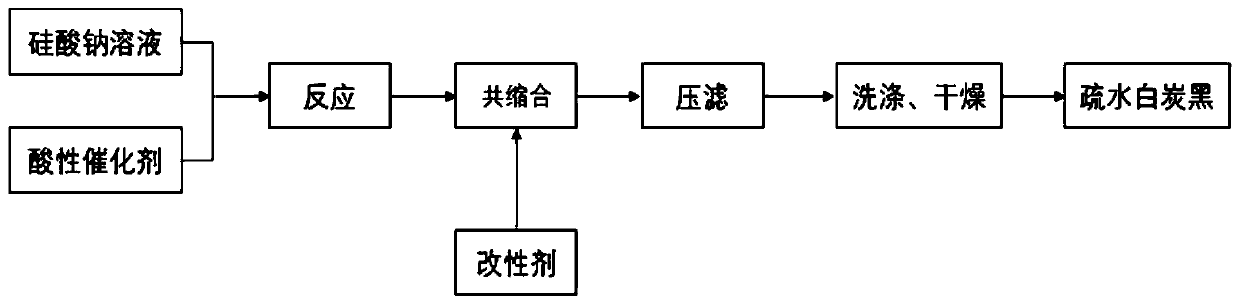

Preparation method of hydrophobic white carbon black with controllable particle size and core-shell structure

A technology of hydrophobic silica and core-shell structure, which is applied in the field of silica, can solve the problems of large modifier consumption, high technical threshold of gas phase method, and affecting compatibility, so as to improve vulcanization efficiency, shorten vulcanization time, The effect of improving rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 100g of sodium silicate solution with a concentration of 1mol / L and a modulus of 3.2 into the reactor, heat the reactor to 50°C, and stir at a speed of 45rpm, then add sulfuric acid to the above solution to make the pH of the solution 10.0, React at a constant temperature of 50°C for 30 minutes; continue to add sulfuric acid to reduce the pH value of the system to 4.0, and react at 50°C for 60 minutes to obtain a suspension of white carbon black.

[0042] Add 100g of absolute ethanol to the silica suspension, mix well, add 3g of methyltrimethoxysilane, and then react at a constant temperature at 70°C for 7h to obtain a hydrophobically modified silica suspension. After the liquid is press-filtered, washed and dried, hydrophobically modified white carbon black is obtained.

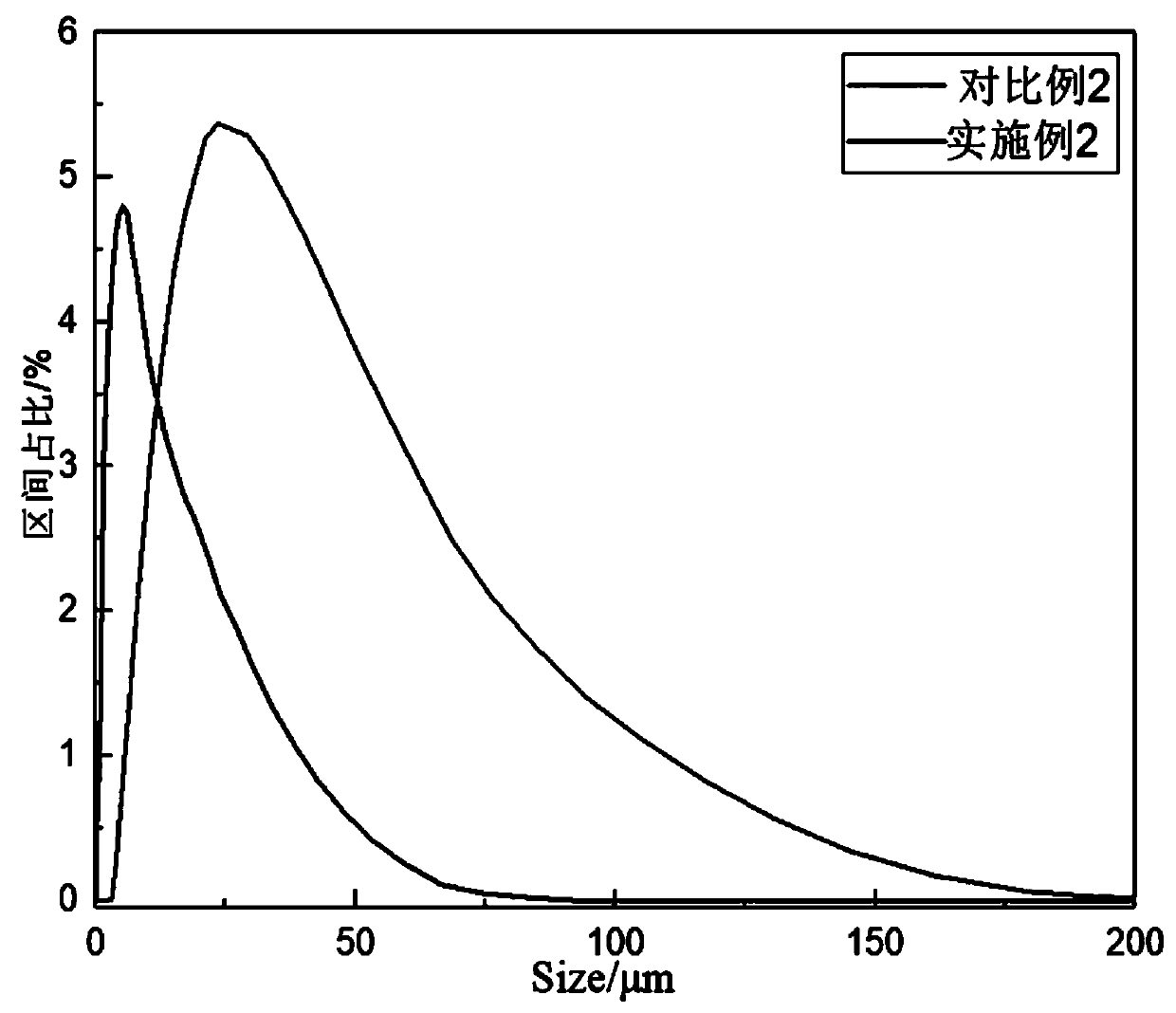

Embodiment 2

[0044] Add 100 g of sodium silicate solution with a concentration of 0.5 mol / L and a modulus of 3.5 into the reaction kettle, heat the reaction kettle to 85 ° C, and the stirring speed is 70 rpm, then add hydrochloric acid to the above solution to lower the pH value of the solution to 10.5, react for 24 minutes; continue to add hydrochloric acid to the reaction kettle to reduce the pH value of the solution to 3.5, and react at a constant temperature of 85°C for 40 minutes to obtain a white carbon black suspension.

[0045] Add 10g of isopropanol and 15g of absolute ethanol to the suspension of white carbon black, mix well, add 1g of hexadecyltrimethoxysilane, and then react at a constant temperature of 50°C for 10h to obtain hydrophobically modified white carbon black suspension, after the suspension is press-filtered, washed and dried, hydrophobically modified white carbon black is obtained.

Embodiment 3

[0047] Add 100g of sodium silicate solution with a concentration of 2.4mol / L and a modulus of 3.0 into the reactor, heat the reactor to 50°C, and stir at 55rpm, add p-toluenesulfonic acid to the above solution to make the pH of the solution The pH value dropped to 10.4, reacted at a constant temperature of 50°C for 35 minutes, continued to add p-toluenesulfonic acid to reduce the pH value of the solution to 4.1, and reacted for 43 minutes to obtain a white carbon black suspension.

[0048] Add 120g of absolute ethanol and 40g of butanol to the suspension of white carbon black, mix evenly, add 2g of KH560 and 2.5g of methyltrimethoxysilane, and then react at a constant temperature of 65°C for 2h to obtain hydrophobically modified The white carbon black suspension, the hydrophobically modified white carbon black is obtained after the suspension is press-filtered, washed and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com