Preparation method of high-purity chalcogenide infrared glass

A technology of infrared glass and uniformity, applied in the field of infrared glass materials, can solve the problems of long-term mixing and the generation of component stripes, and achieve the effects of reducing energy consumption, eliminating component stripes, and shortening mixing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

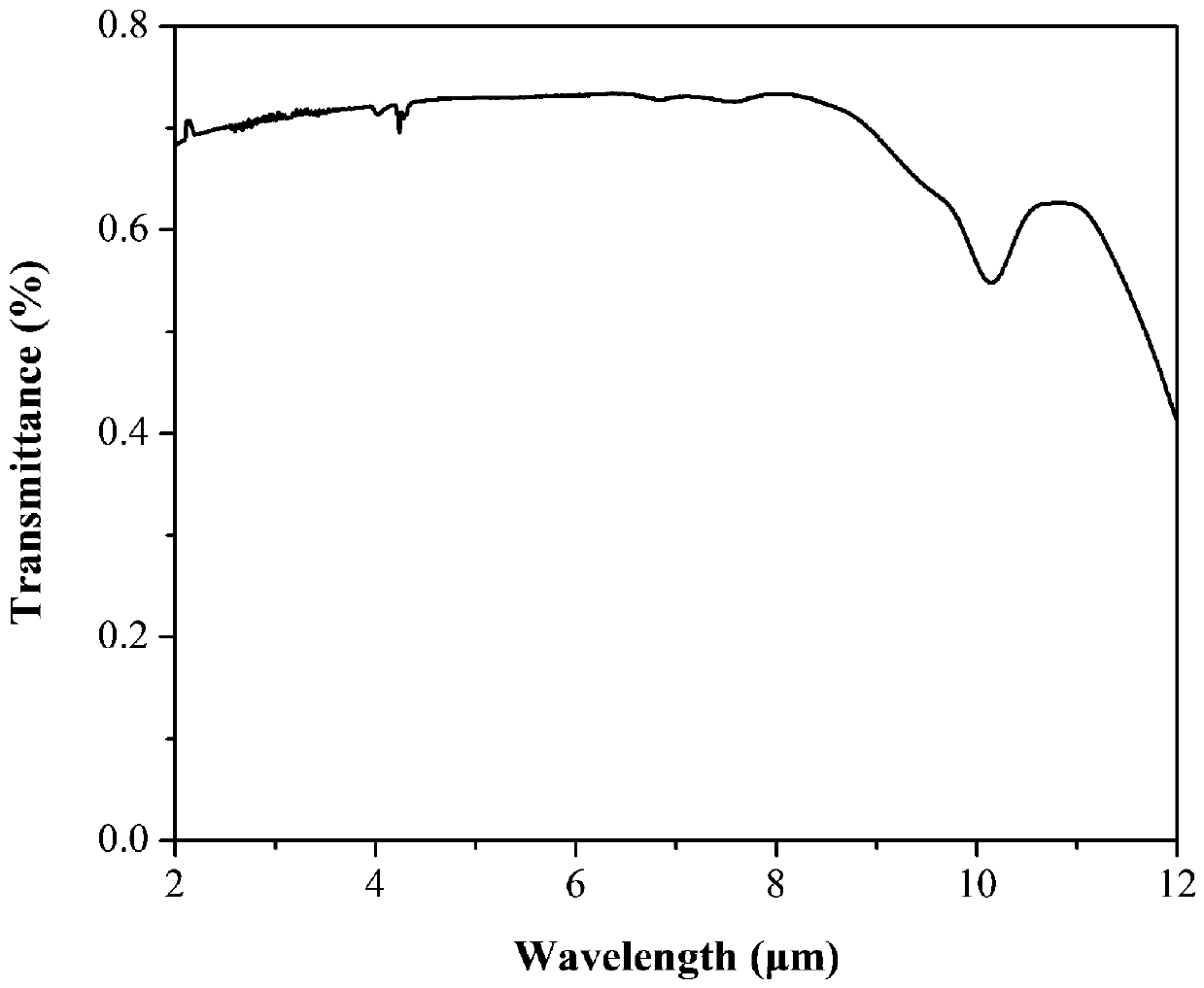

[0021] Implementation example: chalcogenide glass composition is As 38 S 62

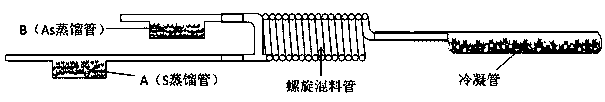

[0022] Using high-purity sulfur with a purity of 5N and high-purity arsenic with a purity of 6N as raw materials, according to the above-mentioned chemical composition ratio, weigh the materials in a glove box filled with argon, and fill them with pre-cleaned and pre-calcined hydroxyl content lower than In the 10ppm quartz distillation tubes A and B, pass high-purity argon gas into the distillation tubes and connect with the quartz spiral tube with a hydroxyl content lower than 10ppm, and heat the distillation tubes A and B to 425°C and 600°C respectively, so that the gaseous The S and As simple substances are fully mixed at the molecular scale in a spiral tube heated to 650°C, and then the mixed gaseous As-S infrared glass frit is passed into a cleaned and pre-fired quartz ampoule with a hydroxyl content lower than 10ppm Condensation; vacuumize the quartz ampoule containing the mixture, when the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com