Preparation method of anti-atomic oxygen polyimide hybrid films containing octamer cage-shaped silsesquioxane structures

An anti-atomic polyimide and silsesquioxane technology, applied in the direction of silicon organic compounds, can solve the problems of inconvenient operation, high cost, cumbersome synthesis steps, etc., and achieve low cost, outstanding heat resistance, and advanced technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

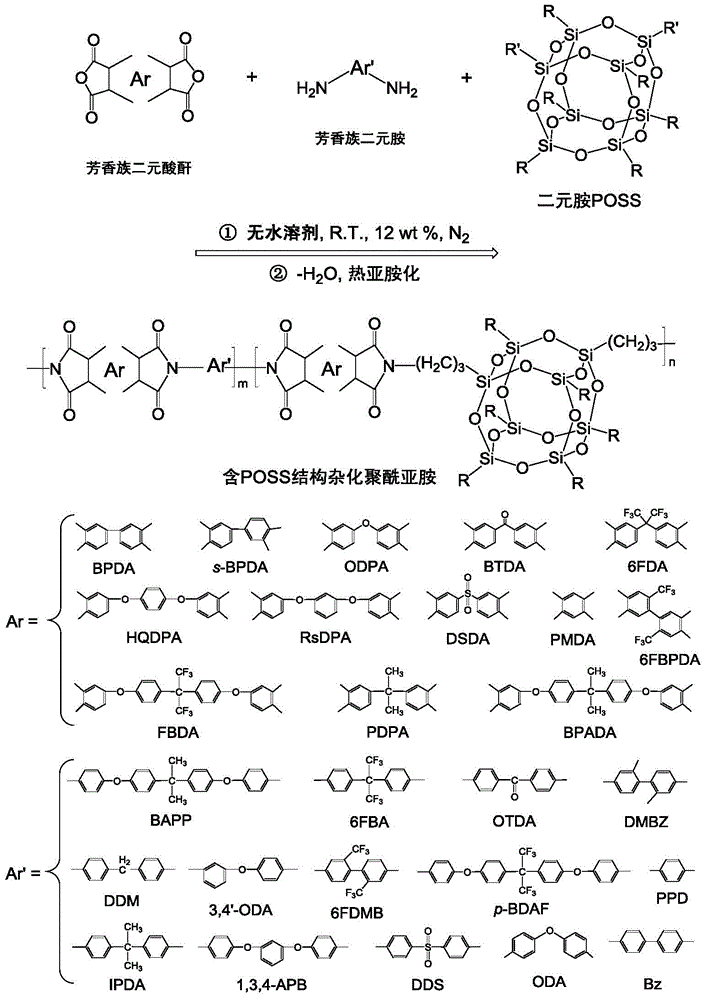

Method used

Image

Examples

Embodiment 1

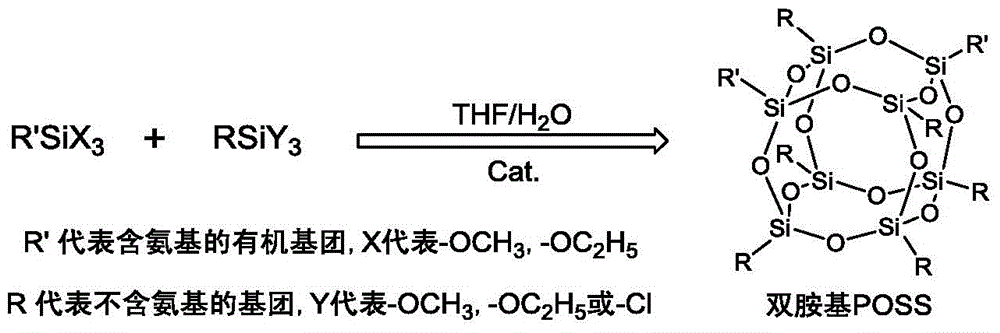

[0052] (1) Synthesis of diamine octapolycage silsesquioxane (diamine POSS)

[0053] Add 50mL tetrahydrofuran, 4mL distilled water, 9.26mL APSM, 30.74mL PTMS and 1mL benzyltrimethylammonium hydroxide (20wt% methanol solution) successively into a reaction vessel equipped with a magnetic stirrer and a thermometer, stir for 2 to 5 minutes, and keep The temperature of the system was kept at 25° C., and the reaction was carried out for 4 days. Then the temperature of the system was raised to 50° C., and the reaction was refluxed for 2 days under magnetic stirring. After the end, it was cooled in a low-temperature environment of -10°C for 24 hours, and a white crude product was precipitated, which was filtered to obtain a white crude product D. Product D was washed twice with 30 mL of acetonitrile / diethyl ether mixture at 0°C (the volume ratio of acetonitrile and diethyl ether was 3:2) to obtain product E. Product E was dissolved in 30 mL of DMAc, then precipitated with 200 mL of d...

Embodiment 2

[0057] (1) Synthesis of diamine octapolycage silsesquioxane (diamine POSS)

[0058] Add 50mL tetrahydrofuran, 5mL distilled water, 9.39mL APSE, 30.61mL PTES and 1.5mL tetraethylammonium hydroxide (25wt% methanol solution) to the reaction vessel equipped with magnetic stirring and thermometer, and stir for 2-5 minutes to maintain the system The temperature was 25°C, and the reaction was carried out for 5 days. Then the temperature of the system was raised to 60° C., and the reaction was refluxed for 3 days under magnetic stirring. After the end, it was cooled in a low-temperature environment of -10°C for 24 hours, and a white crude product was precipitated, which was filtered to obtain a white crude product D. Product D was washed twice with 40 mL of acetonitrile / diethyl ether mixture at 0°C (the volume ratio of acetonitrile and diethyl ether was 3:1) to obtain product E. Product E was dissolved in 20 mL of DMAc, then precipitated with 200 mL of distilled water and filtered. ...

Embodiment 3

[0062] (1) Synthesis of diamine octapolycage silsesquioxane (diamine POSS)

[0063] Add 50mL tetrahydrofuran, 4mL distilled water, 13.72mL ABSM, 26.28mL MTMS and 0.5mL tetramethylammonium hydroxide (20wt% aqueous solution) successively into the reaction vessel equipped with magnetic stirring and thermometer, stir for 2-5 minutes, and maintain the temperature of the system At 25°C, react for 3 days. Then the temperature of the system was raised to 60° C., and the reaction was refluxed for 2 days under magnetic stirring. After the end, it was cooled in a low-temperature environment of -10°C for 24 hours, and a white crude product was precipitated, which was filtered to obtain a white crude product D. Product D was washed twice with 50 mL of acetonitrile / diethyl ether mixture at 0°C (the volume ratio of acetonitrile and diethyl ether was 3:2) to obtain product E. Product E was dissolved in 20 mL of DMAc, then precipitated with 200 mL of distilled water and filtered. This opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com