Patents

Literature

54 results about "Co condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

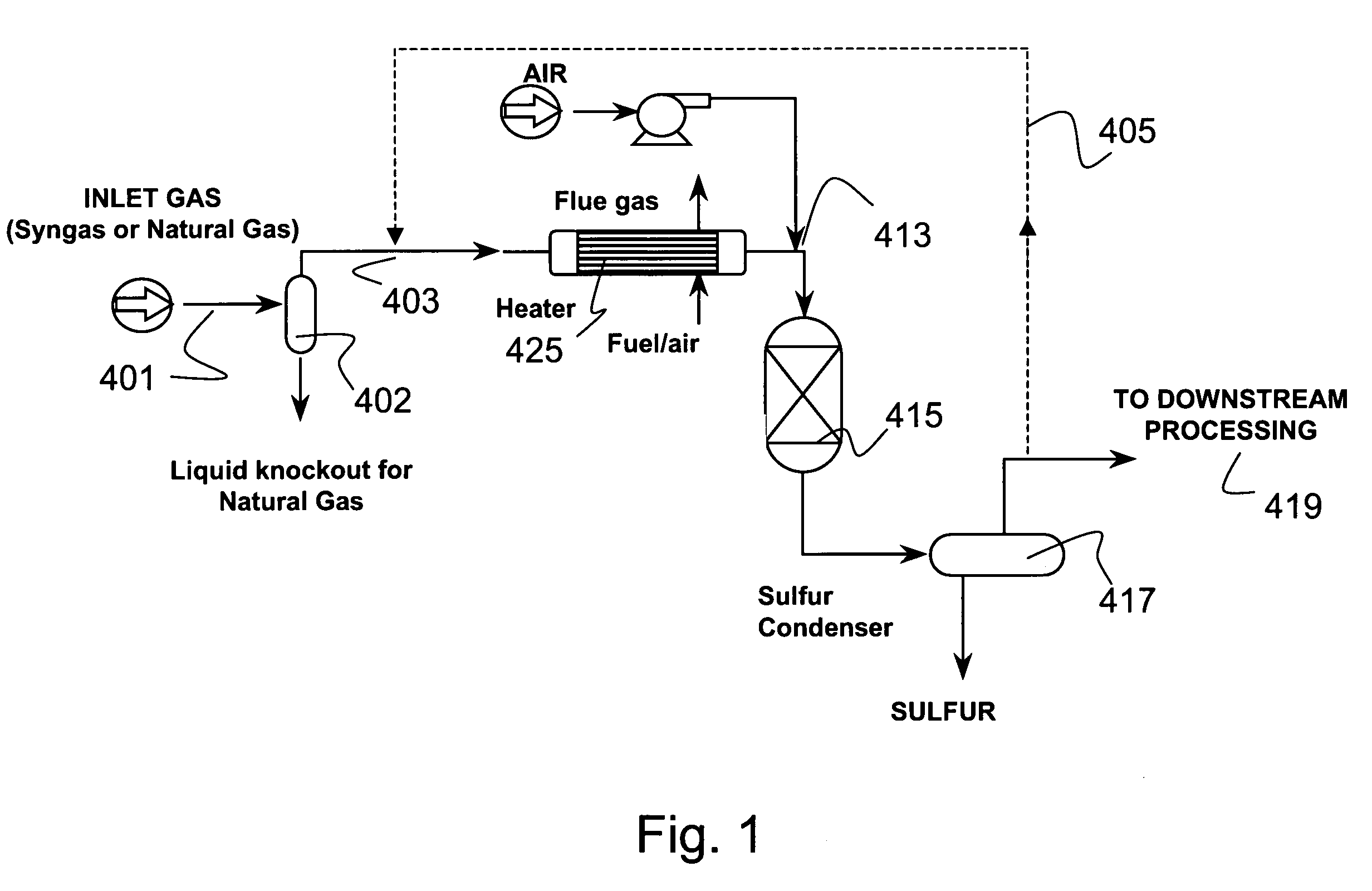

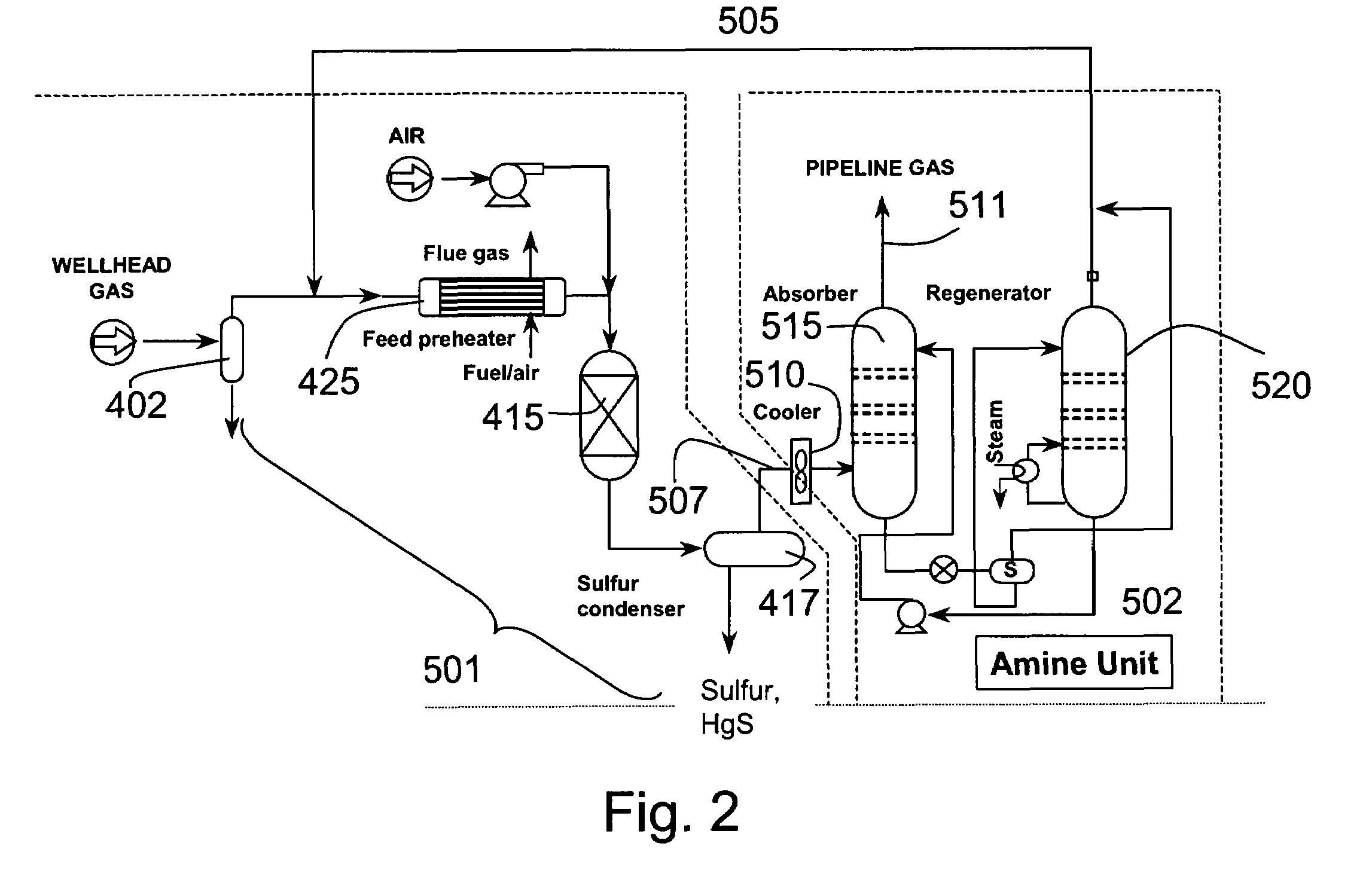

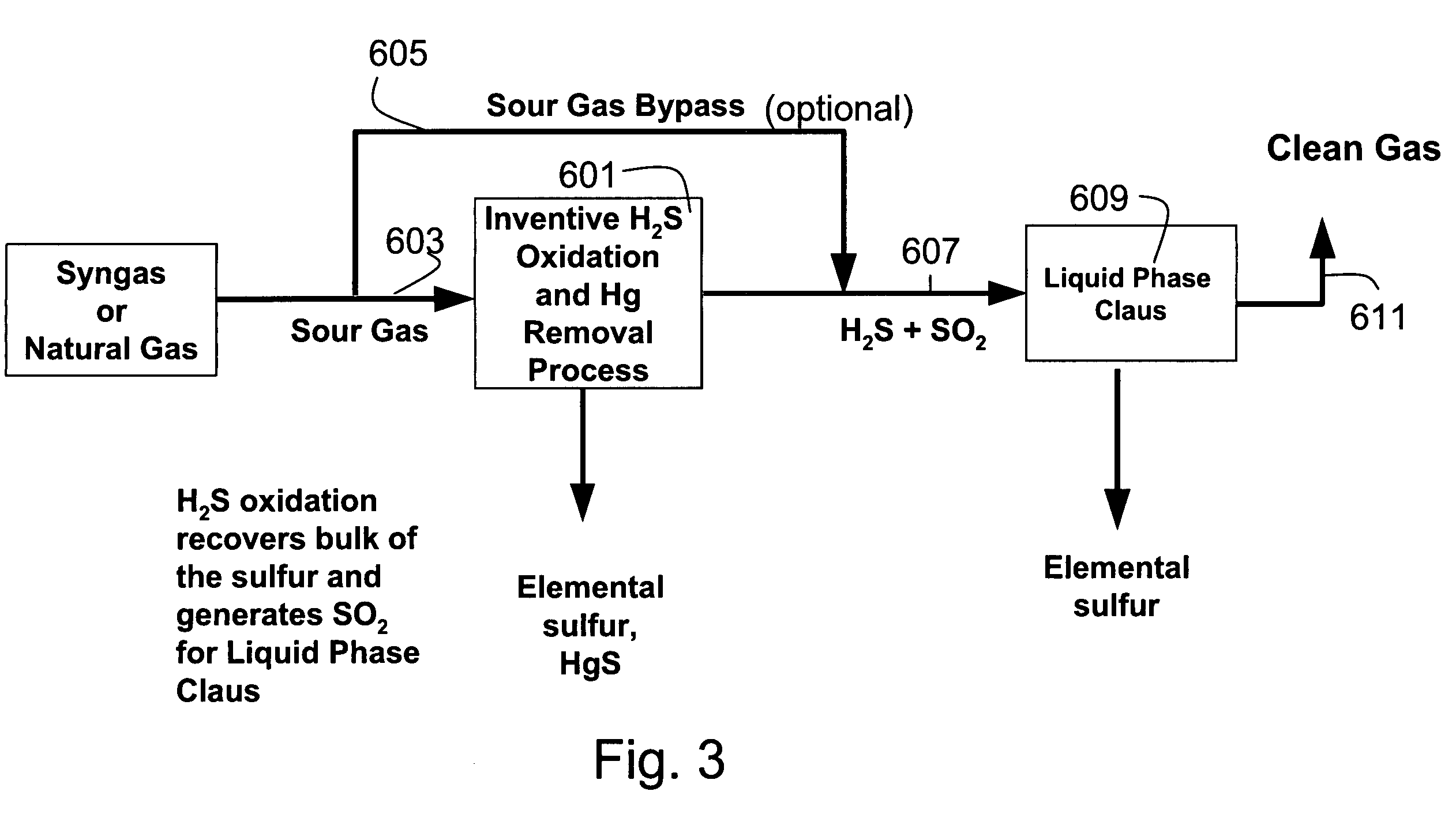

Process for the simultaneous removal of sulfur and mercury

InactiveUS7060233B1Lower capitalReduce operating costsGas treatmentUsing liquid separation agentSulfur containingInorganic sulfide

A process for removing hydrogen sulfide, other sulfur-containing compounds and / or sulfur and mercury from a gas stream contaminated with mercury, hydrogen sulfide or both. The method comprises the step of selective oxidation of hydrogen sulfide (H2S) in a gas stream containing one or more oxidizable components other than H2S to generate elemental sulfur (S) or a mixture of sulfur and sulfur dioxide (SO2). The sulfur generated in the gas stream reacts with mercury in the gas stream to generate mercuric sulfide and sulfur and mercuric sulfide are removed from the gas stream by co-condensation.

Owner:TDA RES

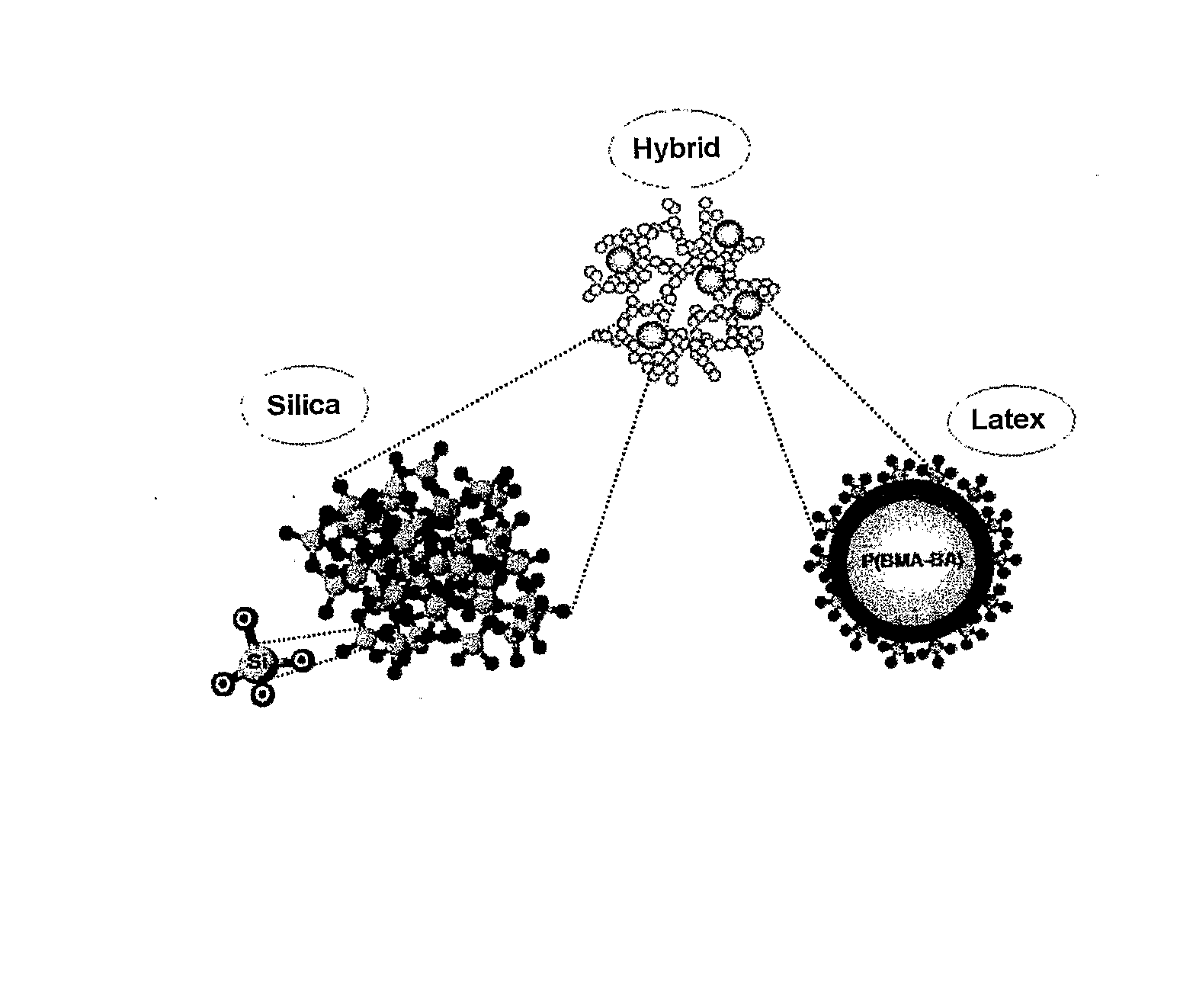

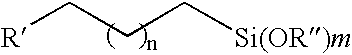

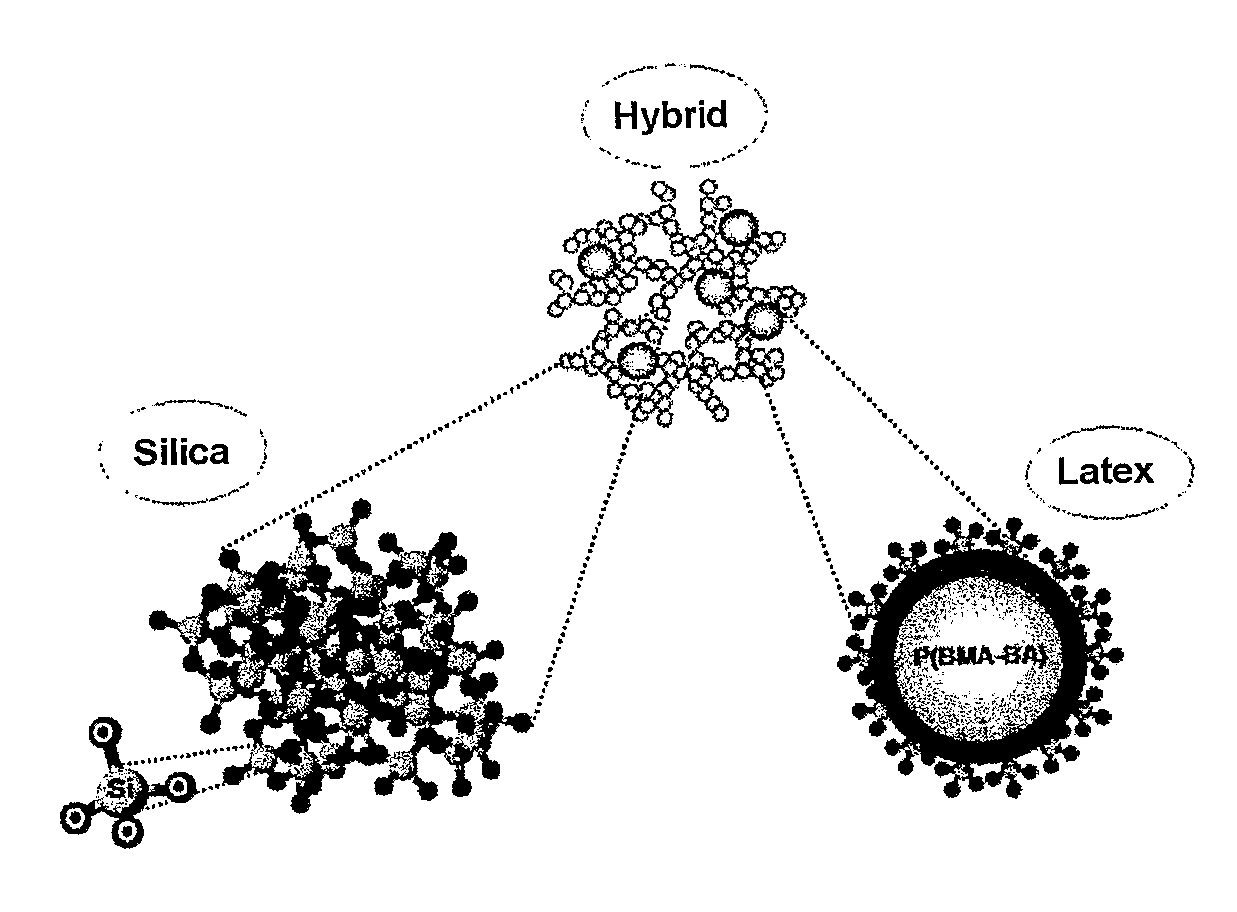

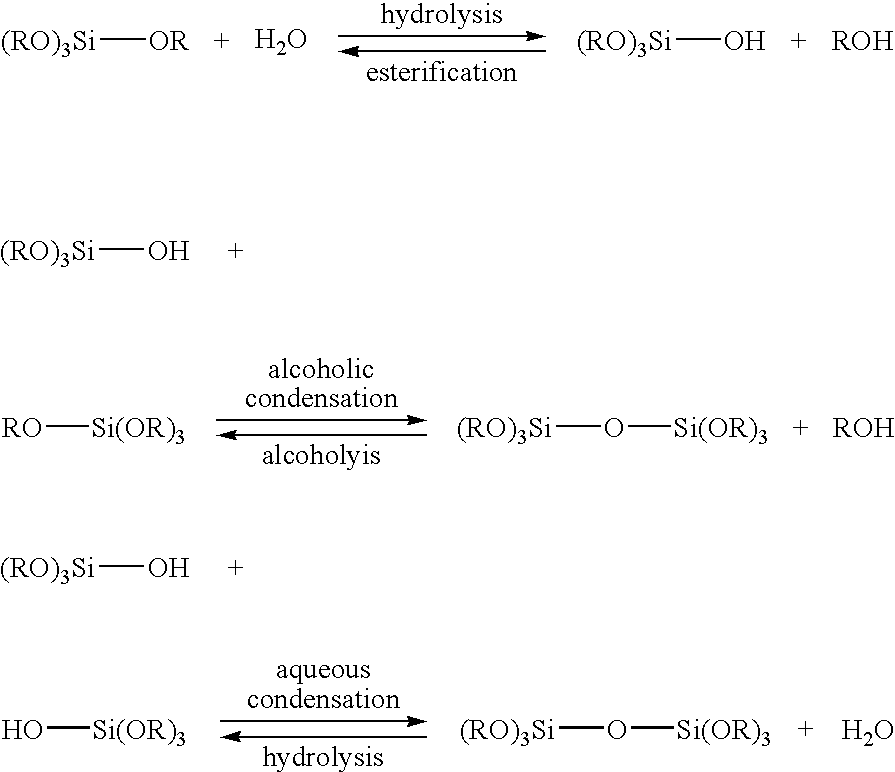

Process for the Preparation, Under Subcritical Conditions, of Monolithic Xerogels and Aerogels of Silica/Latex Hybrids, Modified with Alkoxysilane Groups

InactiveUS20080188575A1Improve insulation performanceHigh mechanical strengthSilicaOther chemical processesColloidal silicaMethacrylate

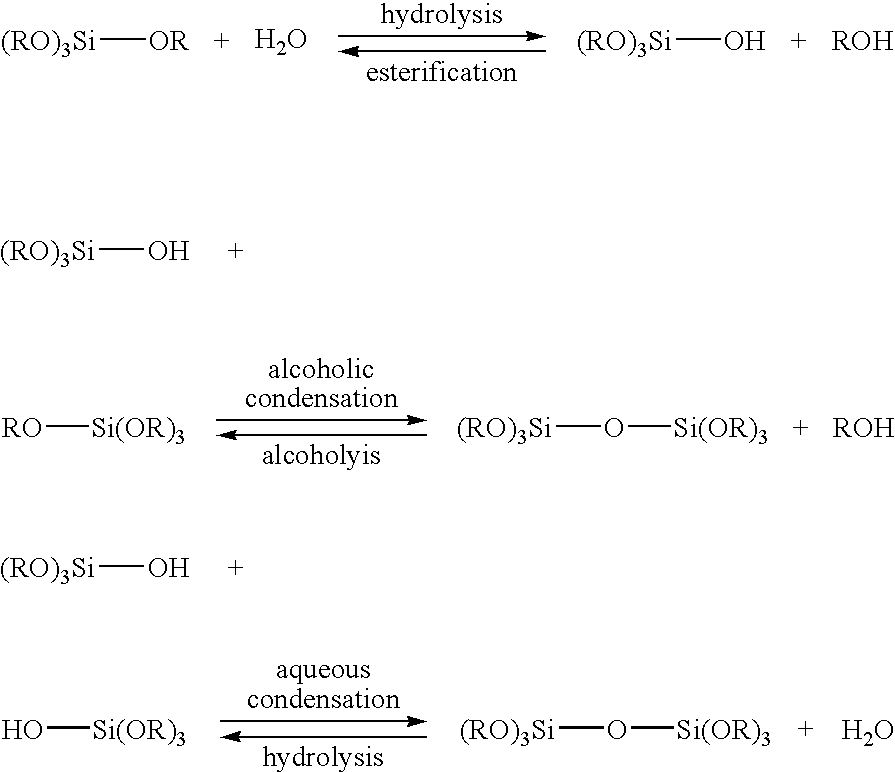

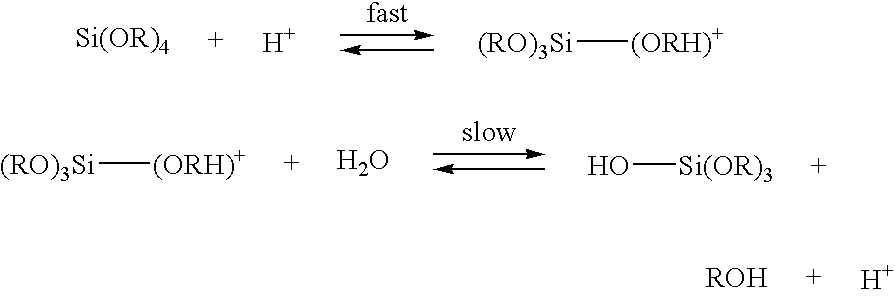

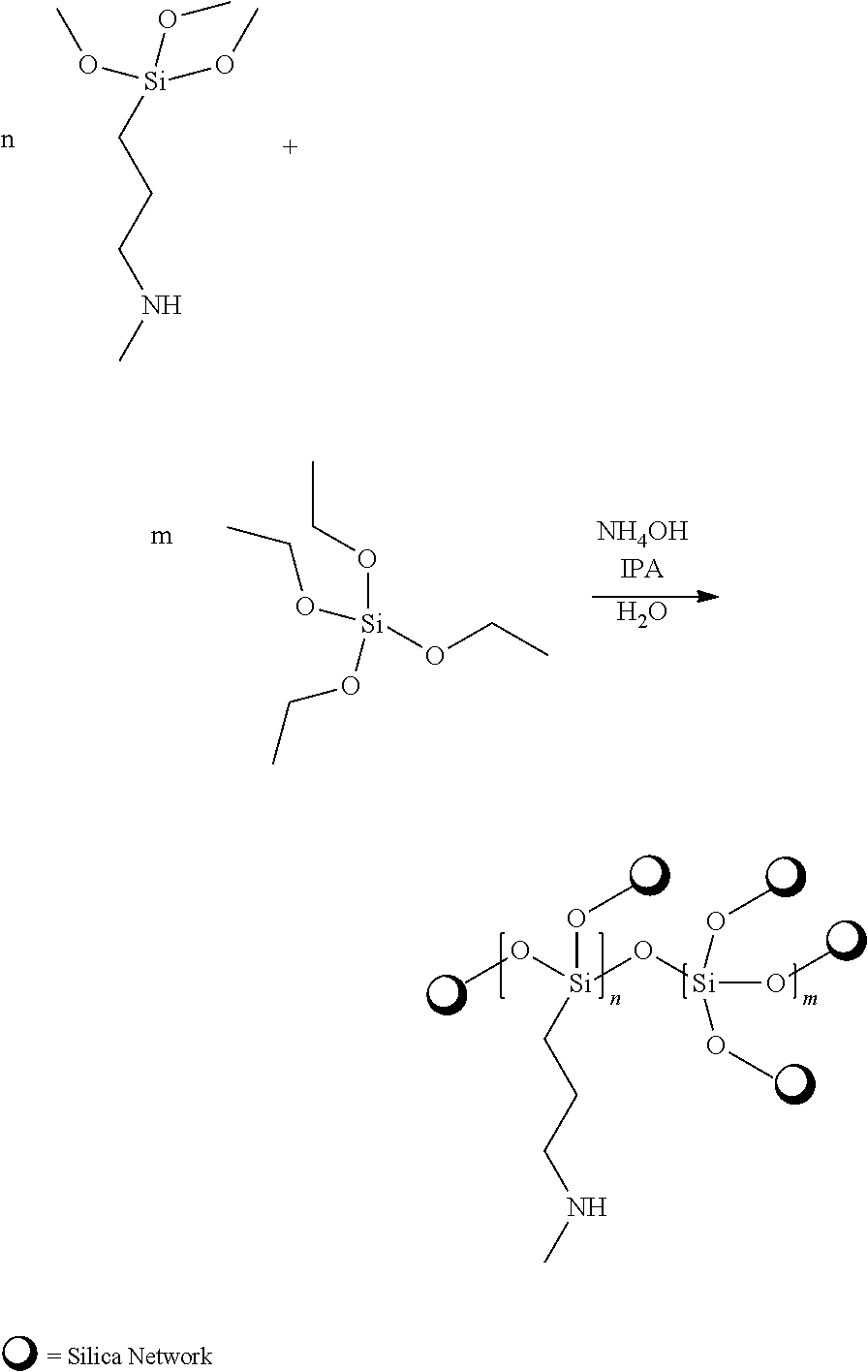

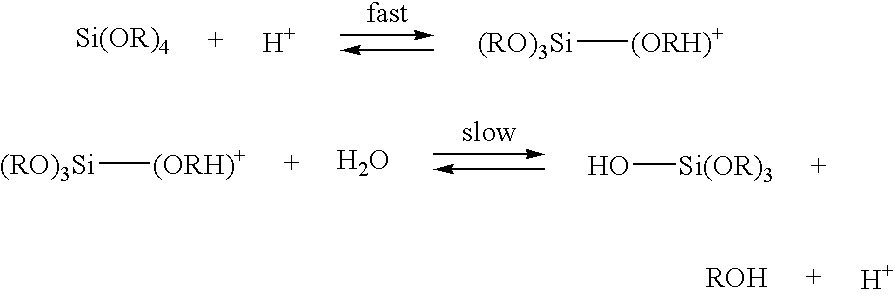

The invention relates to a process for the preparation of monolithic xerogels and aerogels of silica / latex hybrids under subcritical conditions. In the two-stage synthesis of these alcogels in the presence of an acid-base catalyst, the hydrolysis and polycondensation of a silicon alkoxide are carried out in an organic medium containing excess water. A latex consisting of polybutyl methacrylate and polybutyl acrylate, modified with alkoxysilane groups, is first synthesized and then incorporated in the mixture either in the first stage in order to effect its co-hydrolysis with the silicon alkoxide, or in the second stage to effect its co-condensation with the previously hydrolysed colloidal silica. The resulting alcogels are aged, washed, and dried under subcritical conditions. This process gives hybrid products containing 0.1-50 wt-% of latex and having a density of 300-1300 kg / m3, a porosity of 40-85%, a specific surface area of 400-900 m2 / g and a mean pore diameter of 2-12 nm. The products are resistant to atmospheric humidity and moisture, have better mechanical properties than the corresponding inorganic products, and can be used as thermal, acoustic and electrical insulators.

Owner:INST SUPERIOR TECH

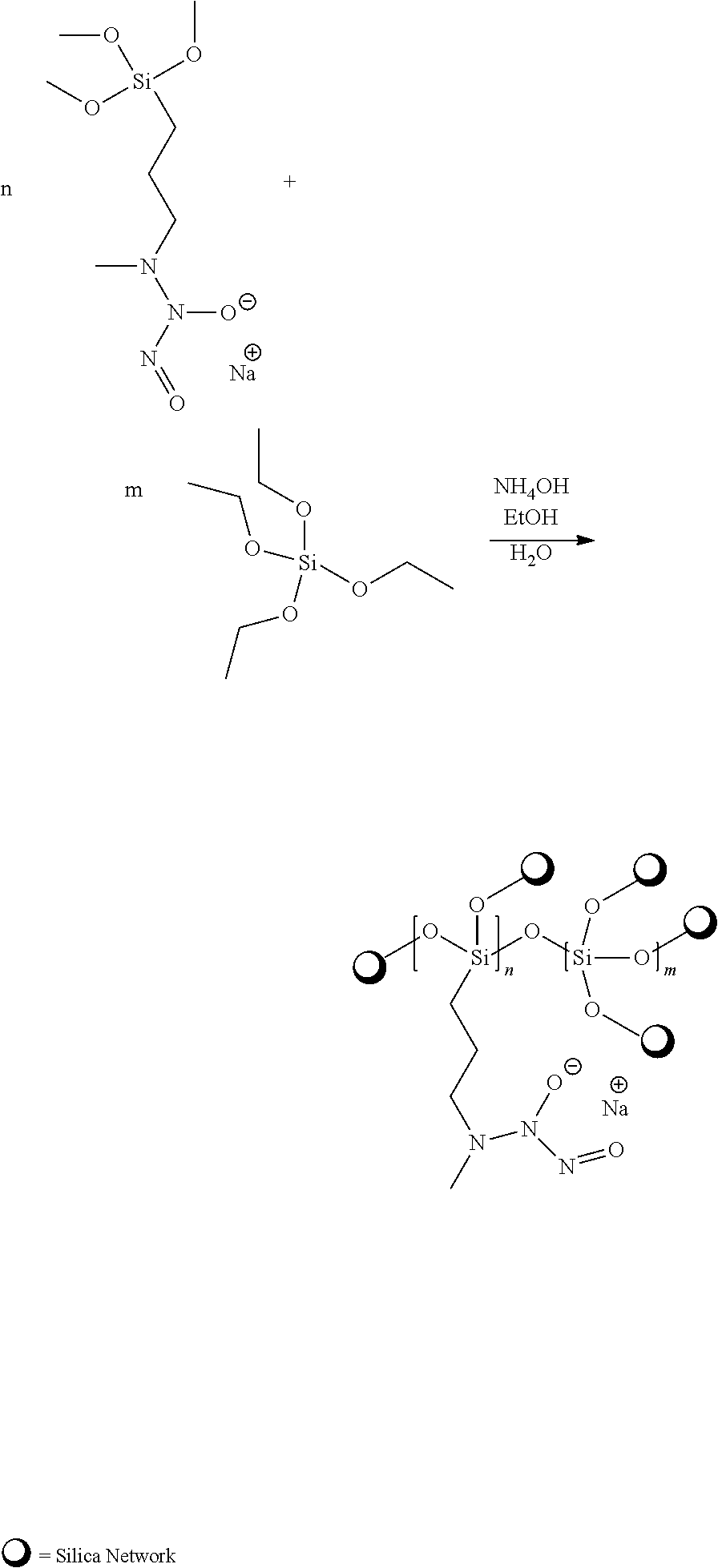

Temperature Controlled Sol-Gel Co-Condensation

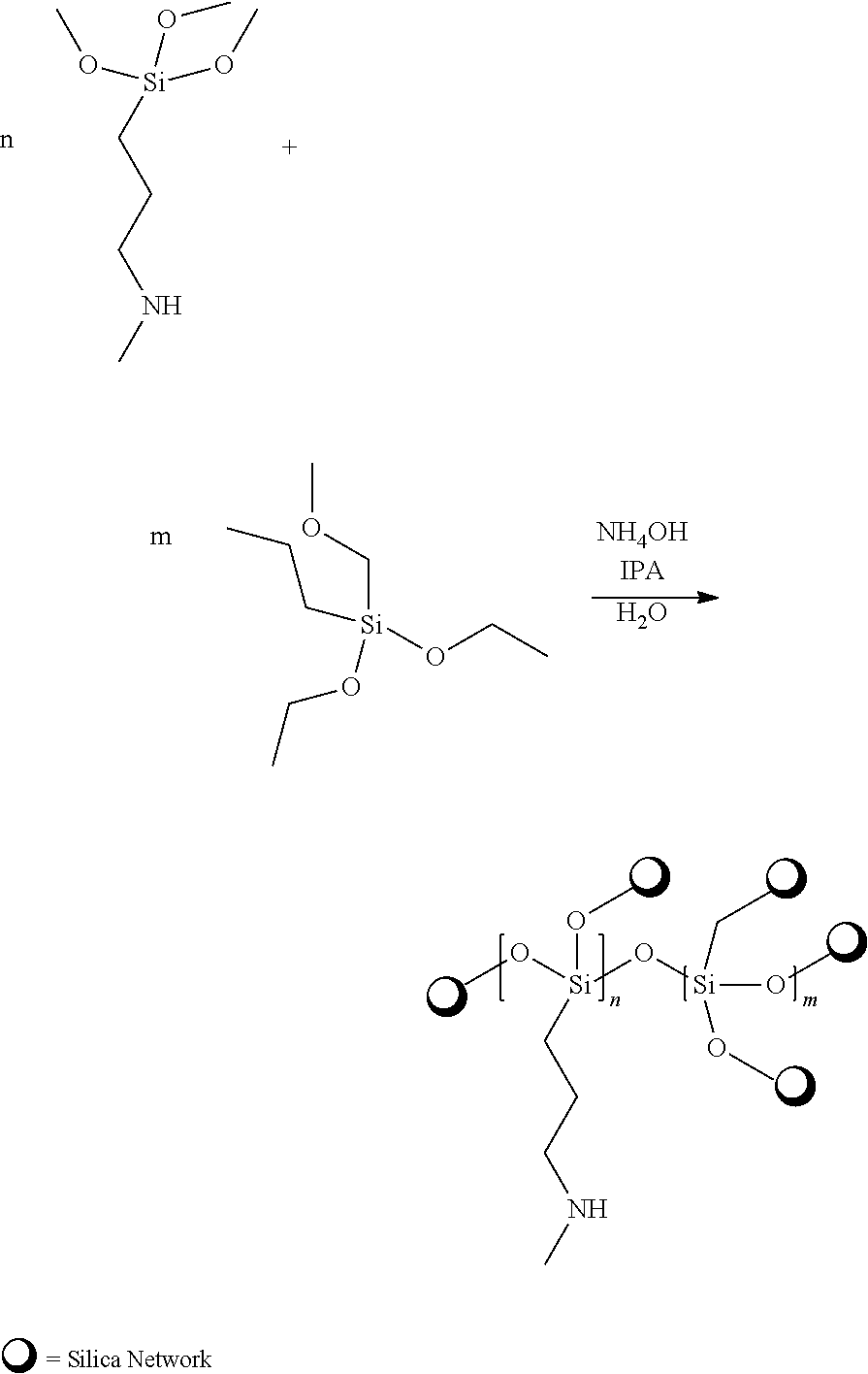

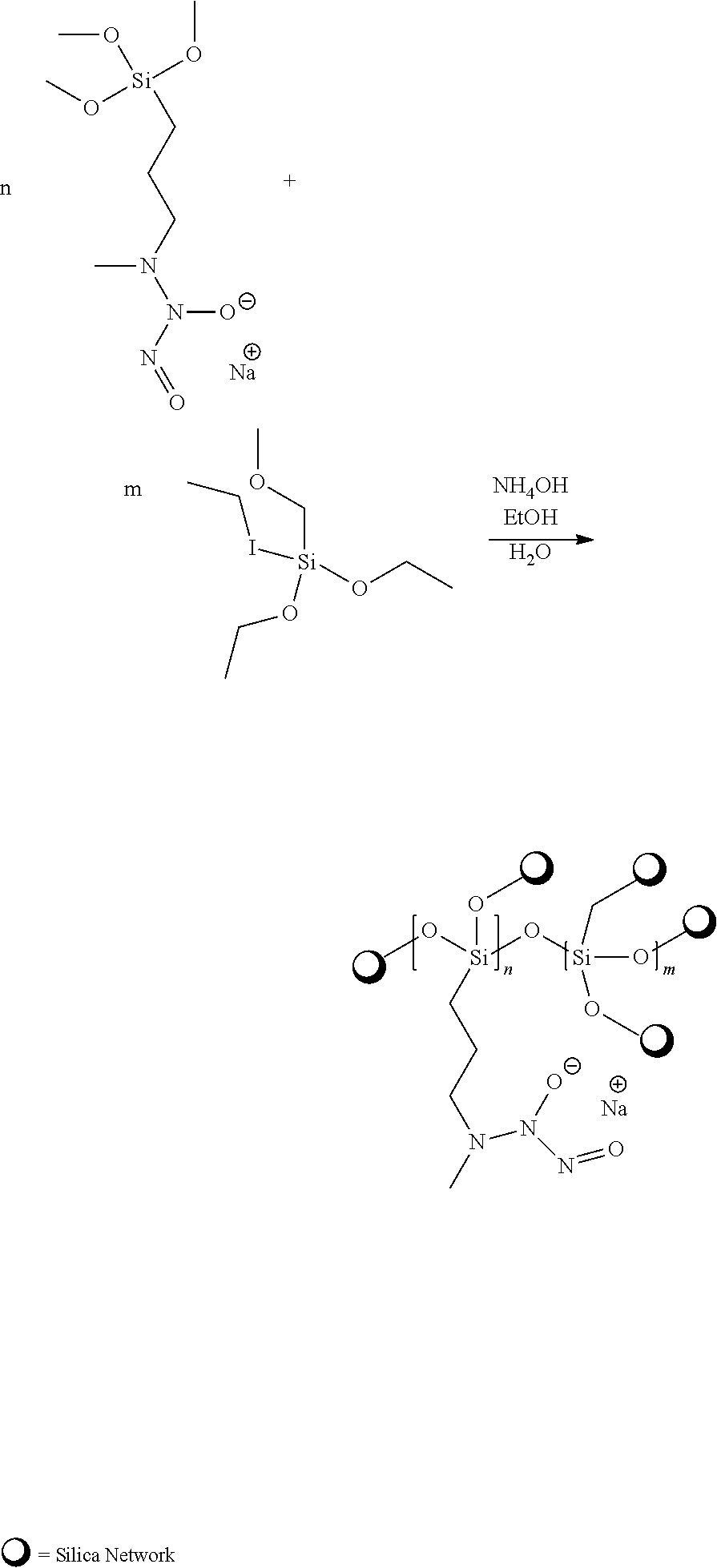

Provided according to some embodiments of the invention are methods of making co-condensed macromolecules that include forming a reaction mixture by combining at leak one reactant and at least one reagent at a first temperature at which the at least one reactant is substantially unreactive in the presence of the at least one reagent; raising the temperature of the reaction mixture to a second temperature at which the at least one reactant is reactive in the presence of the at least one reagent, wherein the reaction of the at least one reactant in the presence of the at least one reagent produces co-condensed macromolecules such as co-condensed silica macromolecules.

Owner:NAVAN INC

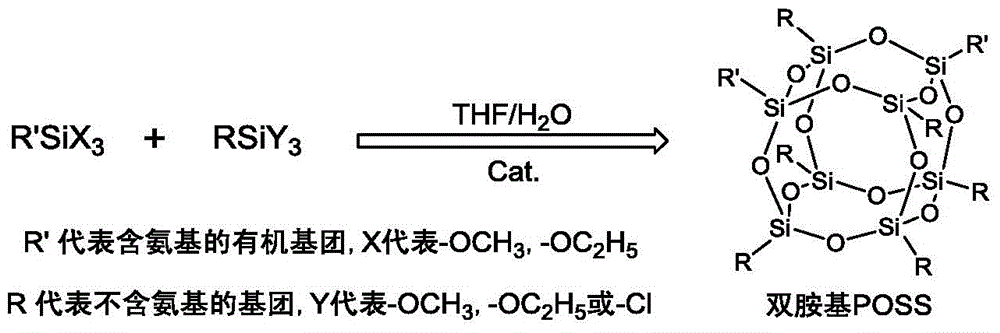

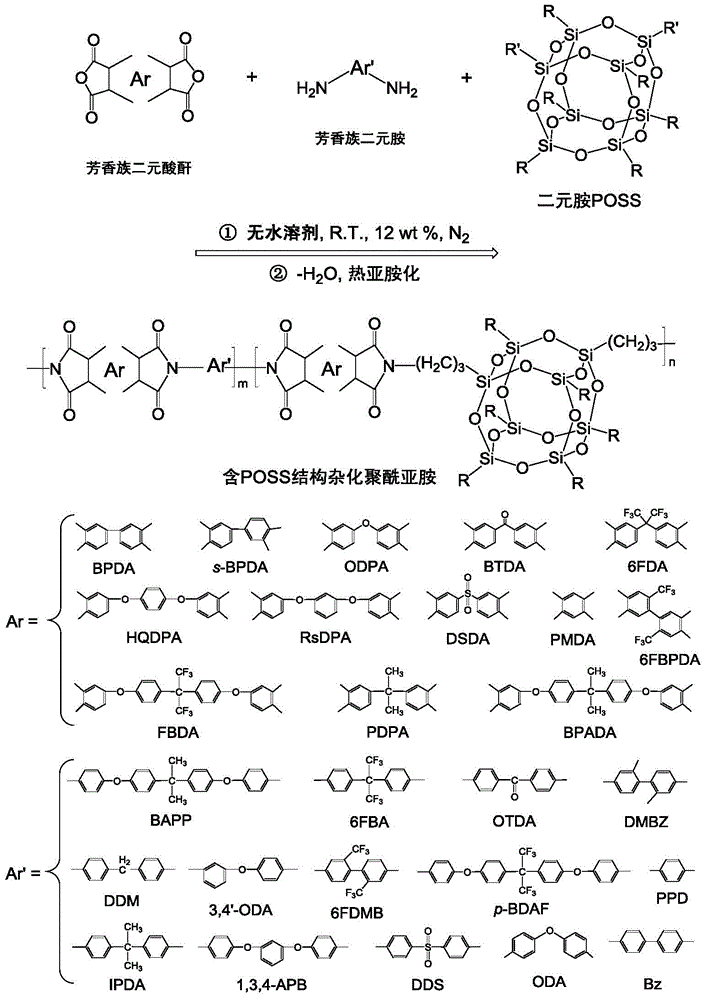

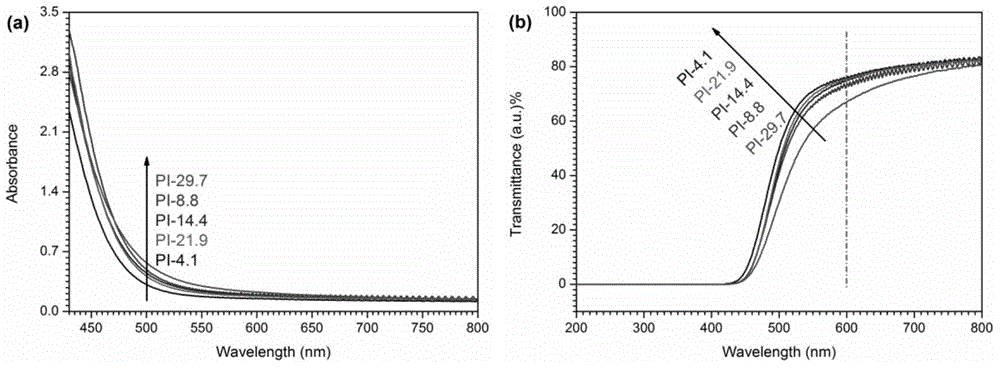

Preparation method of anti-atomic oxygen polyimide hybrid films containing octamer cage-shaped silsesquioxane structures

InactiveCN104356413AMild performanceExcellent anti-AO performanceSilicon organic compoundsSilsesquioxaneHydrolysis

The invention relates to a preparation method of anti-atomic oxygen polyimide hybrid films containing octamer cage-shaped silsesquioxane structures. In order to obtain a POSS polyimide hybrid film with excellent anti-atomic oxygen (AO) performance with low cost and keep the thermal performance and the mechanical performance of the polyimide, the preparation method adopts tetrahydrofuran as a solvent and alkali as a catalyst to synthesize tetrahydrofuran-diamine POSS containing two active amino groups by adopting a hydrolysis co-condensation method which is simple to operate, low in cost and gentle in reaction condition; and introducing the diamine POSS into a polyimide molecular main chain by adopting a co-condensation method to finally obtain the POSS polyimide hybrid films with excellent anti-AO performances. The preparation method disclosed by the invention is gentle in conditions of a reaction process, low in cost, simple in process, capable of greatly lowering the production cost and beneficial to realizing industrial production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

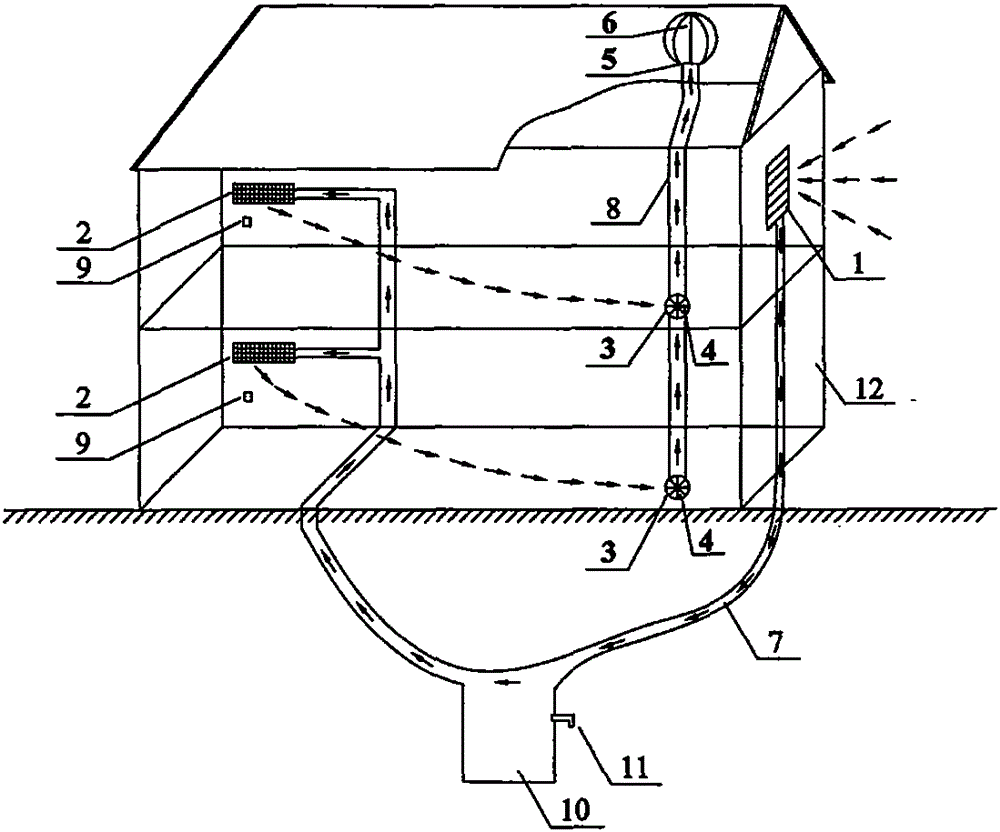

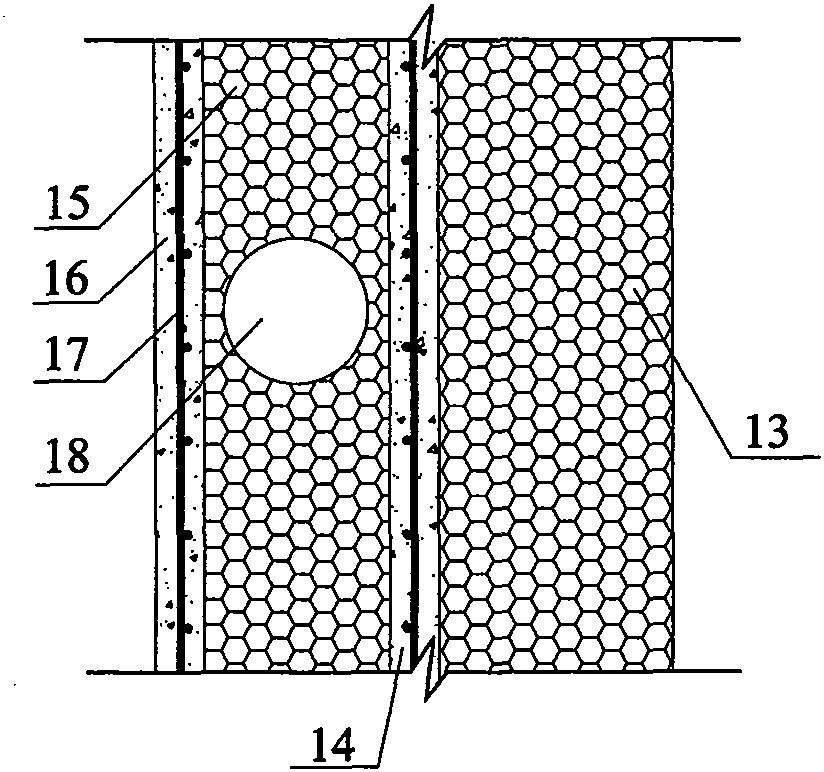

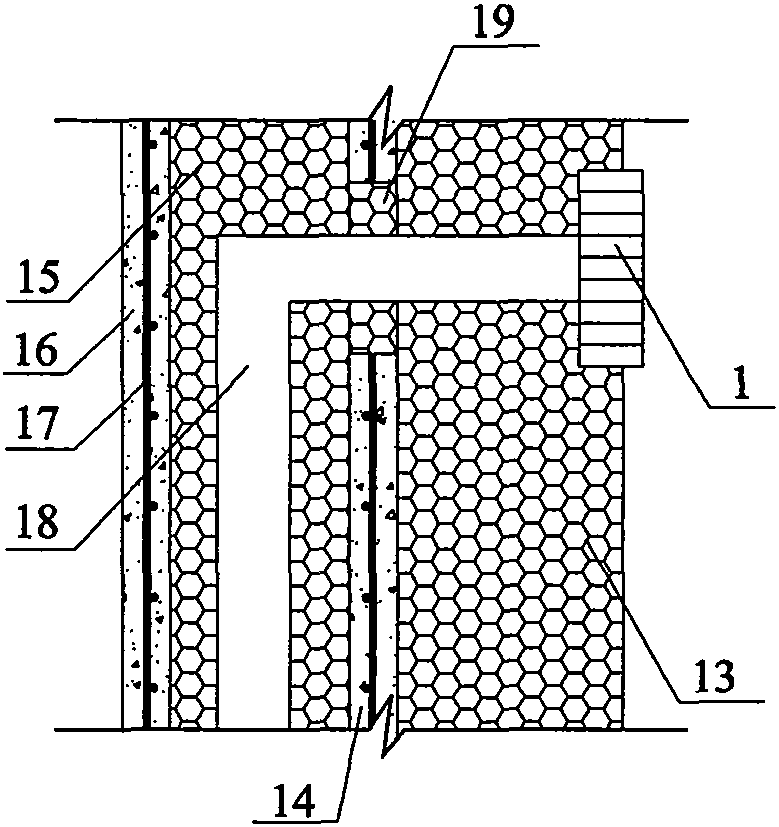

Building structure and equipment integrated passive house and building method thereof

InactiveCN105257021AGood thermal performanceEasy to achieve continuous laying across layersWallsHeat proofingWater storage tankEngineering

The invention relates to a building structure and equipment integrated passive house and a building method thereof, and belongs to the field of energy conservation of buildings. The building structure and equipment integrated passive house comprises an outer window, a bearing exterior wall plate, floors, a roof panel, a ventilating system pipe, an air inlet, an air supply outlet, an air returning opening, a check valve, an air outlet, an unpowered air hood, a CO condensation sensor, a water storage tank and a valve, wherein the outer window is provided with outer window glass and outer sunshade equipment; the outer window glass is provided with a Low E coating film; the bearing exterior wall plate, the floors and the roof panel have CS plate type structures; a portion, which is inlaid in the CS plate type structures, of the ventilating system pipe is defined as an inlaid type ventilating system pipe; the ventilating system pipe comprises a fresh air pipe and a returned air pipe; and the inlaid type ventilating system pipe comprises an inlaid type fresh air pipe and an inlaid type returned air pipe. Comfort level of an indoor environment can be improved, energy consumption of heating and refrigerating of buildings can be greatly reduced, half prefabrication of bearing components and ventilating pipes of the buildings is realized, the passive house is produced in a factory in a standard and series mode, and is assembled in a field, reliability degree of refinement construction of the passive house is guaranteed, construction efficiency is improved, the indoor environment does not have equipment, and an outdoor environment does not have pipelines.

Owner:北京康居认证中心有限公司

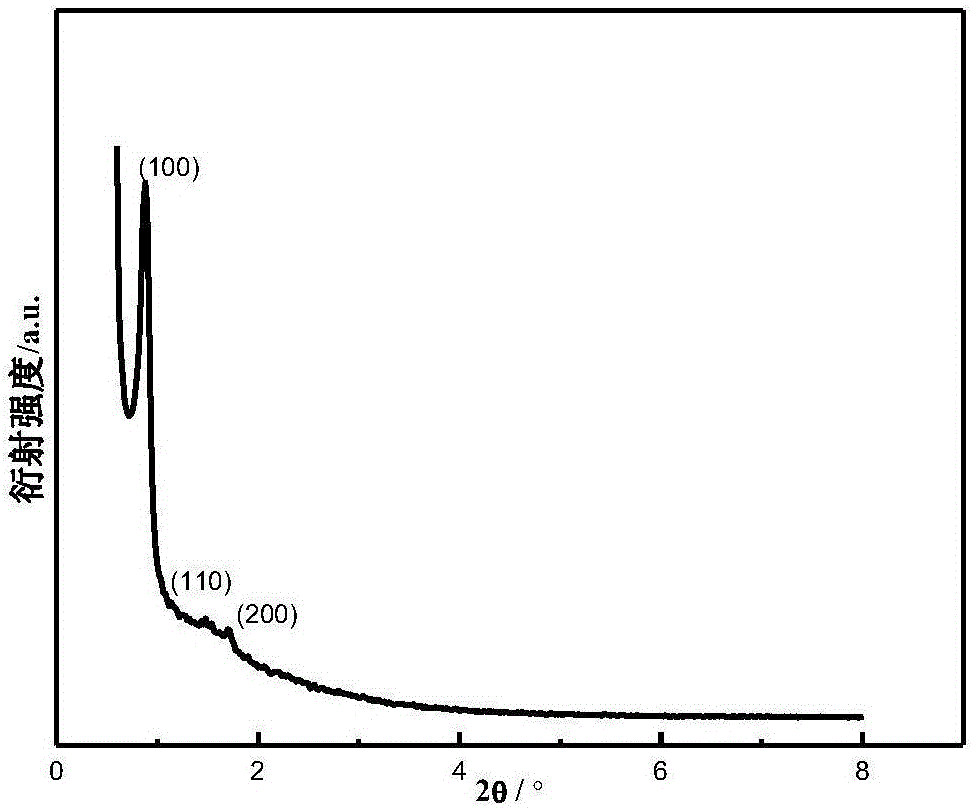

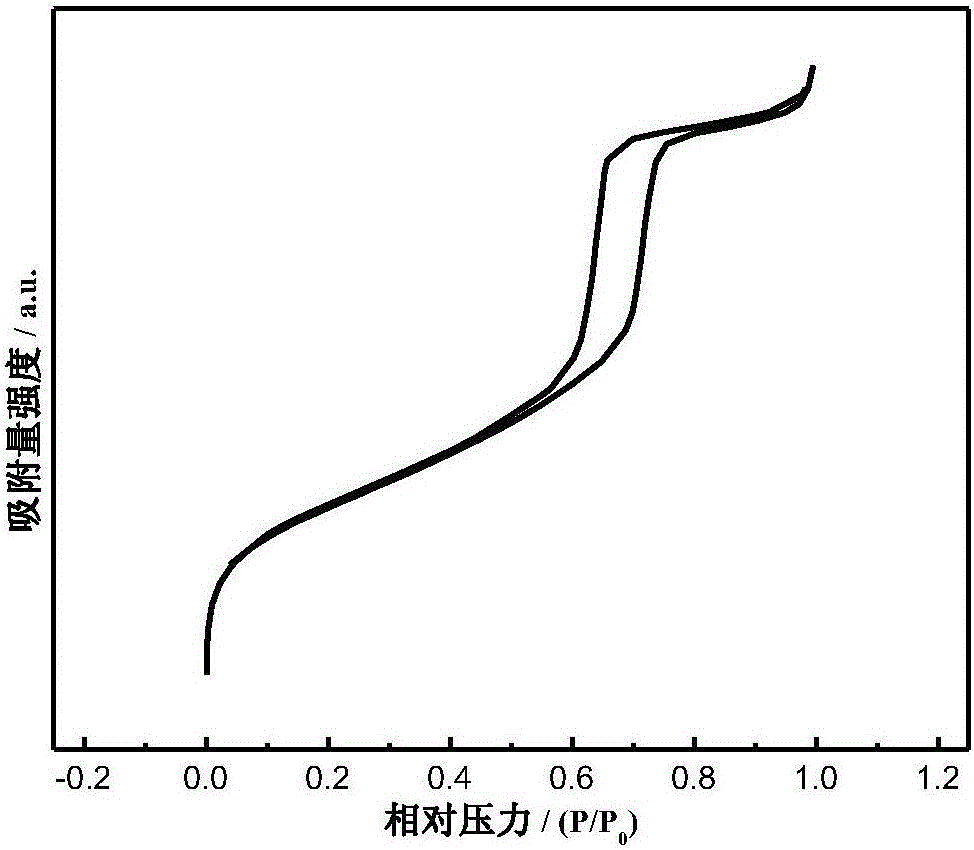

SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester and preparation method and application thereof

ActiveCN106040282AEfficient and stable synthesisReduce separation energy consumptionMolecular sieve catalystsOrganic compound preparationMolecular sieveCarboxylic acid

The invention discloses a SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester. The molecular sieve catalyst is prepared by adopting a template agent, a morphology regulator, a silicon source, a sulfonic acid source and an oxidizing agent through a one-step co-condensation method or a two-step sulfonic acid group post-synthesis method. In the SO3H-SBA-15 molecular sieve catalyst, by the molar ratio of a sulfonic acid group to silicon oxide, the sulfonic acid group supporting amount accounts for 30%-50%. The invention further discloses a method of using the SO3H-SBA-15 molecular sieve catalyst to catalyze the isobutene and the carboxylic acid for carboxylic acid tert-butyl ester synthesis. The molecular sieve catalyst is adjustable in shape, orderly in mesoporous pore passage and capable of efficiently and stably catalyzing the isobutene and the carboxylic acid to selectively synthesize the carboxylic acid tert-butyl ester under the conditions of higher temperature and polymerization inhibitor absence, meanwhile the separation energy consumption and equipment investment of reaction products are reduced, and the SO3H-SBA-15 molecular sieve catalyst has an important significance on development and utilization of atomic economic reaction.

Owner:NANJING UNIV OF TECH +1

Phenol-urea-formaldehyde condensation copolymerization resin wood adhesive and preparation method thereof

InactiveCN101100591ASuitable for productionLow costAldehyde/ketone condensation polymer adhesivesPolymer resinAqueous solution

A binder of phenol-urea-methanal co-condensation polymer resin wood and its production are disclosed. The process is carried out by adding into methanal and urea under single medium environment, adding NaOH aqueous solution 0.1-0.8 mol and methanal aqueous solution with concentration 37% into melt phenol, agitating, adding into urea for the first time, reacting for 10 mins, raising temperature to 90-99 deg. C, keeping temperature, reacting for 30 mins, adding into methanal aqueous solution for the second times, keeping temperature, reacting to reach viscosity to 100-800 Pa / s, adding into urea for the second time, reacting for 20 mins, cooling and discharging. It costs low, has fast curing speed, better gluing effect and can be used to substitute phenolic resin wood binder and to produce artificial board.

Owner:SOUTHWEST FORESTRY UNIVERSITY

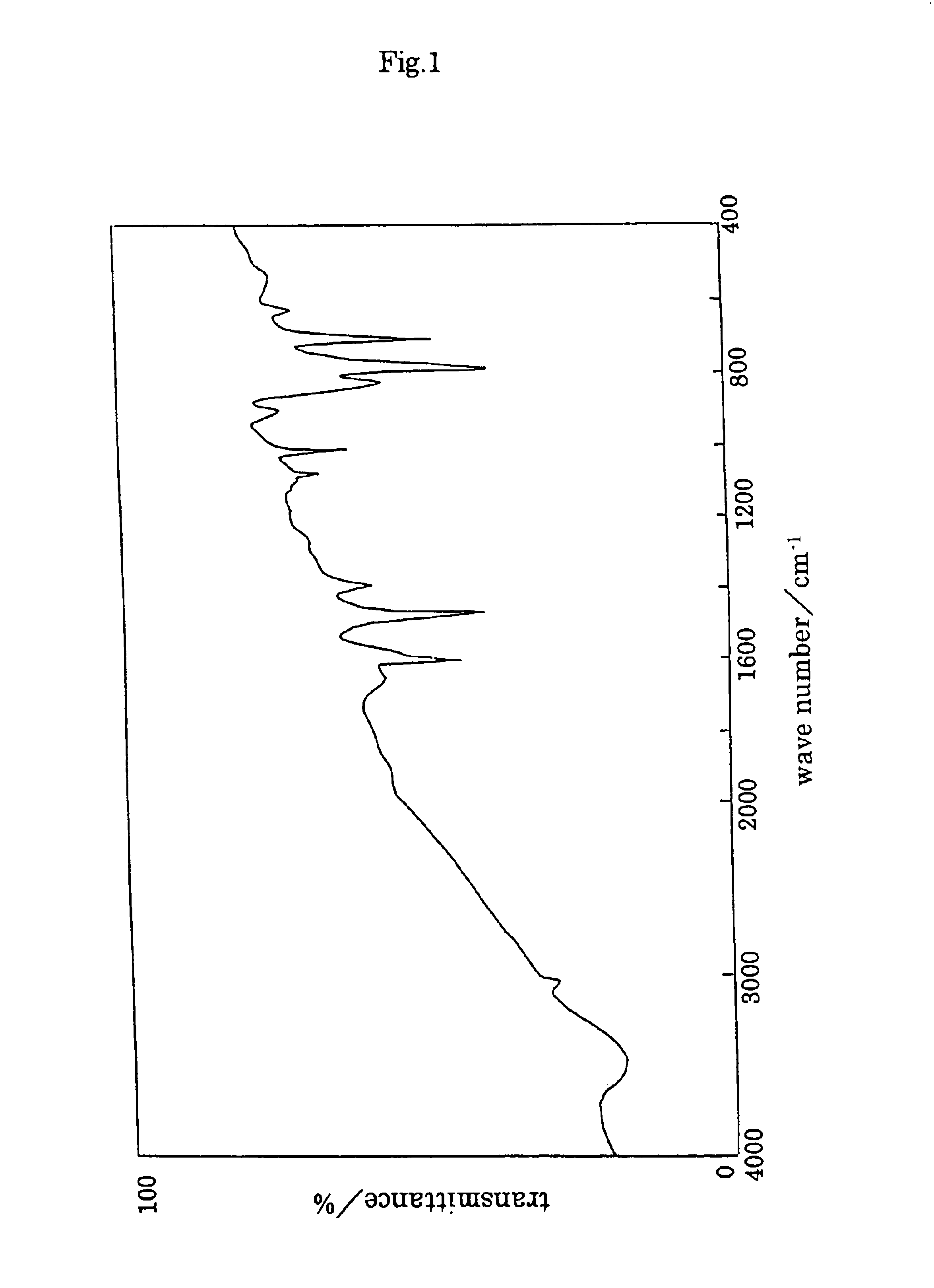

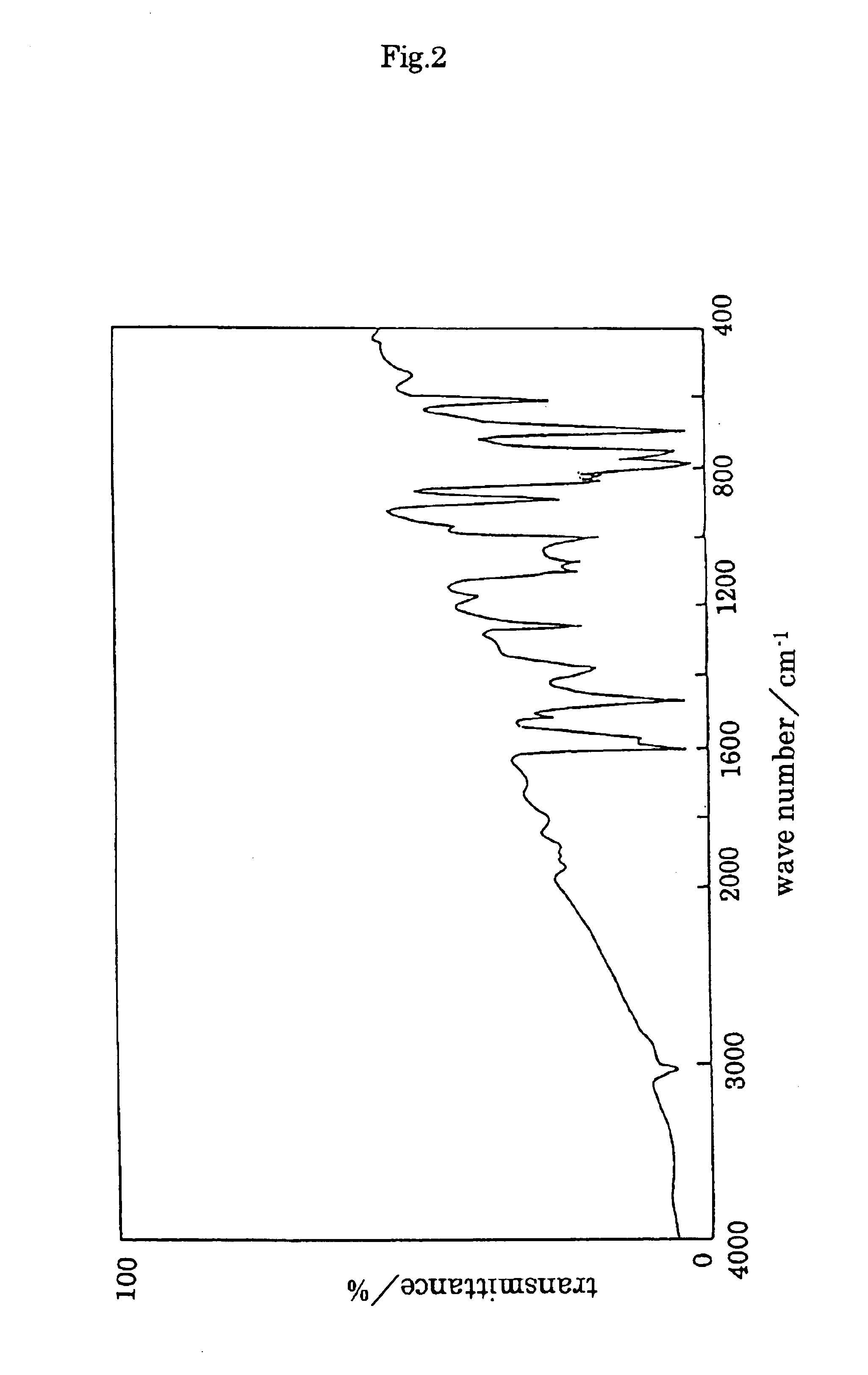

Polymeric compound

A polymer compound which is a polyphenylene co-condensation polymer consisting substantially of paraphenylene group and metaphenylene group and improved in forming ability and functions, wherein the ratio of metaphenylene group is in the range of 60 to 95%.

Owner:JAPAN SCI & TECH CORP

Polyester thermosol and preparation method thereof

The invention provides a polyester hot melt adhesive and a preparation method thereof, comprising the steps that: (1) in the presence of a catalyst, a transesterification is carried out between a dimethyl terephthalate and a diol; (2) a isophthalic acid, a aliphatic dicarboxylic acid and a stabilizer are mixed with the yield products of the step (1), a decompression and a co-condensation process are carried out so as to obtain a copolymer; (3) the mixture of a sorbic acid metal salt and the copolymer of ethylene KEYI acrylic acid are added in the yield products of step (2), then the copolymer is modified so as to obtain the polyester hot melt adhesive. The invention adopts the sorbic acid metal salt and the copolymer of ethylene acrylic acid to modify the colopolymer. The polyester hot melt adhesive obtained therefrom has the advantages of strong bond performance, positive effects of water cleaning and dry cleaning resistances, short opening time and fast solidification. The polyester hot melt adhesive is especially suitable for a production assembly line which calls for rapid bonding.

Owner:南通天洋光伏材料科技有限公司

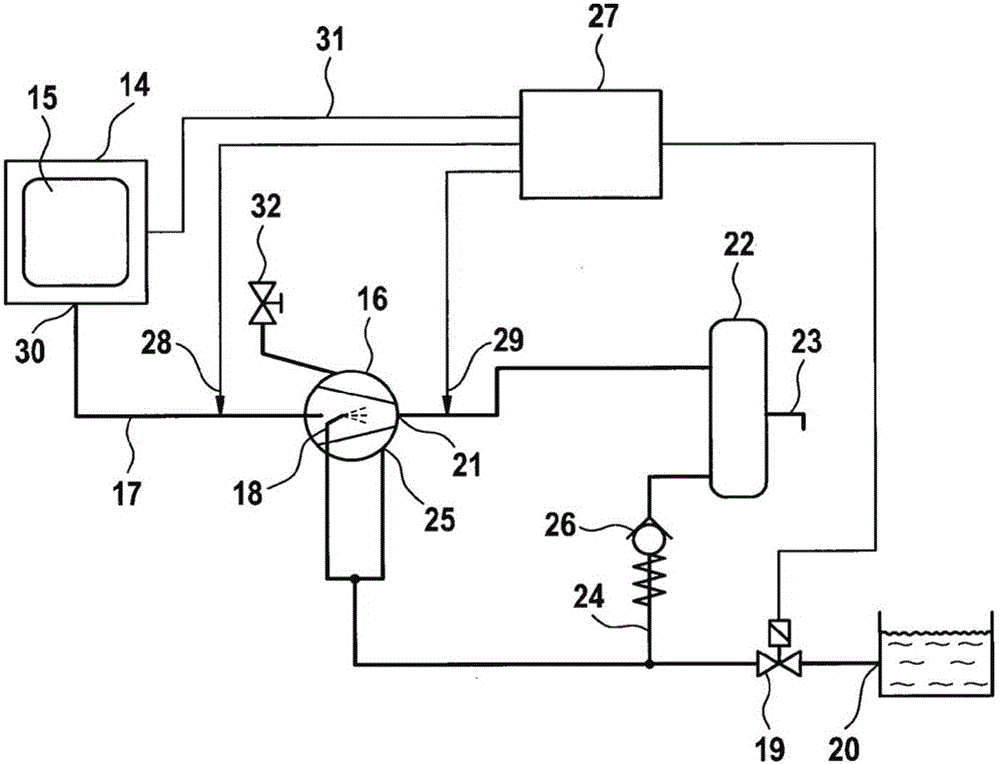

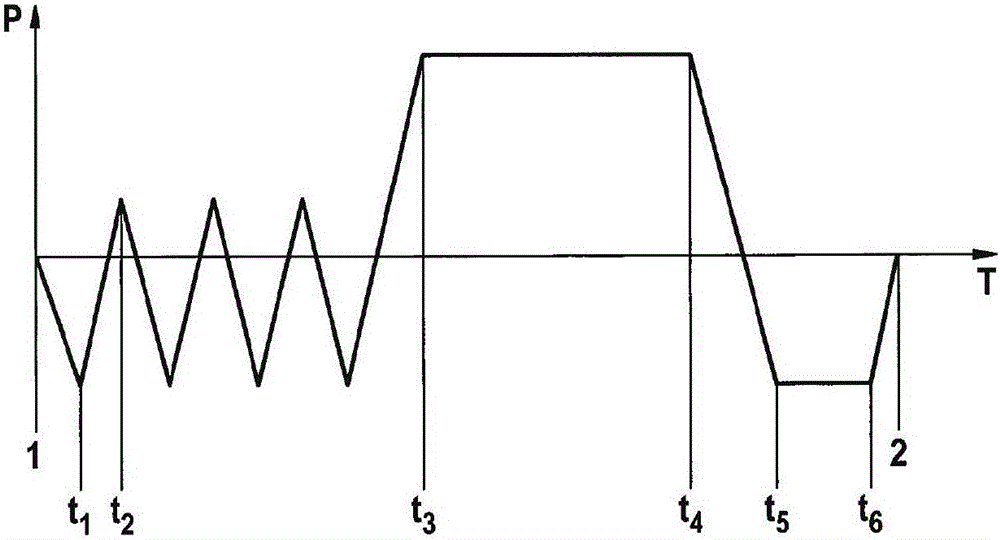

Pump assembly and method for evacuating a vapor-filled chamber

ActiveCN105026758ARotary/oscillating piston combinations for elastic fluidsFlexible member pumpsEngineeringVacuum pump

The invention relates to an assembly comprising a vacuum pump (16) and a chamber (15), wherein a suction tract (17) extends between the chamber (15) and the vacuum pump (16). The vacuum pump (16) is a liquid ring machine. According to the invention, a liquid outlet (18) is arranged in the suction tract (17) in order to add liquid to gas sucked in from the chamber (15). The invention further relates to a method for evacuating a chamber (15) filled with vapor. According to the invention, the vapor is condensed by introducing additional liquid into the suction tract, thus by co-condensation. By supplying liquid selectively only when liquid is required for the condensation of the vapor, water is saved.

Owner:STERLING IND CONSULT GMBH

Crosslinked Organic-Inorganic Hybrid Membranes and Their Use in Gas Separation

InactiveUS20090299015A1Good chemical resistanceGuaranteed high pressure stabilitySemi-permeable membranesProductsCellulose acetateOrganic inorganic

The present invention is for crosslinked membranes and in particular for crosslinked poly(ethylene oxide)-cellulose acetate-silsesquioxane (PEO-CA-Si) organic-inorganic hybrid membranes and their use in gas separation. These crosslinked PEO-CA-Si membranes were prepared by in-situ sol-gel co-condensation of crosslinkable PEO-organotrialkoxysilane and CA-organotrialkoxysilane polymers in the presence of acetic acid catalyst during the formation of membranes. The crosslinkable PEO- and CA-organotrialkoxysilane polymers were synthesized via the reaction between the hydroxyl groups on PEO (or on CA) and the isocyanate on organotrialkoxysilane to form urethane linkages under mild conditions. The crosslinked PEO-CA-Si membranes exhibited both increased selectivity of CO2 / N2 and CO2 permeability as compared to a CA membrane, suggesting that these membranes are very promising for gas separations such as CO2 / N2 separation.

Owner:UOP LLC

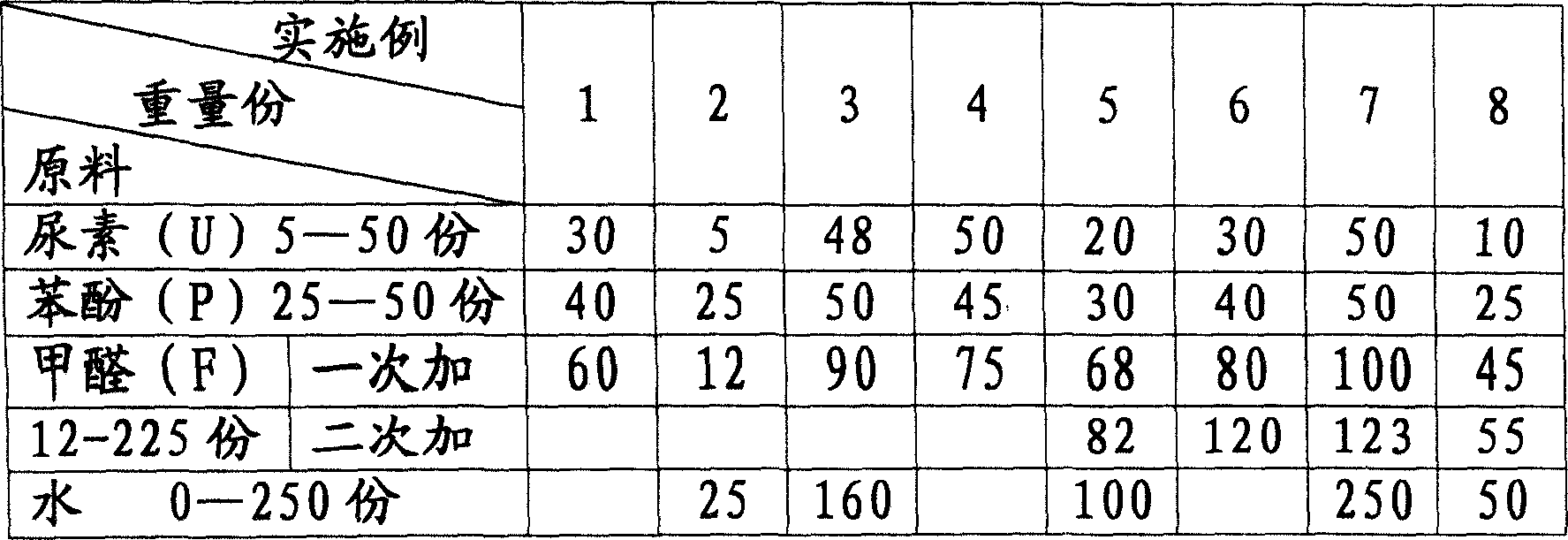

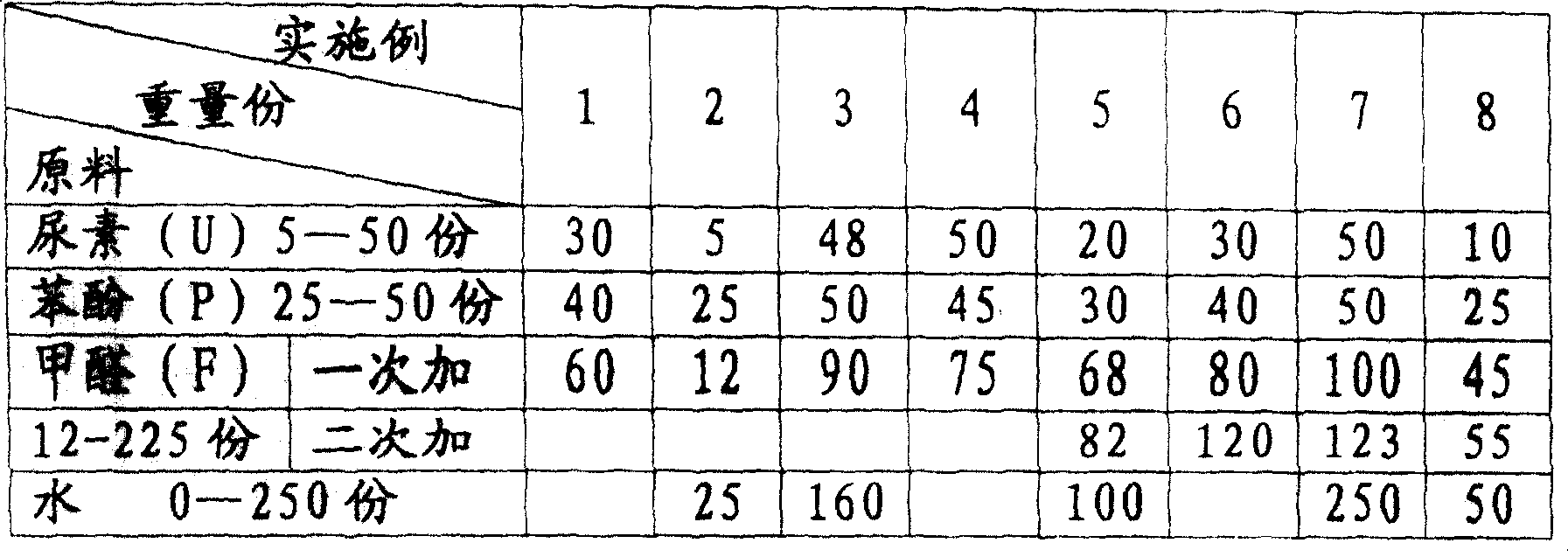

Urea-phenol-formaldehyde co-condensation polymer resin and its production process

The present invention is urea-phenol-formaldehyde condensation polymer resin and its production process. The material includes urea in 5-50 weight portions, phenol in 25-50 weight portions, formaldehyde in 12-225 weight portions and water in 0-250 weight portions. The production process includes the following steps: smelting phenol in the reaction kettle, adding urea and formaldehyde, regulating pH to 6-8, heating to 75-100 deg.c, maintaining for 30-100min, regulating pH to 3.0-5.5 for condensation reaction at viscosity not lower than 20S, regulating pH to 7.5-12, adding water and formaldehyde optionally, controlling temperature in 80-95 deg.c to react to terminal. The urea-phenol-formaldehyde condensation polymer resin is yellow or brown transparent colloid liquid with pH 7.5-12, free phenol in 0.5-10 %, free aldehyde less than 2.0 %, and solid content 30-75 % and storage life over 1 month. It is used as adhesive for timber, friction plate, etc.

Owner:ZHEJIANG FORESTRY UNIVERSITY

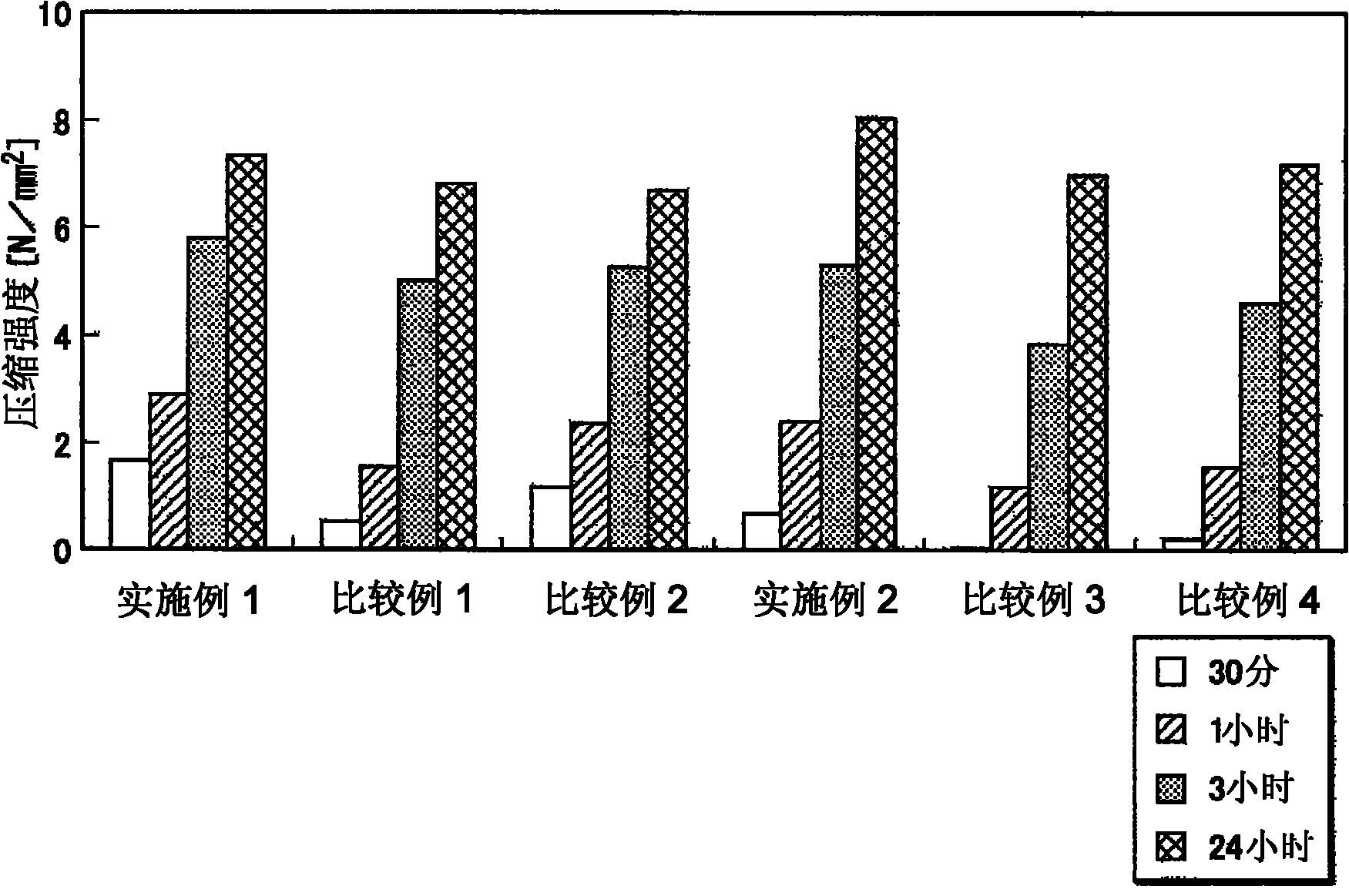

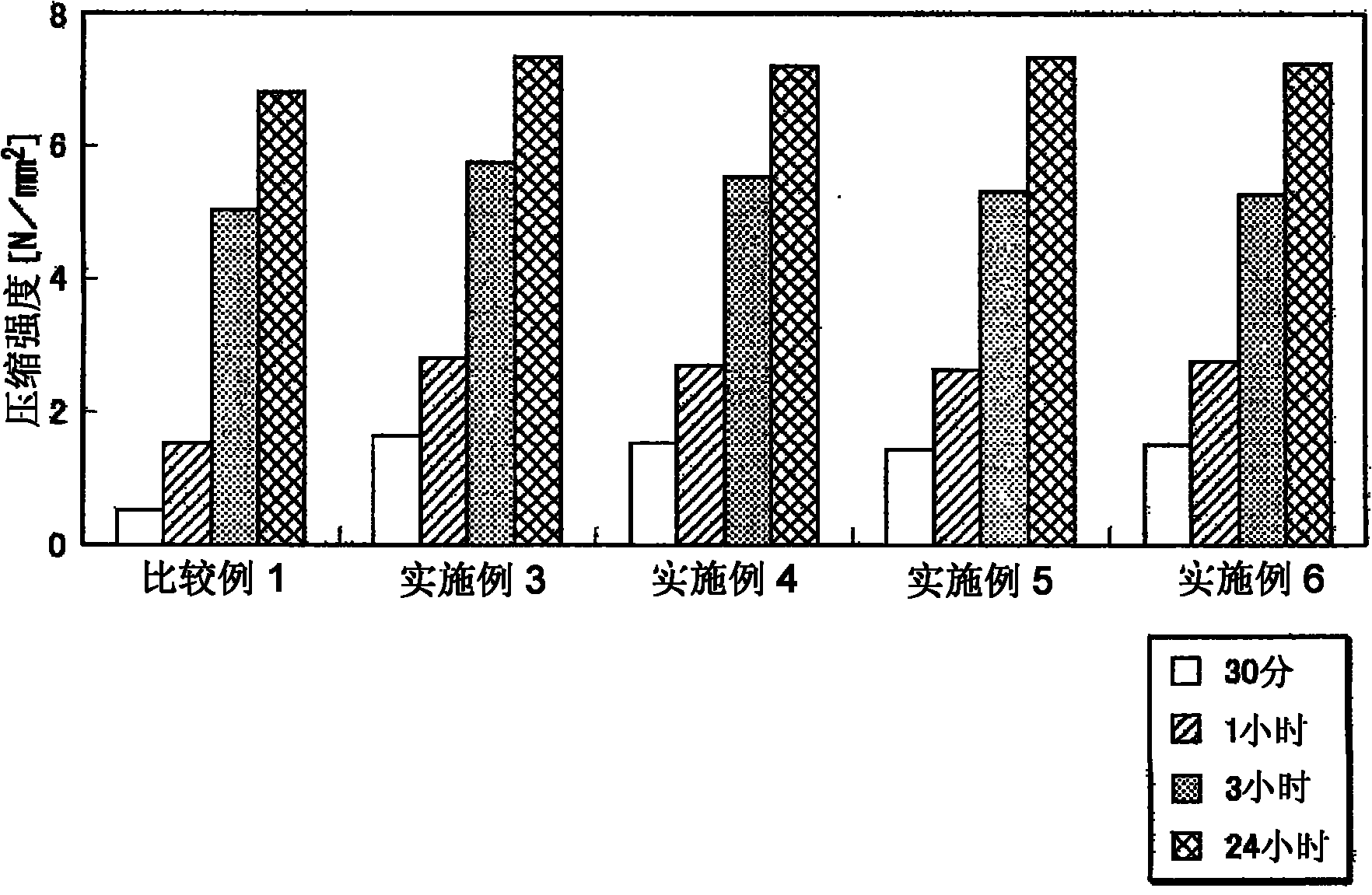

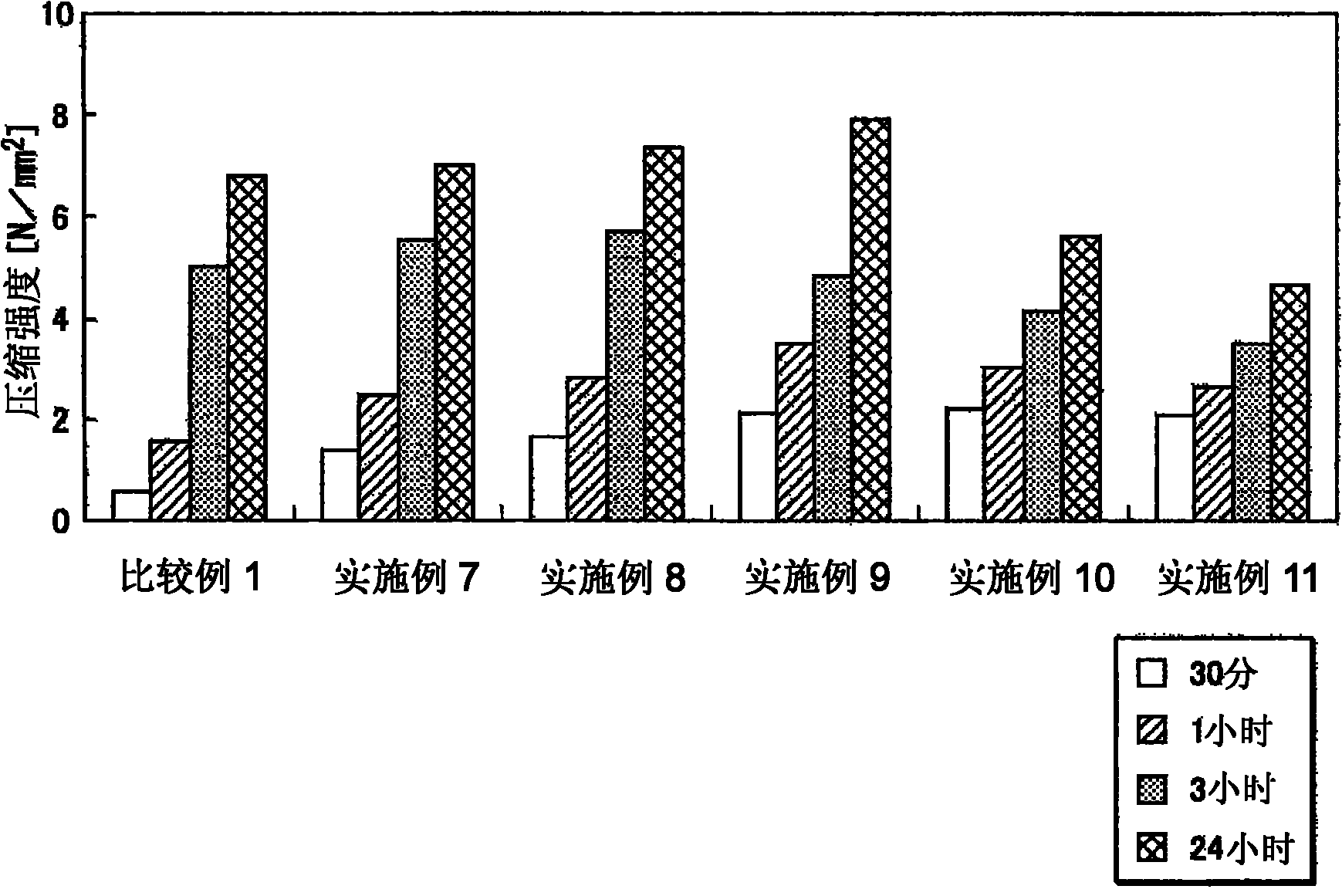

Binder composition for casting mold formation and process for producing casting mold using the binder composition for casting mold formation

InactiveCN102105241AImprove mold strengthImprove initial strengthFoundry mouldsFoundry coresMetal chlorideAlkaline earth metal

A binder composition for casting mold formation which can give a casting mold having sufficient strength without complicating the production step; and a process for producing a casting mold using the binder composition for casting mold formation. The binder composition for casting mold formation is characterized by comprising an acid-curable resin, water, and the chloride of a metal. The composition is further characterized in that the acid-curable resin comprises furfuryl alcohol and one or more products of the condensation or co-condensation of one or more members selected from a group consisting of furfuryl alcohol, phenols, and urea with an aldehyde, and that the metal is an alkaline earth metal and / or a zinc-family element.

Owner:GUN EI CHEM IND

Crosslinked organic-inorganic hybrid membranes and their use in gas separation

InactiveUS7790803B2Improve gas separation performanceInherent disadvantageProductsSemi-permeable membranesAcetic acidCellulose acetate

The present invention is for crosslinked membranes and in particular for crosslinked poly(ethylene oxide)-cellulose acetate-silsesquioxane (PEO-CA-Si) organic-inorganic hybrid membranes and their use in gas separation. These crosslinked PEO-CA-Si membranes were prepared by in-situ sol-gel co-condensation of crosslinkable PEO-organotrialkoxysilane and CA-organotrialkoxysilane polymers in the presence of acetic acid catalyst during the formation of membranes. The crosslinkable PEO- and CA-organotrialkoxysilane polymers were synthesized via the reaction between the hydroxyl groups on PEO (or on CA) and the isocyanate on organotrialkoxysilane to form urethane linkages under mild conditions. The crosslinked PEO-CA-Si membranes exhibited both increased selectivity of CO2 / N2 and CO2 permeability as compared to a CA membrane, suggesting that these membranes are very promising for gas separations such as CO2 / N2 separation.

Owner:UOP LLC

Production method of rapid-to-install composite ceiling wall board

ActiveCN108688263AHigh impact strengthHigh tensile strengthSynthetic resin layered productsAldehyde/ketone condensation polymer adhesivesFiberGlass fiber

The invention discloses a production method of a rapid-to-install composite ceiling wall board. The production method includes steps of: S1) raw material selection; S2) resin synthesis; S3) compositewall board preparation; and S4) performance test on the composite wall board and finish product production. Under a weak alkaline condition, melamine, phenol and formaldehyde are subjected to co-condensation to form melamine-phenol-formaldehyde resin, which then serves as a basic resin to prepare a series of laminated boards; by adding glass fibers, the composite ceiling wall board is improved inimpact strength, tensile strength, elasticity modulus and Rockwell hardness; the melamine-phenol-formaldehyde resin has long storage time, and the composite ceiling wall board is improved in formaldehyde release quantity and is enhanced in flame retarding performance.

Owner:ANHUI YANGZI FLOORING

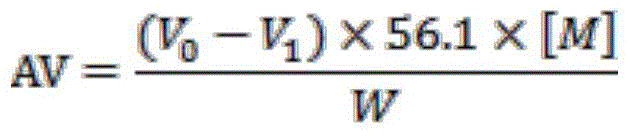

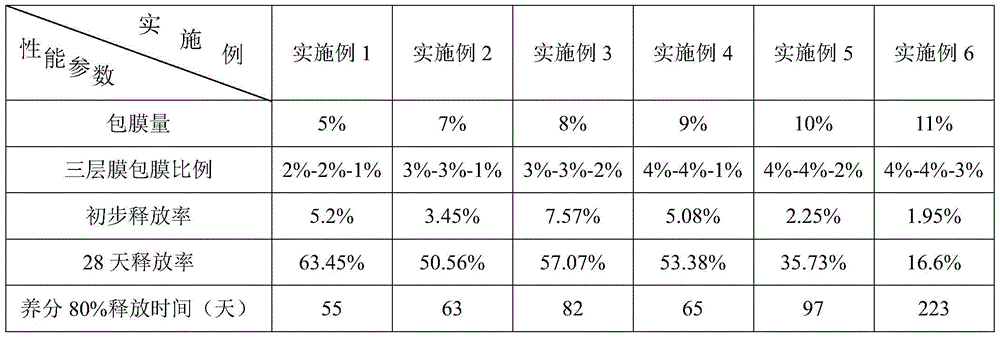

Unsaturated polyester coated controlled-release fertilizer prepared from PET wastes and preparation method thereof

InactiveCN105753611AReduce pollutionReduce manufacturing costLayered/coated fertilisersFertilizer mixturesControlled releasePolyester

The invention relates to unsaturated polyester coated controlled-release fertilizer prepared from PET wastes and a preparation method thereof and belongs to the technical field of controlled-release fertilizers.The unsaturated polyester coated controlled-release fertilizer comprises granulated fertilizer 1, unsaturated polyester coating inner layers 2 on the surface of the granulated fertilizer 1, unsaturated polyester coating middle layers 3 on the surfaces of the coating inner layers 2, and unsaturated polyester coating outer layers 4 on the surfaces of the coating middle layers 3, and the weights of the coating inner layers 2, the coating middle layers 3 and the coating outer layers 4 account for 1-5%, 1-5% and 1-3% of total weight of the fertilizer, respectively, wherein unsaturated polyester is made by subjecting PET wastes, diol, a catalyst and an active diluent as raw materials to reactions such as alcoholysis, esterification and co-condensation.The controlled-release fertilizer with different release periods of time can be prepared by adjusting a coating ratio, the PET wastes are resourcefully reused, waste is turned into wealth, environmental pollution is reduced, and the production cost of the coated controlled-release fertilizer is greatly reduced.

Owner:INST OF PLANT PROTECTION & SOIL FERTILIZER HUBEI ACAD OF AGRI SCI

Temperature controlled sol-gel co-condensation

Provided according to some embodiments of the invention are methods of making co-condensed macromolecules that include forming a reaction mixture by combining at leak one reactant and at least one reagent at a first temperature at which the at least one reactant is substantially unreactive in the presence of the at least one reagent; raising the temperature of the reaction mixture to a second temperature at which the at least one reactant is reactive in the presence of the at least one reagent, wherein the reaction of the at least one reactant in the presence of the at least one reagent produces co-condensed macromolecules such as co-condensed silica macromolecules.

Owner:NAVAN INC

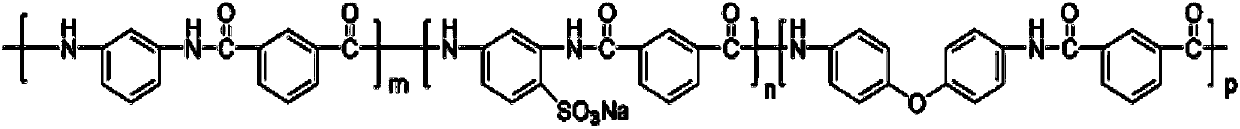

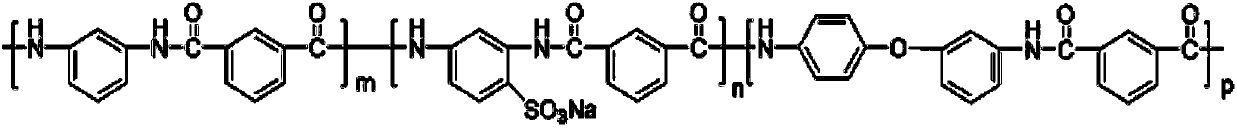

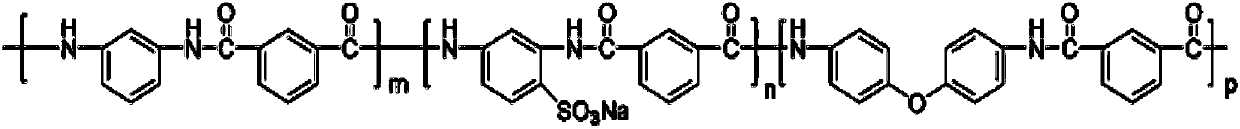

Modified poly(isophthaloyl metaphenylene diamine) for realizing easy dyeing effect of cationic dyes, and preparation method and application thereof

ActiveCN107814928AImprove solubilityImprove spin performanceMonocomponent copolyamides artificial filamentOrganic solventAramid

The invention relates to a modified poly(isophthaloyl metaphenylene diamine) for realizing easy dyeing effect of cationic dyes, and a preparation method and application thereof. The modified poly(isophthaloyl metaphenylene diamine) is prepared from the following components of MPD (m-phenylenediamine), IPC (isophthaloyl dichloride), 2,4-diaminobenzenesulfonic acid sodium salt, and ether-containingaromatic diamine, and is prepared by performing co-condensation on the four types of monomers in an organic solvent at low temperature. The prepared modified poly(isophthaloyl metaphenylene diamine) has the advantages that the logarithmic viscosity number can reach 1.5 to 2.1dL / g, the good dissolving property is realized in the organic solvent, the spinnability is better, and the modified poly(isophthaloyl metaphenylene diamine) can be further prepared into fiber or resin. The prepared fiber has the advantages that the easy dyeing effect of the cationic dye in common-pressure boiled water dyeing bath can be realized, the high temperature-resistant property is excellent, the mechanical property is better, and the problem of difficulty in dyeing by the conventional method due to no dyeing affinity groups because of tight arrangement of meta-aramid molecules is solved.

Owner:DONGHUA UNIV

Urea-phenol-formaldehyde co-condensation polymer resin and its production process

The present invention is urea-phenol-formaldehyde condensation polymer resin and its production process. The material includes urea in 5-50 weight portions, phenol in 25-50 weight portions, formaldehyde in 12-225 weight portions and water in 0-250 weight portions. The production process includes the following steps: smelting phenol in the reaction kettle, adding urea and formaldehyde, regulating pH to 6-8, heating to 75-100 deg.c, maintaining for 30-100min, regulating pH to 3.0-5.5 for condensation reaction at viscosity not lower than 20S, regulating pH to 7.5-12, adding water and formaldehyde optionally, controlling temperature in 80-95 deg.c to react to terminal. The urea-phenol-formaldehyde condensation polymer resin is yellow or brown transparent colloid liquid with pH 7.5-12, free phenol in 0.5-10 %, free aldehyde less than 2.0 %, and solid content 30-75 % and storage life over 1 month. It is used as adhesive for timber, friction plate, etc.

Owner:ZHEJIANG FORESTRY UNIVERSITY

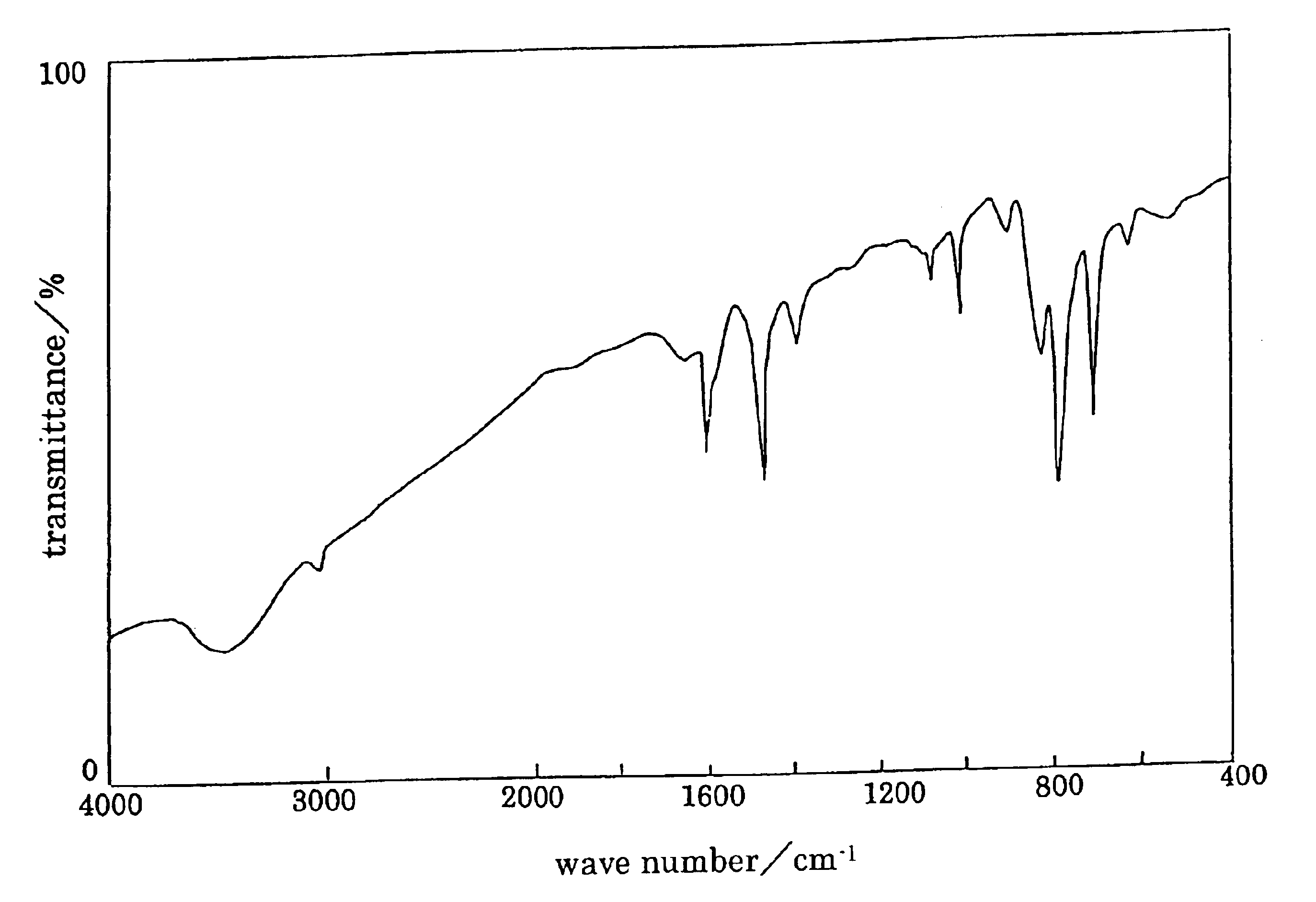

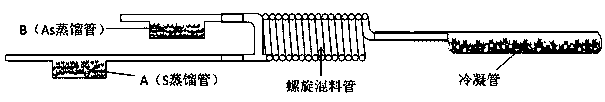

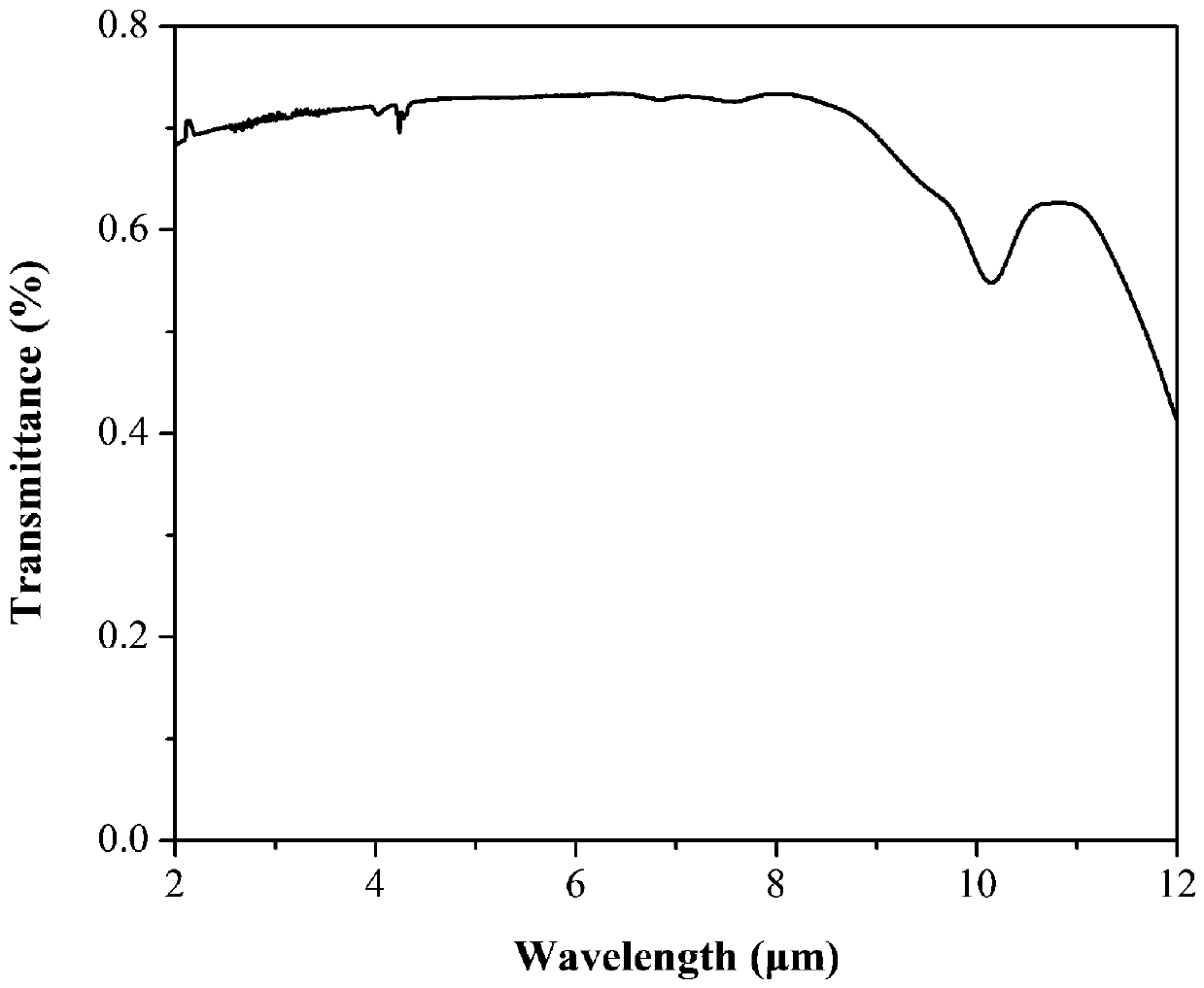

Preparation method of high-purity chalcogenide infrared glass

The invention discloses a preparation method of high-purity chalcogenide infrared glass which is a distillation-co-condensation method, and belongs to a preparation method of chalcogenide glass. The method comprises: using high-purity argon as power to drive different activated materials to mix in a molecular form in a quartz spiral tube, and condensing in a quartz ampoule; evacuating and sealing the quartz ampoule and then placing in a rocking furnace for rocking, and cooling and annealing to obtain the high-purity chalcogenide infrared glass. The infrared glass prepared by the invention is free of composition stripes due to non-uniform mixing in a mixing process, average transmittance (@2-6 Mum) of the infrared glass is greater than 70 %, and the prepared high-purity chalcogenide glass is 0.25 dB / m in lowest loss.

Owner:北京玻璃研究院有限公司

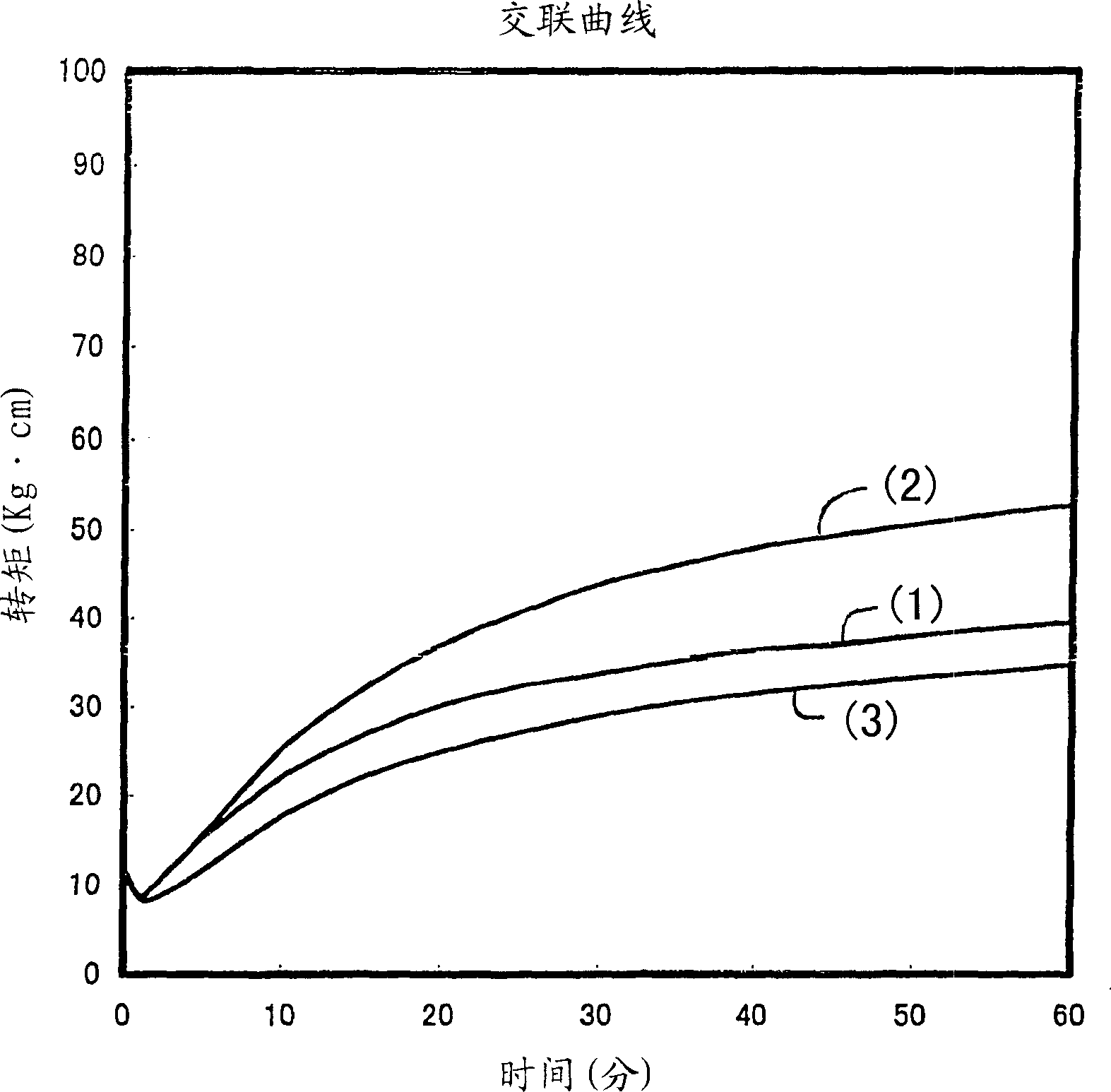

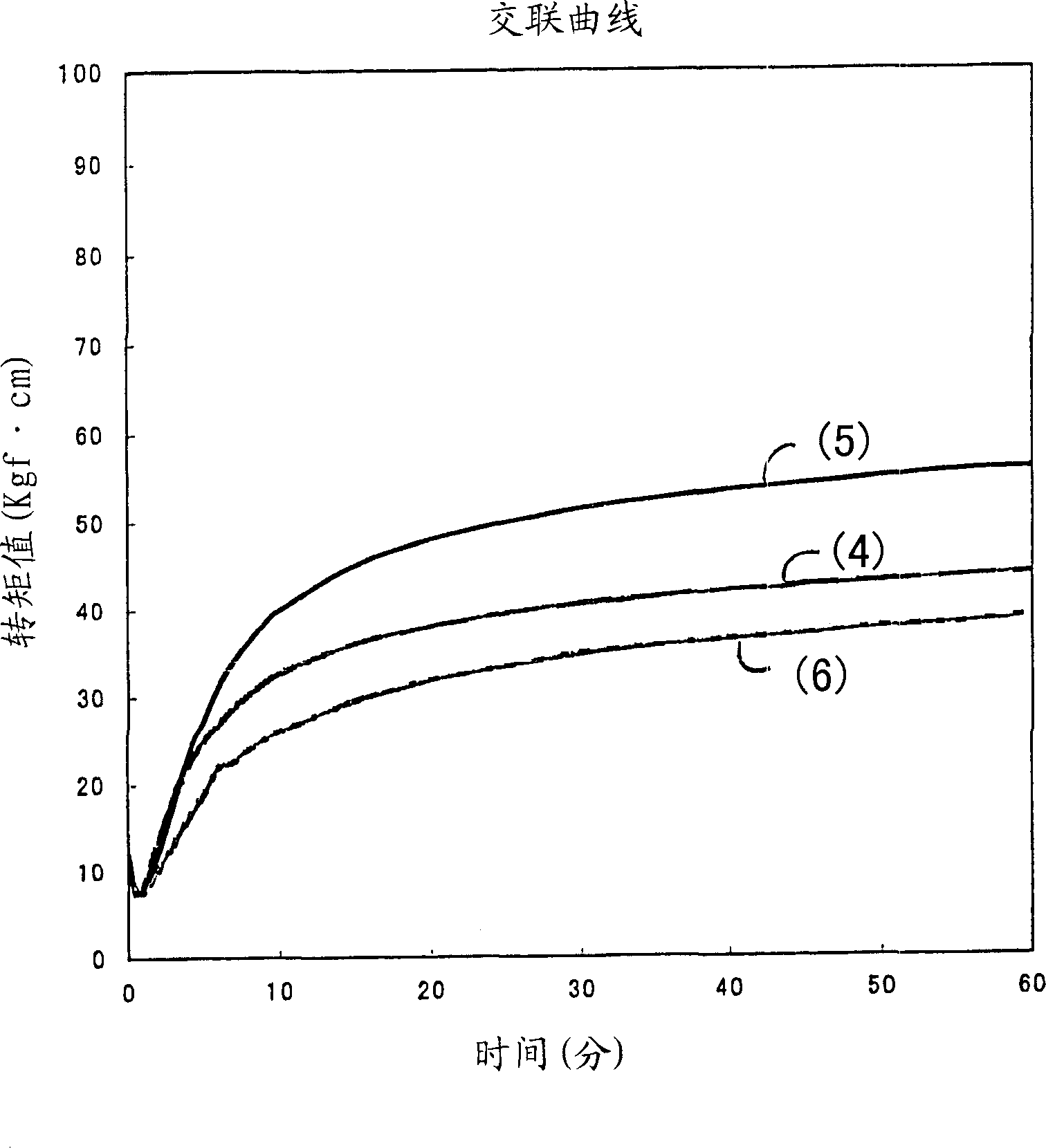

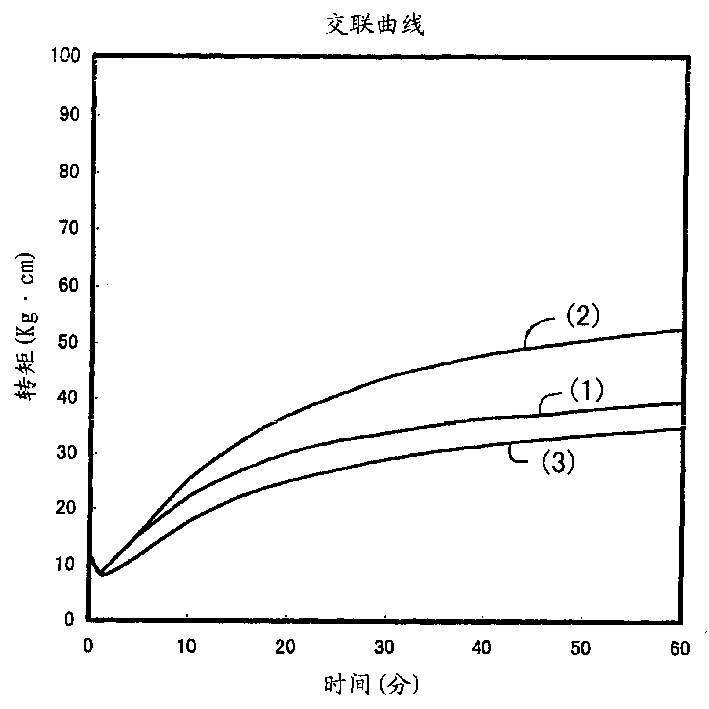

Resinous crosslinking agents and rubbers crosslinked with resinous crosslinking agents

Resinous crosslinking agents with which rubbers can be crosslinked at a higher rate than with conventional resinous crosslinking agents without using a crosslinking accelerator causative of corrosion. One of the resinous crosslinking agents comprises a mixture of a resol type phenol / formaldehyde co-condensation resin and a novolak type phenolic / formaldehyde co-condensation resin. The other resinous crosslinking agent comprises a resol resin obtained through the co-condensation of a p-alkylphenol compound, a phenol compound not having a substituent in the para-position, and formaldehyde. The crosslinked rubber is obtained by using the resin crosslinking agent.

Owner:TAOKA CHEM COMPANY

Polylactic acid-based bio-based polyesteramide and preparation method thereof

The invention relates to polylactic acid-based bio-based polyesteramide and a preparation method thereof. The preparation method comprises fully mixing 100 parts of a polylactic acid prepolymer and 10 to 100 parts of a polyamide prepolymer, putting the mixture into a reactor with a stirring device, then adding 0.5 to 5 parts of a catalyst into the reactor, feeding nitrogen gas into the reactor, carrying out vacuum-pumping, repeating the nitrogen feeding and vacuum-pumping processes 3 times so that air in the reactor is replaced and pressure in the reaction system is kept in a range of -0.04 to -0.08MPa through vacuum-pumping, carrying out a melting reaction process at a temperature of 120 to 150 DEG C for 1-3h, then heating the reaction product to 160 to 200 DEG C, and carrying out melting co-condensation for 3 to 7h to obtain the polyamide ester copolymer. The invention provides the simple and low-cost polyester amide preparation method. A polyamide chain segment is introduced into a polylactic acid chain segment by copolymerization modification so that the thermal stability of the polylactic acid is improved and an application range of polylactic acid in the field of film packaging is widened.

Owner:HUBEI UNIV OF TECH

Manufacturing method of polyester fiber for industry

InactiveCN106319686AImprove flexibilityImprove athletic abilityConjugated synthetic polymer artificial filamentsArtifical filament manufactureAntioxidantPolyethylene glycol

The invention relates to a manufacturing method of polyester fiber for industry. The manufacturing method includes following steps: 1), mixing organic calcium carbonate crystal whisker, organic wollastonite nano raphioid fiber, organic barium sulfate nanopowder, theylene glycol, propylene glycol, butylenes glycol, p-hydroxybenzoic acid and sodium germinate to prepare a high-strength high-modulus composite alcohol solution; 2), mixing organic magnesium hydroxide crystal whisker, mica powder, polyethylene glycol, propylene glycol, high-temperature antioxidant 1098, ethylene glycol antimony and protonizing agent phosphoric acid to prepare a high-strength high-modulus composite promoter; 3), subjecting the high-strength high-modulus composite alcohol solution, the high-strength high-modulus composite promoter, purified terephthalic acid and ethylene glycol to co-condensation polymerization to prepare high-strength high-modulus polyester, and spinning to obtain the polyester fiber. By the manufacturing method, flexibility and mobility of molecular chains are improved, and the polyester fiber is endowed with high crystallinity and high processing constancy; the polyester fiber has high strength and modulus, excellent impact resistance and quite good market prospect.

Owner:ZHEJIANG SHENGYUAN CHEM FIBER

Method for preparing HMW (High Molecular Weight) p-aramid polymer through ternary co-condensation

InactiveCN108359091AEasy to solveFast activation energyMonocomponent copolyamides artificial filamentPolymer scienceDiaminodiphenyl ether

The invention discloses a method for preparing HMW (High Molecular Weight) p-aramid polymer through ternary co-condensation. The method comprises the following steps: 1, preparing an NMP (N-Methyl Pyrrolidone)-CaCl2 solvent system; 2, cooling the NMP-CaCl2 solvent system, and adding 3,4'-diaminodiphenyl ether and p-phenylenediamine under the protection of nitrogen, thus obtaining a p-phenylenediamine-NMP-CaCl2 solution system; 3, adding p-phthaloyl chloride in the p-phenylenediamine-NMP-CaCl2 solution system, thus obtaining a raw material solution system; carrying out first-step copolycondensation; 4, after colloid appears in a solution of the first-step copolycondensation, rising the reaction temperature, and carrying out second-step copolycondensation, thus obtaining the p-aramid polymer. According to the method disclosed by the invention, a two-step copolycondensation reaction method which is carried out at a high temperature after a low temperature is adopted, ordered proceeding ofreaction is ensured, increment of side effects is avoided, and the intrinsic viscosity of the obtained p-aramid polymer in a dissolved state is 1.95 to 2.13 dL / g.

Owner:THE NORTHWEST RES INST OF CHEM IND

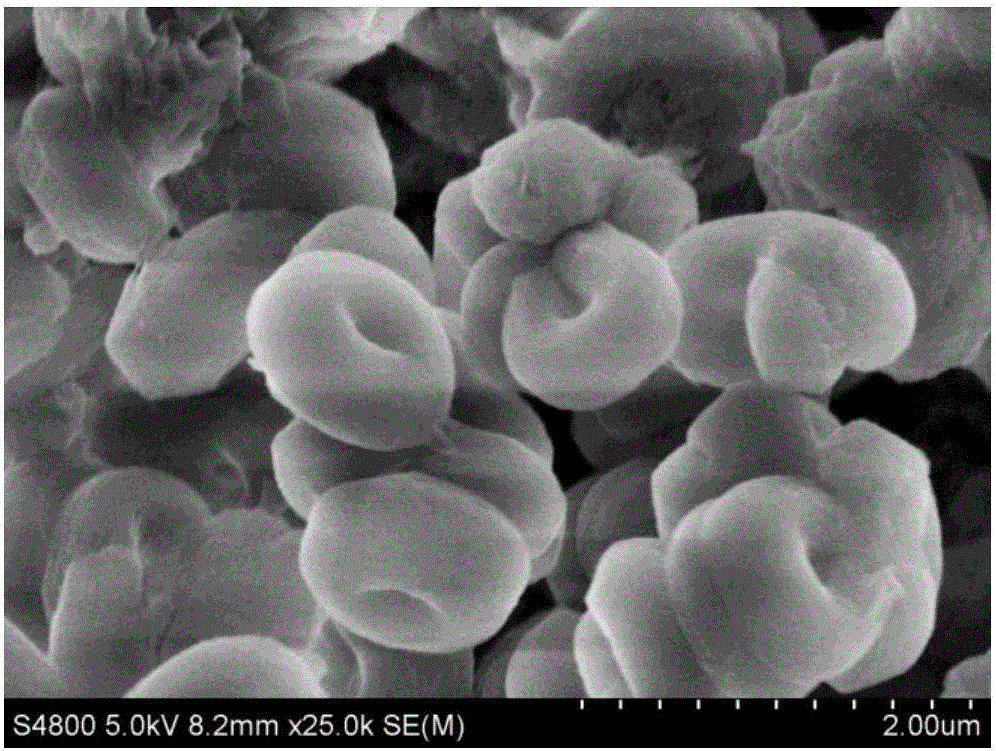

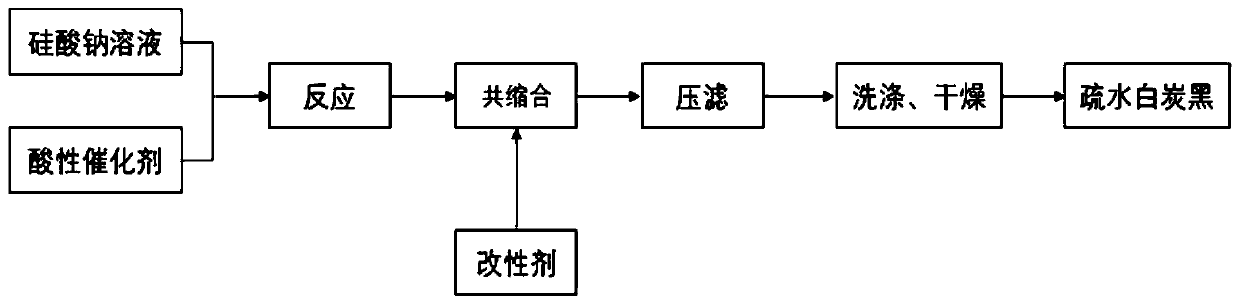

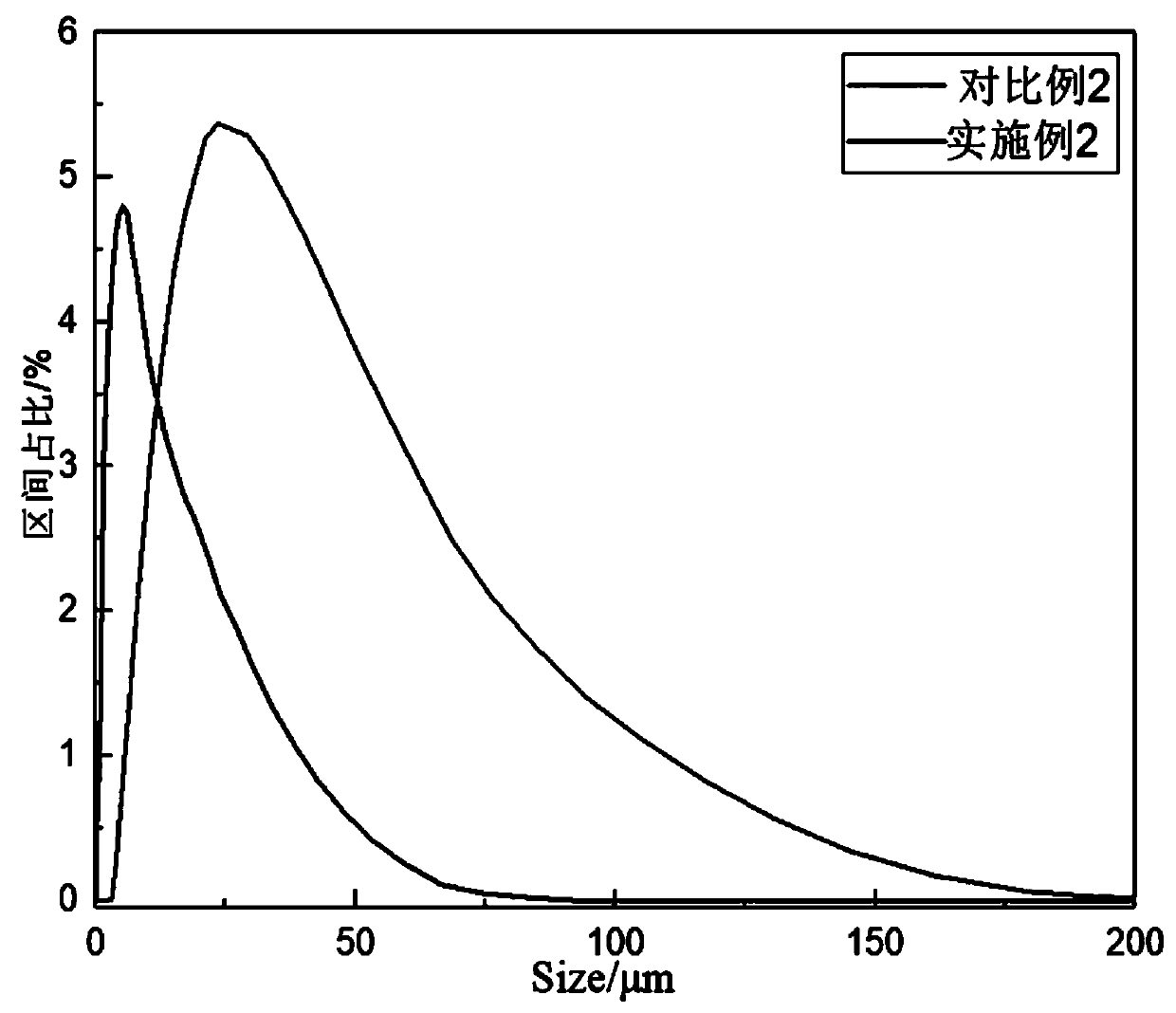

Preparation method of hydrophobic white carbon black with controllable particle size and core-shell structure

PendingCN110589843AImprove reinforcementLarge specific surface areaSilicaMicroballoon preparationPolymer scienceSODIUM SILICATE SOLN

The invention belongs to the field of white carbon black, and discloses a preparation method of hydrophobic white carbon black with controllable particle size and a core-shell structure. The preparation method disclosed by the invention comprises the following steps of: preparing a sodium silicate solution, adding an acid catalyst into the sodium silicate solution, adjusting the pH value of an obtained system to be 10 to 10.5, reacting for 20-35 minutes, continuously adding the acidic catalyst, regulating the pH value of the system to 3.5-4.6, reacting for 40-60 minutes, adding a hydrophobic modifier, adding a cosolvent, reacting for 1-12 hours at 50-80 DEG C, and carrying out filter pressing, washing and drying to obtain the hydrophobic white carbon black with the core-shell structure. According to the preparation method, the number of hydroxyl groups on the surface of the white carbon black is reduced through a co-condensation method of the white carbon black and the hydrophobic modifier, and aggregation of the white carbon black in the drying process is reduced, so that the preparation of the white carbon black with controllable particle size, good hydrophobicity, high specificsurface area and high oil absorption is realized.

Owner:HENGDIAN GRP ZHEJIANG INNUOVO SILICON MATERIAL

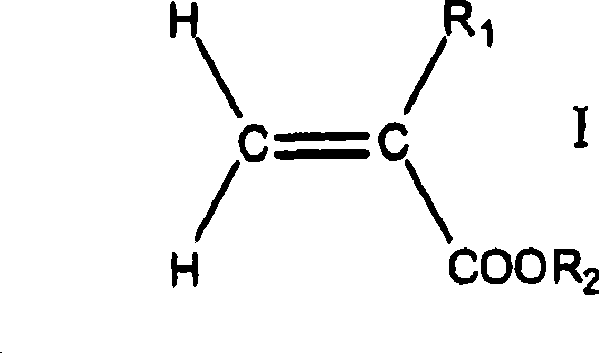

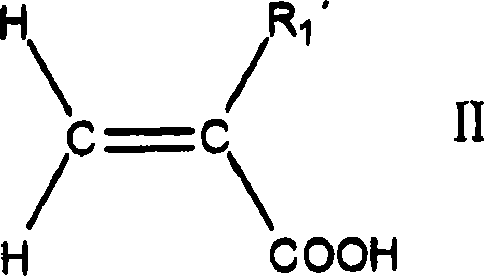

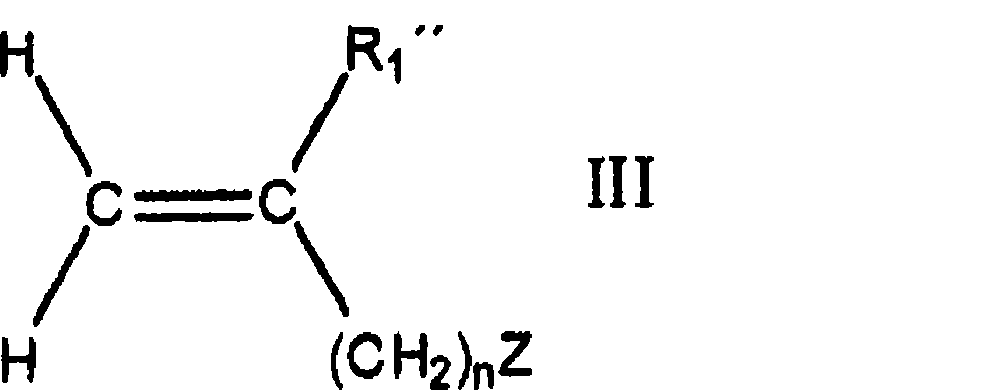

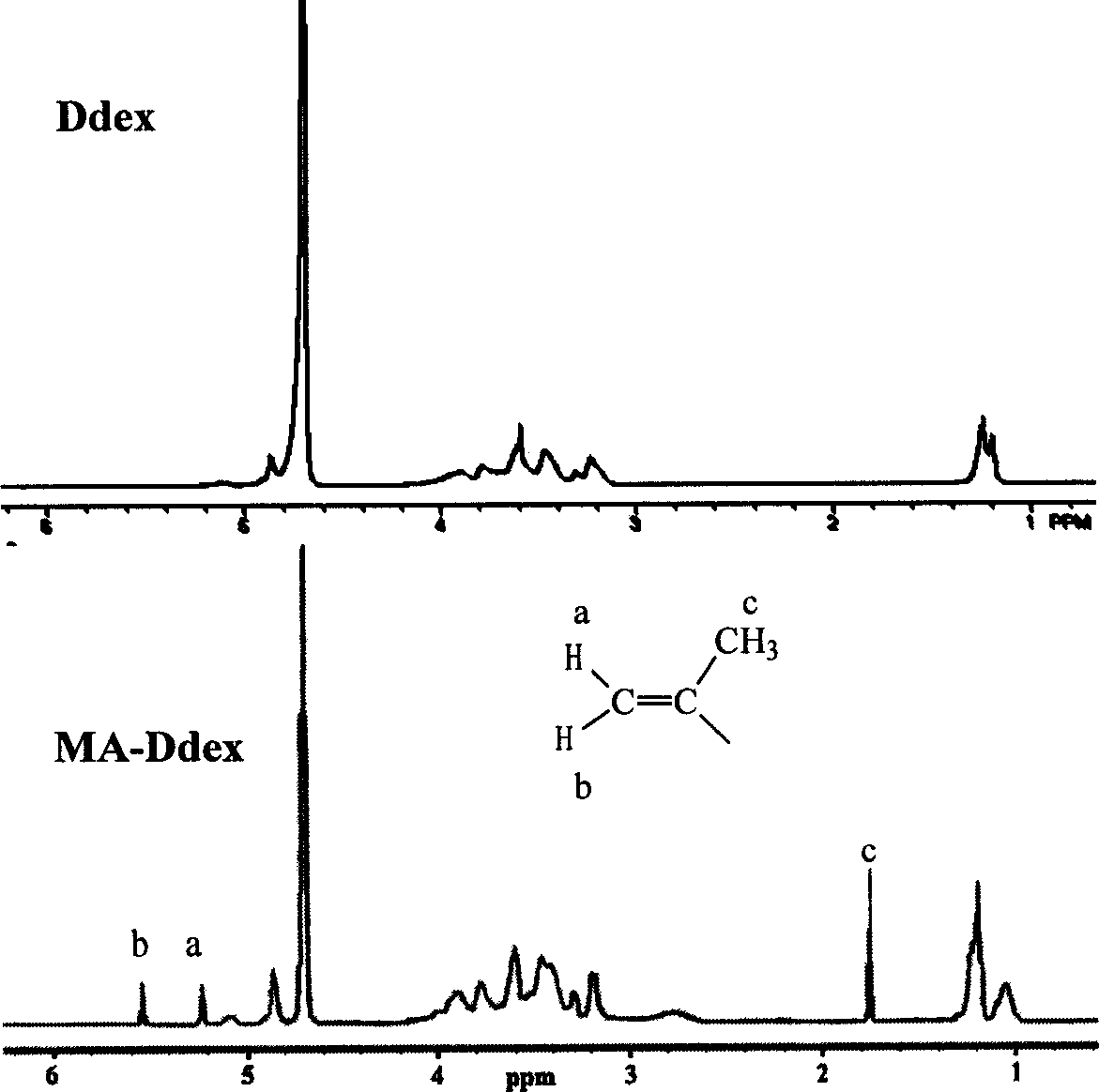

Adhesives based on polyester graft poly(meth)acrylate copolymers

The invention relates to an adhesives based on polyester graft poly(meth)acrylate copolymers. Specifically, the invention relates to the use of mixtures comprising polymer types A, B and AB as adhesives or in adhesives, where the polymer type A is a co-polyester, which is manufactured under co-condensation of unsaturated, aliphatic dicarboxylic acids, the polymer type B is (meth)acrylate homo- and / or -copolymer and the polymer type AB is a grafting copolymer made from the polymer type A and polymer type B, is claimed.

Owner:EVONIK DEGUSSA GMBH

Water-dispersive nano-grade ibuprofen injecta and preparing method

InactiveCN1742714ANo hidden danger of pollutionNo physiological toxicityOrganic active ingredientsPowder deliveryWater dispersibleDouble bond

The present invention uses polysaccharide and polysaccharide containing double bond as covering material of medicine, controls the ratio of medicine and polysaccharide and adopts co-condensation-polymerization technique to obtain the water-dispersible brufen injection preparation whose grain-size is 20-1000nm.

Owner:ZHEJIANG UNIV

Process for the preparation, under subcritical conditions, of monolithic xerogels and aerogels of silica/latex hybrids, modified with alkoxysilane groups

InactiveUS7737189B2Improve insulation performanceHigh mechanical strengthSilicaOther chemical processesMethacrylateColloidal silica

The invention relates to a process for the preparation of monolithic xerogels and aerogels of silica / latex hybrids under subcritical conditions. In the two-stage synthesis of these alcogels in the presence of an acid-base catalyst, the hydrolysis and polycondensation of a silicon alkoxide are carried out in an organic medium containing excess water. A latex consisting of polybutyl methacrylate and polybutyl acrylate, modified with alkoxysilane groups, is first synthesized and then incorporated in the mixture either in the first stage in order to effect its co-hydrolysis with the silicon alkoxide, or in the second stage to effect its co-condensation with the previously hydrolysed colloidal silica. The resulting alcogels are aged, washed, and dried under subcritical conditions. This process gives hybrid products containing 0.1-50 wt-% of latex and having a density of 300-1300 kg / m3, a porosity of 40-85%, a specific surface area of 400-900 m2 / g and a mean pore diameter of 2-12 nm. The products are resistant to atmospheric humidity and moisture, have better mechanical properties than the corresponding inorganic products, and can be used as thermal, acoustic and electrical insulators.

Owner:INST SUPERIOR TECH

High-toughness and water-resistant modified melamine urea-formaldehyde resin

InactiveCN104387542AExtend polymerization timeImprove water resistancePolyethylene glycolAlkylphenol

The invention provides high-toughness and water-resistant modified melamine urea-formaldehyde resin. The high-toughness and water-resistant modified melamine urea-formaldehyde resin is prepared from the following raw materials in parts by weight: 80 parts of urea, 160-220 parts of formaldehyde, 10-20 parts of melamine, 5-10 parts of fatty acid amide, 5-8 parts of polyethylene glycol, 3-6 parts of alkylphenol ethoxylate, 2-5 parts of sodium dihydrogen phosphate, 1-3 parts of hydrochloric acid and 20-30 parts of water. The high-toughness and water-resistant modified melamine urea-formaldehyde resin provided by the invention can effectively improve the toughness and water resistance of the urea-formaldehyde resin. A resin modifying component contained in the high-toughness and water-resistant modified melamine urea-formaldehyde resin provided by the invention can participate in co-condensation polymerization reaction of the resin to change the resin structure and reduce crosslinking density, thereby increasing foam strength, increasing toughness, reducing brittleness, being rich in elasticity and increasing stability.

Owner:CHONGZHOU HERUI TECH

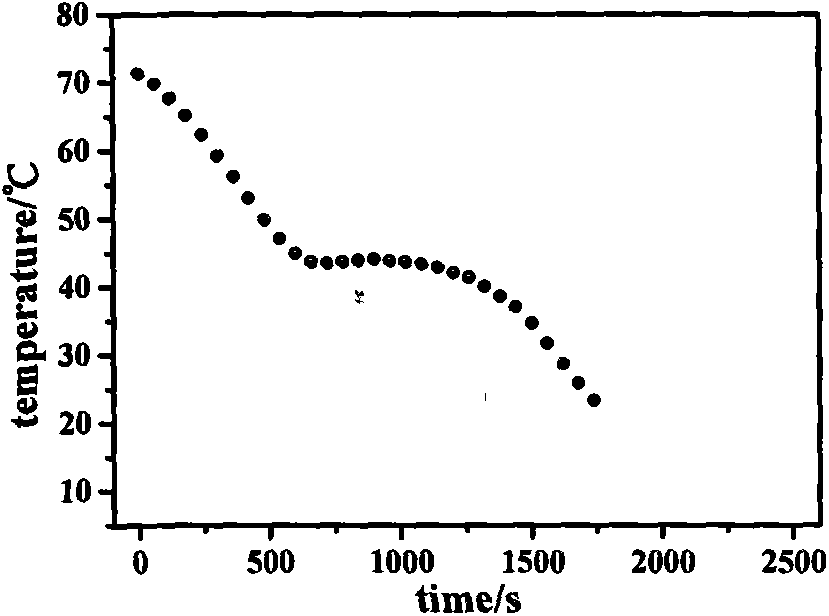

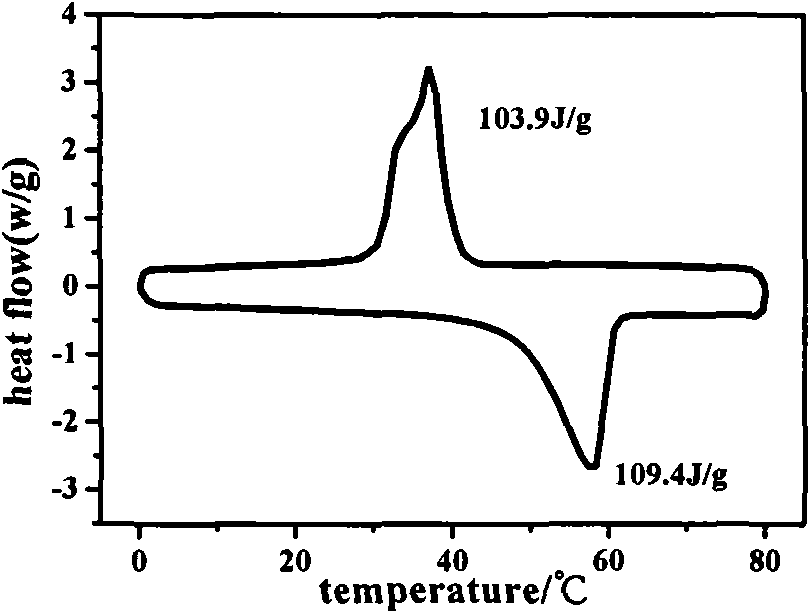

Synthetic method of phase change material polytetramethylene glycol amine aldehyde condensation crosslinking copolymer

InactiveCN103936953AInsoluble and infusibleFew reaction stepsChemical industryHeat-exchange elementsChemical reactionPolytetramethylene glycol

The invention discloses a synthetic method of a phase change material polytetramethylene glycol amine aldehyde condensation crosslinking copolymer. The synthetic method comprises the following steps: by adopting a method of combining an alcohol aldehyde condensation reaction and an ammonium aldehyde condensation reaction and taking polytetramethylene glycol as a phase change function material, an amine compound and an aldehyde compound as a crosslinking agent, controlling a certain temperature and power of hydrogen in a water medium for a chemical reaction; carrying out a co-condensation reaction on an alcoholic hydroxyl group, an amino and a carbonyl group to form a novel chemical bond; and removing water to synthesize the crosslinking copolymer. During reaction, polytetramethylene glycol in different use levels is taken as the phase change function material to synthesize the crosslinking copolymer with different enthalpies of phase change and different phase change temperatures. The synthetic method is simple in process, high in yield and free from byproducts. The synthesized crosslinking copolymer inhibits free movement of a polytetramethylene glycol molecular chain and has the characteristics of indissolvableness and insolubility, so that the crosslinking copolymer becomes a solid-solid phase change material in true sense and can be widely applied to energy storage and insulation in the fields of solar energy collection, load shifting of power supply, waste heat recovery, buildings, cloth, electronic equipment and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com