Binder composition for casting mold formation and process for producing casting mold using the binder composition for casting mold formation

A manufacturing method and adhesive technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as hindering the spheroidization of castings, deterioration of the working environment, and unsatisfactory sulfuric acid, so as to improve the strength of the casting mold and the initial strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

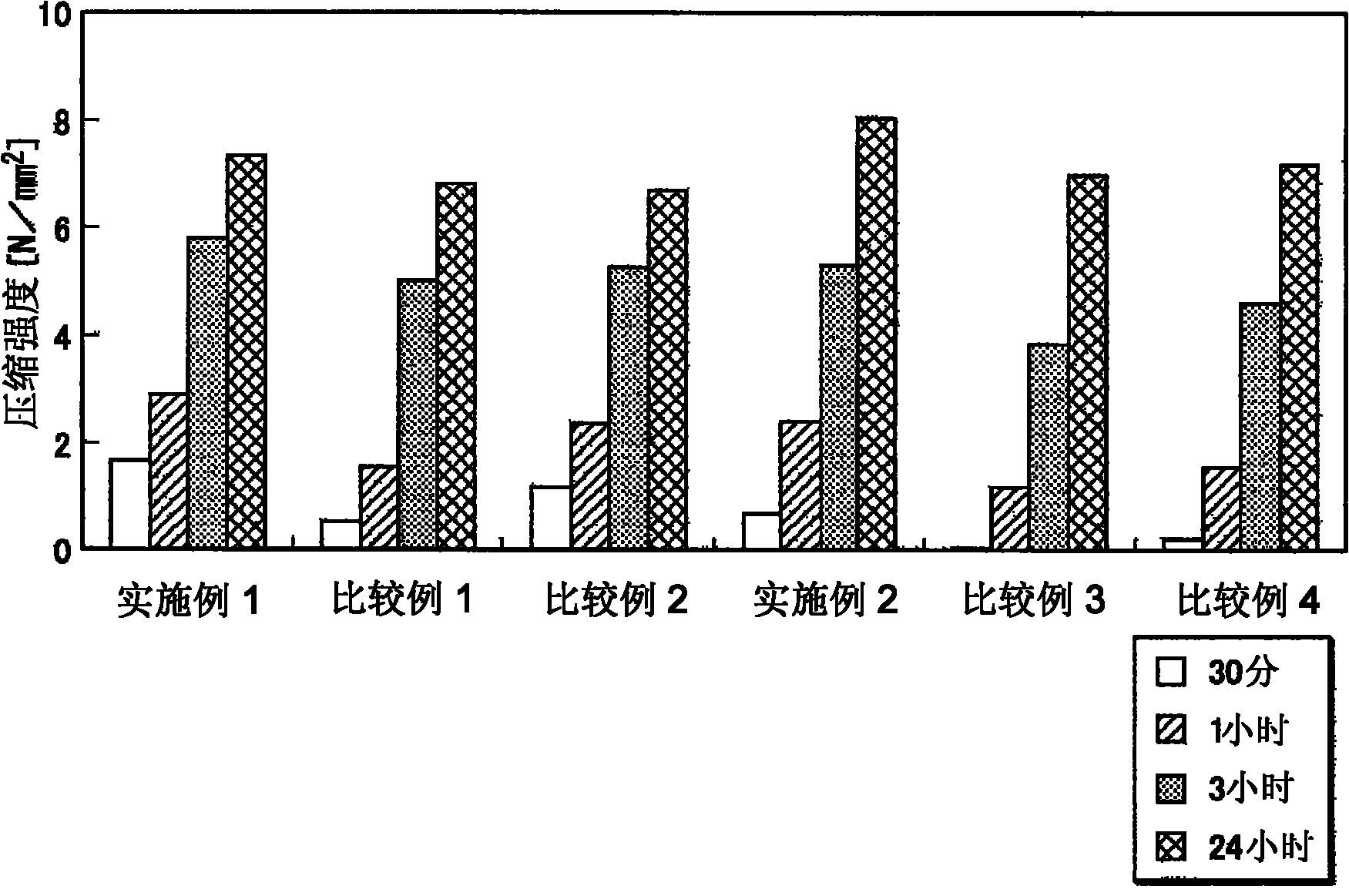

Embodiment 1

[0107] (adhesive composition)

[0108] Add 859.2 parts by mass of furfuryl alcohol, 47.05 parts by mass of urea, 65.9 parts by mass of paraformaldehyde 92% by mass, and 2.0 parts by mass of aqueous sodium hydroxide solution of 15% by mass into a four-port thermometer, cooler and stirrer In the flask, it was made to react at 80 degreeC for 1 hour, after that, 3.0 mass parts of hydrochloric acid of 10 mass % was added, and it was made to react further for 3 hours. After that, add 2.0 mass parts of 15% aqueous sodium hydroxide solution and 28.84 mass parts of urea by mass, and further make it react for 30 minutes, and then add a silane coupling agent (N-β (aminoethyl) γ-aminopropyl Methyldimethoxysilane) 2 parts by mass to obtain 1010 parts by mass of an adhesive composition (A) containing a (co)condensate obtained by condensation of urea, furfuryl alcohol, and aldehydes, free furfuryl alcohol, and water. The water content in 1010 parts by mass of the adhesive composition (A) wa...

Embodiment 2

[0124] Except using alumina sand (manufactured by (strain) Cosmo, aluminum sand 350# new sand) instead of quartz sand, the test piece is made in the same way as in Example 1, and it is measured in the same way as in Example 1 from the beginning of curing through 30 minutes, 1 Compressive strength and bulk density after 1 hour, 3 hours and 24 hours. The results are shown in Table 1.

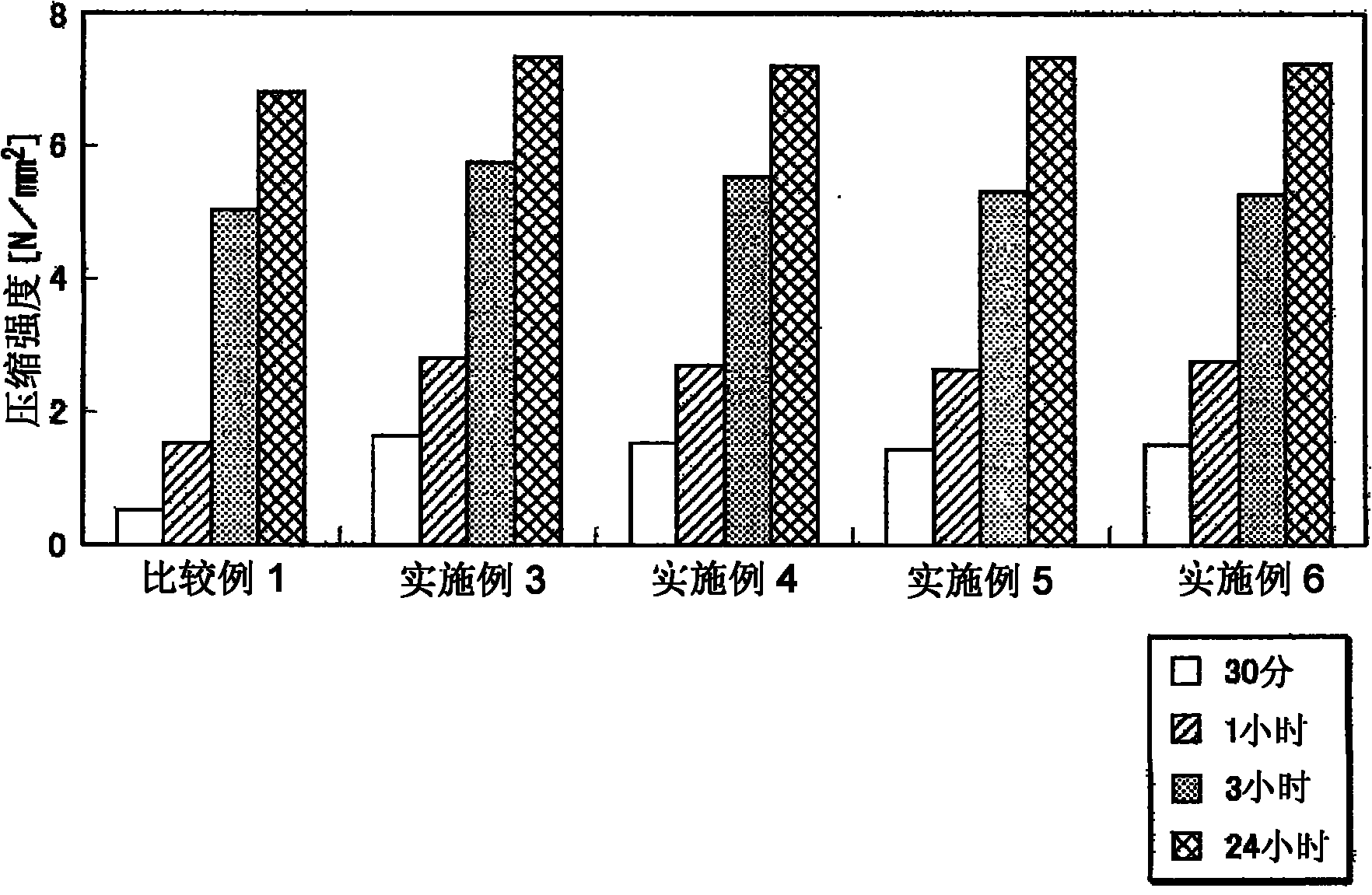

Embodiment 3~6

[0142] To 100 mass parts of quartz sand, add 1 mass part of the following various binder compositions and curing agent (containing 67% by mass of xylene sulfonic acid and 75% by mass of sulfuric acid by mass in aqueous solution) 0.4 mass Parts are mixed with a Sichuan formula universal mixer to obtain the mixed molding sand of each embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com