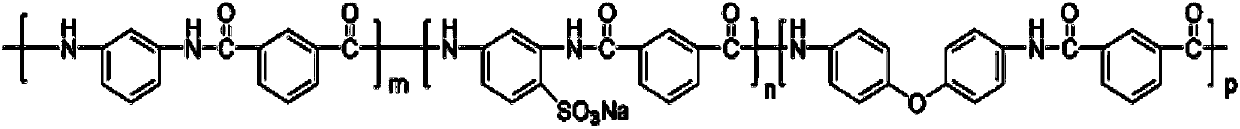

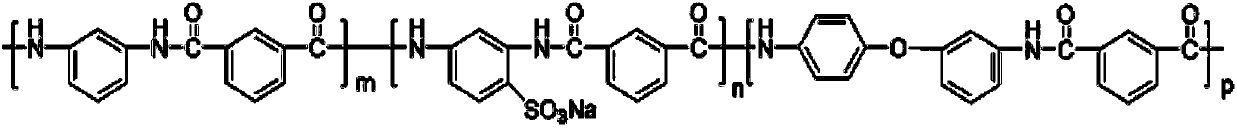

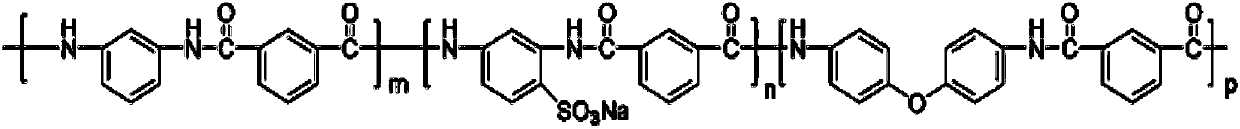

Modified poly(isophthaloyl metaphenylene diamine) for realizing easy dyeing effect of cationic dyes, and preparation method and application thereof

A poly-m-phenylene isophthalamide, cationic dye technology, applied in the direction of one-component copolyamide rayon, textile and papermaking, one-component synthetic polymer rayon, etc., can solve the dye uptake rate Limited, unsuitable, waste of slurry, etc., to save time and material costs, improve processing performance, and achieve bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) In a dry environment where the humidity is kept below 30%, nitrogen is passed through a 250mL four-neck flask equipped with a mechanical stirrer and a thermometer for 20min, nitrogen is filled to catch oxygen, and MPD, 2,4-diaminobenzenesulfonic acid Add sodium, 4,4'-ODA, 150mL N,N-dimethylacetamide DMAC into the above four-neck flask, stir at room temperature for 25min to dissolve, and obtain a diamine solution, in which MPD, sodium 2,4-diaminobenzenesulfonate, The molar ratio of 4,4'-ODA is 90:7:3.

[0034] (2) Transfer the entire dissolving device of the diamine solution obtained in step (1) to a low-temperature refrigerated circulating bath at -15°C for 15 minutes to make the temperature of the diamine solution drop to -10°C, add IPC, and adjust the amount of IPC added Rate control The temperature of the reaction solution is kept at 15-20°C. After the first addition of IPC, the reaction device is transferred to room temperature and stirred at a high speed (1000r...

Embodiment 2

[0038] (1) In a dry environment where the humidity is kept below 30%, nitrogen is passed through a 250mL four-neck flask equipped with a mechanical stirrer and a thermometer for 20min, nitrogen is filled to catch oxygen, and MPD, 2,4-diaminobenzenesulfonic acid Add sodium, 3,4'-ODA, 150mL N,N-dimethylacetamide DMAC into the above four-neck flask, stir at room temperature for 25min to dissolve, and obtain a diamine solution, in which MPD, sodium 2,4-diaminobenzenesulfonate, The molar ratio of 3,4'-ODA is 90:7:3;

[0039] (2) Transfer the entire dissolving device of the diamine solution obtained in step (1) to a low-temperature refrigerated circulating bath at -15°C for 15 minutes to make the temperature of the diamine solution drop to -10°C, add IPC, and adjust the amount of IPC added Rate control The temperature of the reaction solution is kept at 15-20°C. After the first addition of IPC, the reaction device is transferred to room temperature and stirred at a high speed (1000r...

Embodiment 3

[0043] (1) In a dry environment where the humidity is kept below 30%, nitrogen is passed through a 250mL four-neck flask equipped with a mechanical stirrer and a thermometer for 20min, nitrogen is filled to catch oxygen, and MPD, 2,4-diaminobenzenesulfonic acid Add sodium, 4,4'-ODA, and 150mL NMP into the above-mentioned four-neck flask, stir and dissolve at room temperature to obtain a diamine solution, wherein the molar ratio of MPD, sodium 2,4-diaminobenzenesulfonate, and 4,4'-ODA is 93:5:2.

[0044] (2) Transfer the entire dissolving device of the diamine solution obtained in step (1) to a low-temperature refrigerated circulating bath at -15°C for 15 minutes to make the temperature of the diamine solution drop to -10°C, add IPC, and adjust the amount of IPC added Rate control The temperature of the reaction solution is kept at 15-20°C. After the first addition of IPC, the reaction device is transferred to room temperature and stirred at a high speed (1000r / min) for 20 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inherent viscosity | aaaaa | aaaaa |

| Inherent viscosity | aaaaa | aaaaa |

| Inherent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com