Method for preparing starfruit-shaped SnO2/C micro-nano particles through electrostatic spinning and prepared product

A micro-nano particle and electrospinning technology, applied in tin oxide and other directions, can solve the problems of complex control factors of product microscopic morphology, and achieve the effect of narrow particle size distribution, strong controllability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.1 Mix 1.000g of PVP, 0.250g of TBAB, 1.50mL of liquid paraffin and 0.460g of crystalline tin tetrachloride (SnCl 4 ·5H 2 O) Add to the mixed solvent of 5.0mL ethanol and 5.0mLDMF, stir to obtain a transparent solution;

[0033] 1.2 The above solution was electrospun to obtain precursor fibers. The spinning parameters were: positive voltage 20KV, negative voltage 0.5KV, receiving distance 20cm, and syringe advancing speed 0.004mm / s.

[0034]1.3 Place the precursor fibers in a tube furnace at N 2 After reaction at 500°C for 2h under protection (the heating rate is 5°C / min), the sample was cooled with the furnace to obtain the final product.

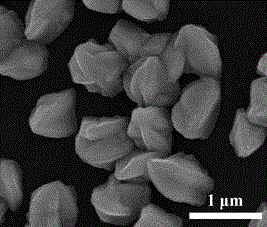

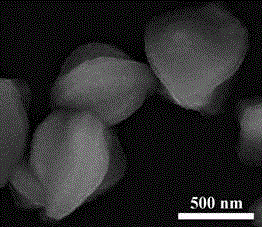

[0035] SEM of the product as figure 1 and 2 as shown, image 3 It is a physical photo of carambola, and it can be found by comparison that the product obtained in the present invention is carambola-like particles, and its thickness range is 0.60-0.70 μm, and the length range is 0.90-1.05 μm; the XRD result of the product is as...

Embodiment 2

[0037] 2.1 Mix 0.581g of PVP, 0.179g of TBAB, 1.25mL of liquid paraffin and 0.253g of SnCl 4 ·5H 2 O was added to the mixed solvent of 4.0mL ethanol and 2.5mLDMF, and stirred to obtain a transparent solution;

[0038] 2.2 The above solution was electrospun to obtain a precursor fiber. The spinning parameters were: positive voltage 16KV, negative voltage 0.5KV, receiving distance 16cm, and syringe advancing speed 0.001mm / s.

[0039] 2.3 Place the precursor fibers in a tube furnace at N 2 After being reacted at 550°C for 3h under protection (the heating rate is 5°C / min), the sample was cooled with the furnace to obtain carambola-shaped SnO with a thickness ranging from 0.90-1.10μm and a length ranging from 1.35-1.65μm. 2 / C particles.

Embodiment 3

[0041] 3.1 Mix 1.786g of PVP, 0.393g of TBAB, 1.95mL of liquid paraffin and 0.924g of SnCl 4 ·5H 2 O was added to a mixed solvent of 6.0 mL ethanol and 8.5 mL DMF, and stirred to obtain a transparent solution;

[0042] 3.2 The above solution was electrospun to obtain a precursor fiber. The spinning parameters were: positive voltage 25KV, negative voltage 0.5KV, receiving distance 25cm, and syringe advancing speed 0.002mm / s.

[0043] 3.3 Place the precursor fibers in a tube furnace at N 2 After being reacted at 600°C for 10h under protection (the heating rate is 5°C / min), the sample was cooled with the furnace to obtain carambola-like SnO with a thickness ranging from 3.10-3.40 μm and a length ranging from 4.65-5.10 μm. 2 / C particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com