Graphene aerogel as well as preparation method and application thereof

A graphene aerogel and graphene technology, applied in the field of graphene aerogel and its preparation, can solve the problems of complex process and high temperature, and achieve the effects of simple operation, high utilization rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

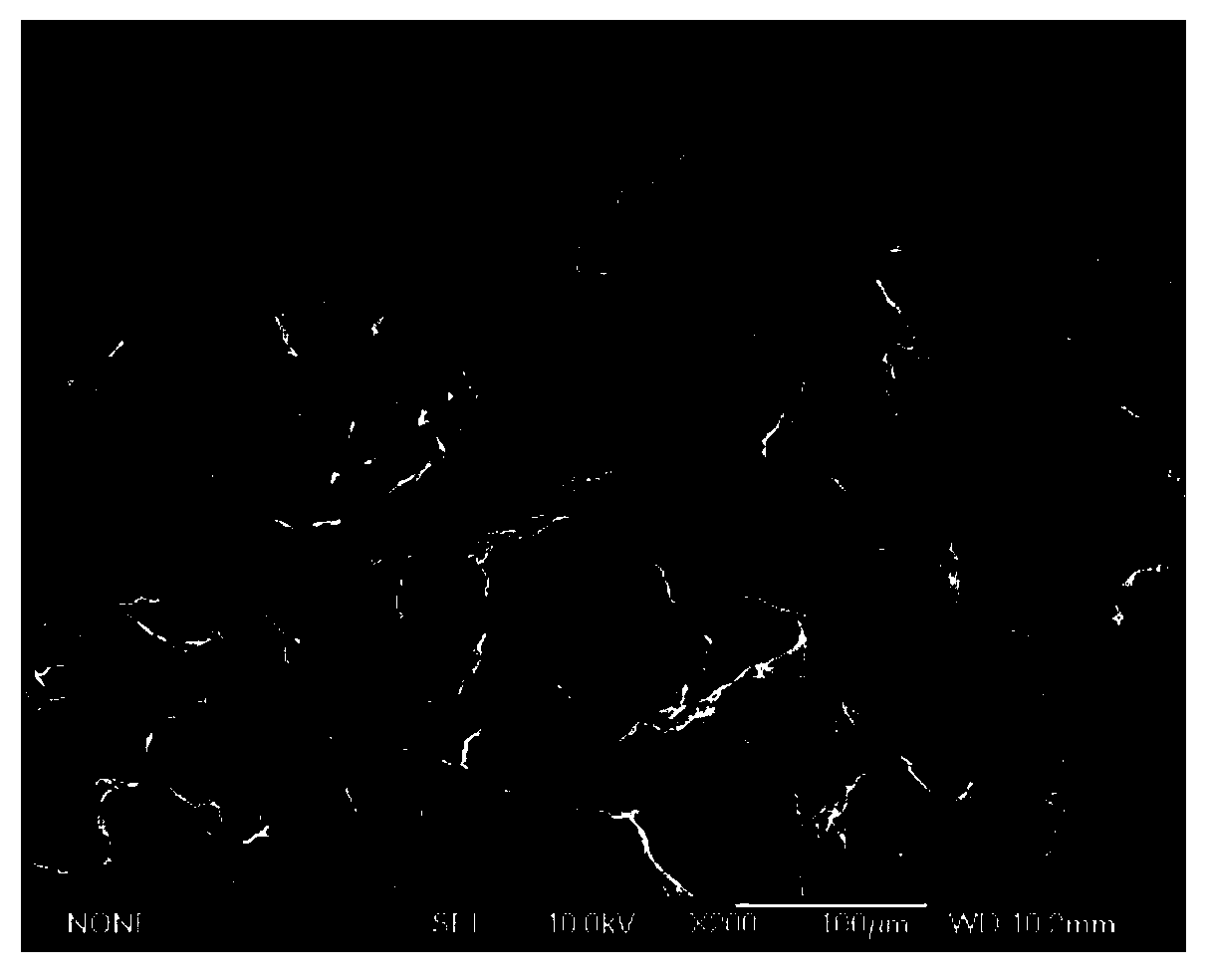

Embodiment 1

[0036] (1) Utilize the improved oxidative exfoliation graphite method to prepare graphene oxide dispersion liquid:

[0037] Add 10g of graphite, 150ml of 98% sulfuric acid, and 30ml of nitric acid into a 500ml Erlenmeyer flask and stir at room temperature for 24 hours, slowly pour it into 1L of water to collect the solid, wash it 3 times, and dry it at 80°C for 4 hours. Repeat the pre-oxidation process twice. The dried pre-oxidized graphite was put into a box furnace and thermally expanded at 900°C for 10s to obtain thermally expanded graphite oxide. In a 500ml wide-mouth Erlenmeyer flask, mix 5g of heat-expandable graphite oxide with 300ml of sulfuric acid, 5g of K 2 S 2 o 8 , 7g of phosphorus pentoxide mixed and heated at 80°C for 4 hours, diluted with 2L of water,

[0038] Filter and wash, and dry in air for 3 days to obtain pre-oxidized heat-expandable graphite. Mix dry pre-oxidized heat-expandable graphite with 200ml of sulfuric acid at a low temperature of 0-5°C, ad...

Embodiment 2

[0044] Repeat Example 1, except for the following differences, other conditions are the same:

[0045] Step (1) Preoxidized graphite is thermally expanded at 400°C for 30s to obtain thermally expanded graphite oxide;

[0046] Step (4) irradiate the sealed irradiation reactor with a cobalt 60 gamma ray source with a dose of 50kGy, form an amino-modified graphene hydrogel in a thin tubular reactor, and dry it with supercritical carbon dioxide to obtain a slender rod-shaped graphene gas. gel. Its nitrogen content, carbon-oxygen ratio and density are shown in Table 1. The resulting slender rod-shaped graphene airgel is placed into a photo of the character "King" as shown in image 3 shown. The rod-shaped graphene airgel has good oil absorption performance, and the adsorption capacity reaches 110g / g (taking n-decane as an example).

Embodiment 3

[0048] Repeat Example 1, except that there are following differences, other conditions are all the same: step (4) irradiates the sealed irradiation reactor with a cobalt 60 gamma ray source, and the dose is 5kGy to form amino-modified graphite in the cylindrical reactor Alkene hydrogel. Its nitrogen content, carbon-oxygen ratio and density are shown in Table 1. The photo of the graphene airgel obtained is similar to Example 1. The cylindrical graphene airgel has good oil absorption performance, and the adsorption capacity reaches 112g / g (taking n-decane as an example).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com