Pump assembly and method for evacuating a vapor-filled chamber

A component, chamber technology that can be used in parts of pumping devices for elastic fluids, pump elements, rotary piston/oscillating piston pump components, etc., and can solve problems such as large amounts of water, low condensing temperatures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

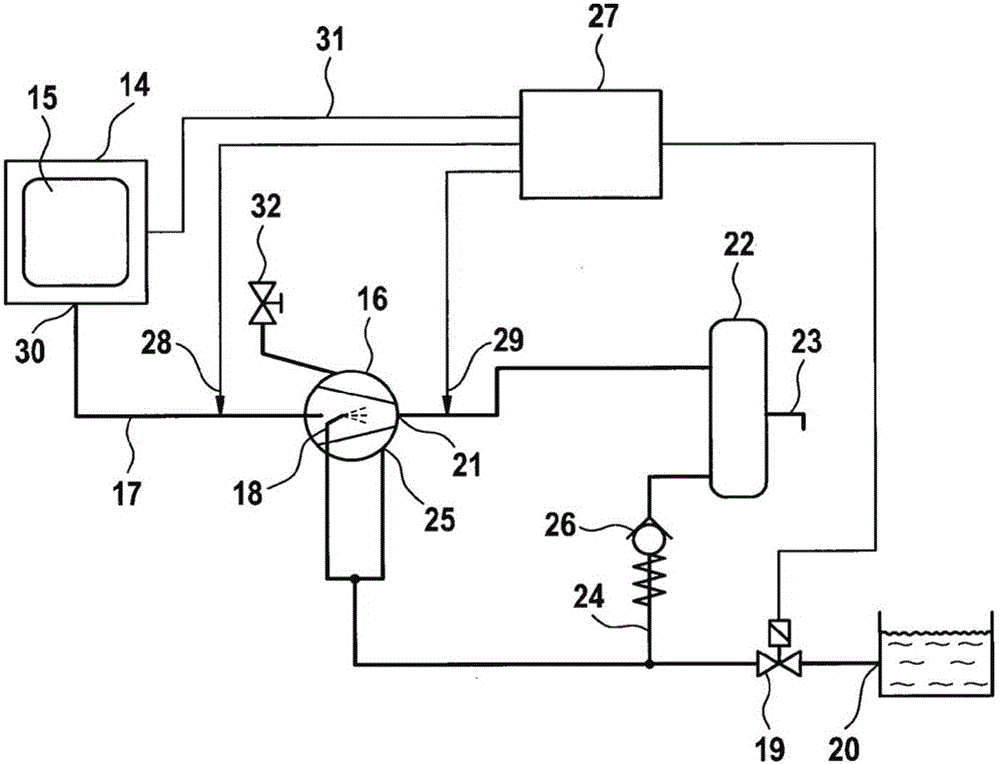

[0032] figure 1 Among other things, the assembly according to the invention comprises an autoclave 14 as used especially in hospitals to sterilize clothing, towels, bedding and also instruments. The autoclave 14 comprises a chamber 15 which can be closed such that the chamber 15 is sealed. Thus, the chamber 15 can be placed under overpressure or vacuum.

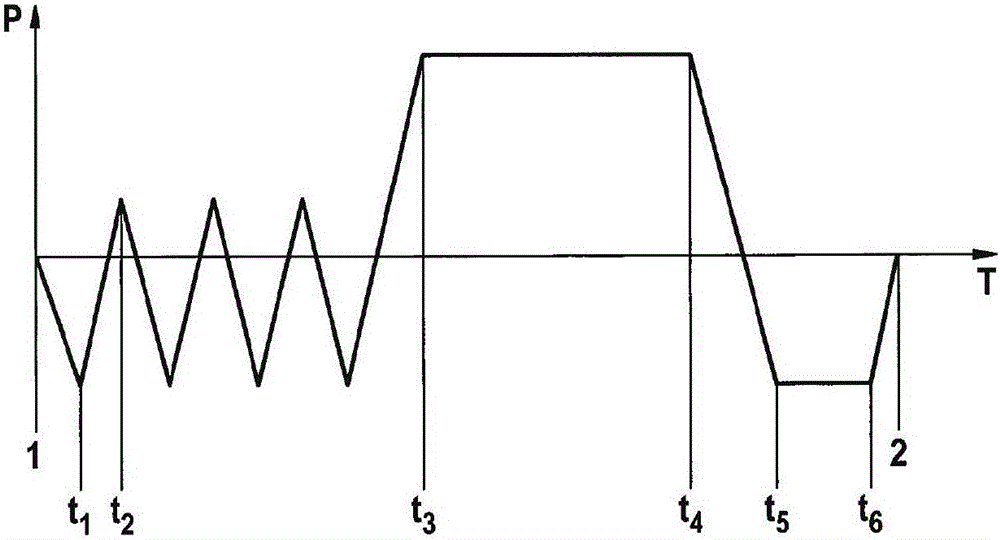

[0033] Taking towels as an example, with the help of figure 2Explain the sanitization cycle. exist figure 2 In the graph of , the pressure P in the chamber 15 is applied over time T. In the initial state, the chamber 15 is at an atmospheric pressure of about 1 bar. flap (not in figure 1 shown in ) is opened, and a towel is placed in chamber 15.

[0034] The chamber is evacuated to a pressure of approximately between 100 mbar and 120 mbar until time t1 . This draws air containing bacteria out of the chamber 15 . A steam flow is then generated, by means of which the chamber 15 is completely filled with steam between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com