Method of depositing metal organic framework material by oxygen auxiliary cathode

A technology for assisting cathode and depositing metal, applied in the direction of electrolytic organic material coating, etc., can solve the problems of inability to precisely control the thickness, low cost, impure material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

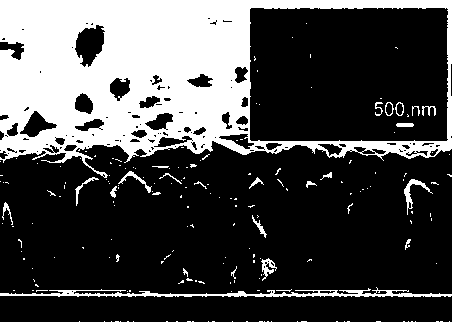

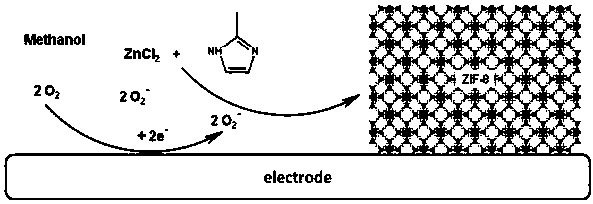

[0060] Oxygen-assisted deposition of ZIF-8 on HOPG includes the following steps:

[0061] (1) Preparation containing 10mM ZnCl 2 , 20mM HmiM and 100mM (NBu 4 )PF 6 Methanol solution, pass high-purity air for 30min before deposition;

[0062] (2) It is obtained by electrochemical deposition on the surface of the cathode conductive substrate by using the constant voltage method (three-electrode system). Among them, the working electrode is HOPG, the counter electrode is Pt wire, and the reference electrode is Ag / AgCl electrode. -0.5V, 2h; -0.7V, 2h; 6h, 12h; -0.9V, 2h; -1V, 2h.

[0063] HOPG treatment: Graphite needs to be exposed immediately after use to prevent surface contamination or fracture, which will affect conductivity and crystal growth. When necessary, use high-temperature-resistant double-sided adhesive to stick to the graphite surface, gently rub and press, and finally peel off the layer before use. To ensure the continuity of the graphite sheet, no hydrophilic...

Embodiment 2

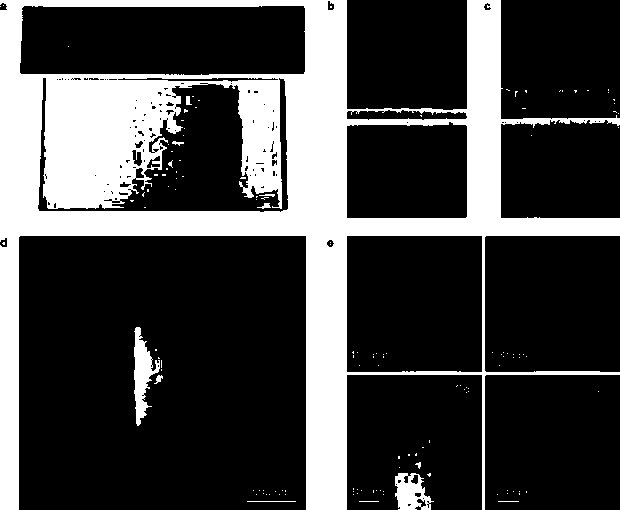

[0069] Oxygen-assisted deposition of ZIF-8 on ITO includes the following steps:

[0070] (1) Preparation containing 10mM ZnCl 2 , 20mM HmiM and 100mM (NBu 4 )PF 6 methanol solution;

[0071] (2) It is obtained by electrochemical deposition on the surface of the cathode conductive substrate by cyclic voltammetry (three-electrode system), wherein the working electrode is ITO, the counter electrode is Pt wire, the reference electrode is Ag / AgCl electrode, and the voltage range -0.8V~0V, scan rate 100mV / s, deposition time respectively 10 min, 15 min, 30 min, 60 min, 120 min, 240 min.

[0072] ITO processing: 100*10 mm 2 The ITO were placed in acetone. Sonicate in ethanol and deionized water for 15 minutes, rinse with deionized water, N 2 Blow dry and place in 1:1:5 H 2 o 2 , NH 3 h 2 O:, H 2 In the mixed solution of O, after heating at 90°C for 2 hours, rinse with deionized water, N 2 blow dry.

[0073] The processing method of Pt and Ag / AgCl electrode is the same as...

Embodiment 3

[0076] Oxygen-assisted deposition of ZIF-8 on carbon fibers includes the following steps:

[0077] (1) Prepared with 10 mM ZnCl 2 , 20 mM HmiM and 100 mM (NBu 4 )PF 6 Methanol solution, pass high-purity air for 30min before deposition;

[0078] (2) It is obtained by electrochemical deposition on the surface of the cathode conductive substrate by constant voltage method (three-electrode system), wherein the working electrode is carbon fiber, the counter electrode is Pt wire, the reference electrode is Ag / AgCl electrode, and -0.9 The voltage of V was deposited for 1 h.

[0079] Carbon fiber treatment: Soak the carbon fiber in H with a volume ratio of 3:7 2 o 2 and concentrated H 2 SO 4 heat treatment at 70°C for 1 h, then rinse repeatedly with deionized water for several times, and finally soak in clean deionized water for later use, take it out and dry it in an oven at 80°C before use, and cool to room temperature. be usable.

[0080] The processing method of Pt and A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com