Low-volatile silicone rubber compound and preparation method thereof

A low volatile content, silicone rubber raw rubber technology, applied in the field of silicone rubber, can solve the problems of high volatile content, large molecular flexibility, weak interaction between molecular chains, etc., to achieve low volatile content, good physical and mechanical properties, and easy processing good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

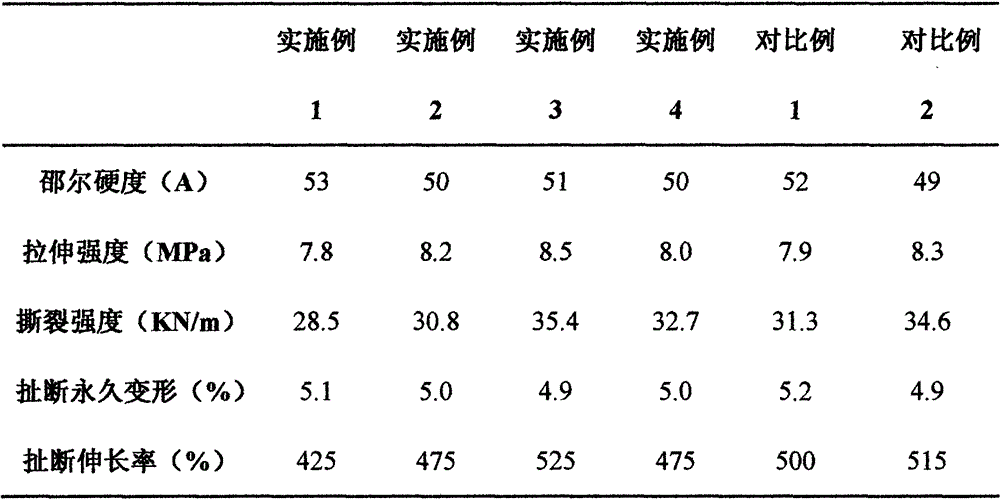

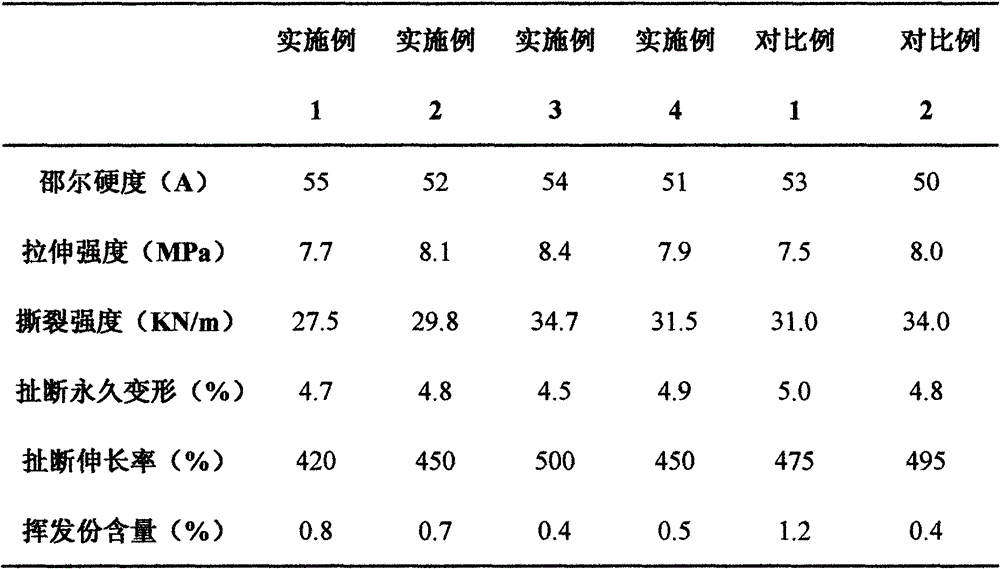

Examples

Embodiment 1

[0028] Example 1: 100 parts of raw silicone rubber, 40 parts of white carbon black, 1 part of hydroxy silicone oil, 1 part of vinyl hydroxy silicone oil, 3 parts of hydrogen-containing silicone oil, and 0.5 parts of release aid.

Embodiment 2

[0029] Example 2: 100 parts of raw silicone rubber, 40 parts of white carbon black, 2 parts of hydroxy silicone oil, 4 parts of vinyl hydroxy silicone oil, 3 parts of hydrogen-containing silicone oil, and 0.5 parts of release aid.

Embodiment 3

[0030] Example 3: 100 parts of raw silicone rubber, 40 parts of white carbon black, 3 parts of hydroxy silicone oil, 5 parts of vinyl hydroxy silicone oil, 3 parts of hydrogen-containing silicone oil, and 0.5 parts of demoulding aid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com