SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester and preparation method and application thereof

A technology of SO3H-SBA-15 and tert-butyl carboxylate, which is applied in the chemical industry, can solve the problems of increasing the investment cost of production equipment, doubling the amount of carboxylic acid, increasing the energy consumption of product separation, and reducing separation energy consumption and equipment. The effect of investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

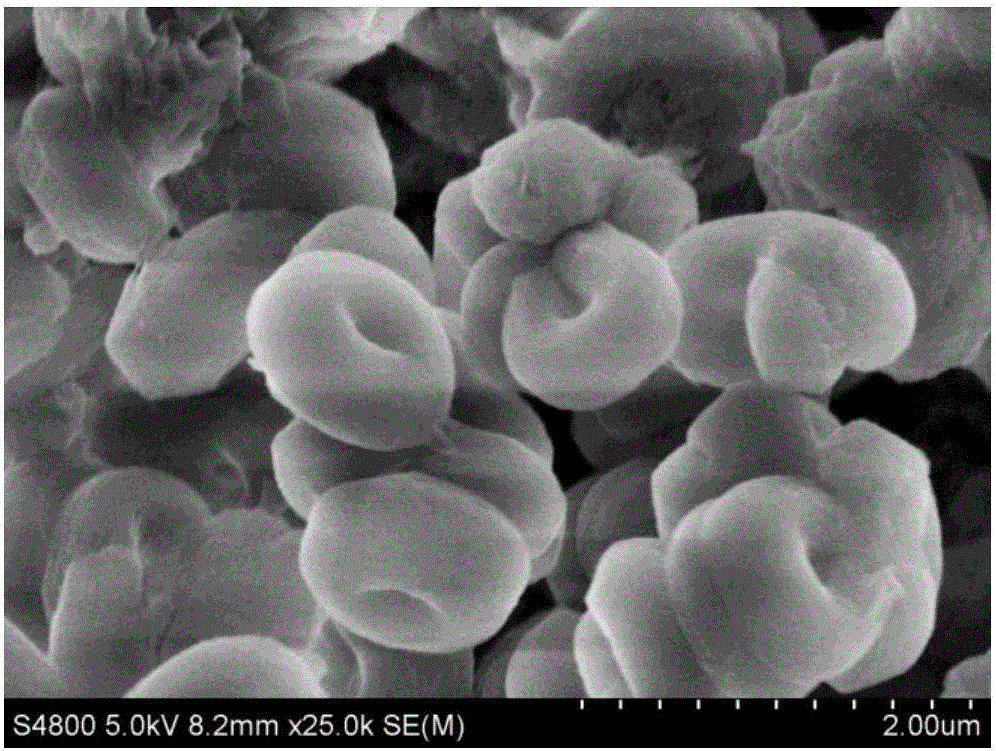

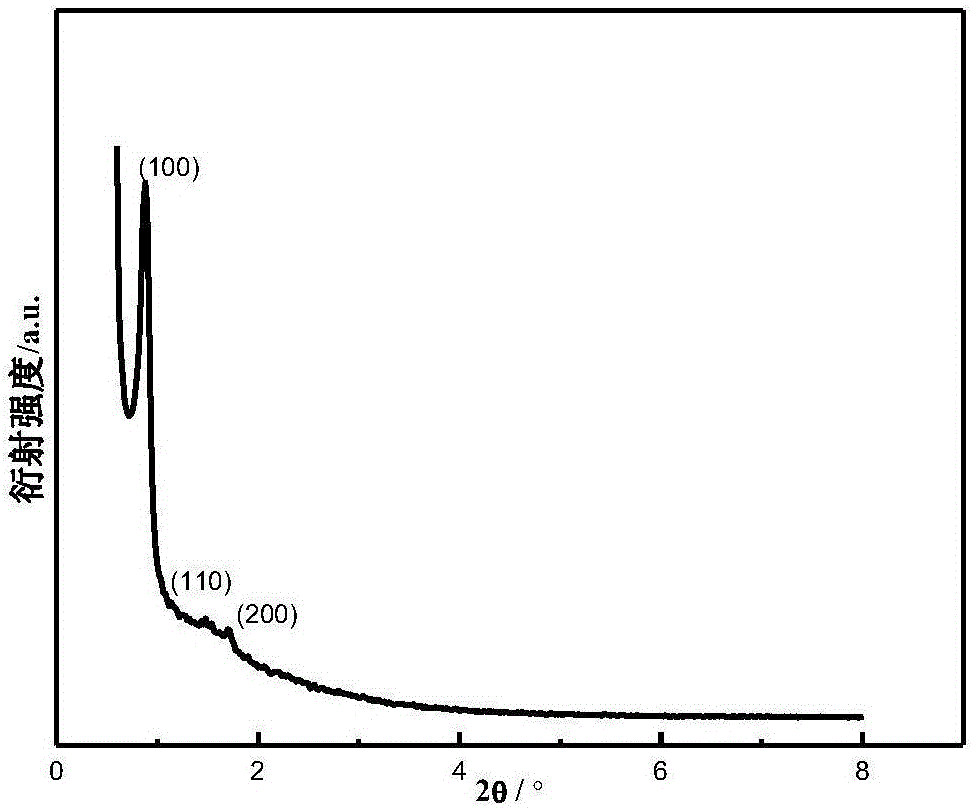

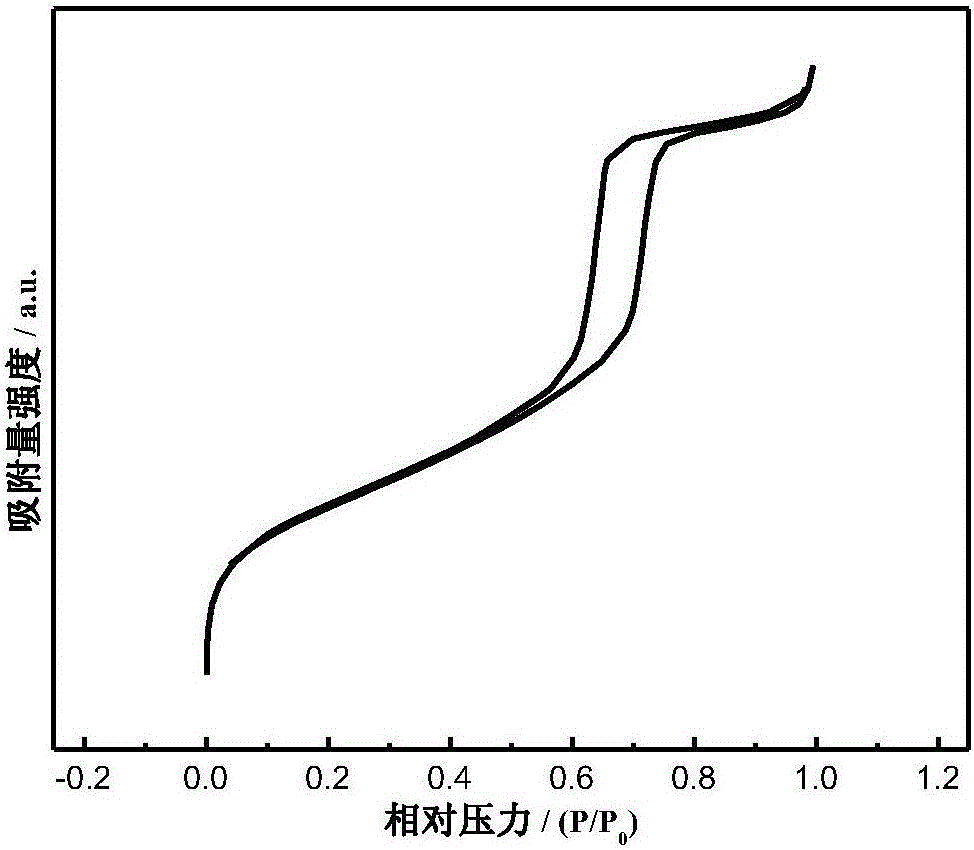

[0040] Embodiment 1 one-step co-condensation method prepares SO 3 H-SBA-15 molecular sieve catalyst

[0041] 4g nonionic surfactant P123, 97g H 2 O, 23.5g hydrochloric acid (36.5wt.%), 30g DMF (99.5wt.%) add three-necked flask successively, in the solution H + The concentration is 1.5 mol / L, the temperature is kept constant at 40°C, the mechanical stirring rate is 400r / min, and stirred for 2h to completely dissolve P123; then add 8.80g tetraethyl orthosilicate (using SiO 2 The mass fraction is 28.4wt.% aqueous solution), stirred for 4h, tetraethyl orthosilicate was completely hydrolyzed; then added 4.51g 3-mercaptopropyltrimethoxysilane (98wt.%) and 56.13g hydrogen peroxide (30wt. %), stirred for 24h, and completely oxidized the mercaptopropyl group in 3-mercaptopropyltrimethoxysilane to sulfonic acid group. The obtained solution was transferred into a hydrothermal synthesis kettle, and crystallized at 100°C for 1d. Afterwards, the crystallized mixed solution was taken out...

Embodiment 2

[0044] Example 2 Two-step sulfonic acid group post-grafting method to prepare SO 3 H-SBA-15 molecular sieve catalyst

[0045] Preparation of donut-shaped SBA-15: 4 g nonionic surfactant P123, 96 g H 2 O, 23.5g hydrochloric acid (36.5wt.%), 30g DMF (99.5wt.%), add three-necked flask successively, H + The concentration is 1.5mol / L, the temperature is controlled at 40°C, the mechanical stirring speed is 400r / min, and stirring is carried out for 2h to completely dissolve P123. Then add 8.80g tetraethyl orthosilicate (as SiO 2 28.4wt.% aqueous solution), stirred at 40°C for 24 hours to completely hydrolyze tetraethyl orthosilicate, and self-assemble under the interaction of template agent P123 and morphology regulator DMF Generate SBA-15 molecular sieves. Then transfer the reaction solution into a hydrothermal synthesis kettle, crystallize at 100°C for 1d, then take out the crystallized mixed solution, cool at room temperature, filter with suction, wash the filter cake with dis...

Embodiment 3

[0050] 144.12 g of acrylic acid and 0.56 g of 1Q-SO with 35% sulfonic acid group loading were added to a 300 mL batch titanium autoclave 3 H-SBA-15 molecular sieve, pass through 56.11g of isobutene (the molar ratio of isobutene and acrylic acid is 1:2), heat to 50°C, pressurize to 0.5MPa, and react for 2h at the stirring speed of 300r / min. The liquid phase reaction solution was collected, centrifuged to remove the catalyst, and then analyzed by gas chromatography. The analysis results showed that the conversion rate of isobutene was 97.7%, the selectivity of tert-butyl acrylate was 98.3%, and the selectivity of diisobutylene was 1.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com