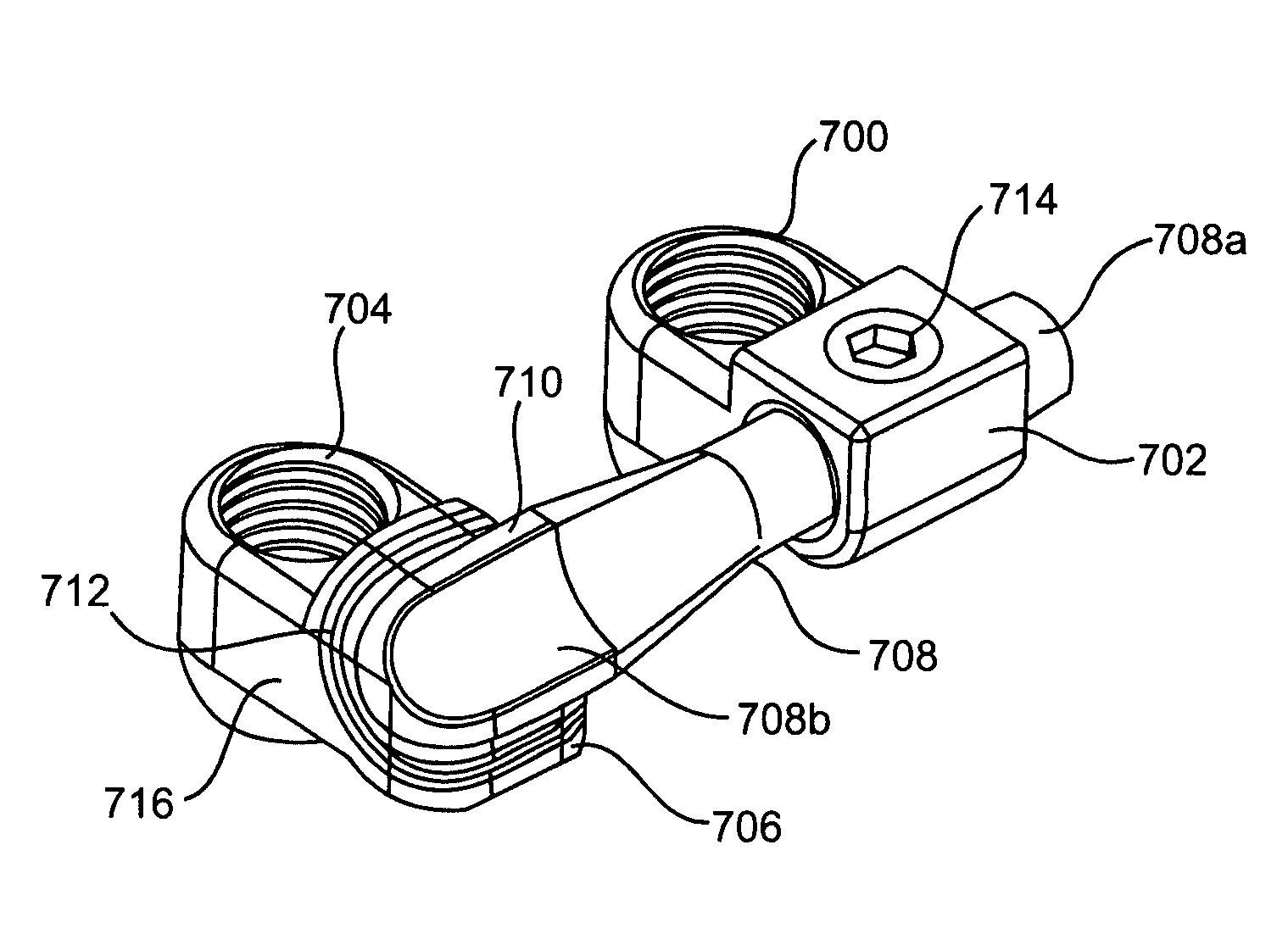

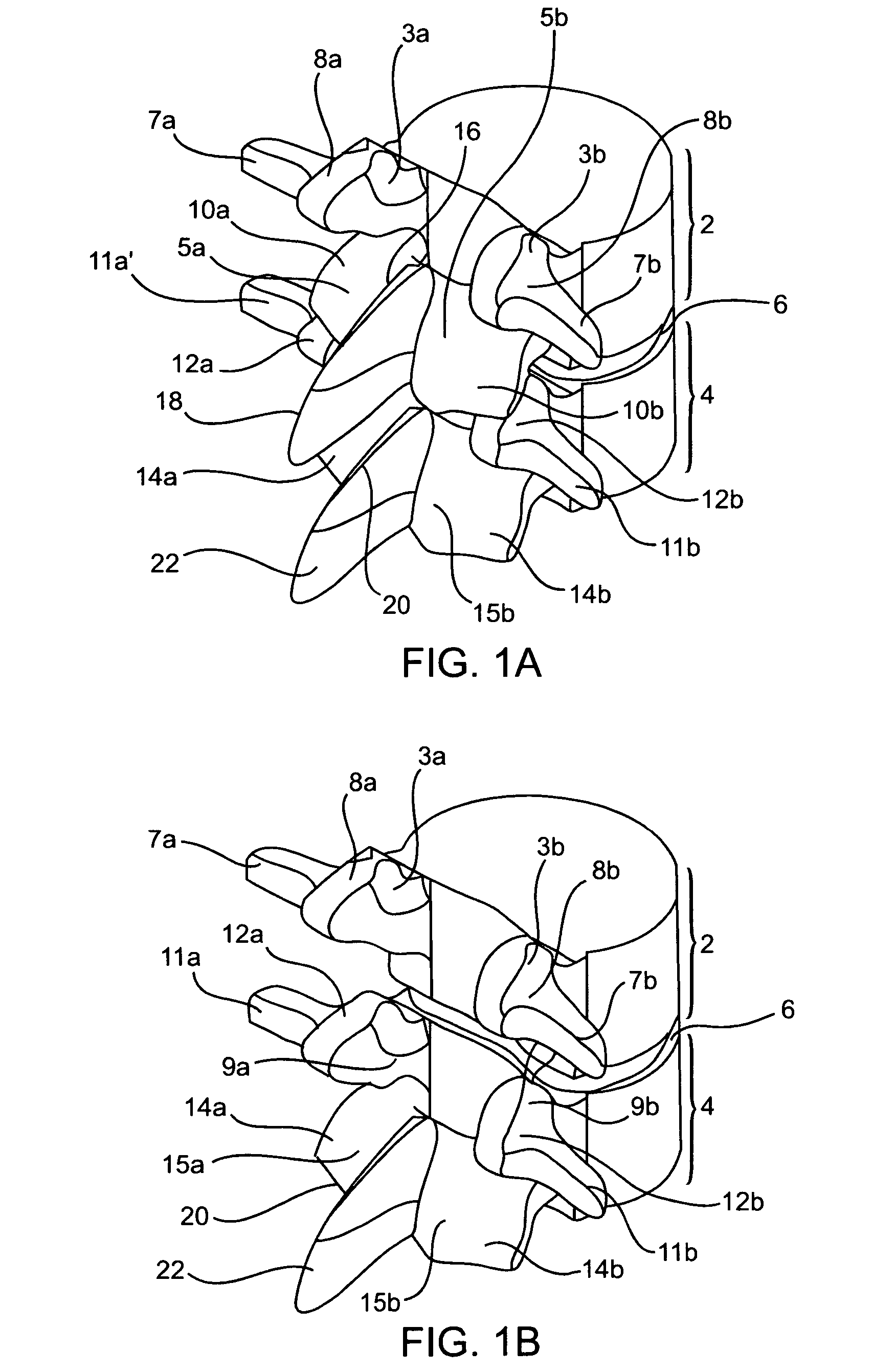

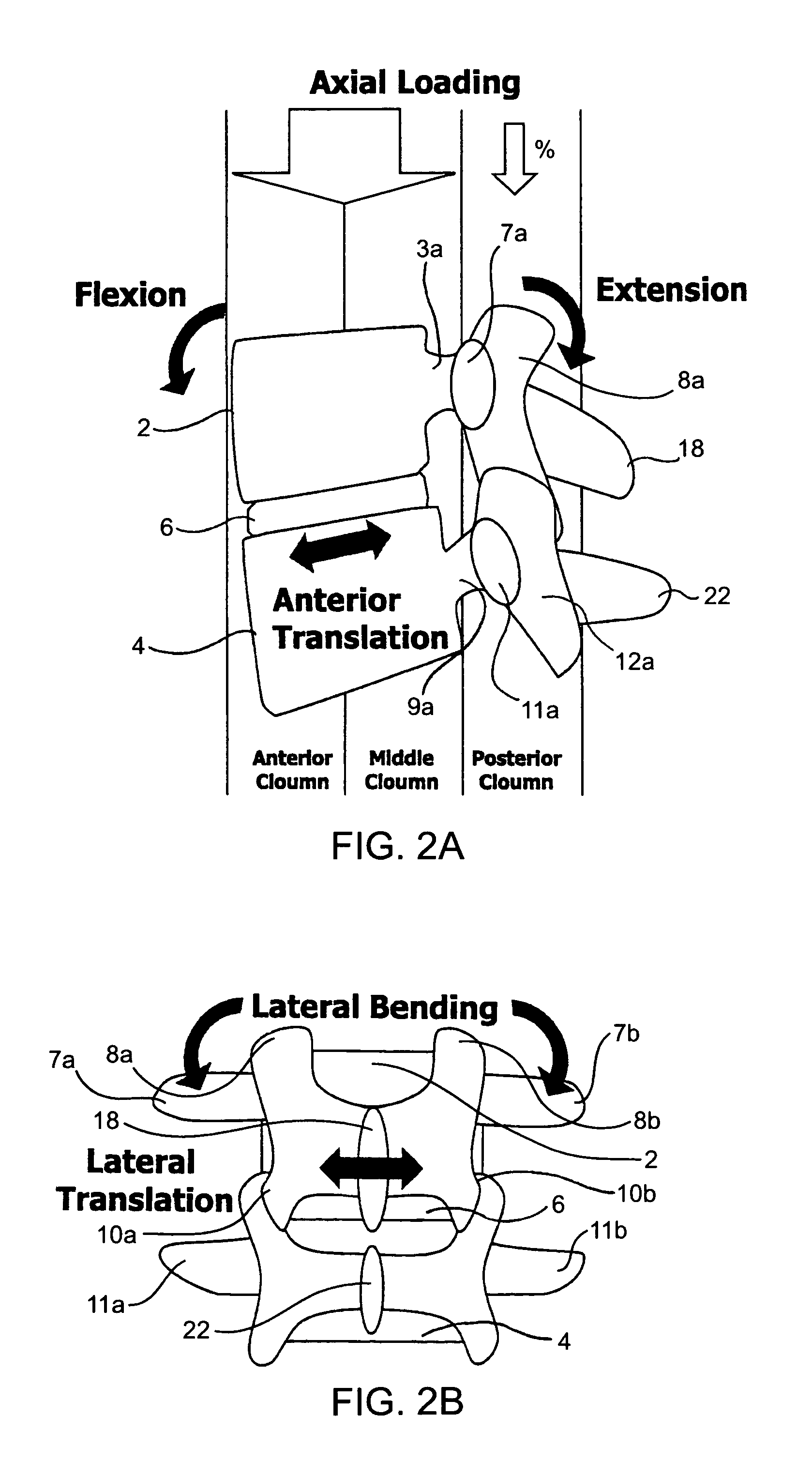

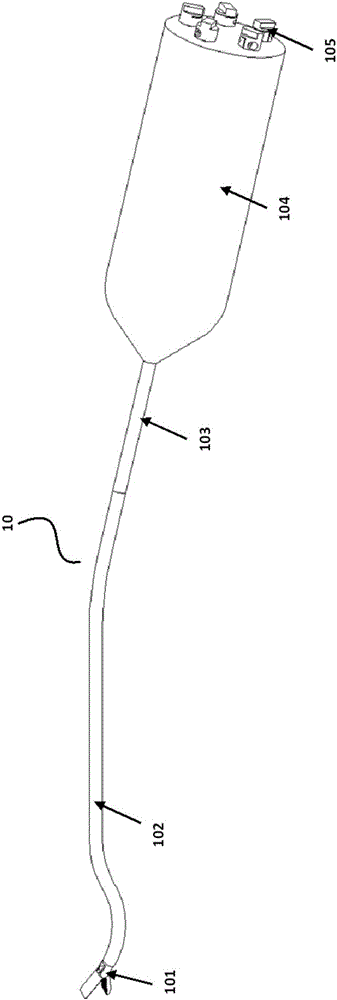

Systems and methods for posterior dynamic stabilization of the spine

ActiveUS20060084982A1Length , stiffness and shape of be adjustableStabilizing spineInternal osteosythesisJoint implantsVertebraSpinal locomotion

Systems and devices for dynamically stabilizing the spine are provided. The systems include a superior component for attachment to a superior vertebra of a spinal motion segment and an inferior component for attachment to an inferior vertebral of a spinal motion segment. The interconnection between the two components enables the spinal motion segment to move in a manner that mimics the natural motion of the spinal motion segment. Methods are also provided for stabilizing the spine and for implanting the subject systems.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

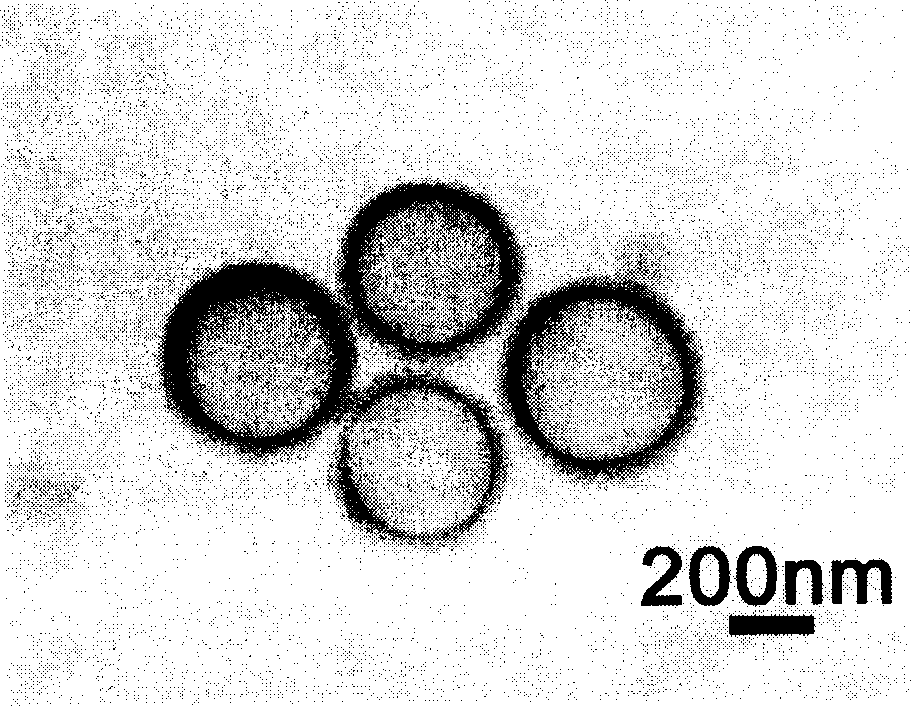

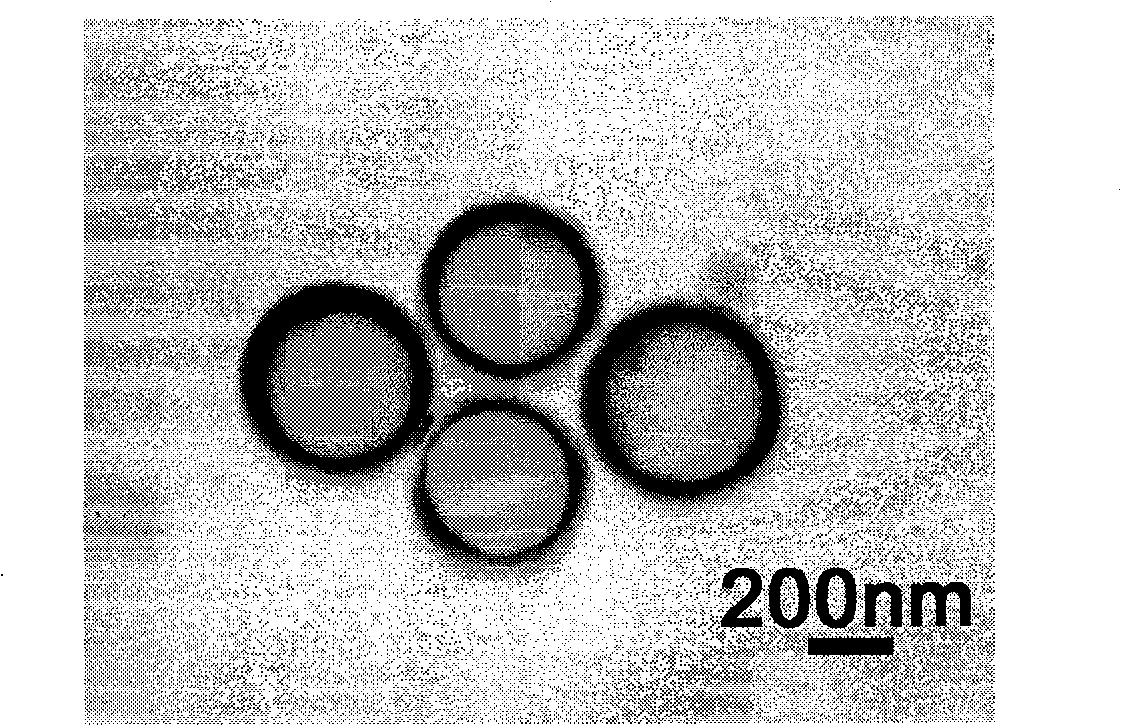

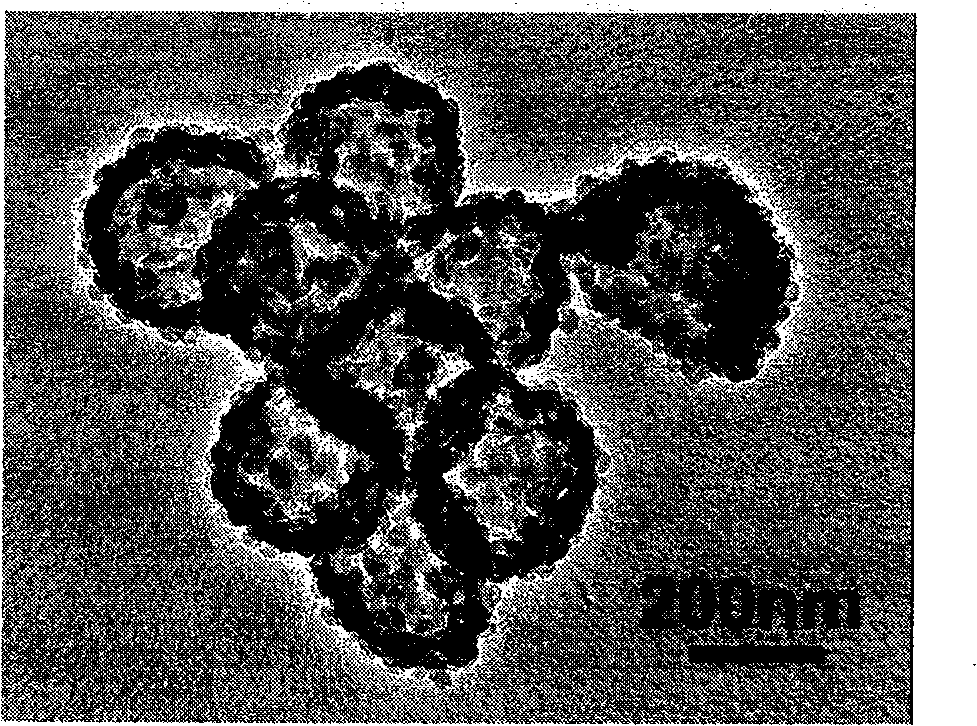

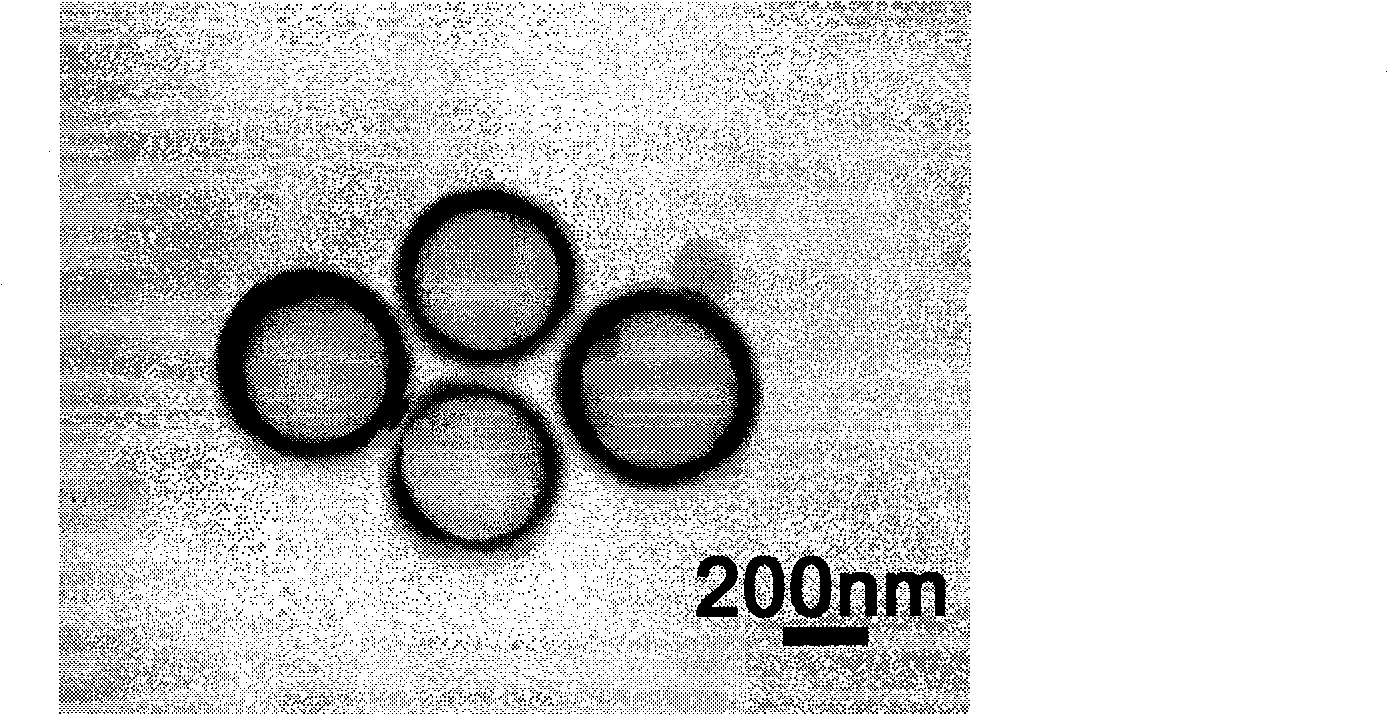

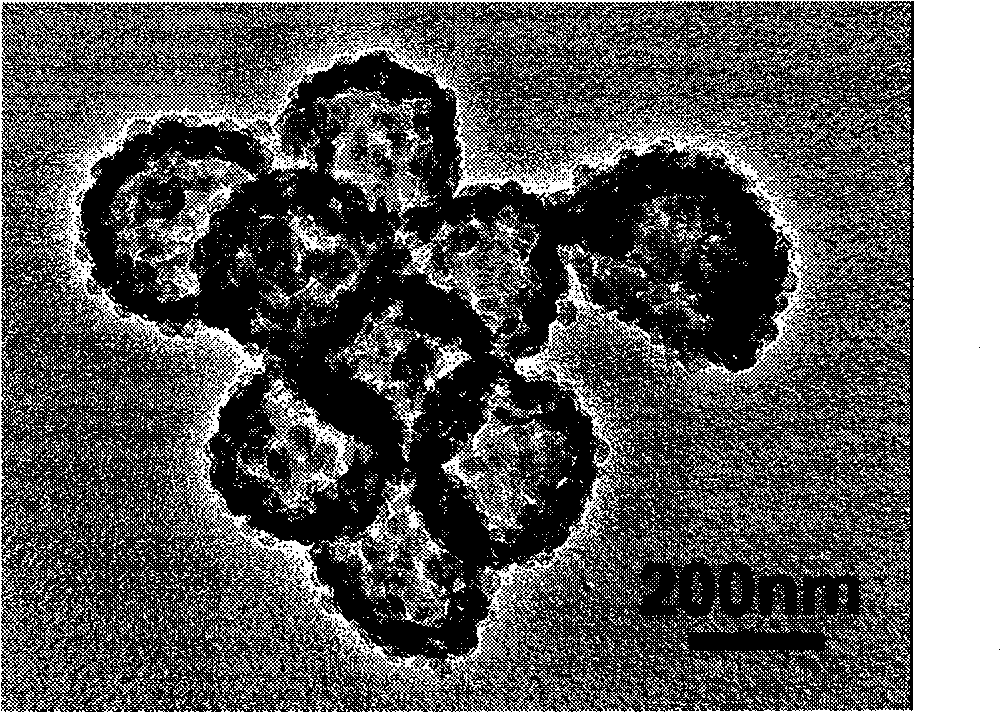

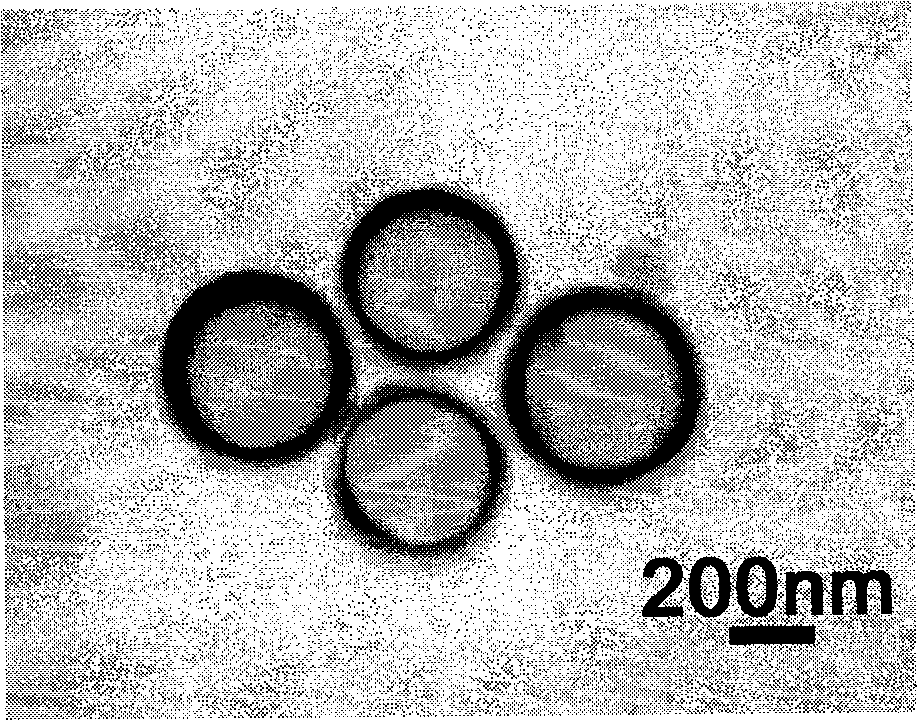

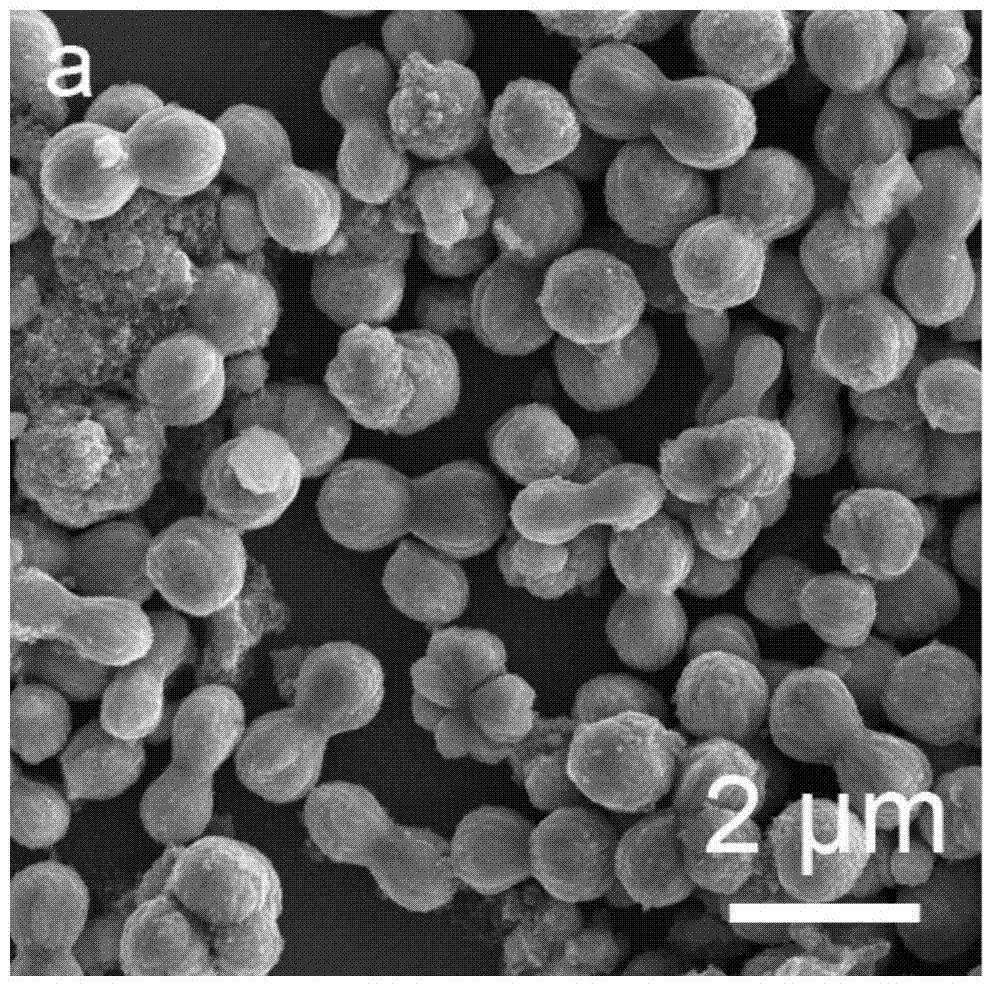

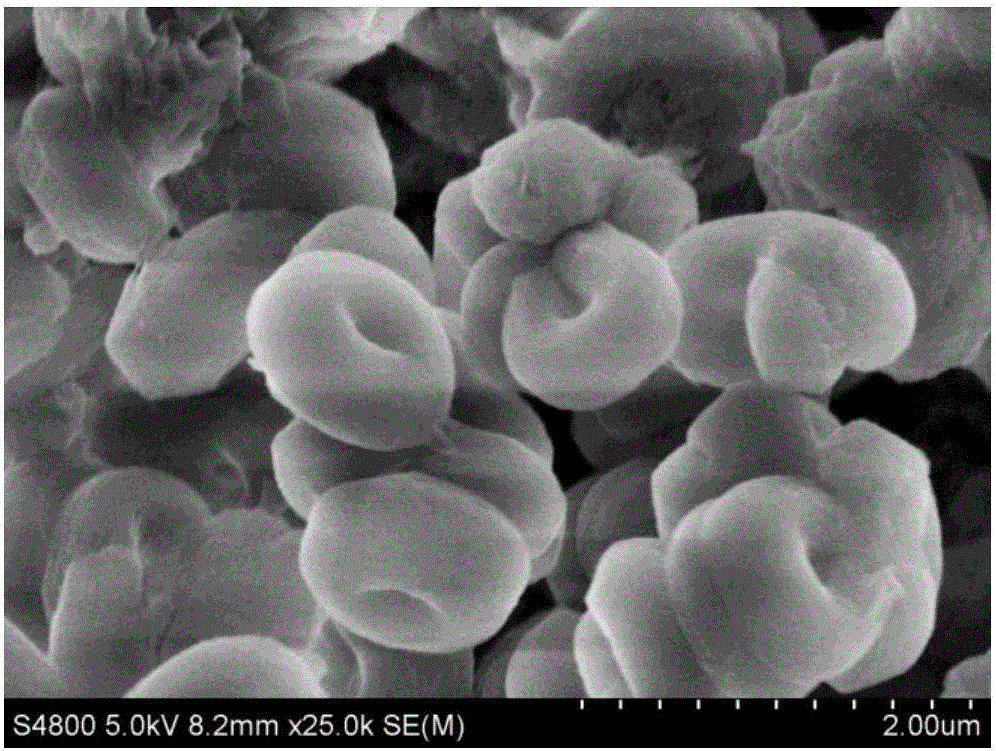

Template process of preparing hollow ball and composite hollow ball

InactiveCN1772363ARealize the intelligent switching processWide adaptabilityMicroballoon preparationMicrocapsule preparationPolymer scienceSolvent

The present invention belongs to the field of hollow material preparing technology, and is especially the preparation process of hollow ball of inorganic matter, metal, organic matter and composite structure with hollow polymer ball as template. The present invention prepares composite hollow ball through combining hollow polymer ball template with sol-gel, deposition reaction, oxidation-reduction process and through forced interface process or surface deposition process; and obtain hollow ball of inorganic matter, metal and organic matter through high temperature sintering or selective solvent extraction to eliminate template polymer. The control of hollow ball structure and size and the compounding of several kinds of matters may be realized through controlling reactant activity, material feeding mode, reactant concentration and circulating reaction process. The hollow ball has excellent dispersivity, high strength and size stability. The present invention also relates to the application of these hollow structure materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

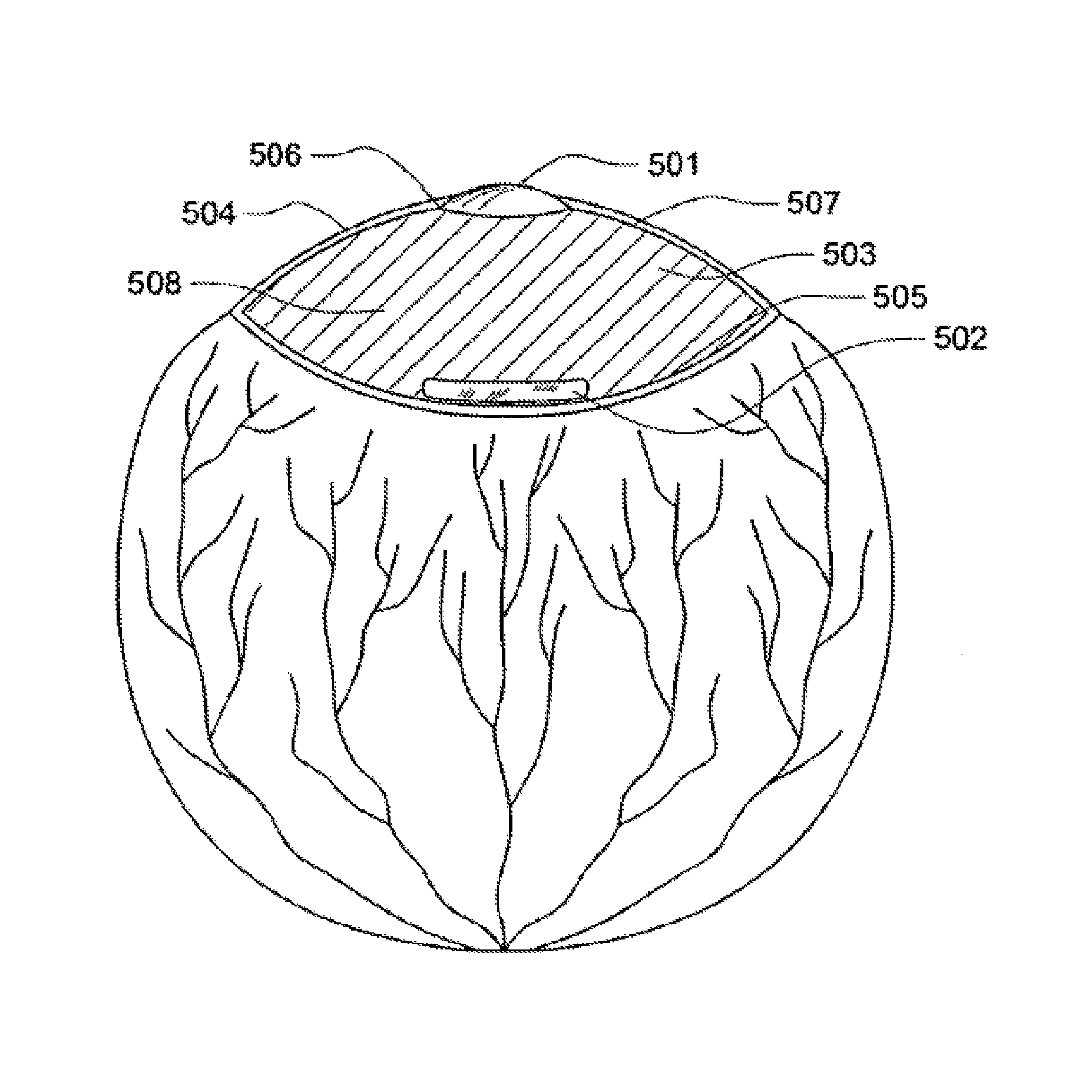

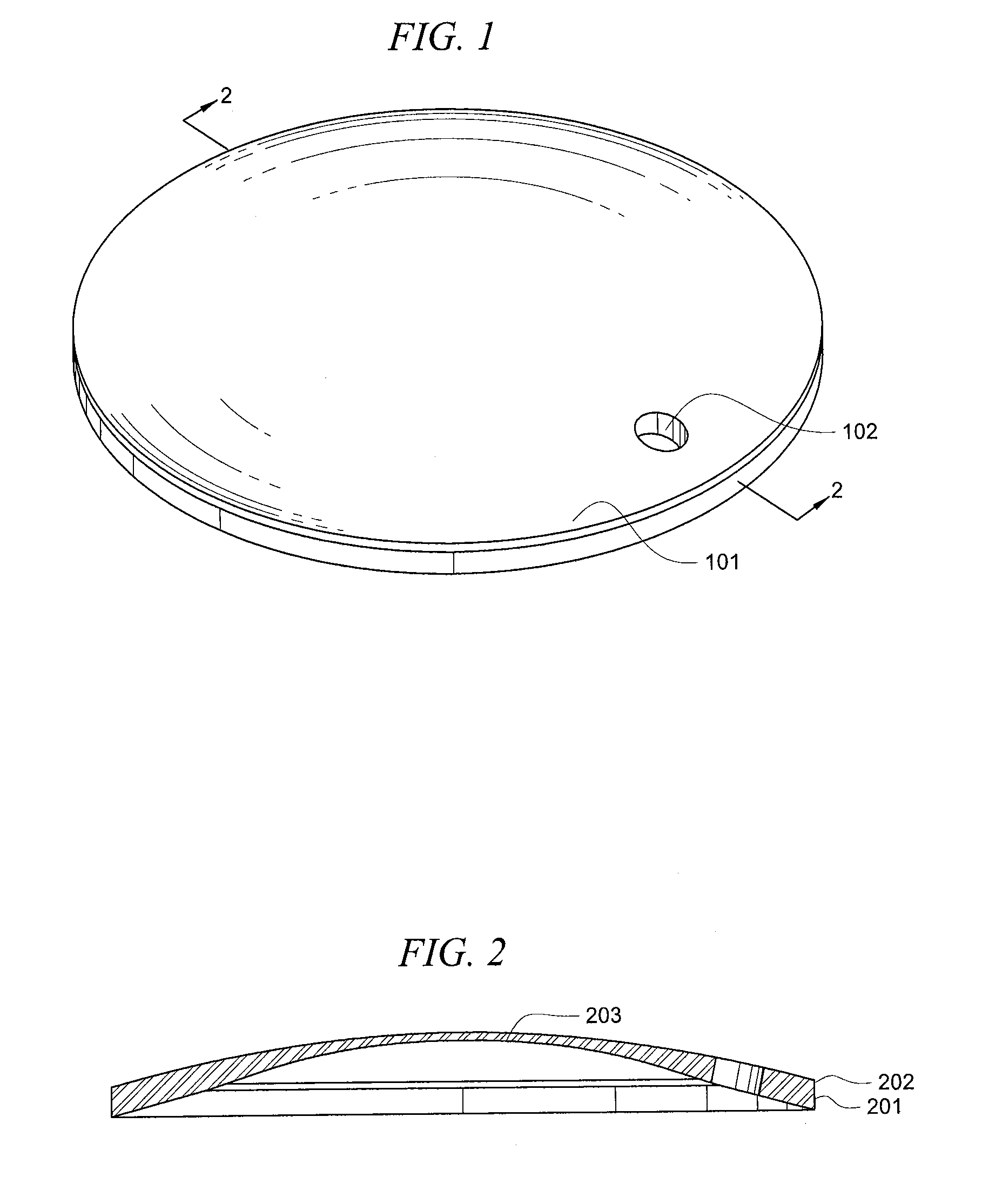

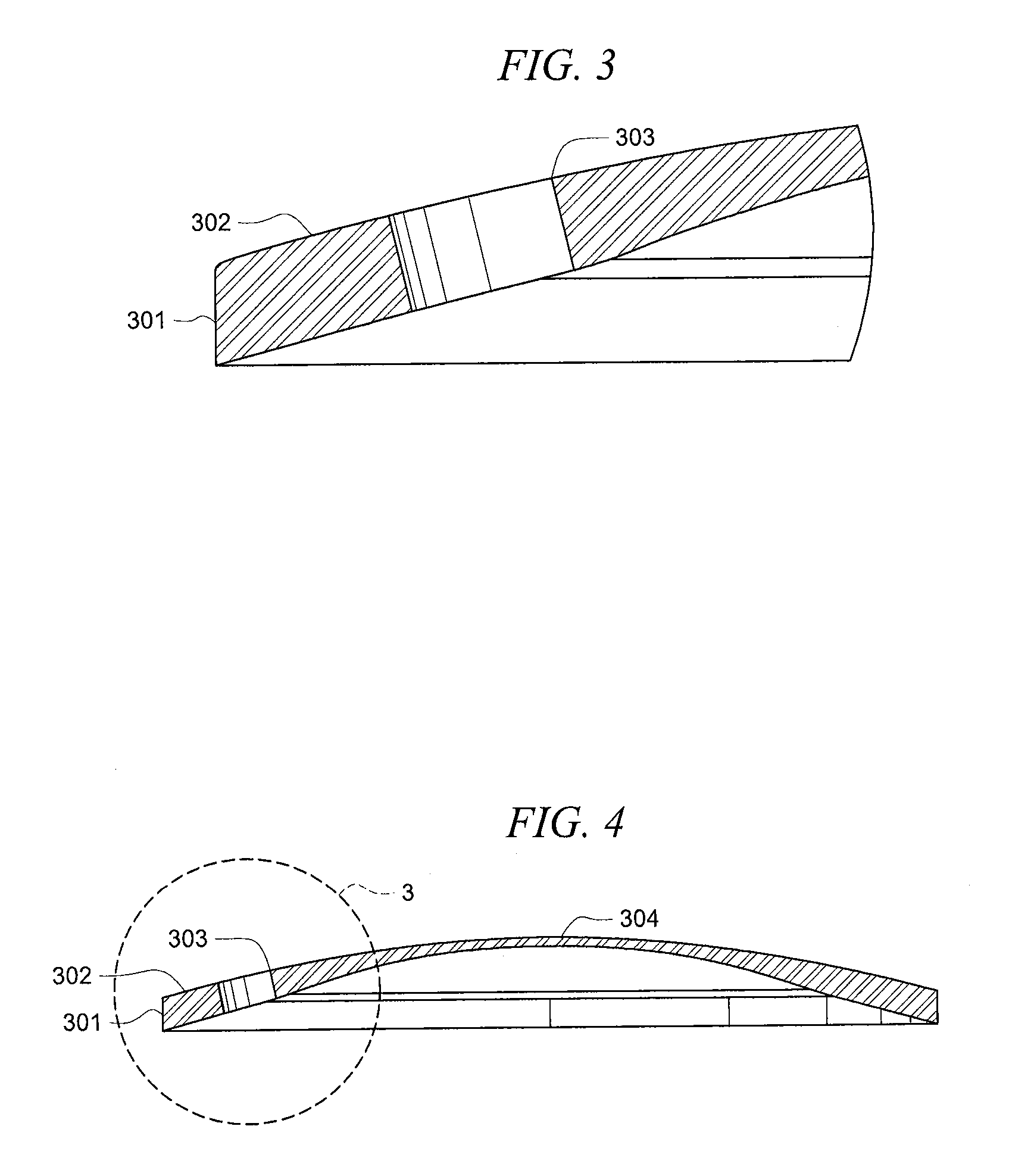

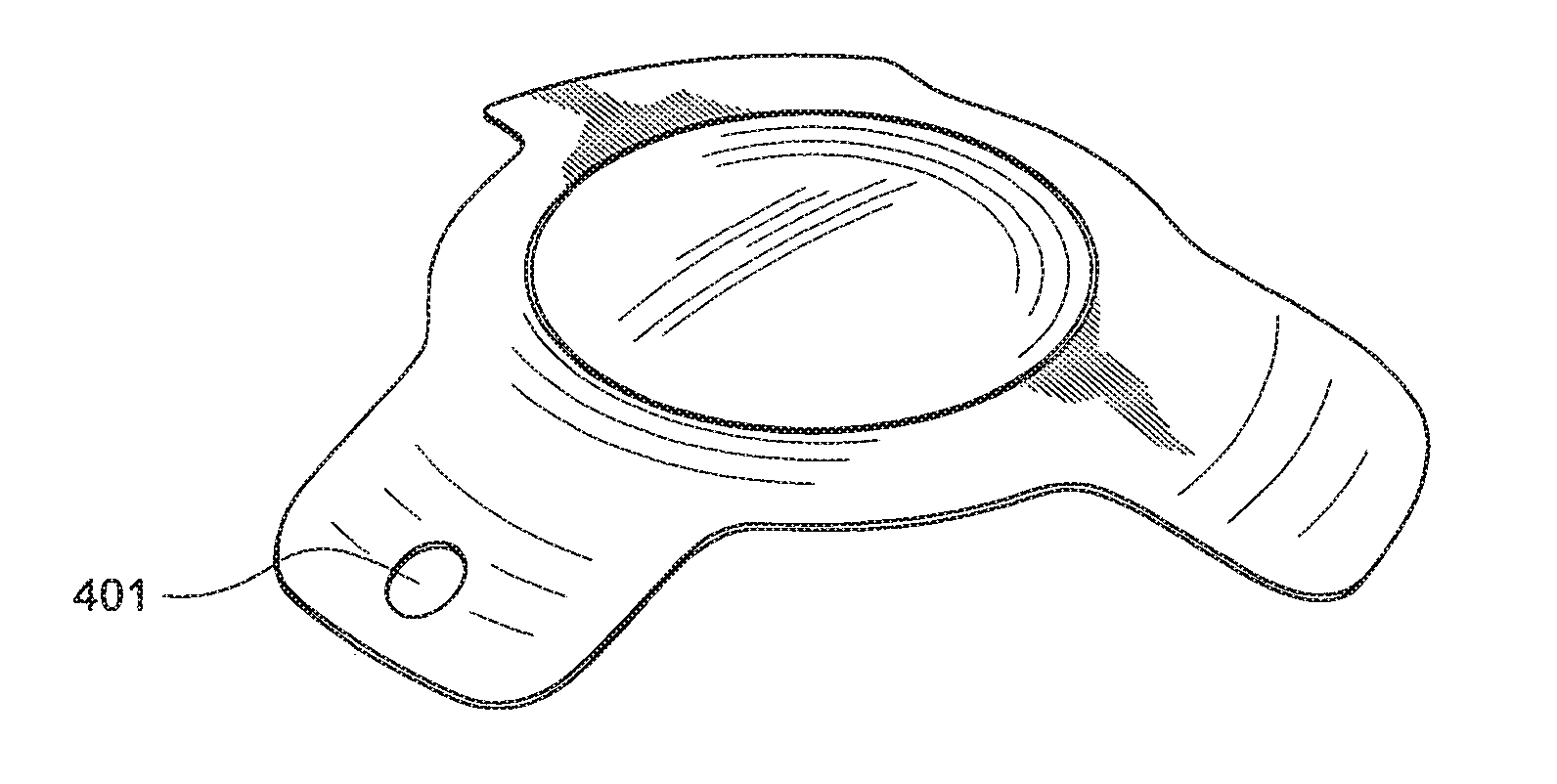

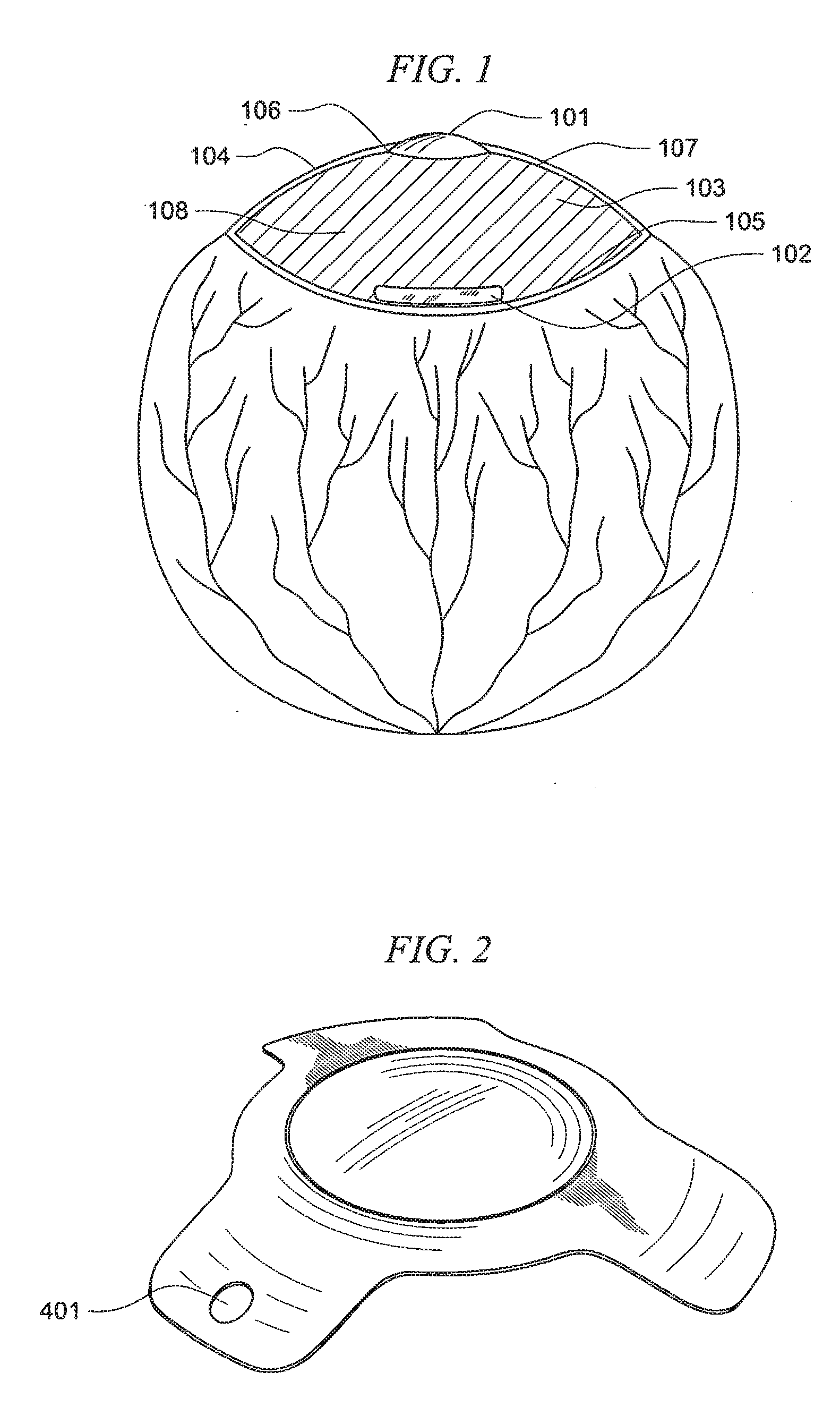

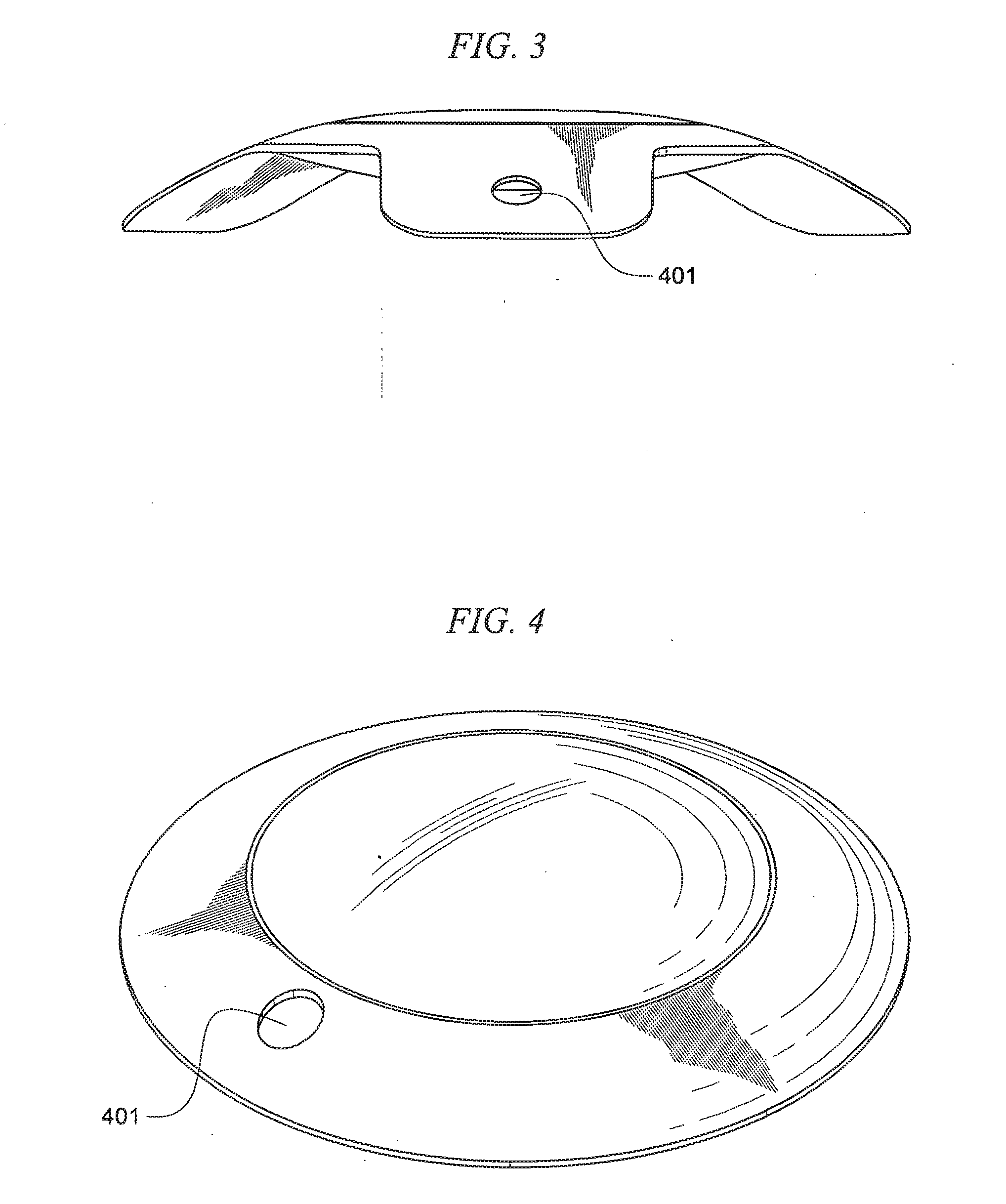

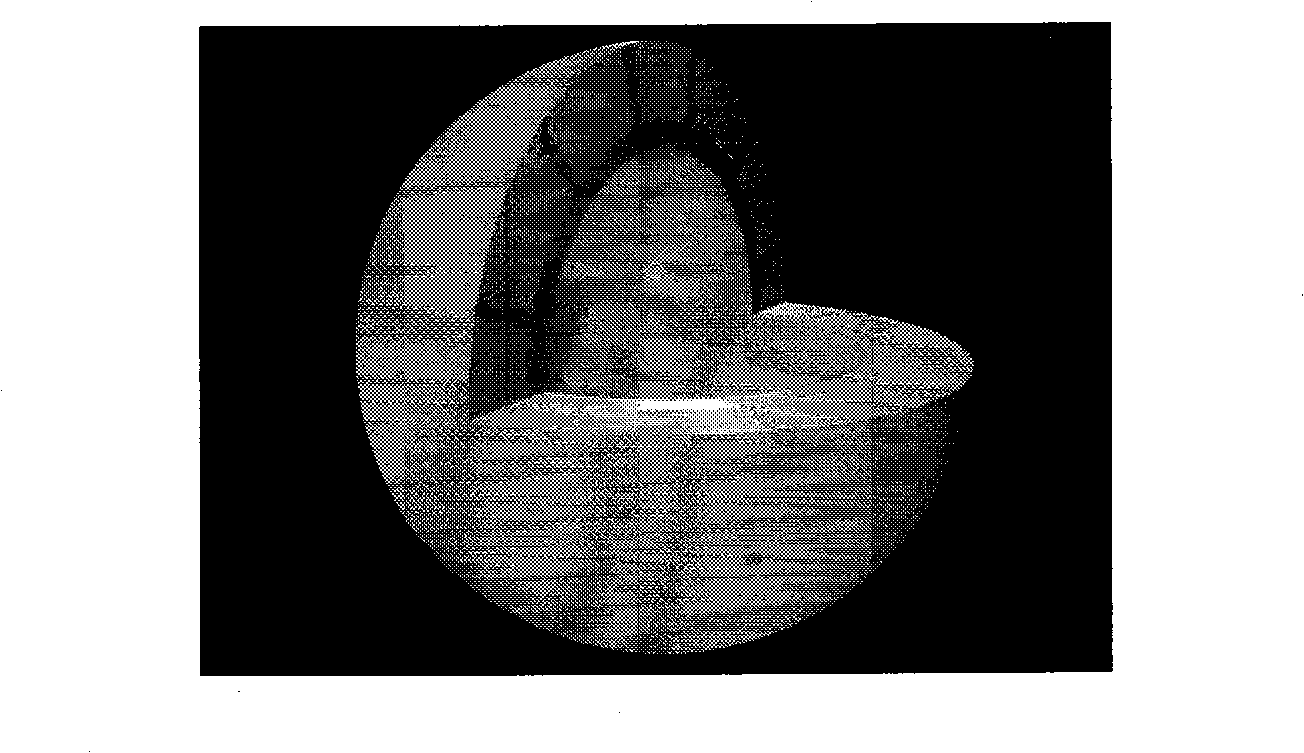

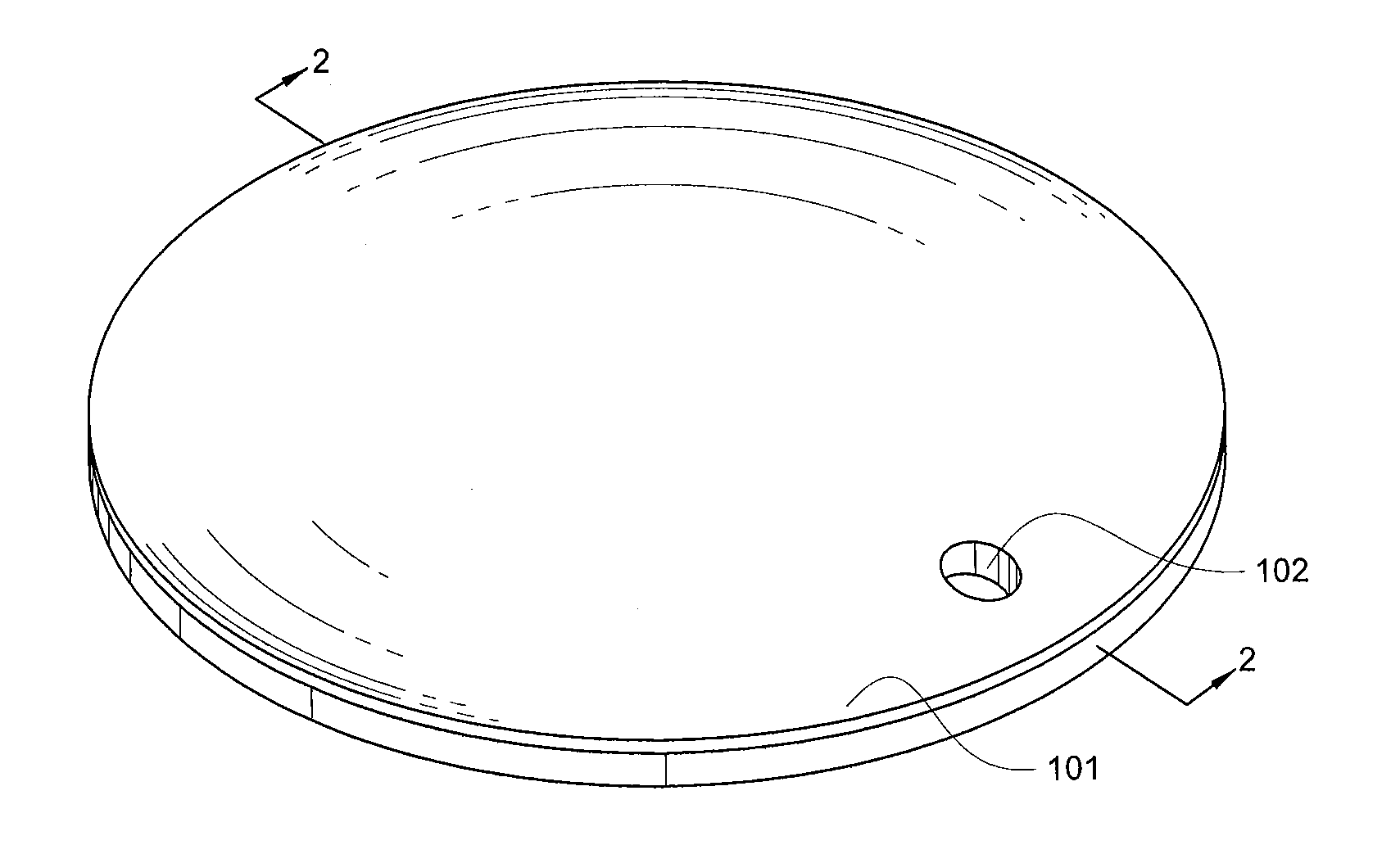

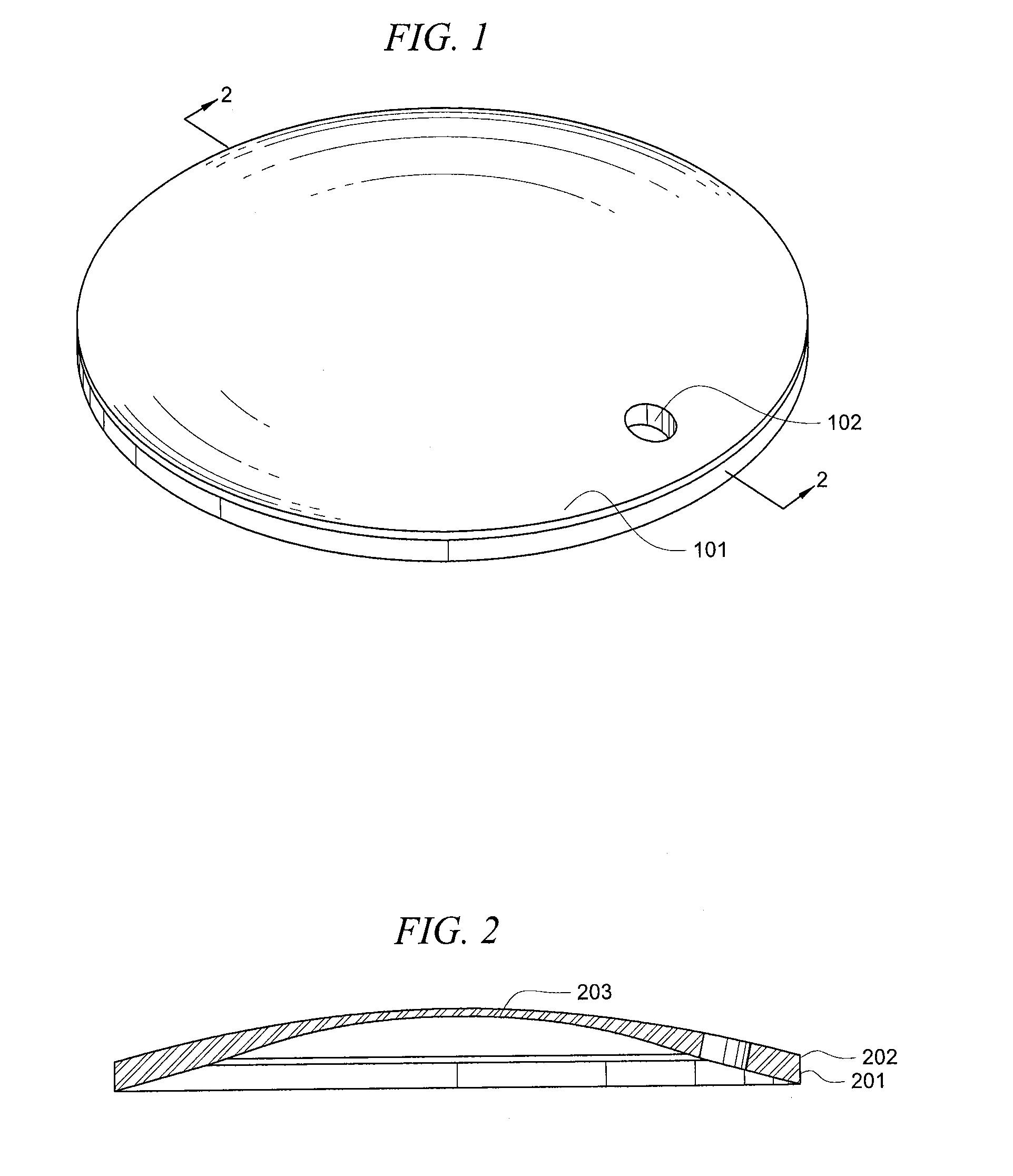

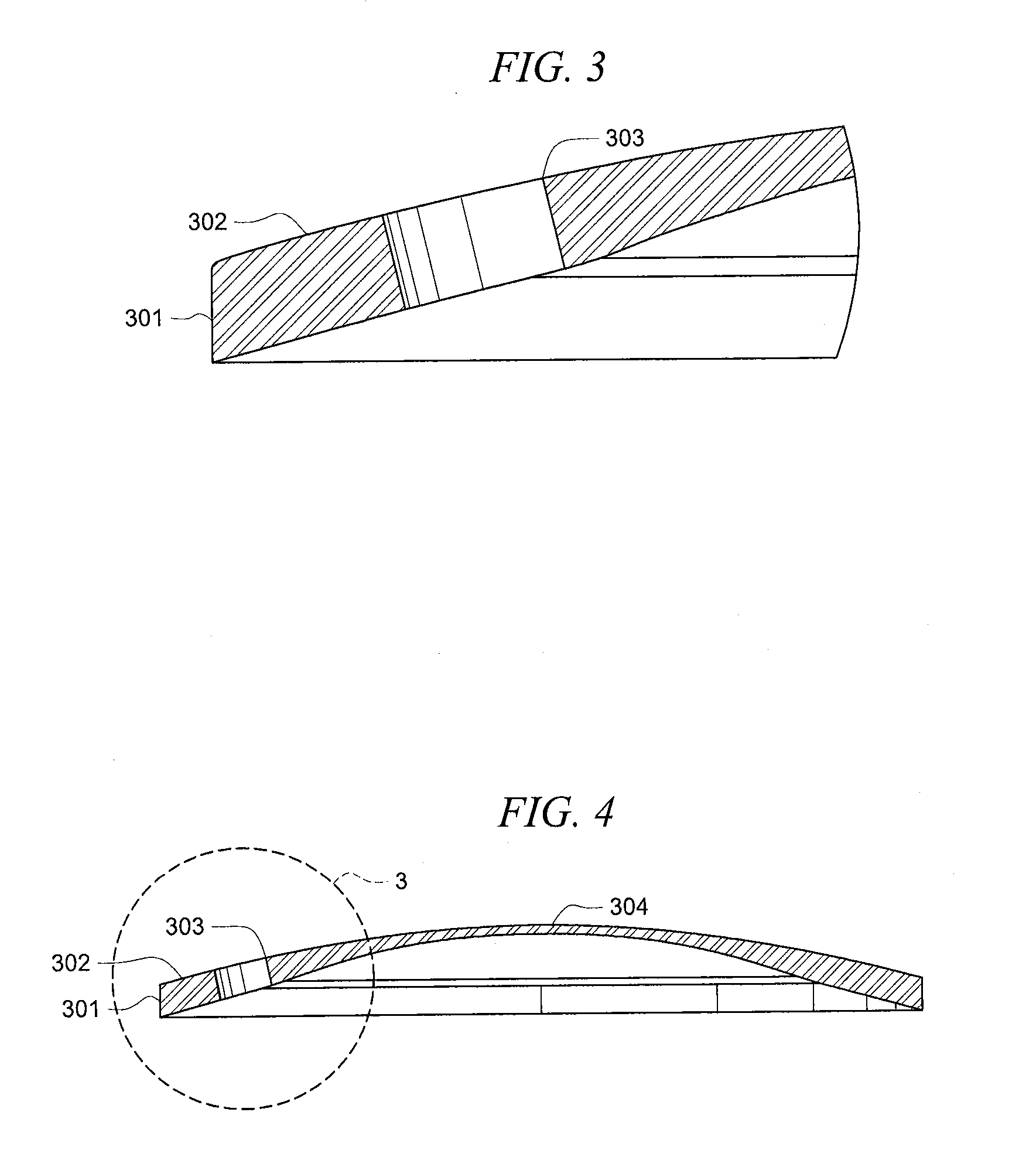

Intraocular lens system with injectable accommodation material

ActiveUS9005282B2Modulus of accommodationModifies its propertyIntraocular lensIntraocular lensLens placode

The invention relates to a intraocular lens system having a flexible anterior lens accommodation material behind the lens. The accommodation material may comprise of one or more macromers, which, when polymerized, adjust the properties of the accommodation material. The anterior lens is flexible such that the curvature of the lens changes during accommodation. The anterior lens may be used alone or in combination with a posterior lens.

Owner:RXSIGHT INC

Multilens Intraocular System with Injectable Accommodation Material

ActiveUS20160113761A1Modulus of accommodationModifies its propertyEye surgeryTissue regenerationOptical propertyAnterior surface

The invention relates to a multi-lens intraocular lens system having an accommodation material between the lenses. The system comprises an posterior lens attached to the posterior surface of the capsular bag and an anterior lens attached to the anterior surface of the capsular bag. The anterior and posterior lenses have different optical properties providing different degrees and types of correction. An accommodation material is place between the anterior and posterior lenses. The accommodation material may comprise of one or more macromers, which, when polymerized, adjust the properties of the accommodation material.

Owner:RXSIGHT INC

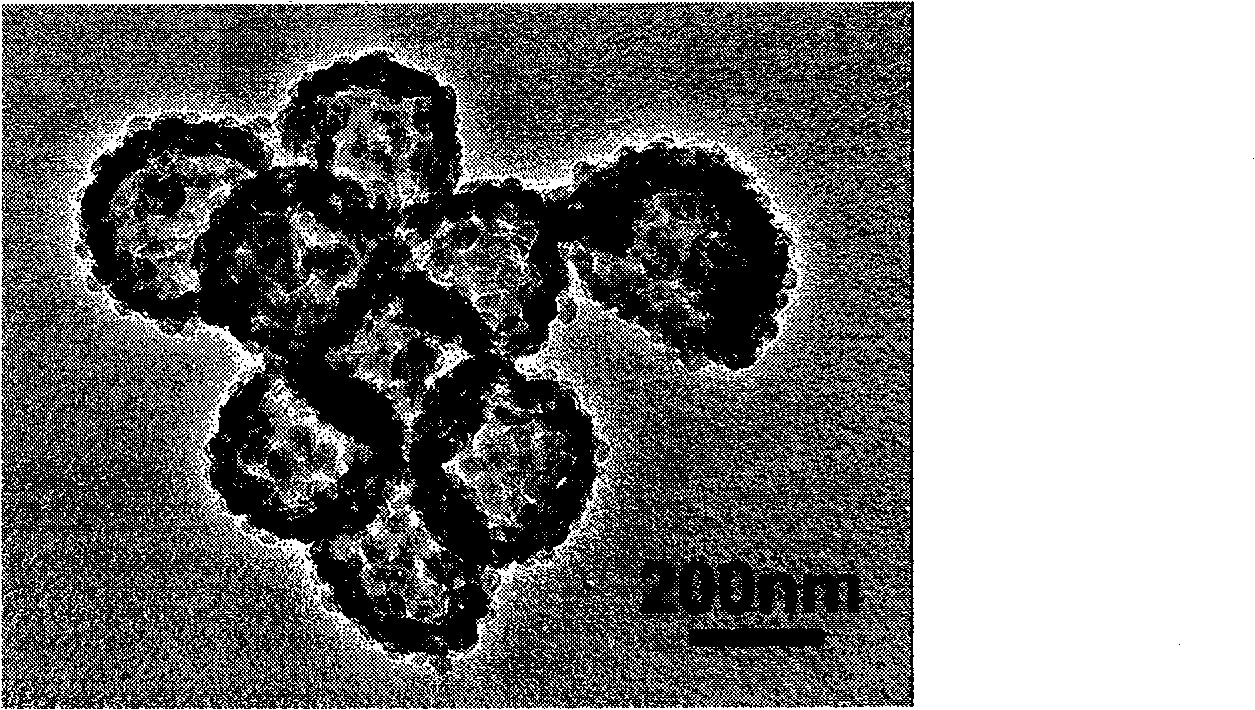

Method for preparing hollow ball with double-layer structure and hollow ball with multi-layer complex structure by template method

ActiveCN101259402AGuaranteed liquidityLarge specific surface areaMicroballoon preparationMicrocapsule preparationSolventMaterials science

The invention belongs to the field of materials with a hollow structure, in particular to a method for preparing double-layer hollow spheres and hollow spheres with multi-layer compound structures by using a template method. The invention prepares the compound hollow sphere by taking a polymer hollow sphere as a template and combining sol-gel, settlement reaction and redox process through the method of forcing interface or surface settlement, removes the template polymer through high sintering or selective extraction of a solvent to obtain the hollow spheres of minerals, metals and organic matters. The structure and the size of the hollow sphere can be controlled through controlling the reagent activity, the feeding mode, the reagent concentration and a circulation reaction method; besides, compounding of various matters can be realized; the hollow sphere of the invention not only has good dispersing performance, but also has excellent strength and size stability. The invention relates to the application of the materials with a hollow structure.

Owner:BEIJING NEW BUILDING MATERIAL

Method for preparing hollow ball and hollow ball with complex structure by template method

InactiveCN101259401AGuaranteed liquidityLarge specific surface areaMicroballoon preparationMicrocapsule preparationSolventSol-gel

The invention belongs to the field of materials with a hollow structure, in particular to a method for preparing hollow spheres of minerals, metals and organic matters and hollow spheres with compound structures as well as hollow spheres with photic, electrical, magnetic and catalytic properties and hollow spheres with compound structures thereof by taking a polymer hollow sphere as a template. The invention prepares the hollow spheres with compound structures by taking the polymer hollow sphere as the template and combining sol-gel, settlement reaction and redox process through the method of forcing interface or surface settlement, removes the template polymer through high sintering or selective extraction of a solvent to obtain the hollow spheres of minerals, metals and organic matters. The structure and the size of the hollow sphere can be controlled through controlling the reagent activity, the feeding mode, the reagent concentration and a circulation reaction method; besides, compounding of various matters can be realized; the hollow sphere of the invention not only has good dispersing performance, but also has excellent strength and size stability. The invention relates to the application of the materials with a hollow structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

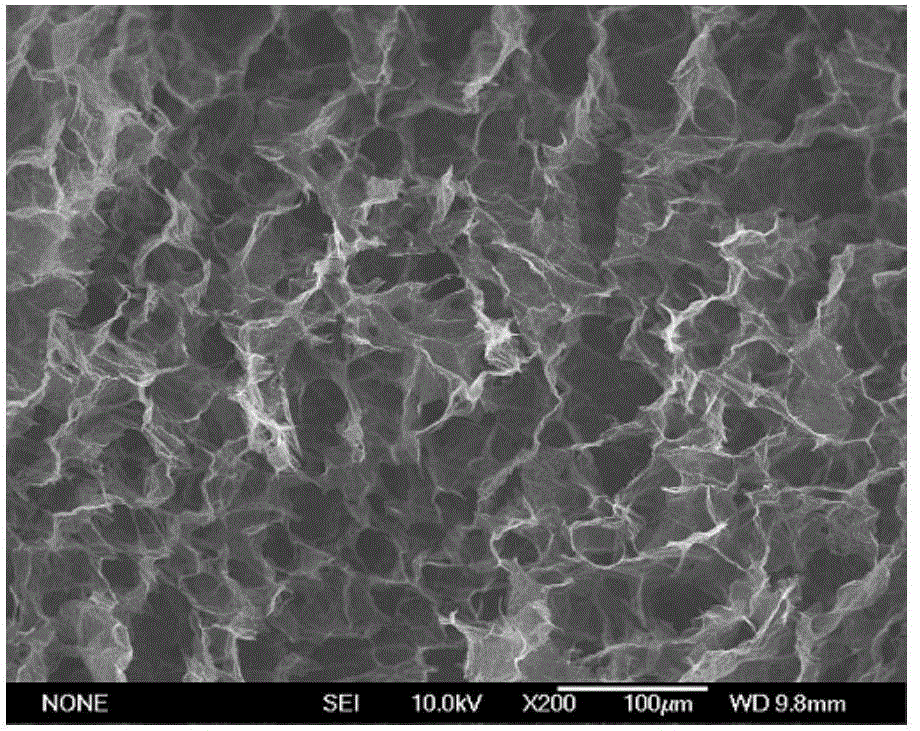

Graphene aerogel as well as preparation method and application thereof

The invention discloses graphene aerogel and a preparation method thereof. The method comprises the following steps: (1) uniformly mixing graphene oxide dispersion liquid with an amine water-soluble compound to obtain graphene oxide mixed liquid, wherein the amine water-soluble compound is selected from one or more of diethylamine, ethidene diamine, propane diamine, butane diamine, diethylene triamine, triethylene tetramine, tetraethylene pentamine, allylamine polymer and N,N'-bis(2-aminoethyl)-1,3-propane diamine; (2) irradiating the graphene oxide mixed liquid by high-energy rays under the anaerobic condition to obtain amino-modified graphene aerogel; (3) performing freeze-drying or supercritical CO2 drying to obtain the graphene aerogel. The graphene aerogel adopts a porous and macroporous structure, is relatively uniform in structure, and can be used for adsorbing an organic solvent; moreover, the preparation method is simple and environment-friendly.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

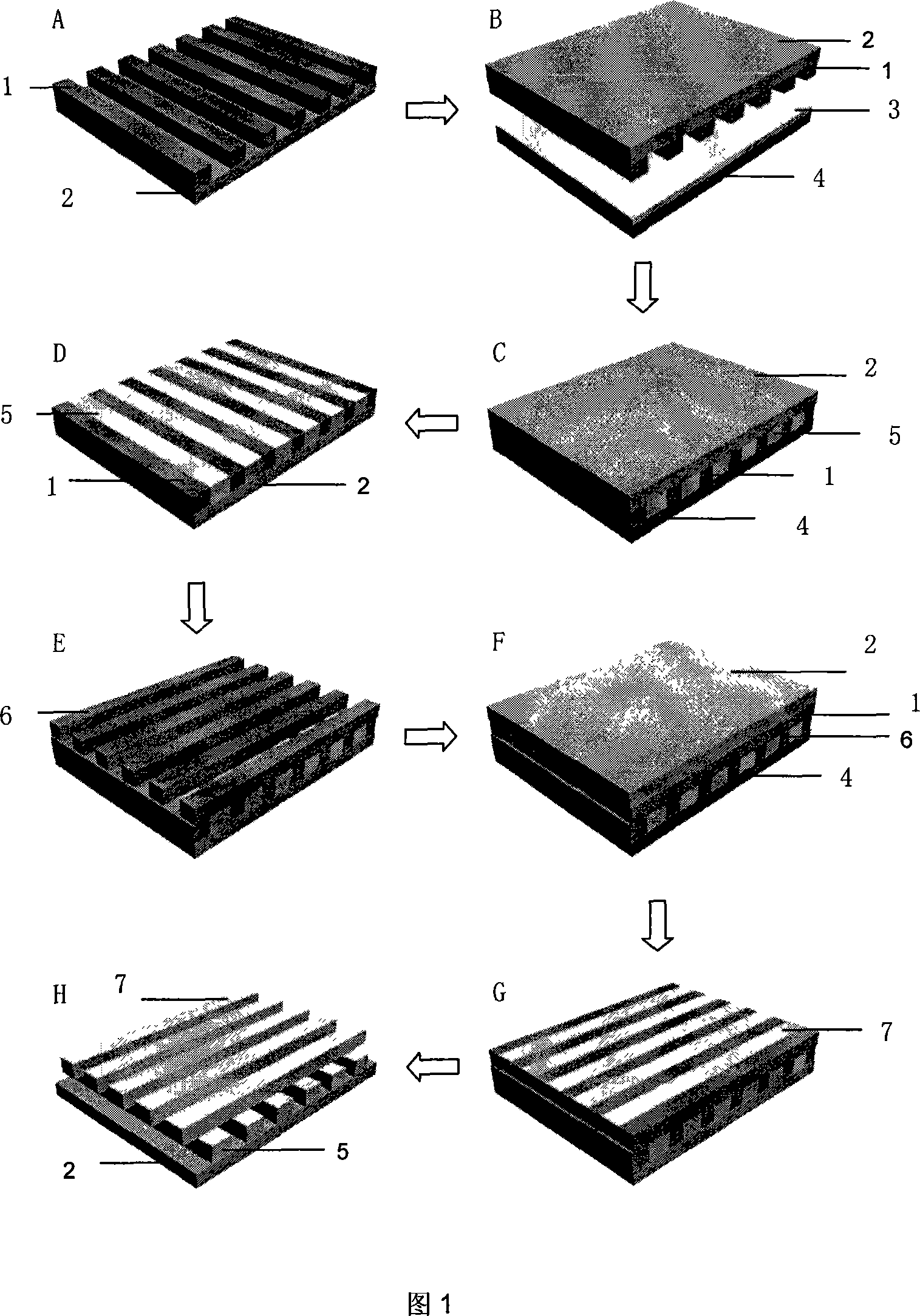

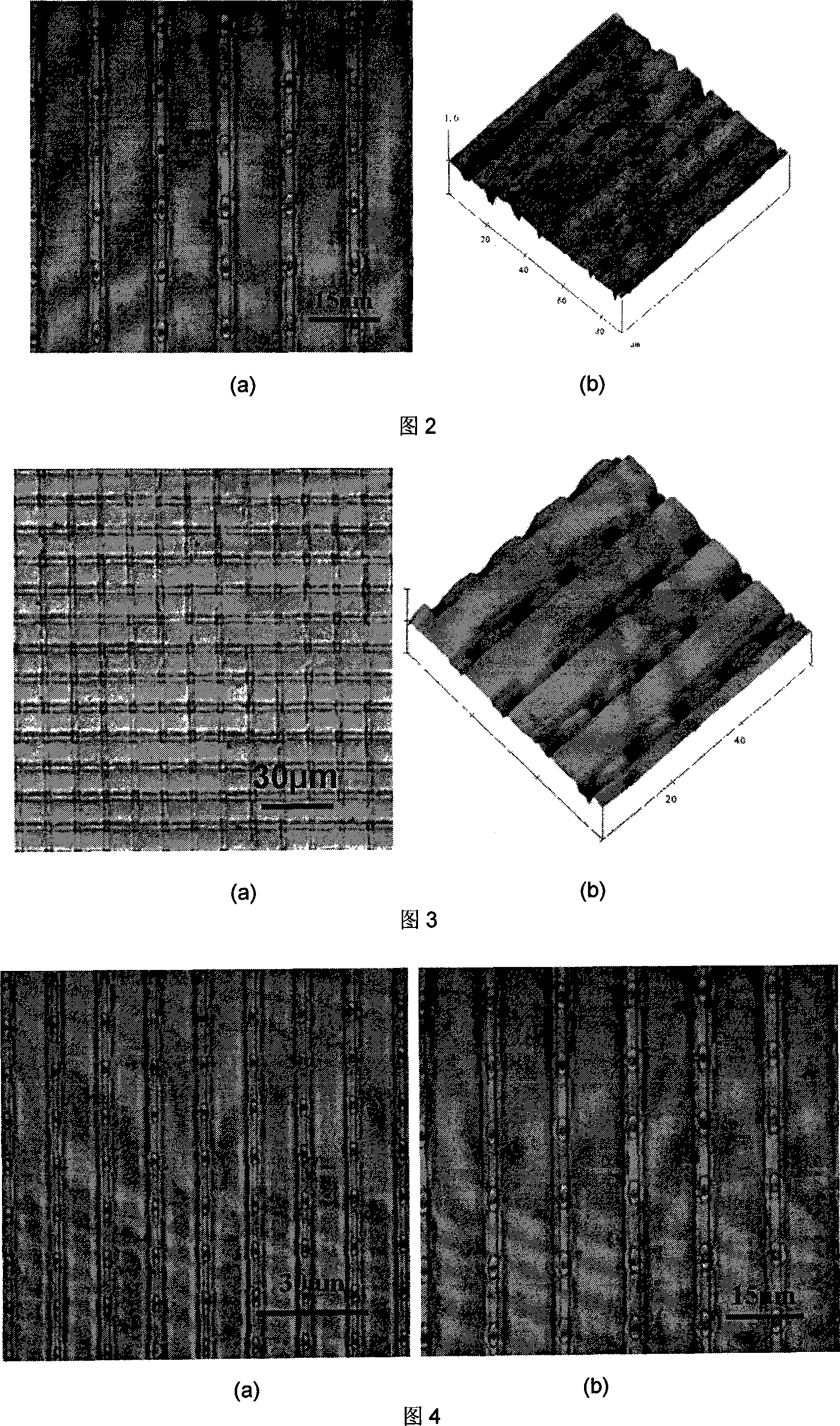

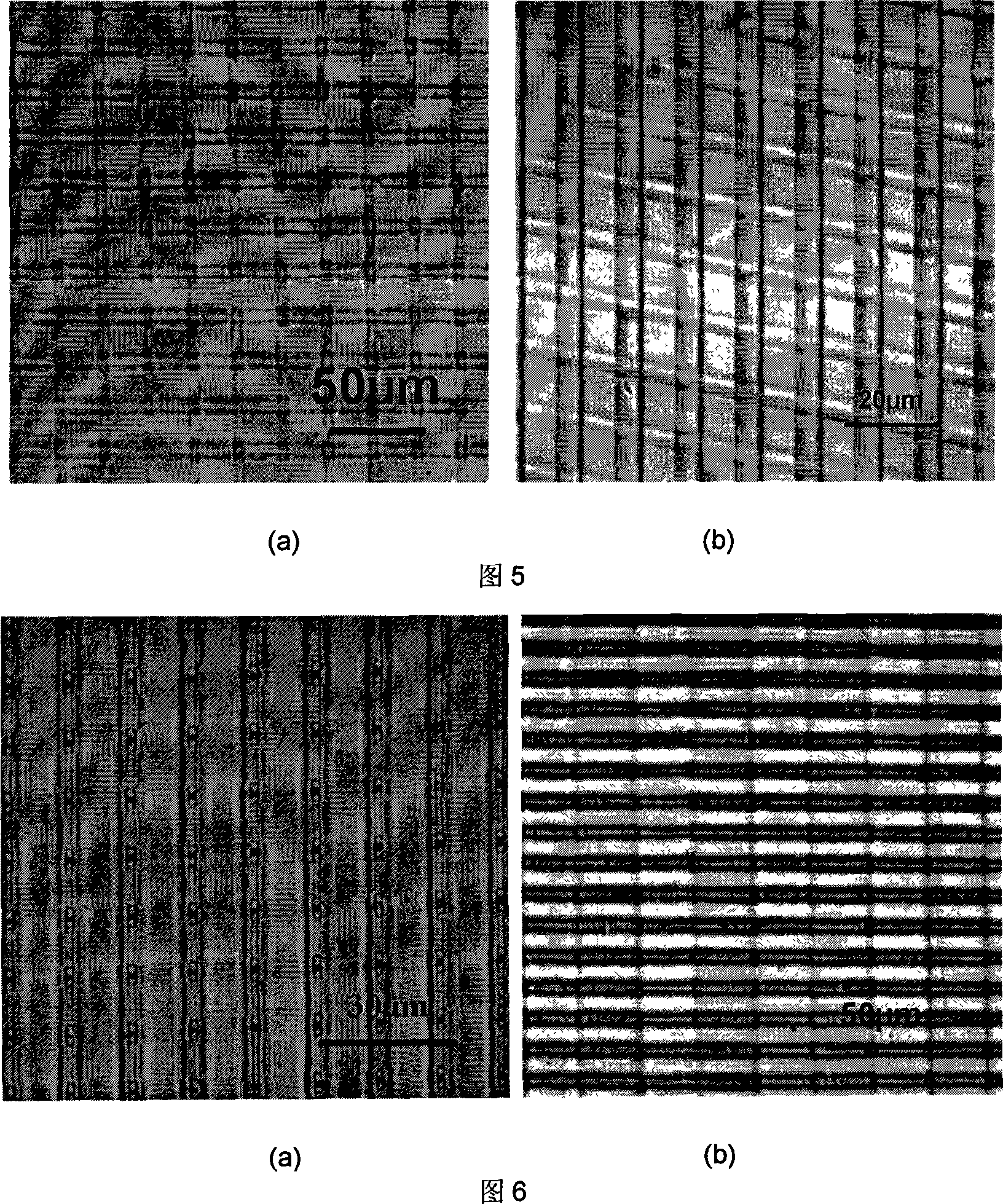

Method for constituting 3-D structure

InactiveCN101024482AShape adjustableAdjustable thicknessDecorative surface effectsPhotomechanical apparatusPhotonic crystalPolymer science

The invention relates to a method to construct 3D microstructure. It includes the following steps: using photoengraving method to construct 2D microstructure surface, extruding polymer performed polymer or ultraviolet glue precursor into the slot on 2D microstructure surface and taking heat or light polymerization to gain target material; constructing polymer or ultraviolet exposal glue array structure, washing sacrificed material at one time to gain the 3D microstructure. The invention has potential application value in the fields of shape, size, thickness, material, photon crystal, catalyst carrier, etc.

Owner:JILIN UNIV

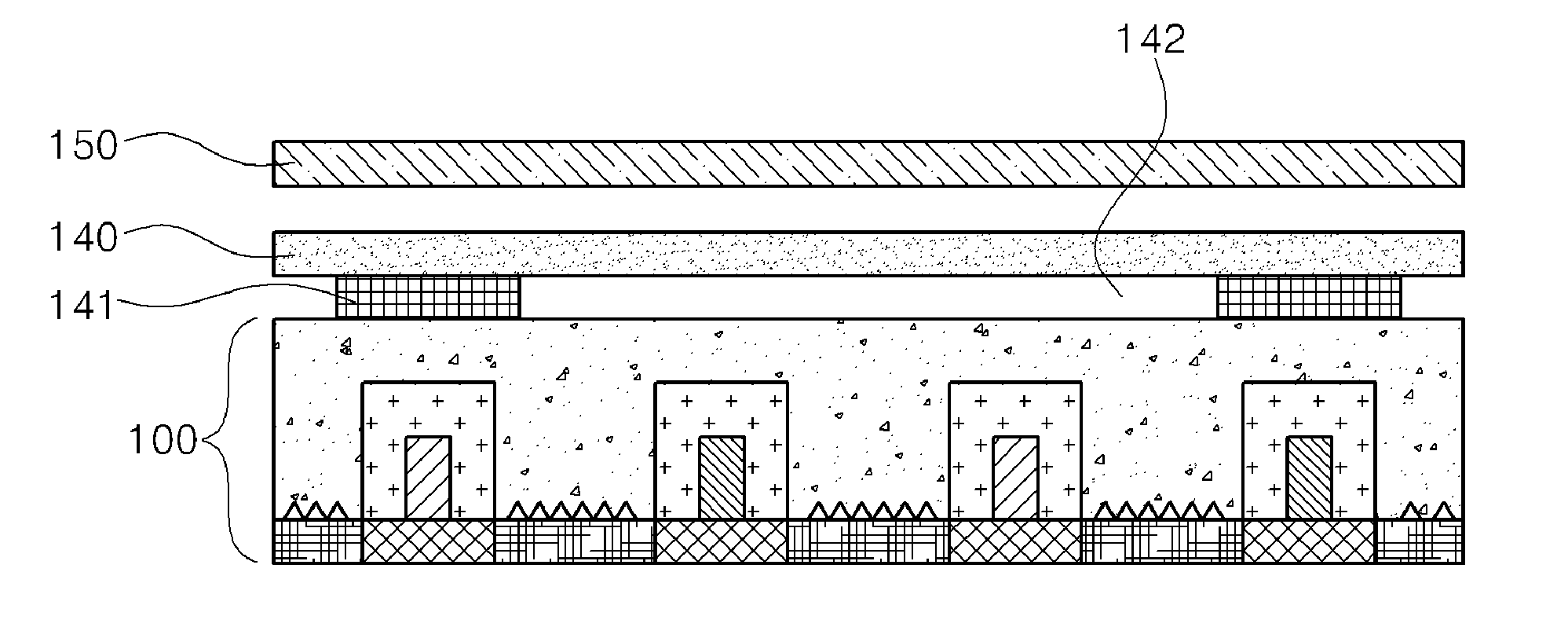

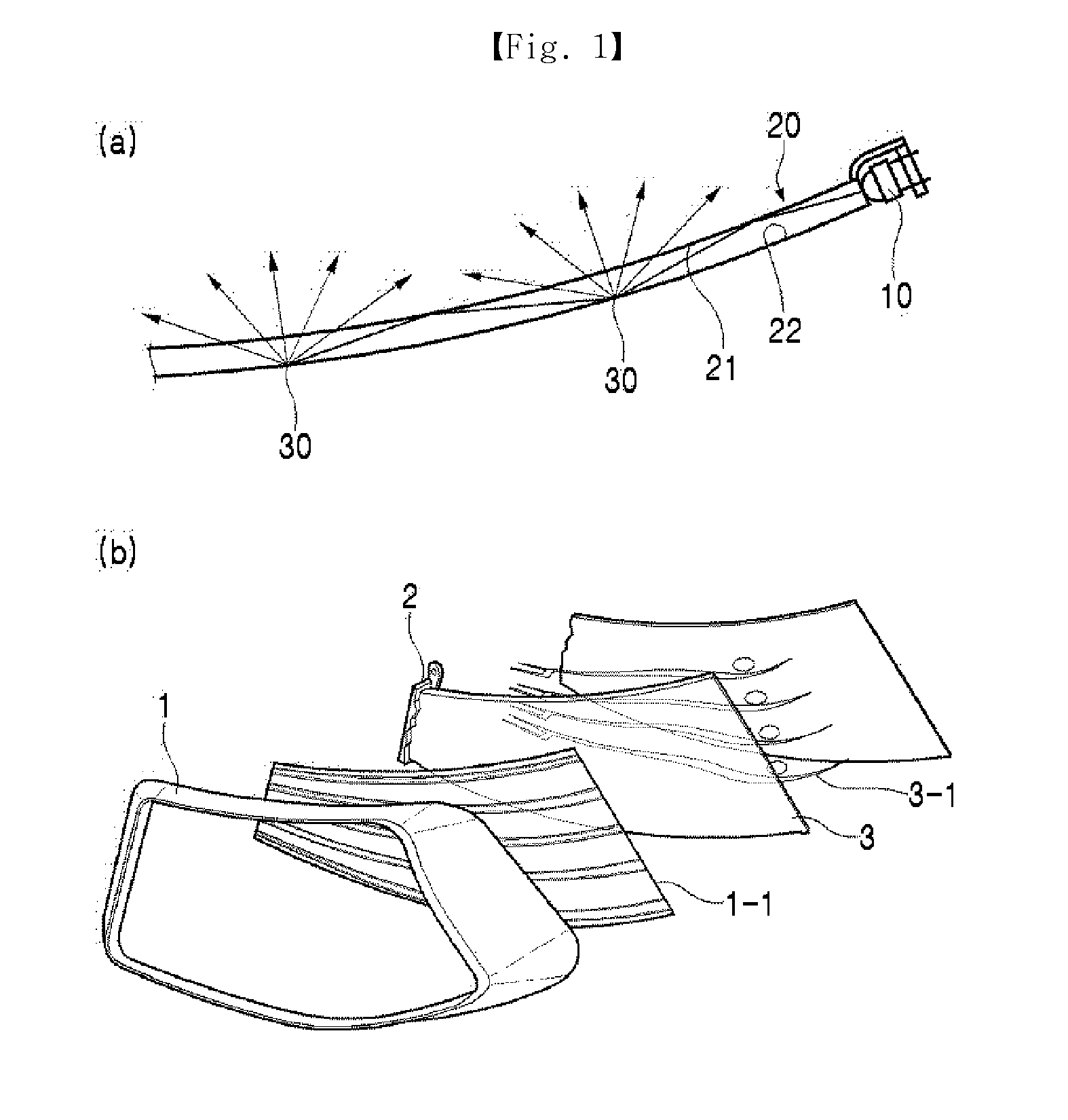

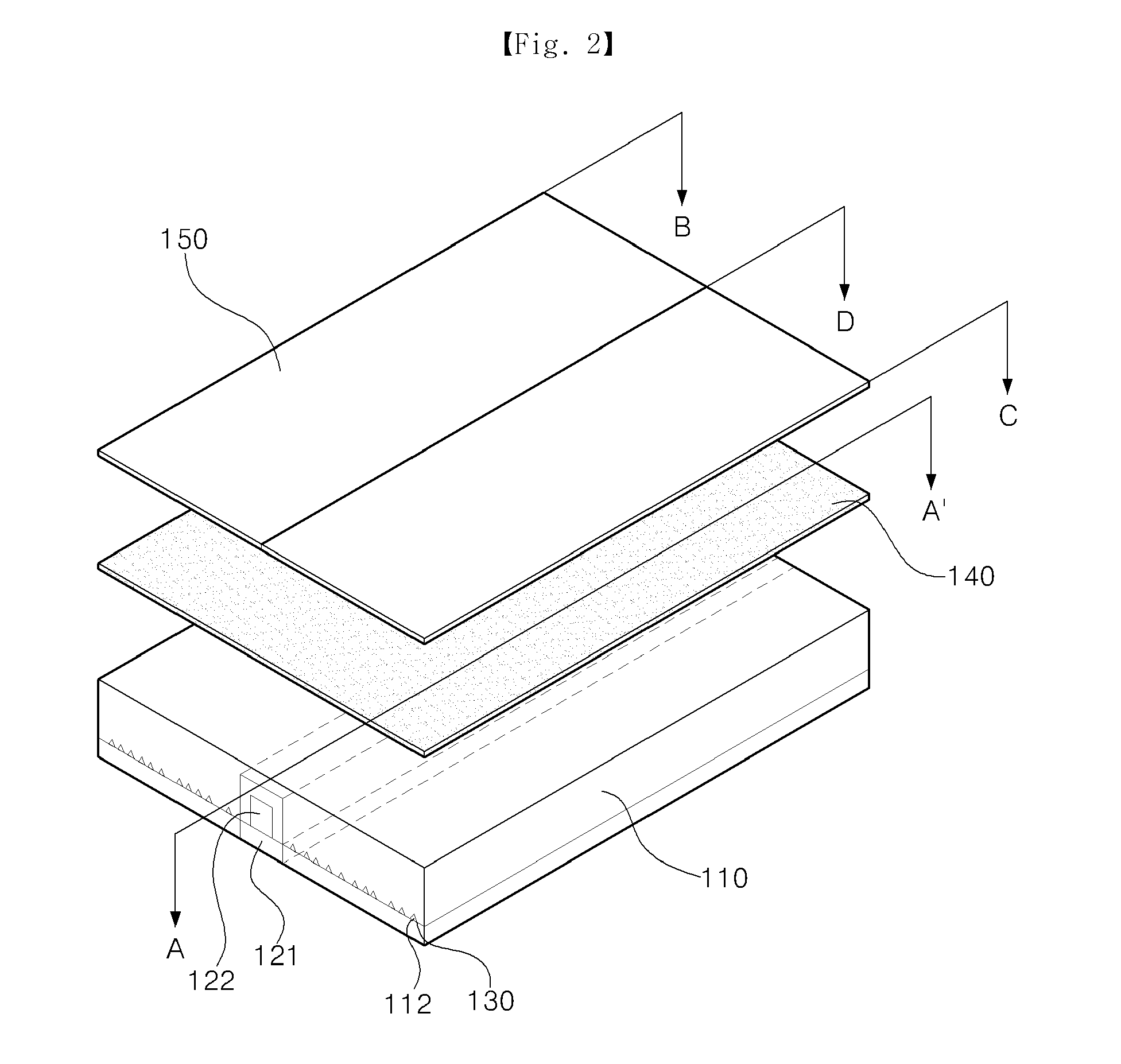

Lighting unit for vehicle

ActiveUS20150338048A1Low costImprove lighting efficiencyMechanical apparatusPoint-like light sourceLight emission

Provided is a lighting unit for a vehicle capable of implementing surface light emission from a single light emitting surface. The light unit can function to implement a light emitting region in which at least two light colors are displayed or different light colors are implemented, or to locally emitting light.

Owner:LG INNOTEK CO LTD

Method for preparing silver nanowire-graphene composite aerogel

The invention discloses a method for preparing silver nanowire-graphene composite aerogel. The method comprises steps as follows: 1) preparation of a graphene oxide aqueous solution: graphene oxide sheets are added to water for mixing, and the graphene oxide aqueous solution with the mass concentration being 0.5-10 mg / mL is prepared; 2) a silver nanowire solution with the mass concentration being 1-20 mg / mL is added to the graphene oxide aqueous solution prepared in the step 1) for mixing, and a mixed solution is prepared; 3) a reducing agent is added to the mixed solution, the reducing agent and the mixed solution react in a closed container, and hydrogel is prepared; 4) the hydrogel is cleaned and dried, and the aerogel is prepared. The particle size of a silver nanowire-graphene composite aerogel material can obviously reduce volume shrinkage of the hydrogel, a large quantity of high-activity silver nanoparticles are loaded in graphene, and the material has the advantages of ultra-large porosity, low density, large specific surface area, adjustable shape, simple preparation process and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method of depositing metal organic framework material by oxygen auxiliary cathode

InactiveCN108130574AAvoid depositionHigh selectivityElectrolytic organic material coatingSupporting electrolyteOrganic solvent

The invention provides a method of depositing a metal organic framework material by an oxygen auxiliary cathode. The method comprises the following steps: (1) preparing a reaction precursor solution which is composed of a 5-50mM metal source, a 10-250mM organic ligand and an organic solvent; and (2) carrying out electrochemical deposition on the surface of a conducting substrate of the cathode toobtain the material. The method provided by the invention does not corrode the deposited electrode, the selecting range of the conducting substrate is wide, the prepared MOF material is regulatable inshape, dimension and thickness in nanoscale, pure, free of adding a supporting electrolyte and low in cost, and can be synthesized in one step. The metal organic framework is simple in method and operation, and industrial production is conveniently achieved.

Owner:SUZHOU UNIV

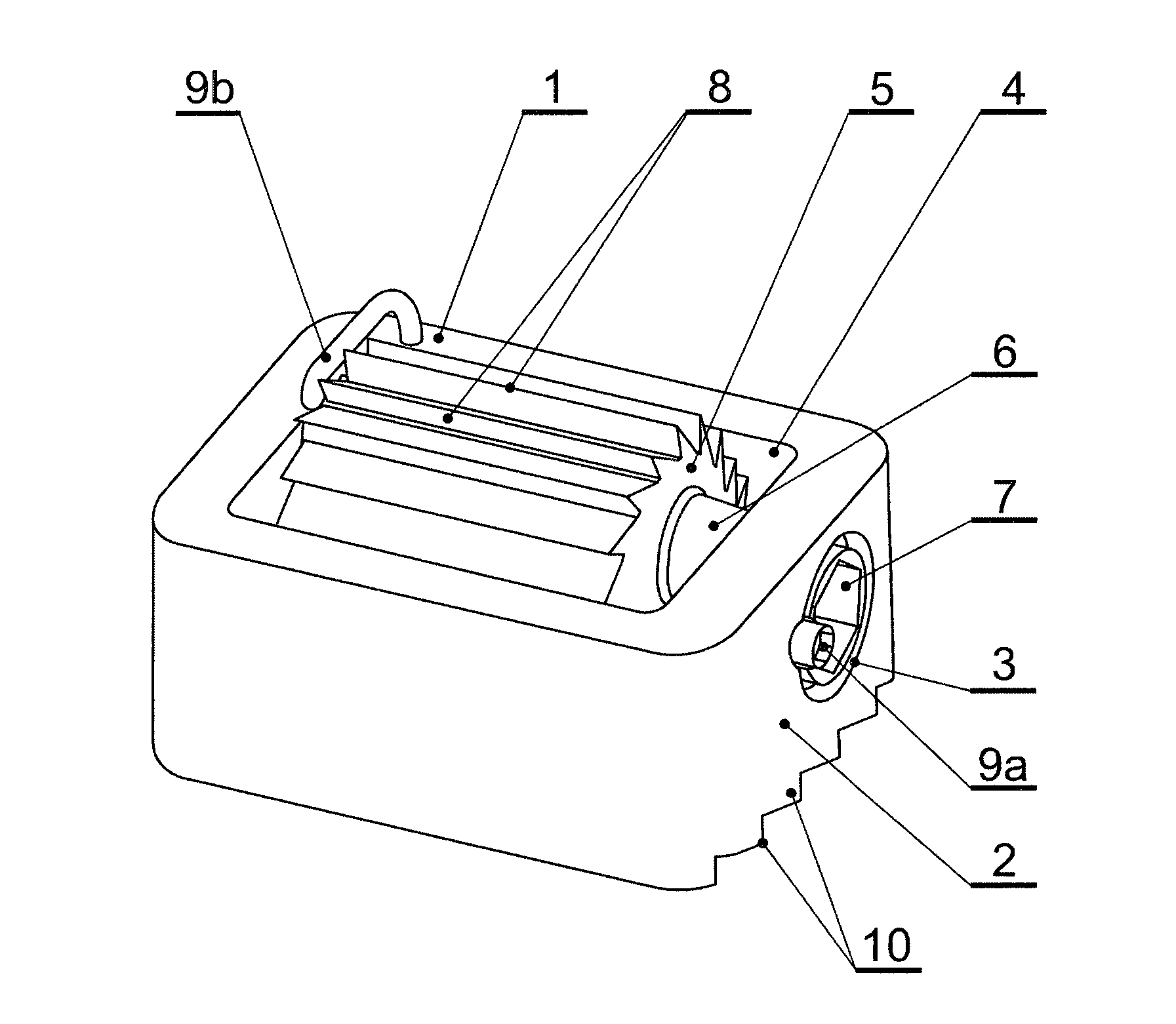

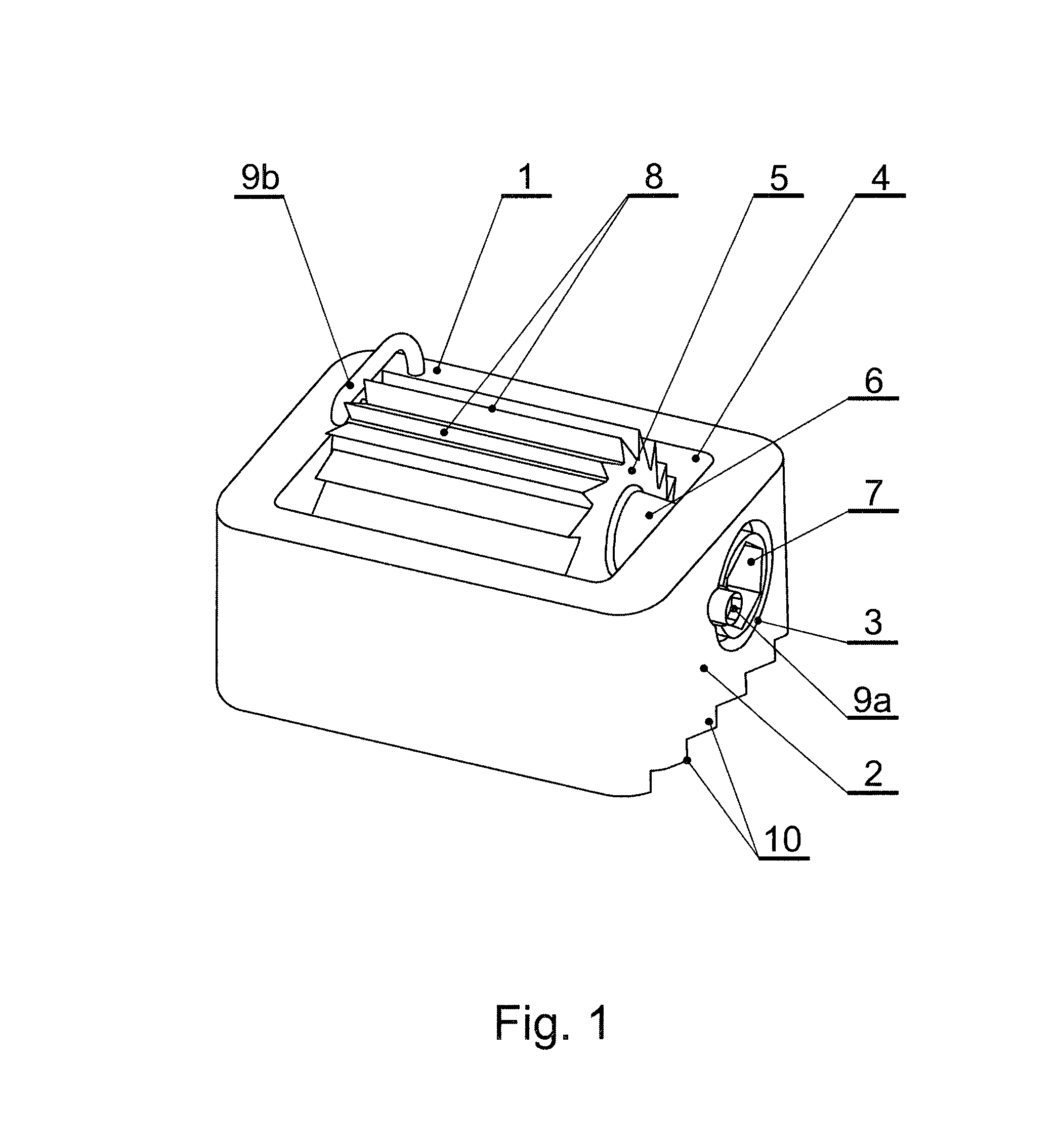

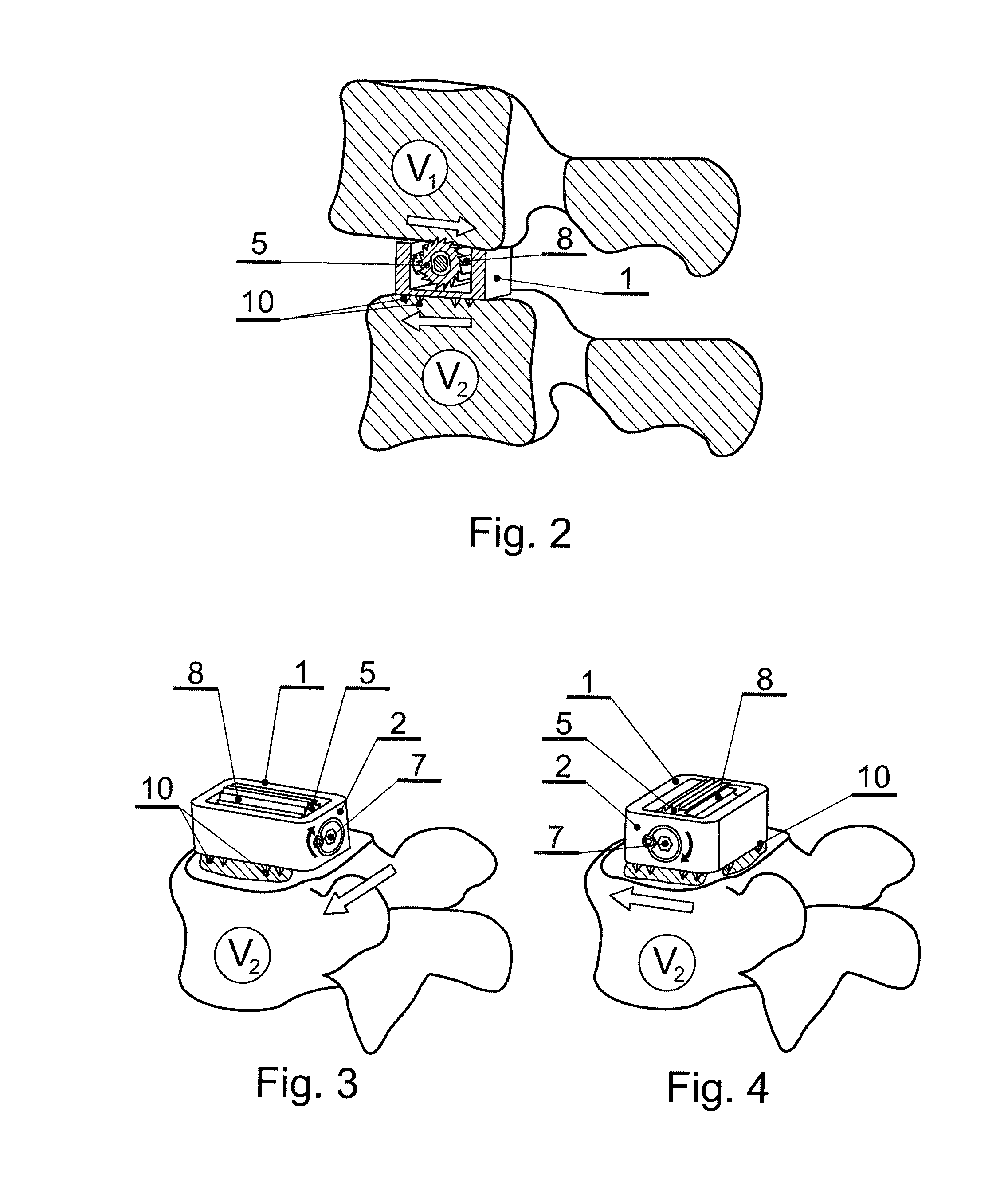

Intervertebral implant for mutual situating of adjacent vertebrae

InactiveUS9198771B2Simple and compact structureRestore normal adjustmentJoint implantsSpinal implantsBiomedical engineeringVertebra

An intervertebral implant for mutual situating of adjacent vertebrae includes a cover and a driving mechanism mounted in the cover. The cover presents a manipulative hole and a seat. The driving mechanism is located in the seat and includes a rotational element with anchoring to engage a vertebra. The implant includes a connecting element located within the diameter of the manipulative hole and operable to be engaged by a driving tool.

Owner:LFC Z O O

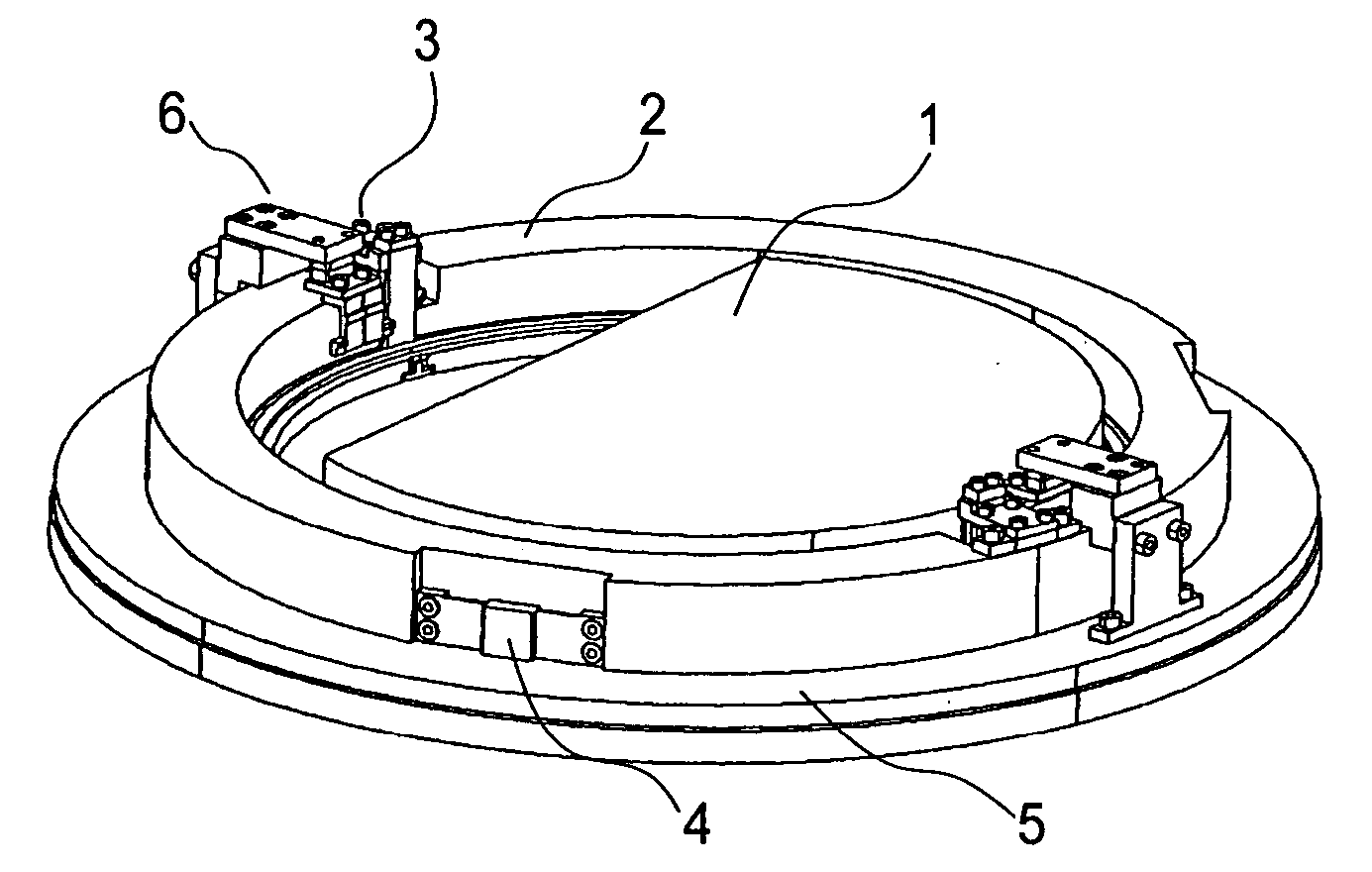

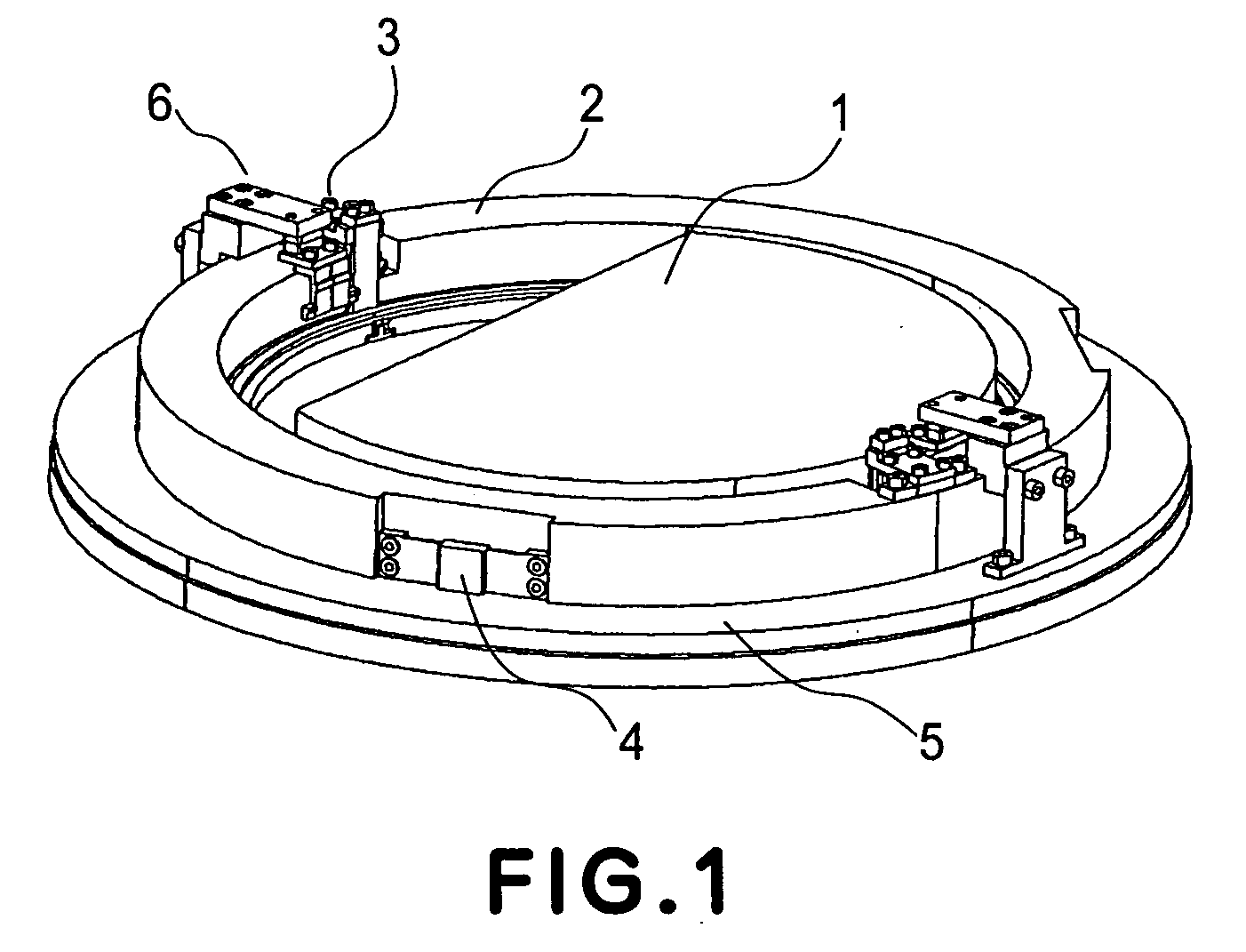

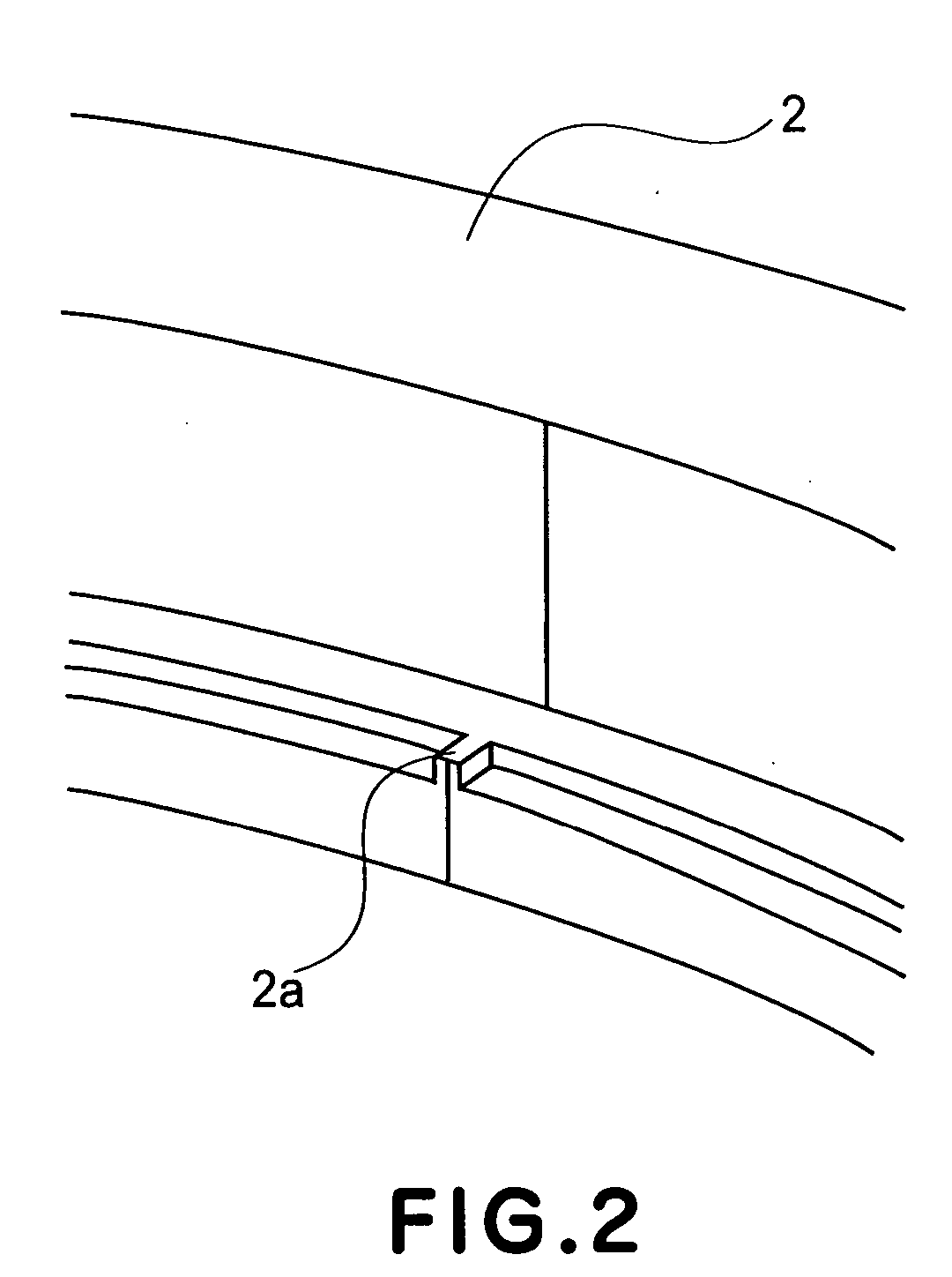

Optical element holding system, barrel, exposure apparatus, and device manufacturing method

Disclosed in this specification are an optical element holding system, a barrel usable therewith, and an exposure apparatus and an exposure method usable therewith. In one preferred form, the optical element holding system includes a ring-like inner holding member which is disposed at an outer periphery of the optical element, for supporting the optical element by use of at least a pair of pieces. The optical element holding system further includes a ring-like outer holding member which is disposed at an outer periphery of the inner holding member and is connected to the inner holding member at plural points. The inner holding member has at least a pair of driving units with an actuator, for supporting the optical element through the actuators.

Owner:CANON KK

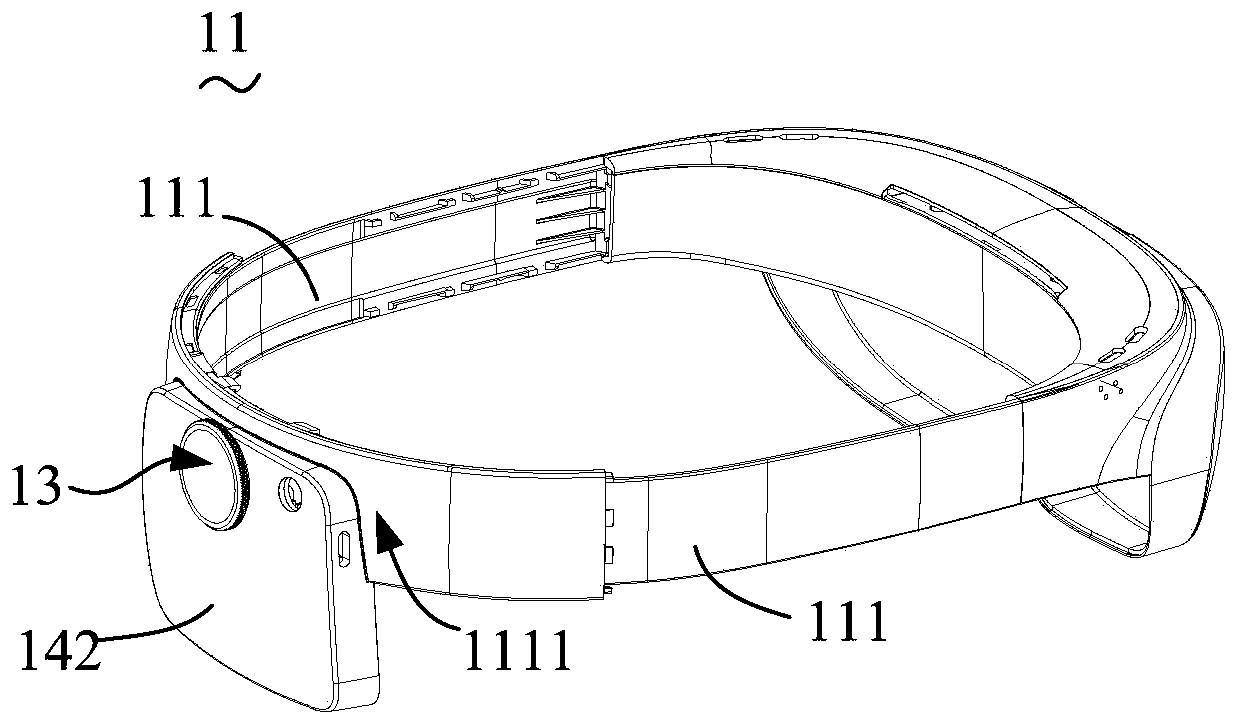

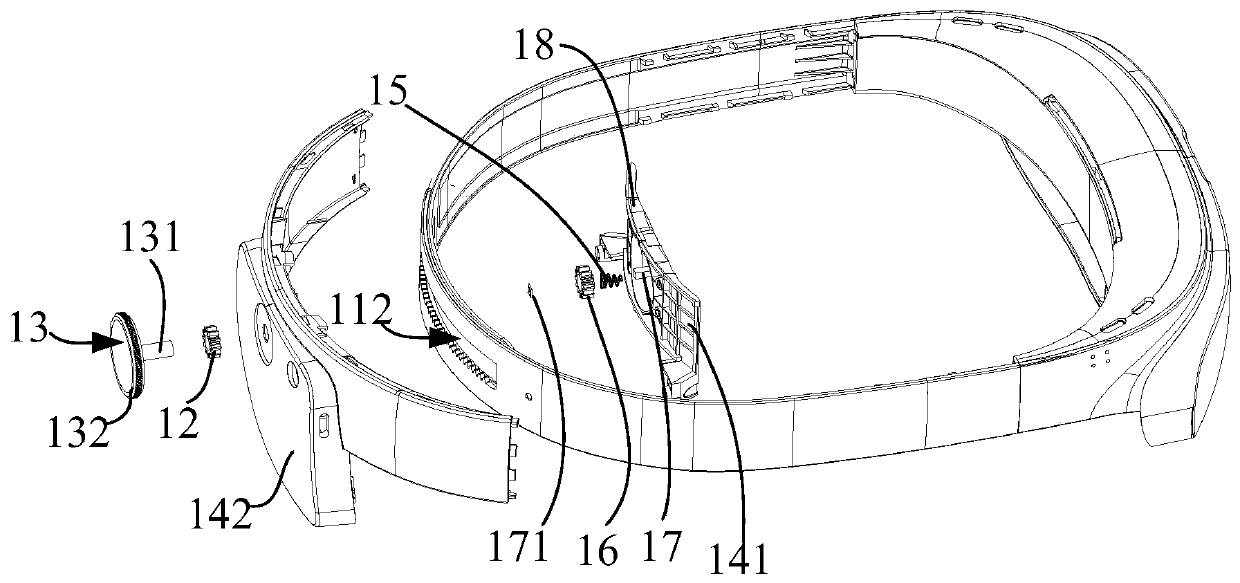

Head mount display support and head mount display

ActiveCN110441910AShape adjustableAdjustable sizeMachine supportsOptical elementsLocking mechanismEngineering

The invention provides a head mount display support and a head mount display. The head mount display support comprises a support main body, a rotary knob shaft, an adjustment gear and a self-locking mechanism, wherein the support main body comprises two telescopic arms; the two telescopic arms are arranged in an overlapped mode; the adjustment gear is fixedly arranged on the rotary knob shaft in asleeving mode; when the rotary knob shaft is pressed, the adjustment gear is driven by the rotary knob shaft to move to the overlapped position of the two telescopic arms to enable the two telescopicarms to move to be close to or to be far from each other; the self-locking mechanism comprises a rear shell, an elastic piece and a locking piece; and the self-locking structure is used for locking the relative positions of the two telescopic arms. The head mount display support and the head mount display can be suitable for various wearing head types, the shape of the head mount display supportcan be conveniently adjusted, and the adjusted head mount display support can be conveniently locked.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

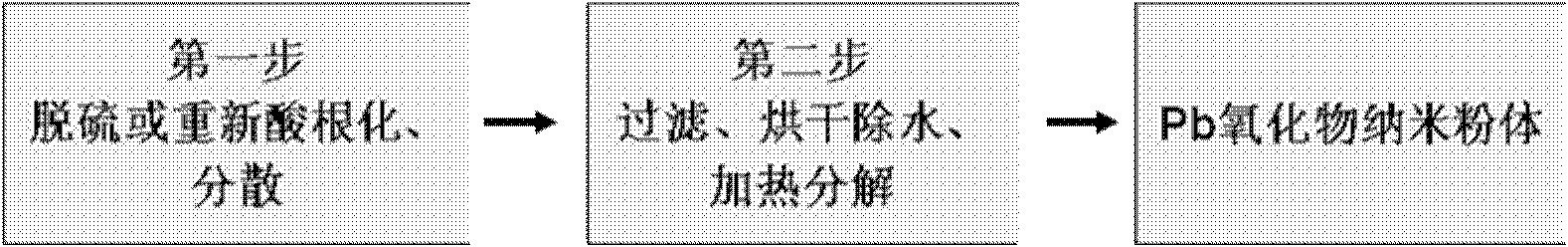

Preparation method of Pb oxide nano powder for recovery and manufacture of lead acid battery

ActiveCN102689921AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologyDecompositionLead salt

The invention discloses a preparation method of a Pb oxide nano powder for recovery and manufacture of a lead acid battery. The method comprises the steps of: (1) reacting lead salt or waste lead acid battery lead paste with an organic or inorganic compound capable of complexing with Pb atom / ion, so as to realize desulphurization or reloading of acid radical; and (2) carrying out treatment processes of filtering, drying for removing water and heating for decomposition, so as to obtain the Pb oxide nano powder. The method of the invention realizes an environment-friendly and energy-efficient recovery and production process with substantially reduced production cost; meanwhile, the prepared Pb oxide powder is beneficial for enhancement of product performance.

Owner:杨春晓

Intraocular lens system with injectable accommodation material

ActiveUS20080033547A1Modifies its propertyShape adjustableIntraocular lensPosterior lensAnterior lens

The invention relates to a intraocular lens system having a flexible anterior lens accommodation material behind the lens. The accommodation material may comprise of one or more macromers, which, when polymerized, adjust the properties of the accommodation material. The anterior lens is flexible such that the curvature of the lens changes during accommodation. The anterior lens may be used alone or in combination with a posterior lens.

Owner:RXSIGHT INC

Systems and methods for posterior dynamic stabilization of the spine

ActiveUS7998175B2Stabilizing spineAdjustable lengthInternal osteosythesisJoint implantsInterconnectionBiomedical engineering

Systems and devices for dynamically stabilizing the spine are provided. The systems include a superior component for attachment to a superior vertebra of a spinal motion segment and an inferior component for attachment to an inferior vertebral of a spinal motion segment. The interconnection between the two components enables the spinal motion segment to move in a manner that mimics the natural motion of the spinal motion segment. Methods are also provided for stabilizing the spine and for implanting the subject systems.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

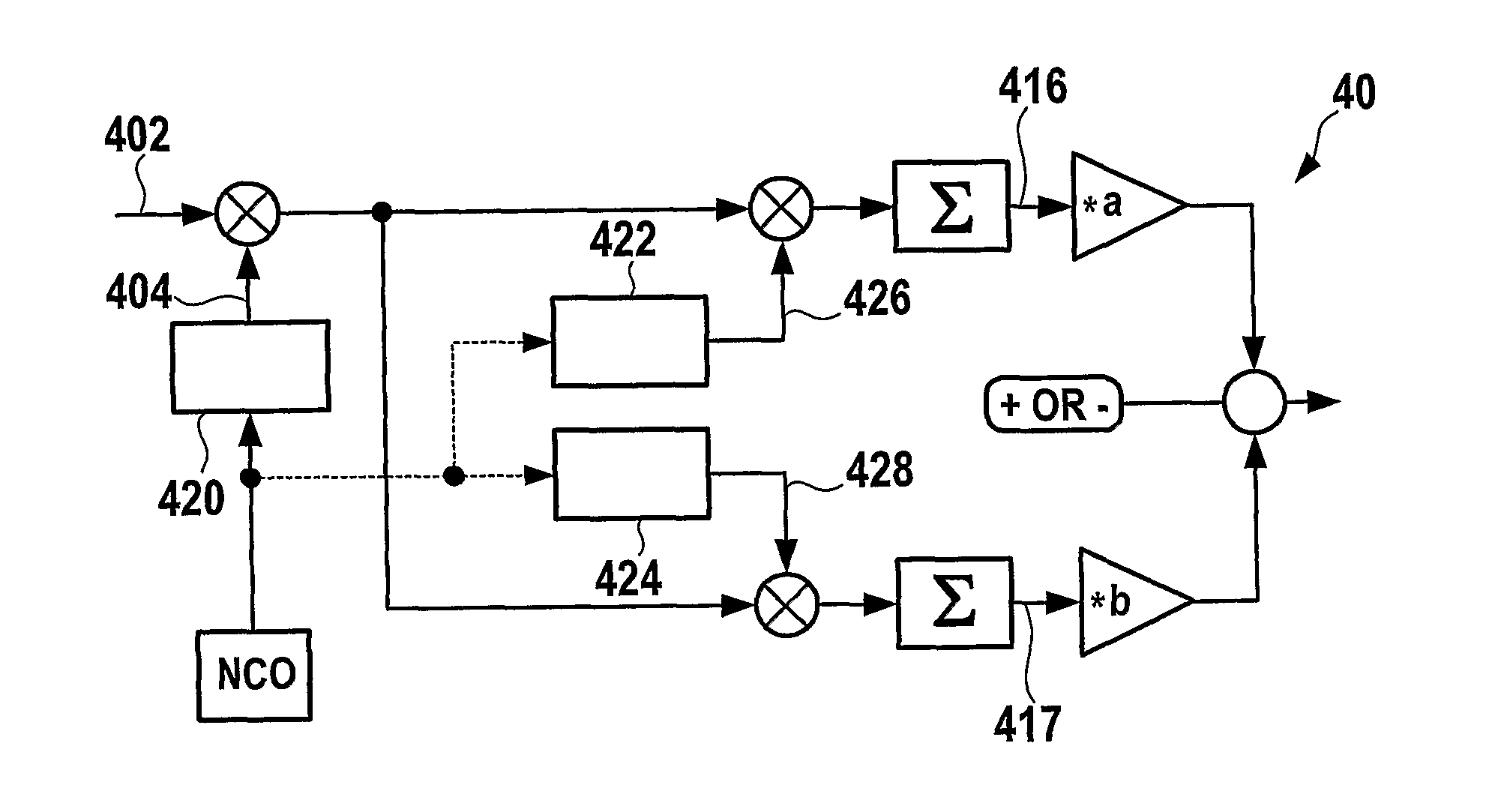

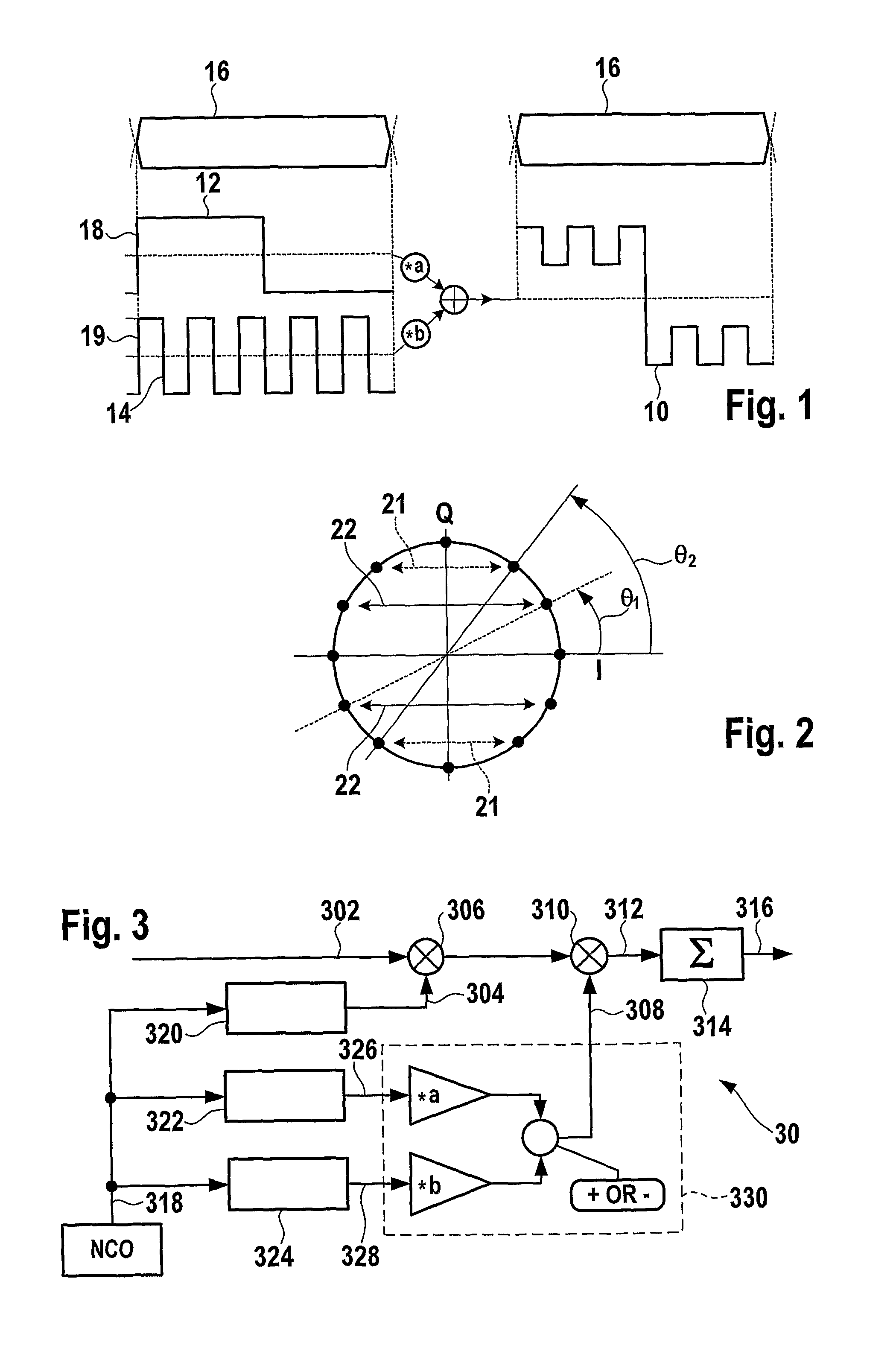

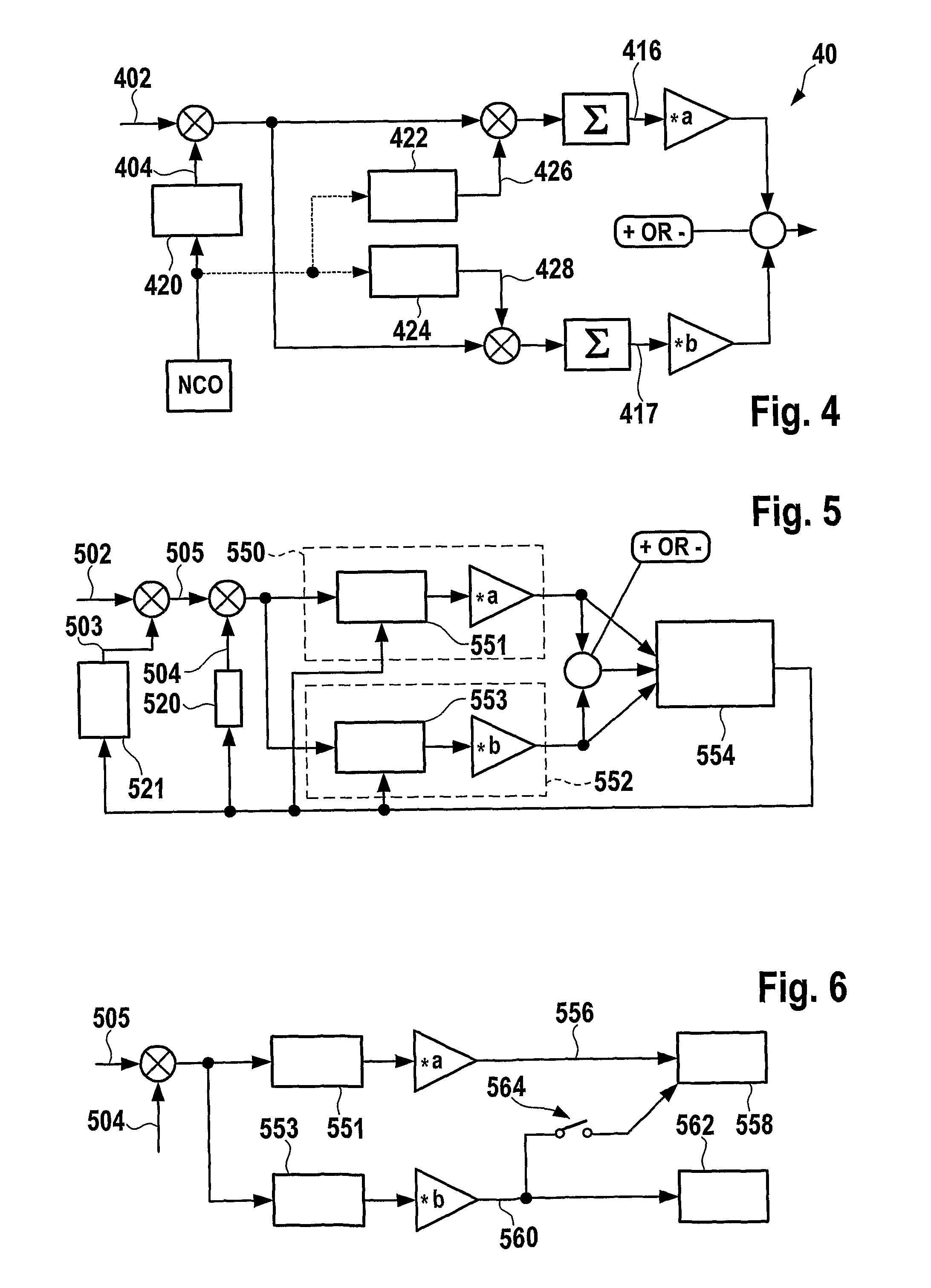

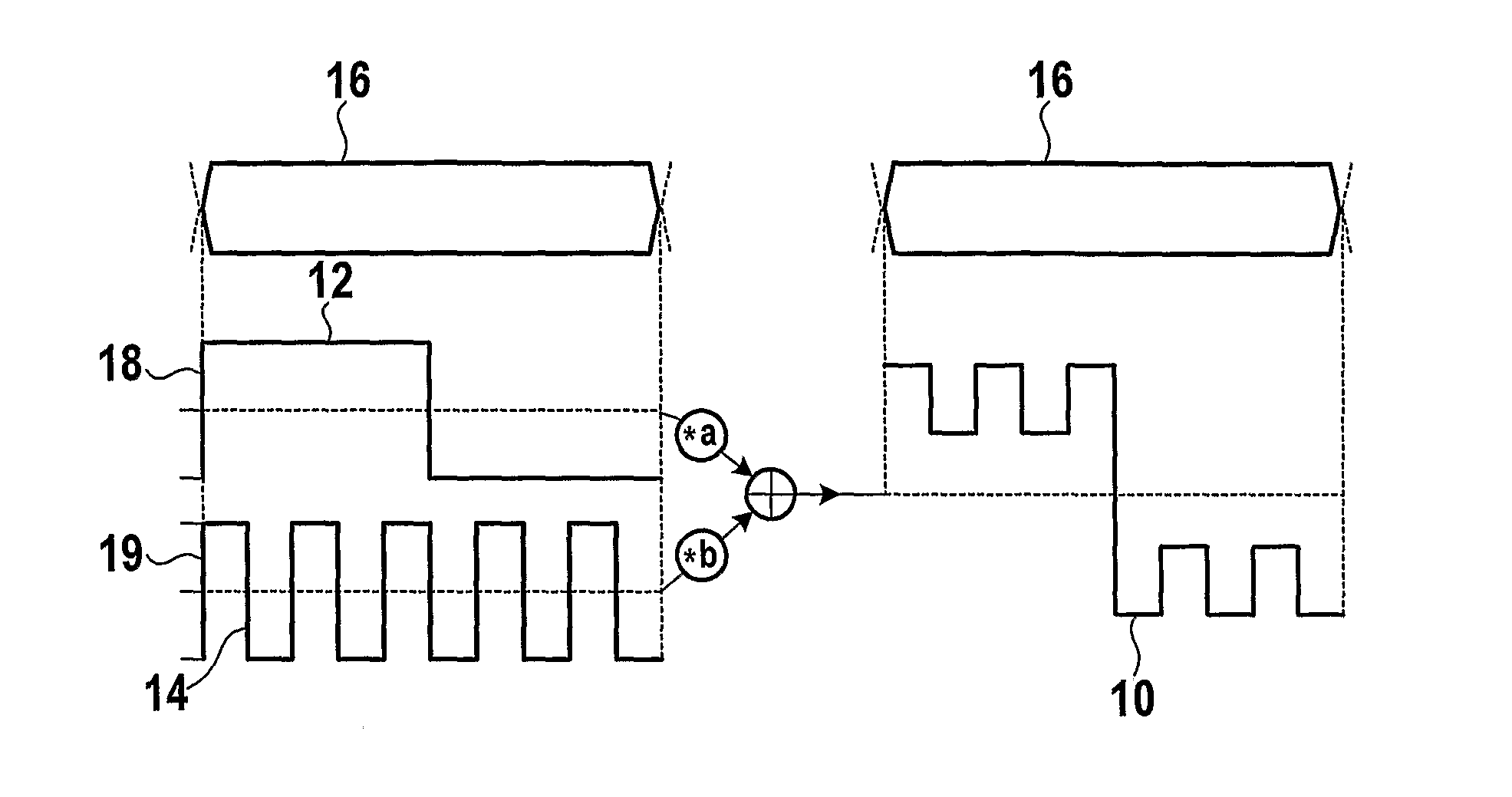

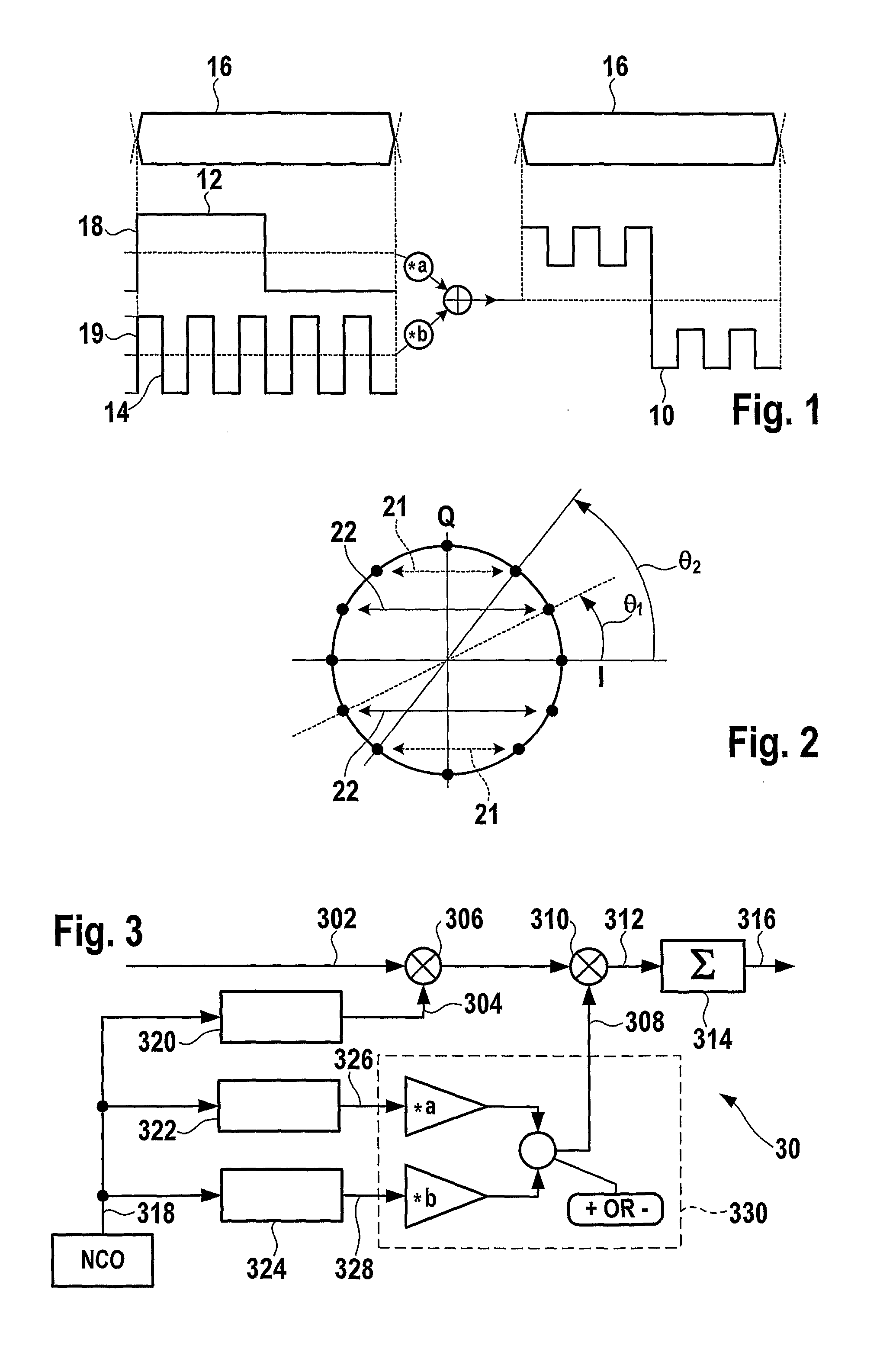

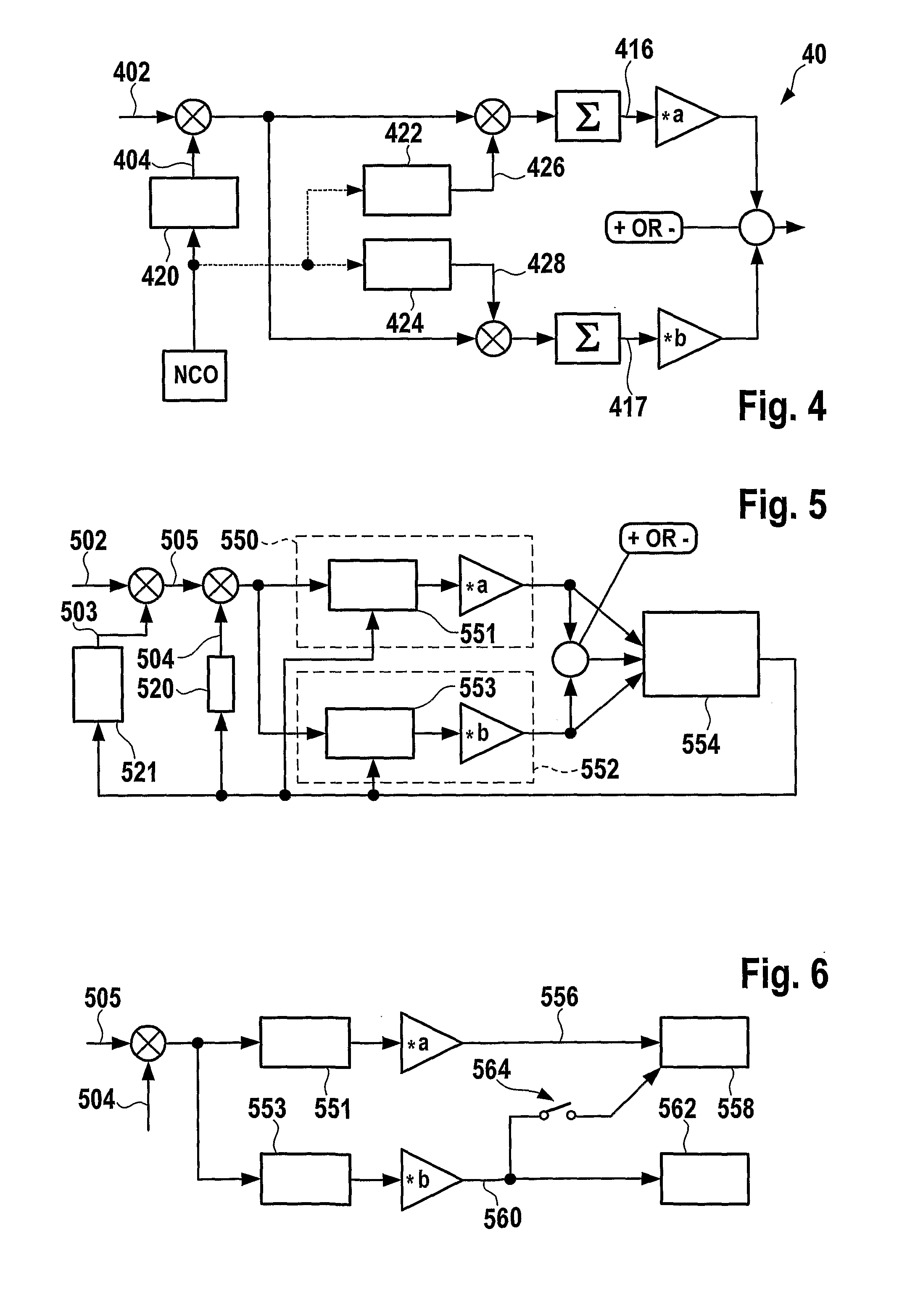

Spread spectrum signal

ActiveUS8189646B2Improve the level ofImprove abilitiesCode division multiplexSatellite radio beaconingCarrier signalSpread spectrum

A spread-spectrum signal comprises a spreading waveform modulating a carrier wave and containing a real linear combination of a first waveform at a first waveform rate and a second waveform at a second waveform rate, the first waveform rate being distinct from the second waveform rate and both waveform rates being distinct and non-zero. The linear combination of the first and the second waveform is modulated with at least one binary sequence comprising a signal identification code.

Owner:CENT NAT DETUD SPATIALES C N E S

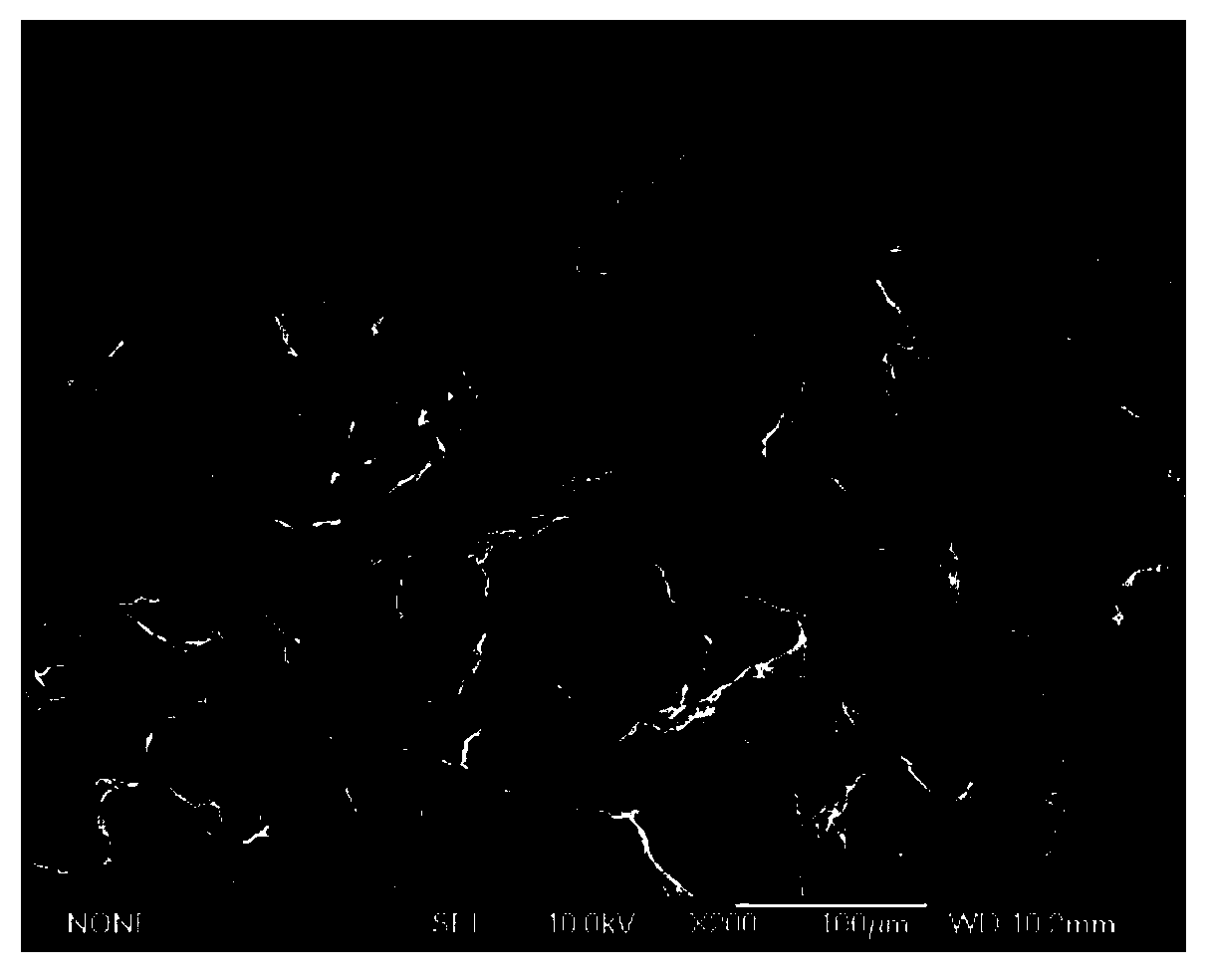

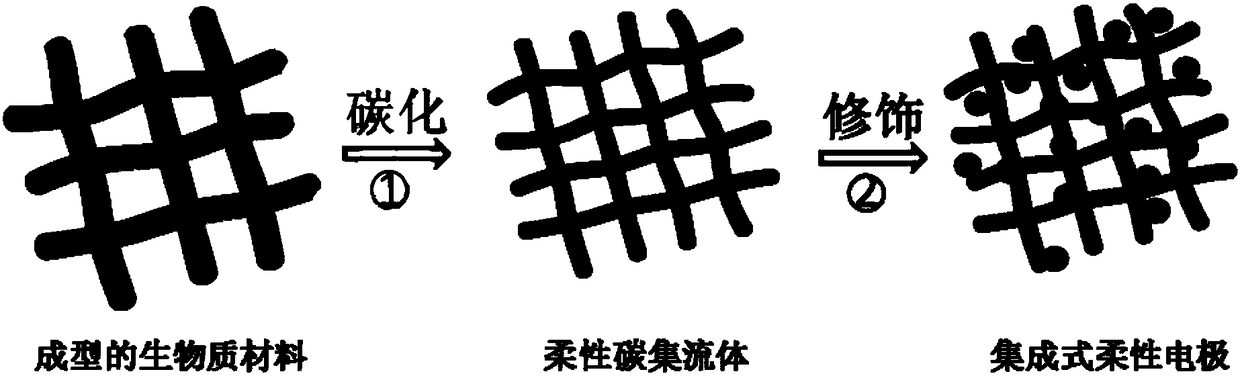

Biomass derived integrated flexible electrode and preparation method thereof

InactiveCN108232369AShape adjustableAdjustable sizeFuel and primary cellsHybrid capacitor electrodesCarbonizationProduct gas

The invention discloses a biomass derived integrated flexible electrode and a preparation method thereof. According to the preparation method, a biomass raw material is ground and subjected to formingpretreatment and carbonization, and a flexible carbon current collector, namely, the biomass derived integrated flexible electrode is obtained; the prepared integrated flexible electrode is further modified, and a modified integrated flexible electrode is obtained. Natural biomass with a porous structure is selected as the raw material in the preparation method, and on the basis of the special hollow structure of the biomass, gas transmission, liquid storage and electronic conduction of ions of the electrode are guaranteed effectively. By means of the pre-forming preparation way in the preparation method, morphology, size and thickness of the integrated flexible electrode are adjustable, and the process can be simplified effectively.

Owner:SOUTH CHINA UNIV OF TECH

Graphene hydrogel, graphene aerogel as well as preparation method and application thereof

ActiveCN106032274AAdjustable densityHigh densityOther chemical processesAlkali metal oxides/hydroxidesHigh energyFreeze-drying

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

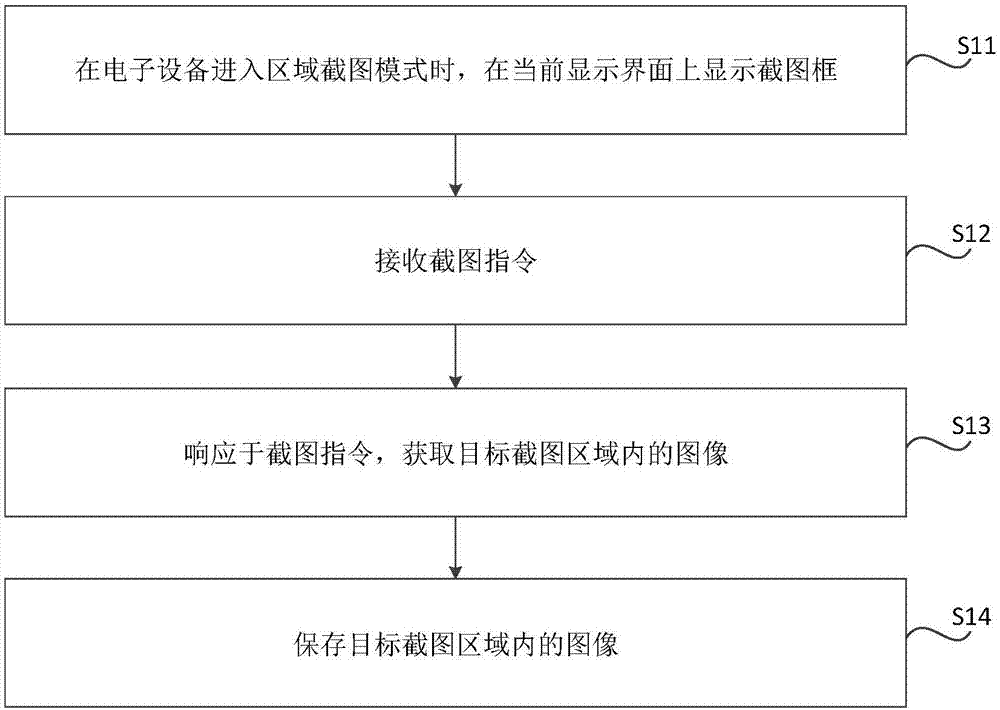

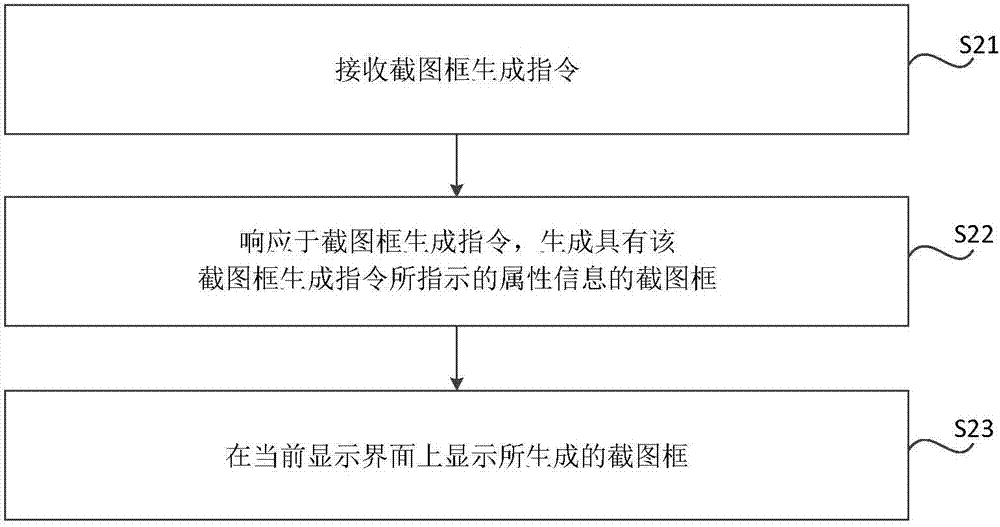

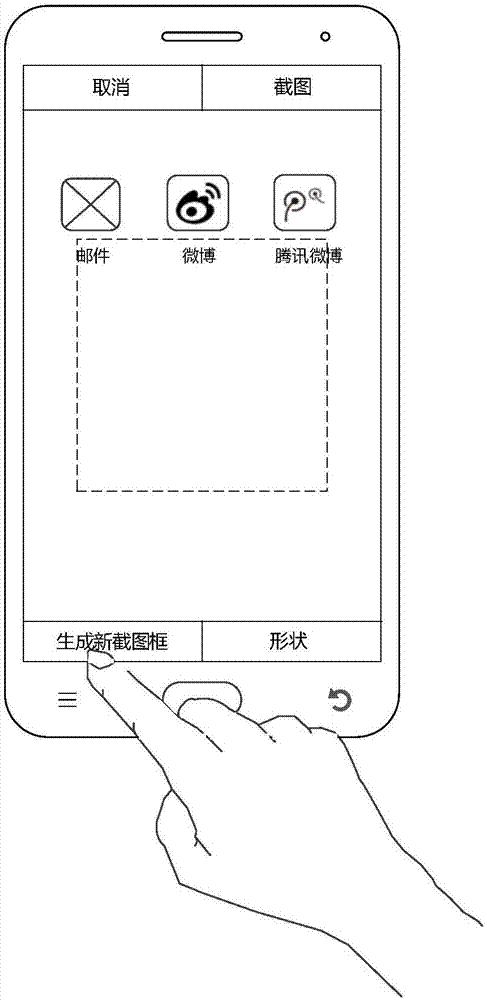

Screen capture method and device and storage medium

InactiveCN107515715AShape adjustableClose to demandInput/output processes for data processingComputer graphics (images)Human–computer interaction

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Method for preparing hollow ball with polymer complex structure by swelling polymerization

ActiveCN101259403AGuaranteed liquidityLarge specific surface areaMicroballoon preparationMicrocapsule preparationPolymer scienceSolvent

The invention belongs to the field of materials with a hollow structure, in particular to a method for preparing hollow spheres of minerals, metals and organic matters and hollow spheres of compound structures as well as hollow spheres with photic, electrical, magnetic and catalytic properties and hollow spheres with compound structures thereof by taking a polymer hollow sphere as a template through a swelling polymerization method. The invention prepares the compound hollow spheres by taking the polymer hollow sphere as a template and combining sol-gel, settlement reaction and redox process through the method of forcing interface or surface settlement, removes the template polymer through high sintering or selective extraction of a solvent to obtain the hollow spheres of minerals, metals and organic matters. The structure and the size of the hollow sphere can be controlled through controlling the reagent activity, the feeding mode, the reagent concentration and a circulation reaction method; besides, compounding of various matters can be realized; the hollow sphere of the invention not only has good dispersing performance, but also has excellent strength and size stability. The invention relates to the application of the materials with a hollow structure.

Owner:BEIJING NEW BUILDING MATERIALS PLC

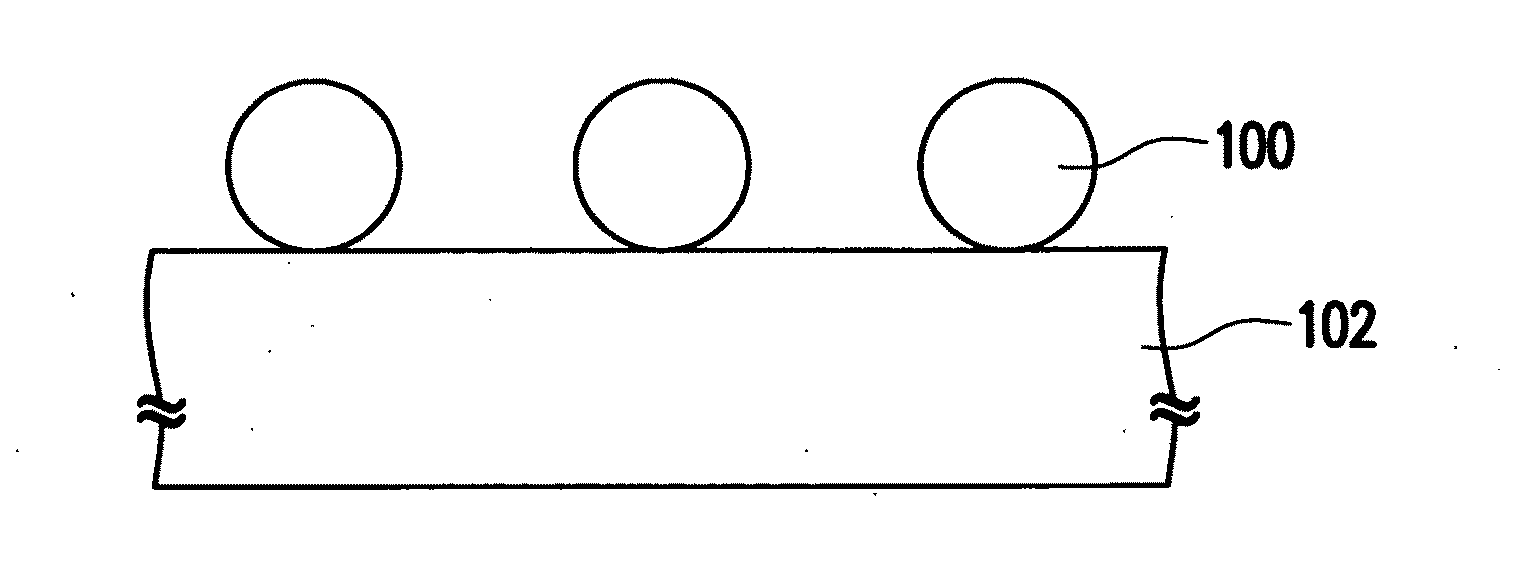

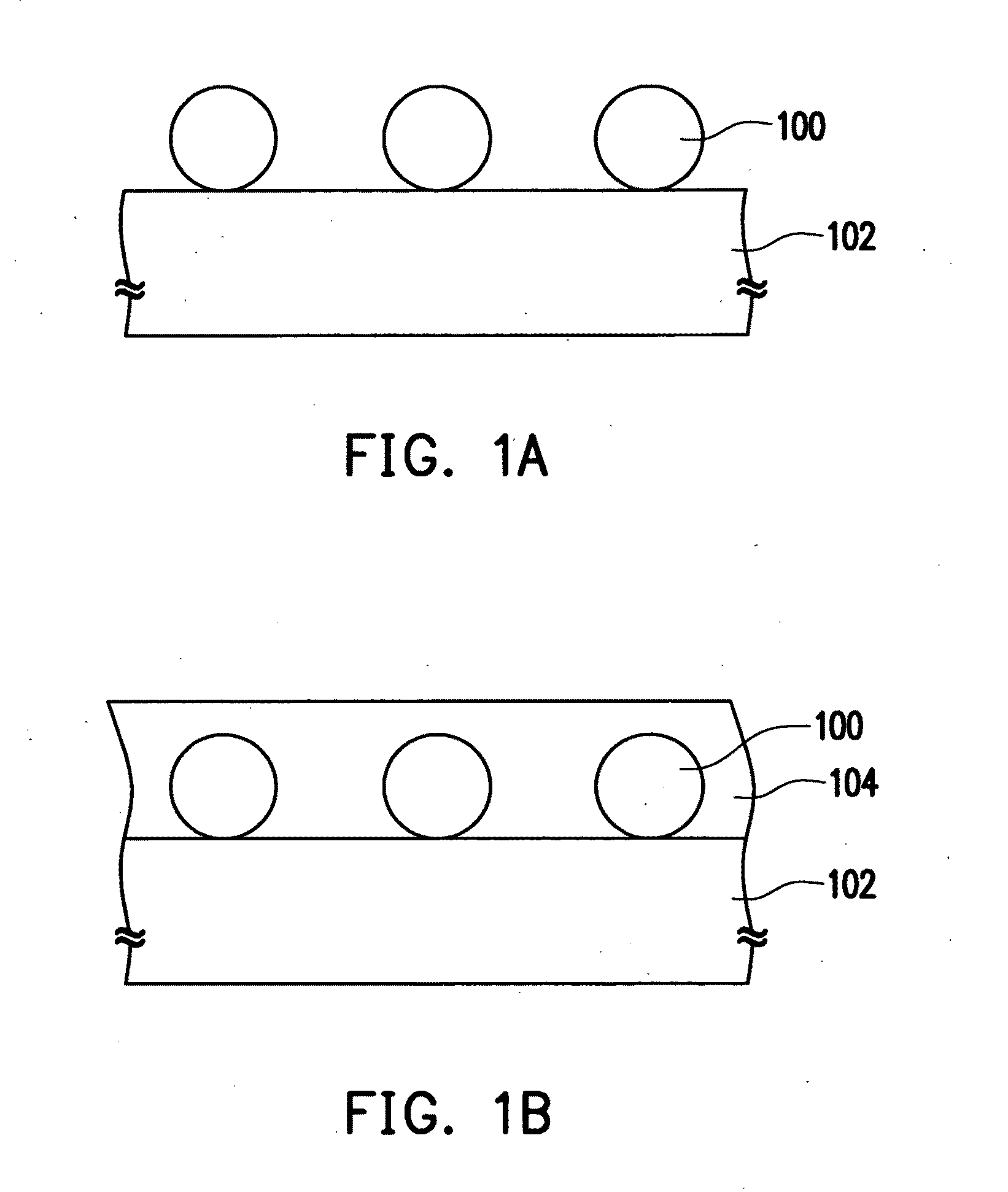

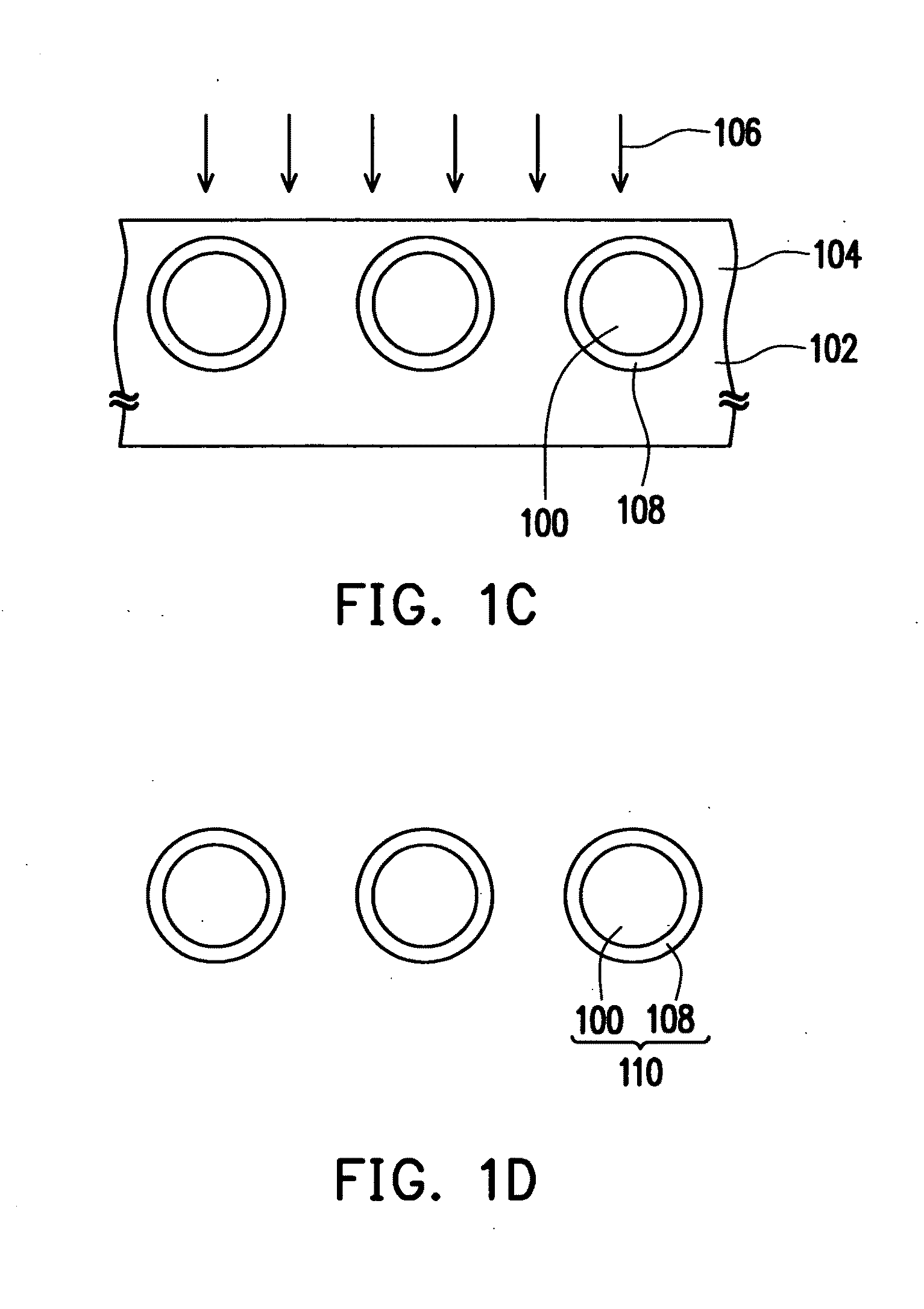

Method of manufacturing core-shell nanostructure

InactiveUS20100166976A1Convenient coatingShape adjustableLiquid surface applicatorsTransportation and packagingThermal energyLight energy

A method for manufacturing core-shell nanostructure is provided. A nanoparticle containing a metal is provided. The nanoparticle is capable of transforming the light energy to the thermal energy. The nanoparticle is distributed onto a first thermosetting material precursor. A second thermosetting material precursor is coated on the first thermosetting material precursor to cover the nanoparticle. The nanoparticle is irradiated by a light source to produce the thermal energy such that the first thermosetting material precursor and the second thermosetting material precursor around the nanoparticle are cured to form a material layer on the nanoparticle. The uncured portion of the first thermosetting material precursor and the uncured portion of the second thermosetting material precursor are removed.

Owner:IND TECH RES INST

Porous material prepared from solid wastes

InactiveCN108558254AIncrease varietyWide range of usesCeramic materials productionCeramicwarePorosityPrill

The invention belongs to the field of environment protection and relates to porous material prepared from solid wastes. The porous material is prepared from, by weight, 50-97% of solid waste parent material, 1-20% of a forming agent, 1-15% of a foaming agent and 1-15% of fluxing agent. By the arrangement, shortcomings that the porous material prepared from existing solid wastes require clay consumption, and the porous material is difficult to control, long in sintering time, high in energy consumption and severe in requirement of process control are overcome; the porous material prepared fromthe solid wastes is widely applicable and adjustable in particle size and shape, volume density, porosity size and percentage of close area of the porosity can be adjusted in a wide range, clay consumption is not needed, and short sintering time is achieved.

Owner:ZEROWASTE ASIA PTE LTD

Method for preparing starfruit-shaped SnO2/C micro-nano particles through electrostatic spinning and prepared product

InactiveCN105668617ANarrow scale distributionUnique shape of the productTin oxidesDimethyl formamideElectrospinning

The invention discloses a method for preparing starfruit-shaped SnO2 / C micro-nano particles through electrostatic spinning and a prepared product. The method comprises steps as follows: PVP (polyvinyl pyrrolidone), TBAB (tetrabutylammonium bromide), liquid paraffin and tin salt are dissolved in a mixed solvent of ethanol and DMF (dimethyl formamide) and stirred, and a transparent solution is obtained; the transparent solution is treated with an electrostatic spinning method, precursor fibers are obtained and calcined under the condition of inert gas protection, and the starfruit-shaped SnO2 / C micro-nano particles are obtained. The starfruit-shaped SnO2 / C micro-nano particles with adjustable sizes are prepared with the combination of a simple electrostatic spinning technology and the heat treatment process under the condition of inert gas protection, the technological process is simple, the synthesis condition is easy to control, the operability is high, the product morphology is unique, the controllability is high, the repeatability is good, the particle size distribution range is narrow, the particle sizes are adjustable, and the method is suitable for industrial production. The obtained starfruit-shaped SnO2 / C micro-nano particles have potential application value in the aspects of a supercapacitor, a lithium ion battery and the like.

Owner:UNIV OF JINAN

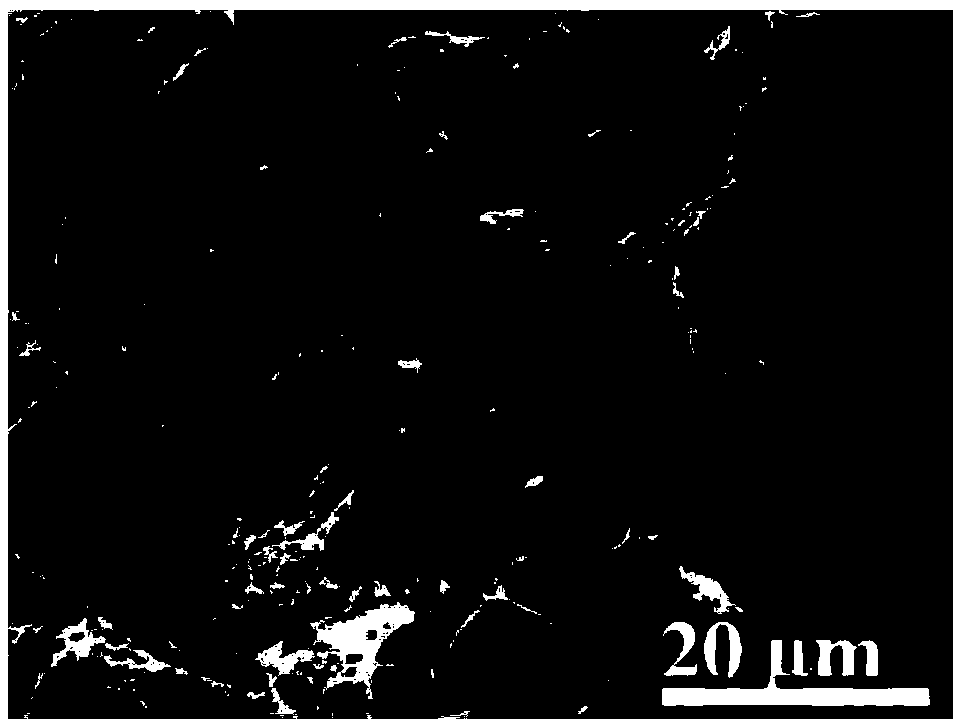

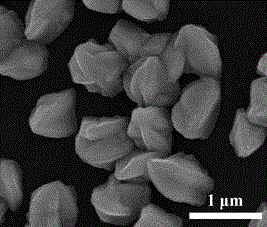

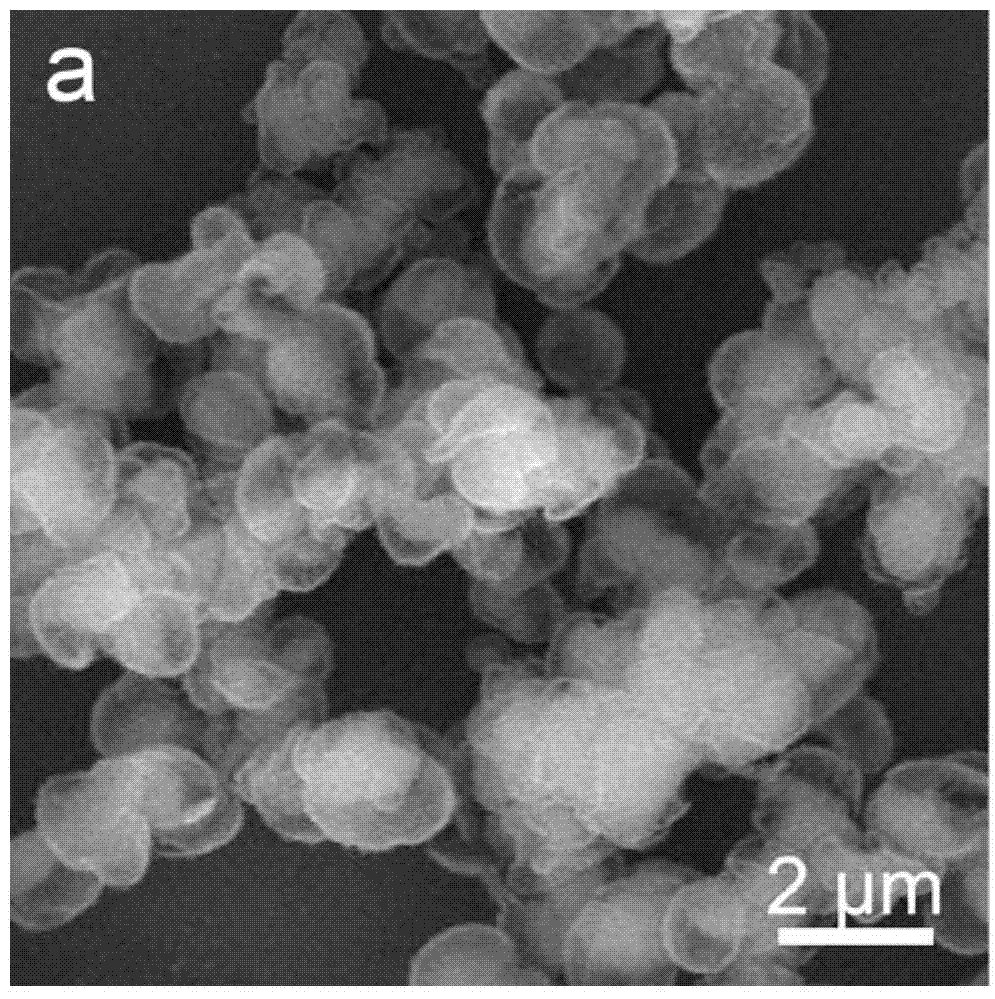

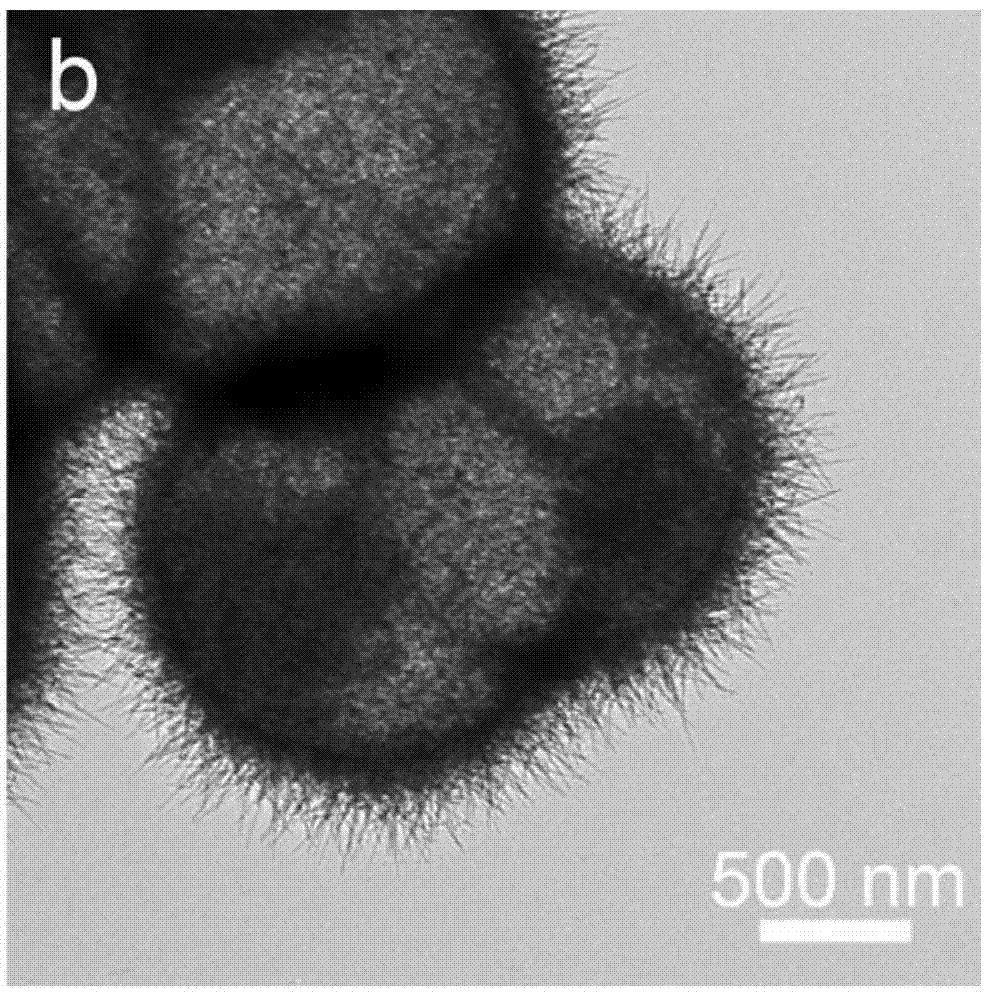

Method for preparing transition metal oxide microspheres with controllable morphology

ActiveCN104743609ASimple stepsExperimental conditions are easy to controlMaterial nanotechnologyManganese oxides/hydroxidesMicrosphereControllability

The invention discloses a method for preparing transition metal oxide microspheres with controllable morphology. According to the method for preparing the transition metal oxide microspheres, the transition metal oxide microspheres are produced according to the steps of introducing catechol compounds into a reaction system and then performing simple hydrothermal reaction, and preferably, a morphology control agent can also be added in the hydrothermal reaction system to control the morphology of the transition metal oxide microspheres. According to the method for preparing the transition metal oxide microspheres with controllable morphology disclosed by the invention, the transition metal oxide microspheres with controllable morphology are produced by adding a special morphology control agent into the hydrothermal reaction system to control the anisotropic growth of the material, not only the technology is simple, the controllability is good and the yield is high, but also the product produced according to the method has uniform size, larger specific surface area and high reaction activity and is suitable for large-scale preparation.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Spread Spectrum Signal

ActiveUS20080137714A1Improve the level ofImprove abilitiesCode division multiplexBeacon systemsCarrier signalSpread spectrum

A spread-spectrum signal comprises a spreading waveform modulating a carrier wave and containing a real linear combination of a first waveform at a first waveform rate and a second waveform at a second waveform rate, the first waveform rate being distinct from the second waveform rate and both waveform rates being distinct and non-zero. The linear combination of the first and the second waveform is modulated with at least one binary sequence comprising a signal identification code.

Owner:CENT NAT DETUD SPATIALES C N E S

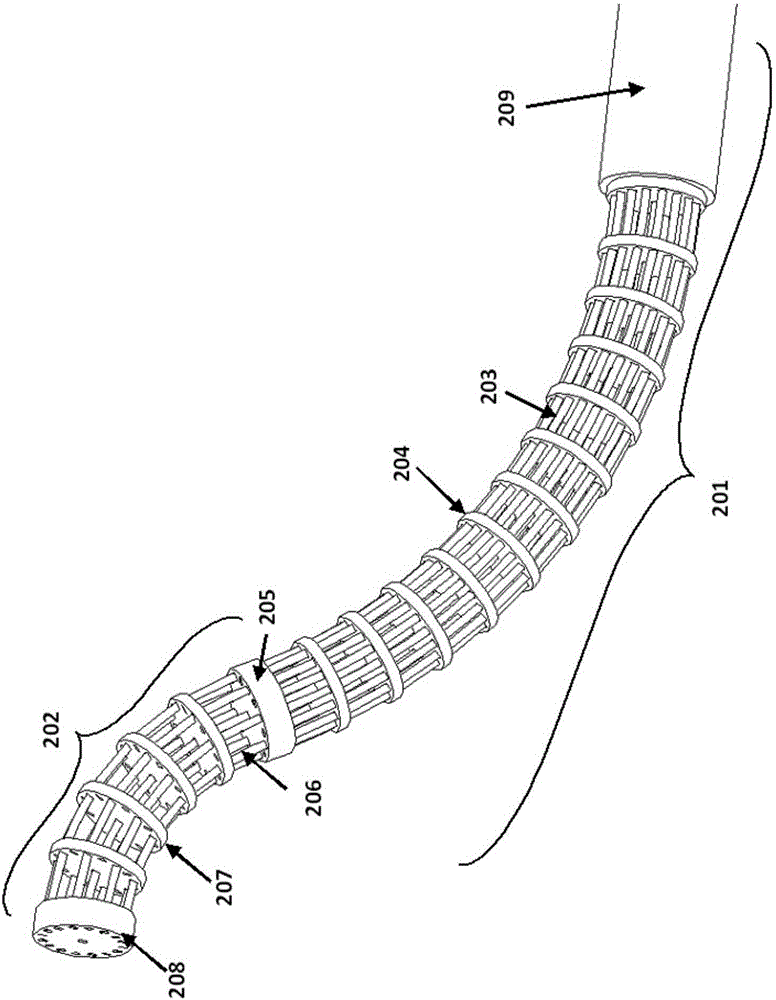

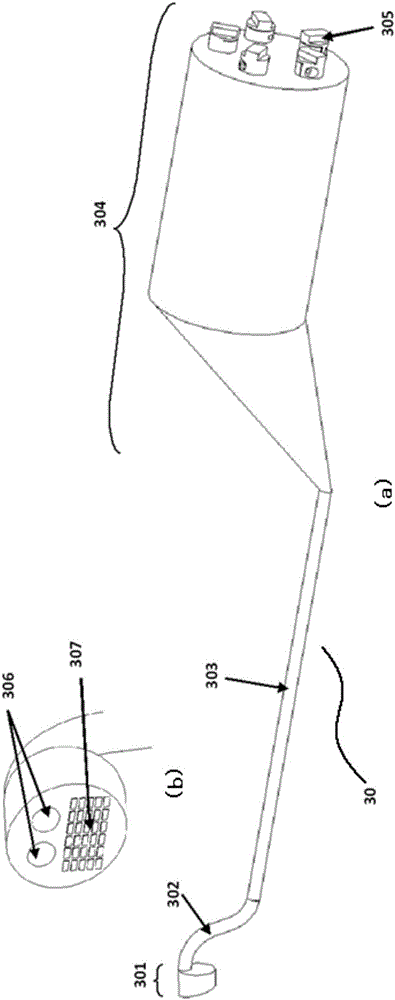

Single-incision laparoscopic surgery system based on flexible arms

ActiveCN106175851AGuaranteed implementabilityMeet size constraintsSurgical robotsDegrees of freedomSingle incision laparoscopic

The invention relates to a single-incision laparoscopic surgery system based on flexible arms. The single-incision laparoscopic surgery system comprises flexible surgery tools, an imaging tool, a catheter and a driving body. Each flexible surgery tool comprises the first flexible arm, a surgery performer and a first driving transmission unit. The imaging tool comprises the second flexible arm, an imaging lighting module and a second driving transmission unit. The catheter comprises a catheter body and a multi-cavity catheter main body. The driving body comprises a framework linked with the catheter, and a plurality of driving modules connected to the framework in a fastened mode and linked with the first driving transmission units and the second driving transmission unit. The overall feed degrees of freedom, the overall rotation degrees of freedom and the turn degrees of freedom of the first flexible arms are achieved through the driving modules via the first driving transmission units linked with the driving modules, and the overall feed degrees of freedom and the turn degrees of freedom of the second flexible arm are achieved through the driving modules via the second driving transmission unit linked with the driving modules. According to the single-incision laparoscopic surgery system, the flexible surgery tools and the imaging tool can enter the human body through the same multi-cavity catheter main body to perform surgery.

Owner:BEIJING SURGERII TECH CO LTD

Blue-jewel-crystal multi-crucible melt growth technolgoy

ActiveCN101024898AThe structure of the temperature field is stableAdjustable temperature gradientPolycrystalline material growthFrom frozen solutionsFurnace temperatureHearth

The invention provides a multi-pot melt growth technique for growing sapphire crystals, comprising: (1) pretreating aluminum oxide raw material; (2) placing the pretreated aluminum oxide blocks and the oriented seed crystals into pots and moving into high temperature descending furnace, sealing the whole system and power-on to raise temperature, starting mechanical pump and diffusion pump in turn, vacuumizing to 10-3-10-4Pa, and when the furnace temperature up to 1500-1800deg.C, charging inert gas and continuing raising temperature to the set temperature (2100-2250deg.C); (3) when the furnace temperature up to the set temperature, preserving heat for 4-8 hours, regulating hearth temperature and pot positions to smelt raw material and seed crystal top to implement inoculation growth and setting solid-liquid interface temperature gradient at 10-50deg.C / cm and controlling pot descending rate at 0.1-3.0mm / h; and (4) after the crystal growth ends, making in-situ annealing treatment. And the process has features of raw material pretreatment, special temperature field design, multi-pot technique, in-situ annealing treatment, etc, and advantages of stable temperature field, adjustable temperature gradient, operating convenience, low average energy consumption, high yielding by one furnace, and beneficial to industrialized production.

Owner:苏州晶生新材料有限公司

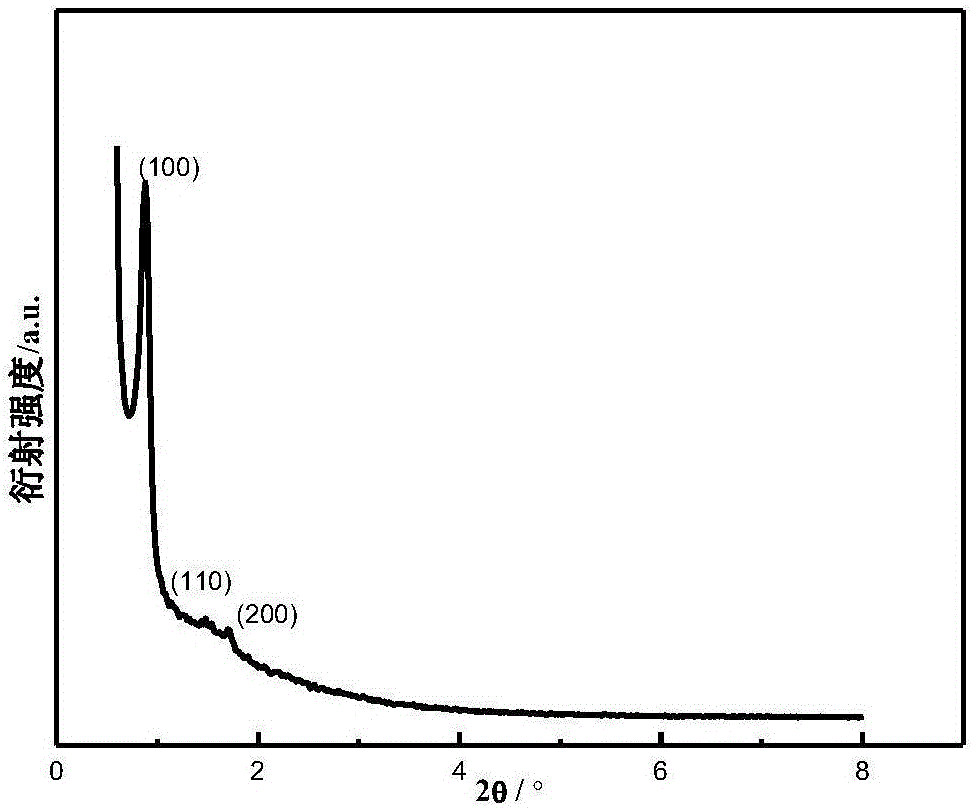

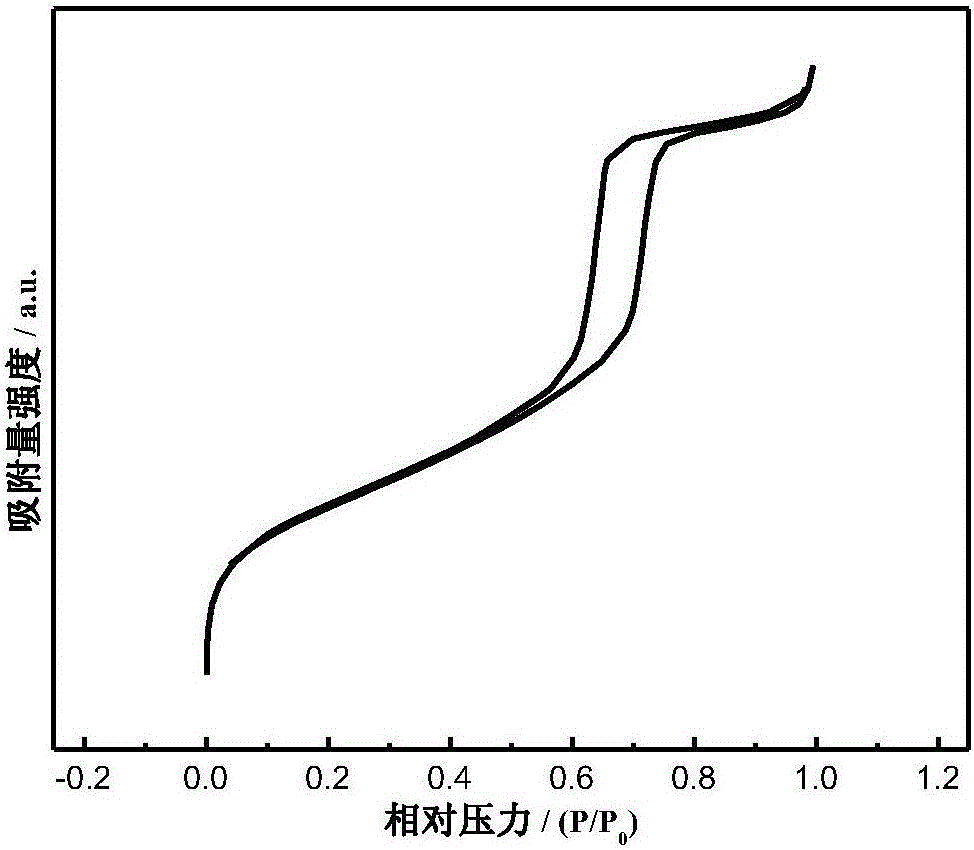

SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester and preparation method and application thereof

ActiveCN106040282AEfficient and stable synthesisReduce separation energy consumptionMolecular sieve catalystsOrganic compound preparationMolecular sieveCarboxylic acid

The invention discloses a SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester. The molecular sieve catalyst is prepared by adopting a template agent, a morphology regulator, a silicon source, a sulfonic acid source and an oxidizing agent through a one-step co-condensation method or a two-step sulfonic acid group post-synthesis method. In the SO3H-SBA-15 molecular sieve catalyst, by the molar ratio of a sulfonic acid group to silicon oxide, the sulfonic acid group supporting amount accounts for 30%-50%. The invention further discloses a method of using the SO3H-SBA-15 molecular sieve catalyst to catalyze the isobutene and the carboxylic acid for carboxylic acid tert-butyl ester synthesis. The molecular sieve catalyst is adjustable in shape, orderly in mesoporous pore passage and capable of efficiently and stably catalyzing the isobutene and the carboxylic acid to selectively synthesize the carboxylic acid tert-butyl ester under the conditions of higher temperature and polymerization inhibitor absence, meanwhile the separation energy consumption and equipment investment of reaction products are reduced, and the SO3H-SBA-15 molecular sieve catalyst has an important significance on development and utilization of atomic economic reaction.

Owner:NANJING UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com