Unsaturated polyester coated controlled-release fertilizer prepared from PET wastes and preparation method thereof

A technology of controlled release fertilizer and polyester coating, applied in the direction of layered/coated fertilizer, fertilizer mixture, application, etc., can solve problems such as environmental pollution and resource waste, and achieve environmental pollution reduction, production cost reduction, and market prospects. expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The unsaturated polyester of the present embodiment is prepared by the following method, comprising the steps of:

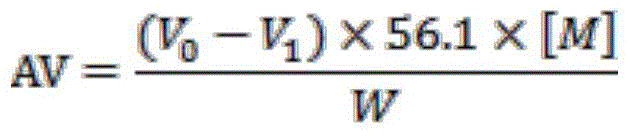

[0042] (1) Put 1000g of PET waste, 200g of ethylene glycol, and 1g of zinc acetate catalyst into a reaction kettle equipped with a thermometer, an electric stirrer, a nitrogen inlet pipe and a fractionation device, heat up to 200°C for alcoholysis, and the alcoholysis time is After 2 hours, after the PET is completely dissolved and there are no suspended particles, the acid value in the reaction system is detected. When the acid value drops to 30mgKOH / g, the reaction is terminated, and the monomer and dimerization of the PET alcoholysis product terephthalic acid diol are obtained. A mixture of body and tetramer;

[0043] (2) After the PET alcoholysis reaction, lower the temperature of the kettle to 150°C, put in 550g of isophthalic acid, then gradually raise the temperature to 155°C, keep it warm for half an hour, and then raise the temperature to 200°C fo...

Embodiment 2

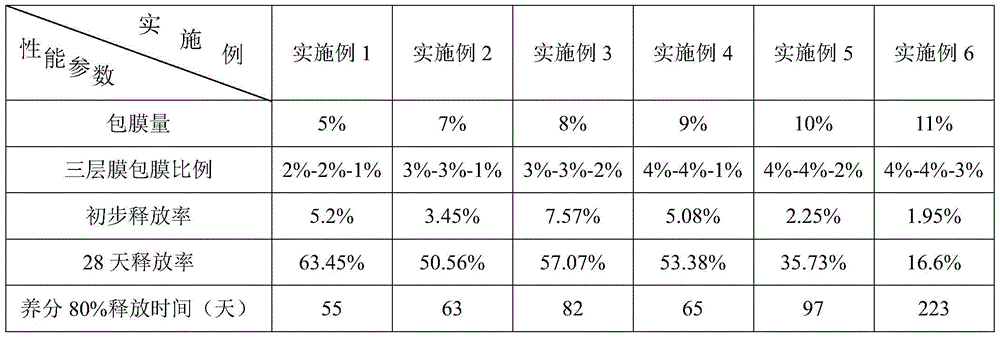

[0050] The preparation method of unsaturated polyester and unsaturated polyester-coated controlled-release fertilizer of this embodiment is the same as that of Example 1, the only difference is that the total coating amount of this embodiment is 7%, that is, coating solution 1, coating The ratios of liquid 2 and hot melt adhesive to the total weight of the fertilizer are 3%, 3%, and 1% respectively.

Embodiment 3

[0052] The preparation method of unsaturated polyester and unsaturated polyester-coated controlled-release fertilizer of this embodiment is the same as that of Example 1, the only difference is that the total coating amount of this embodiment is 8%, that is, coating solution 1, coating The ratios of liquid 2 and hot melt adhesive to the total weight of the fertilizer are 3%, 3%, and 2% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com