Patents

Literature

110results about How to "Improve gas separation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

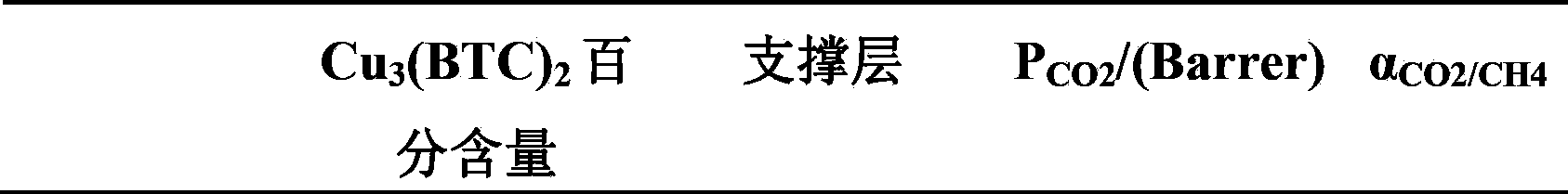

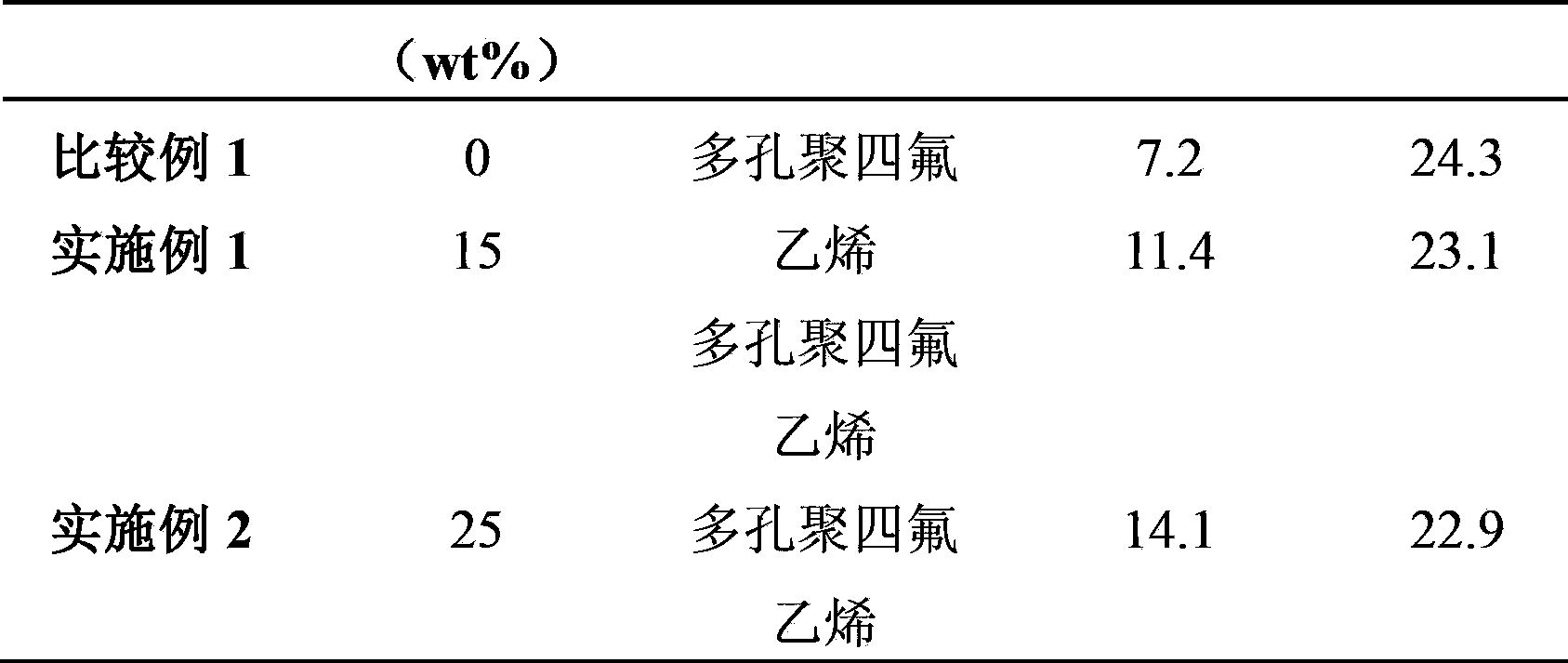

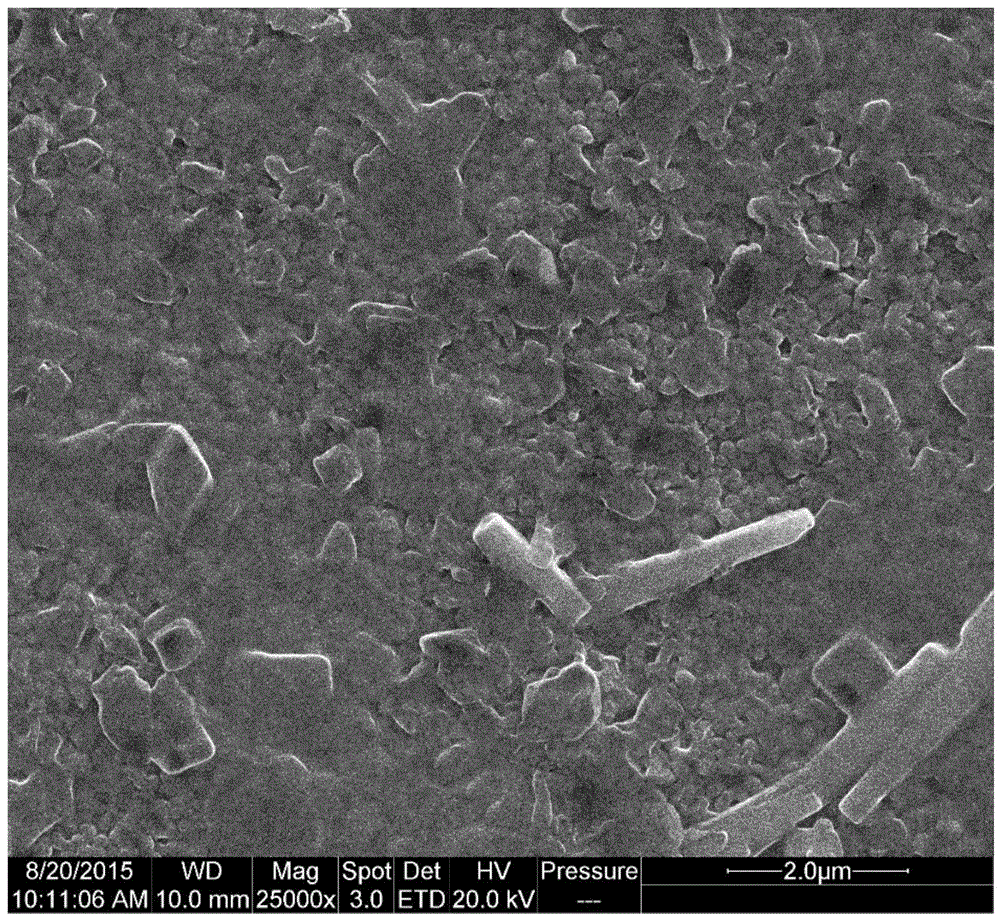

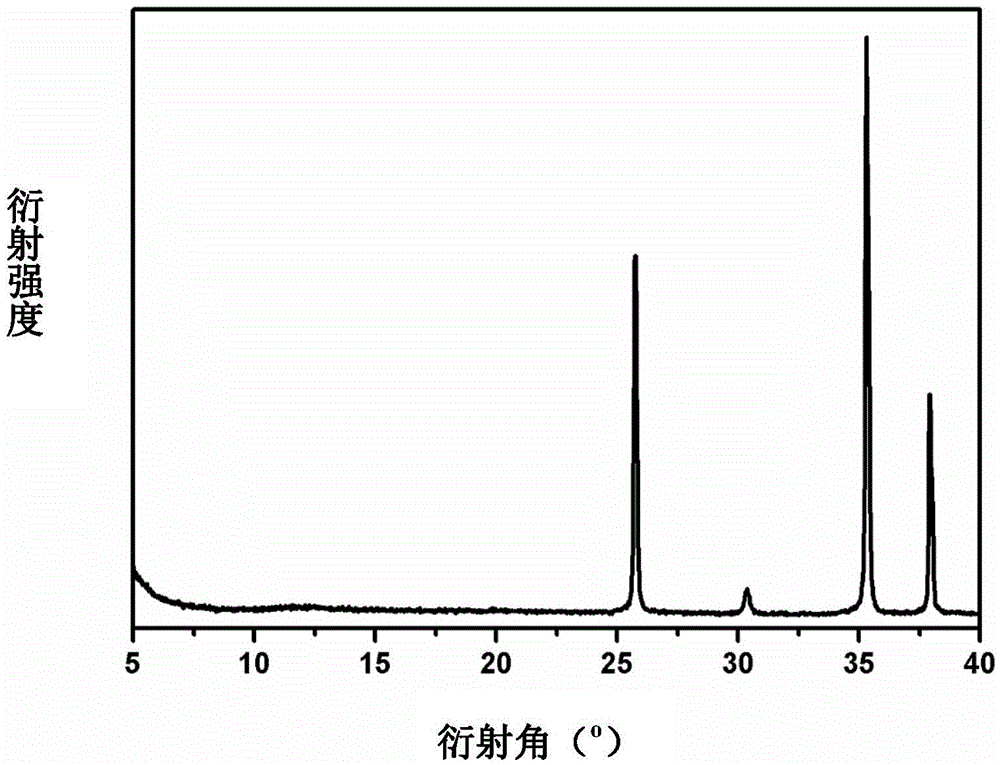

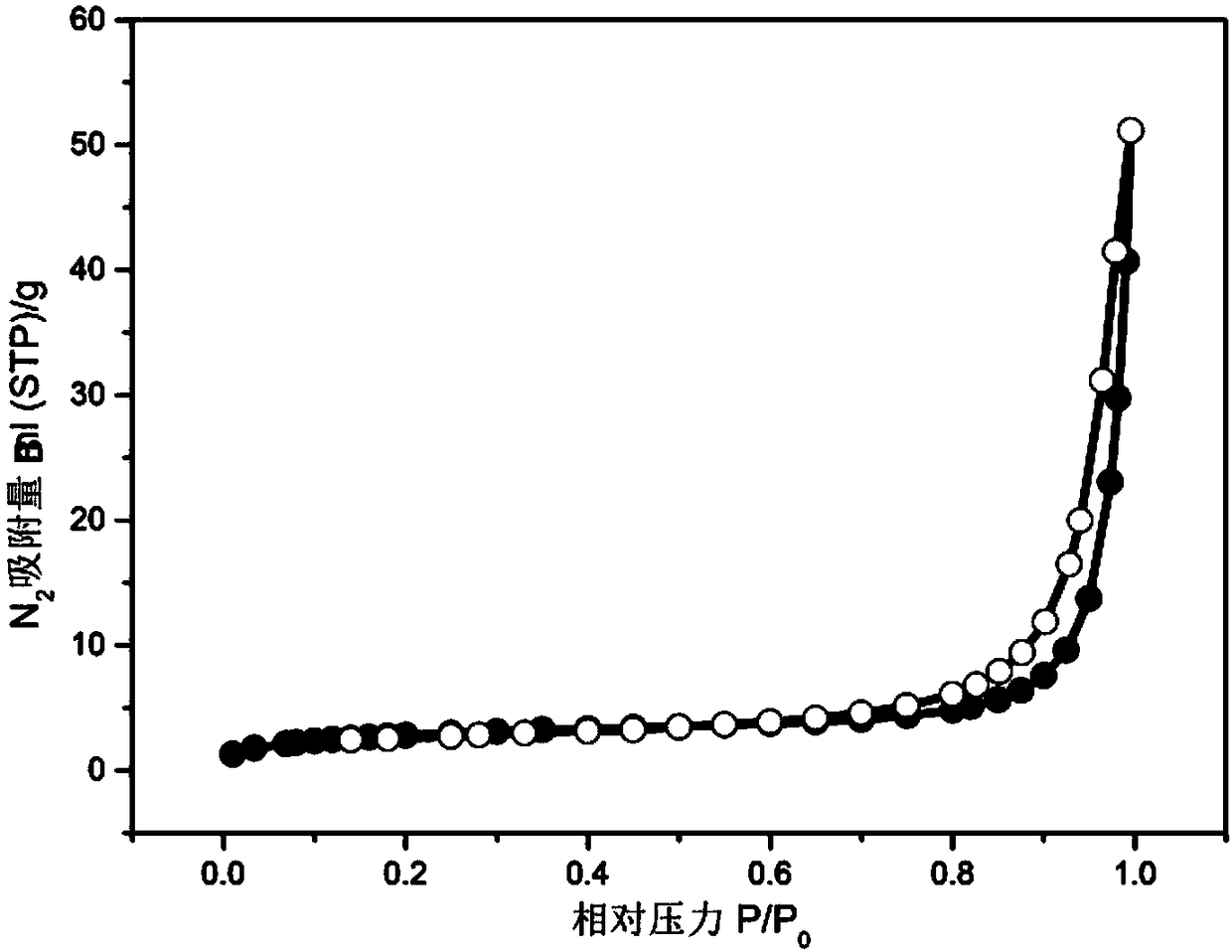

Porous material-polymer gas separation composite membrane

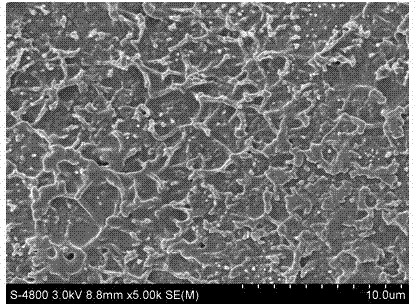

InactiveCN103846013ASimple materialImprove gas permeabilitySemi-permeable membranesDispersed particle separationHollow fibre membraneFiber

The invention belongs to the technical field of membranes and in particular relates to a porous material-polymer gas separation composite membrane. The composite membrane comprises a separation layer and a supporting layer, wherein a porous material-polymer hybrid membrane is adopted as the separation layer; one of a porous flat plate and a tubular or hollow fiber membrane is adopted as the supporting layer; the porous material of the separation layer is metal-organic frame materials (MOFs) with large specific surface area and high gas adsorption. The MOFs are added into the separation layer so that the gas permeation and selectivity of the membrane are obviously improved; the separation layer and the supporting layer are compounded so that the membrane keeps good mechanical property, and the separation layer is allowed to exist in a compact or asymmetric structure. The composite membrane provided by the invention has high gas separation property, good mechanical property and wide industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

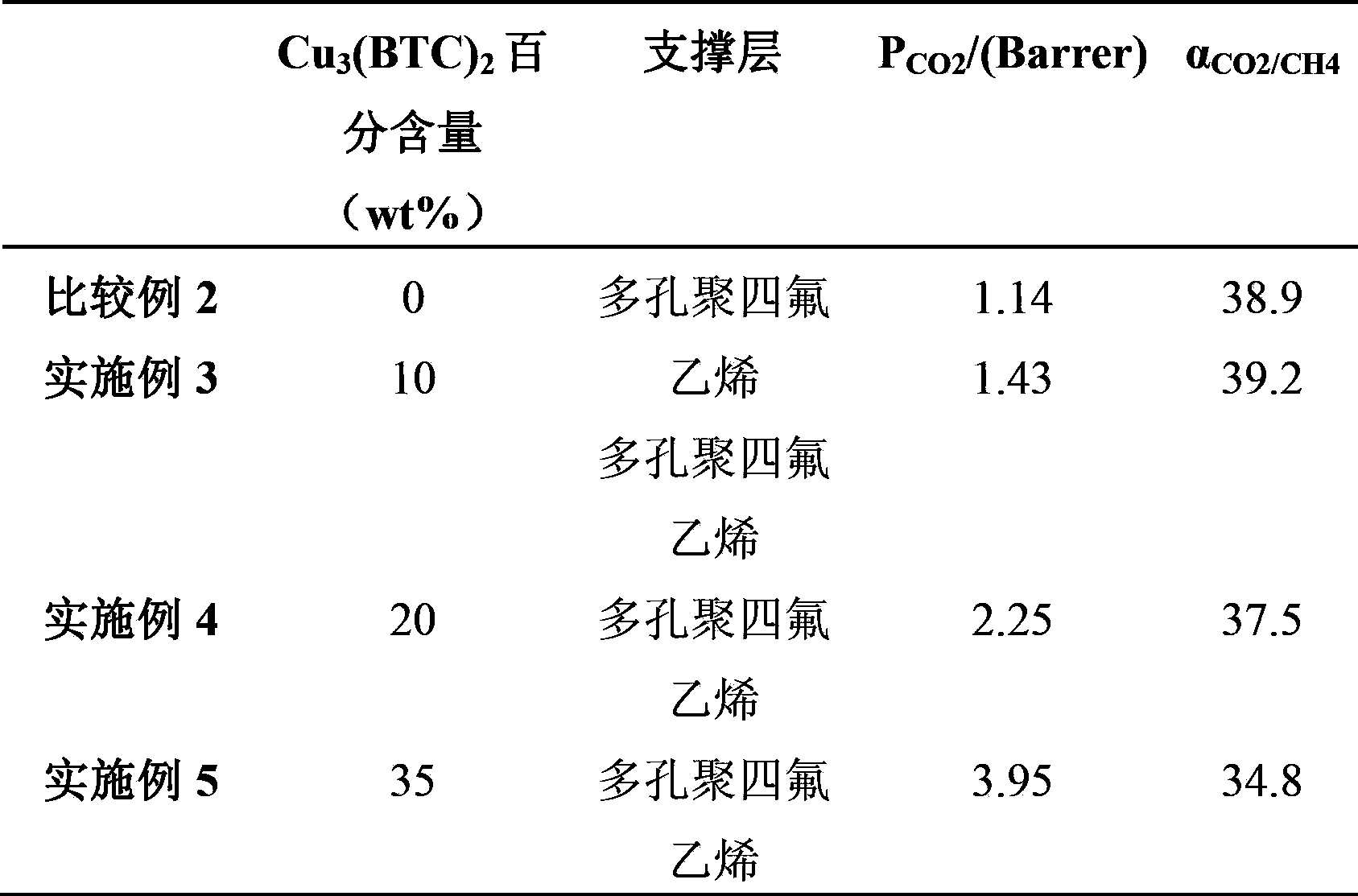

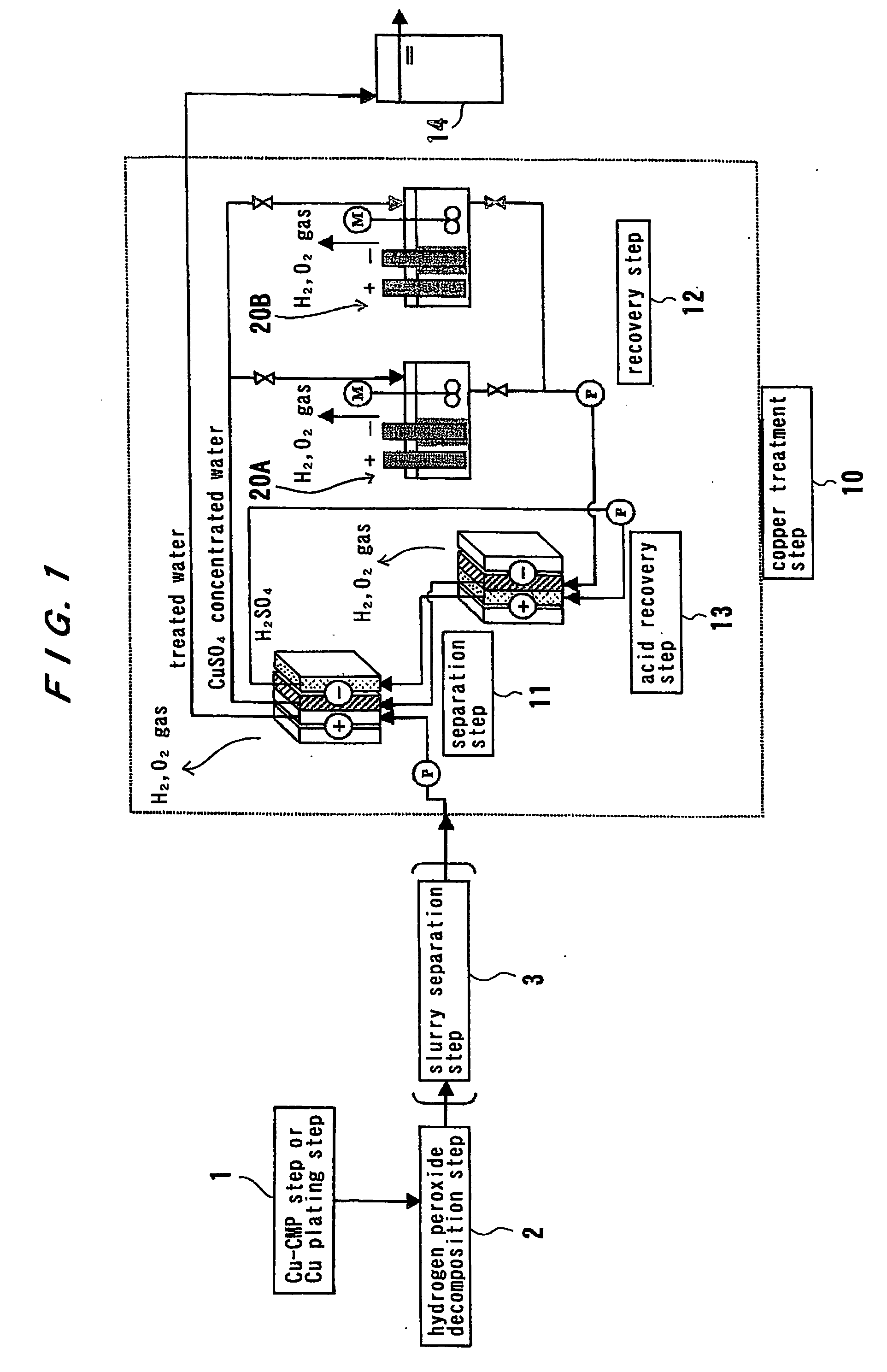

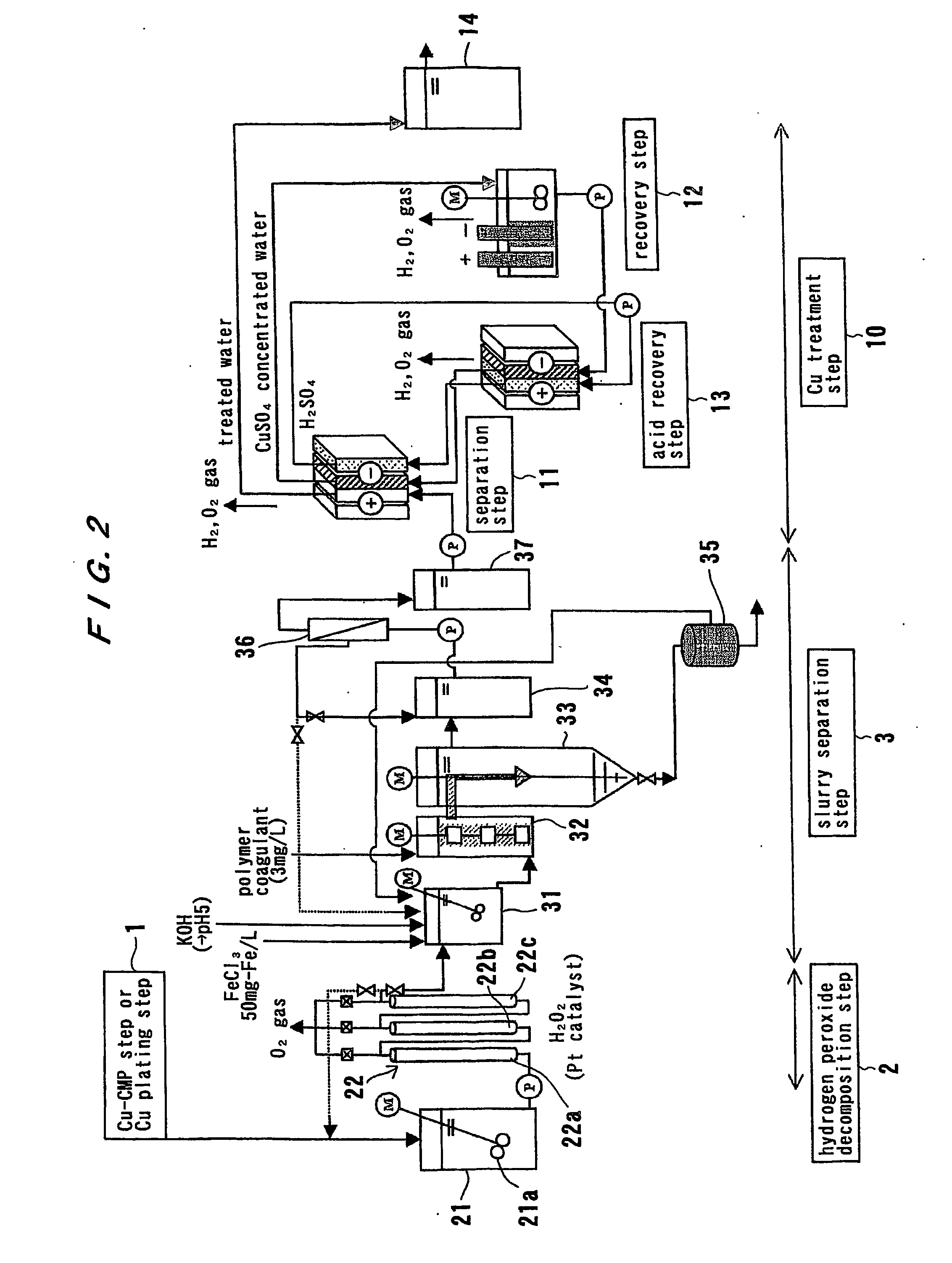

Method and apparatus for treating waste water

InactiveUS20060243604A1Large specific surface areaImprove gas separation performanceLiquid separation by electricityVolume/mass flow measurementElectrolysisCopper

The present invention relates to a method and apparatus for removing and recovering metal such as copper from various kinds of waste water containing copper. A method for treating waste water includes treating waste water in a copper treatment step (10) comprising a combination of electrodialysis operation and electrolytic deposition operation to produce treated water (107) having a lowered copper concentration, and recovering copper from the waste water.

Owner:EBARA CORP

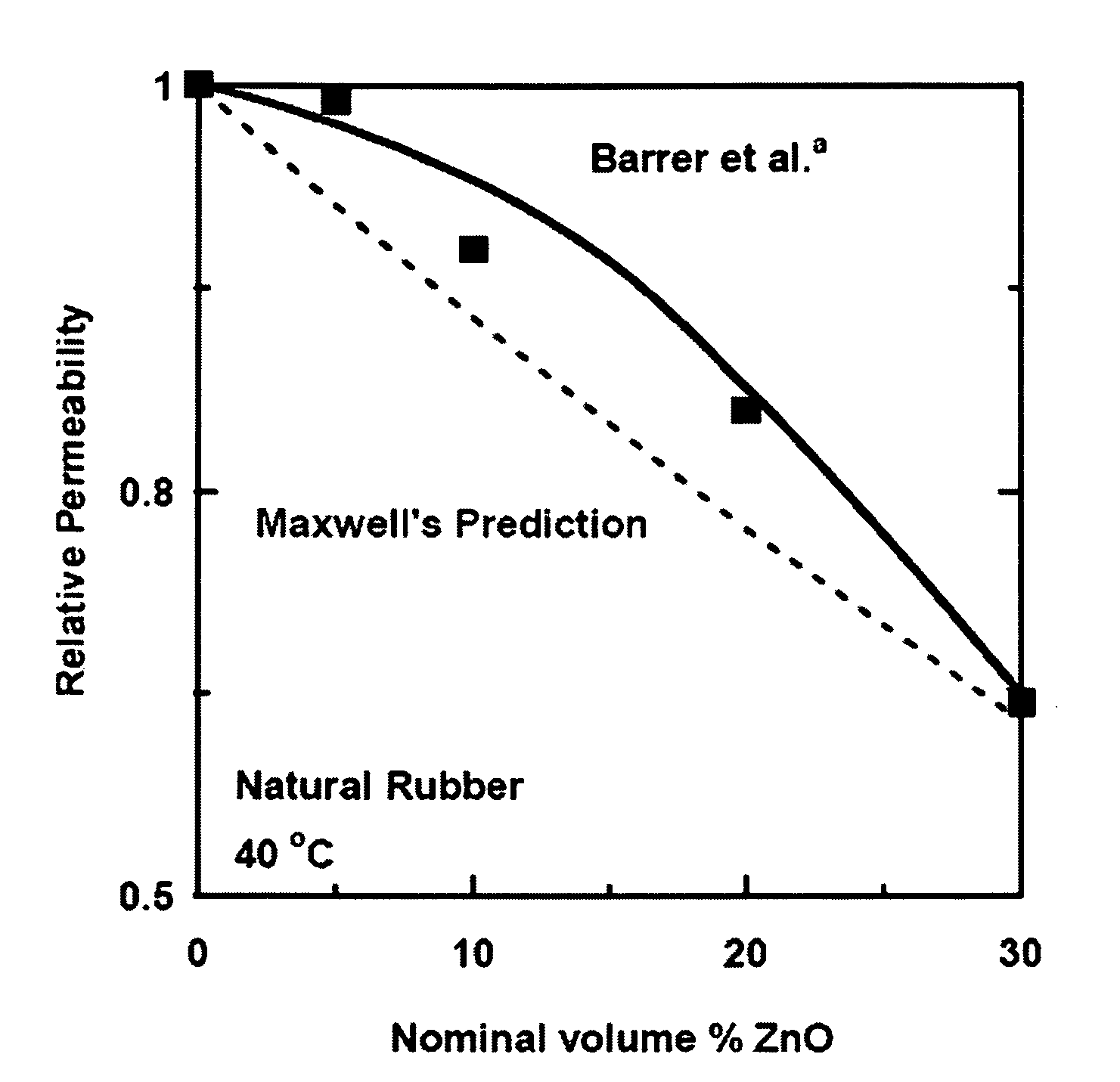

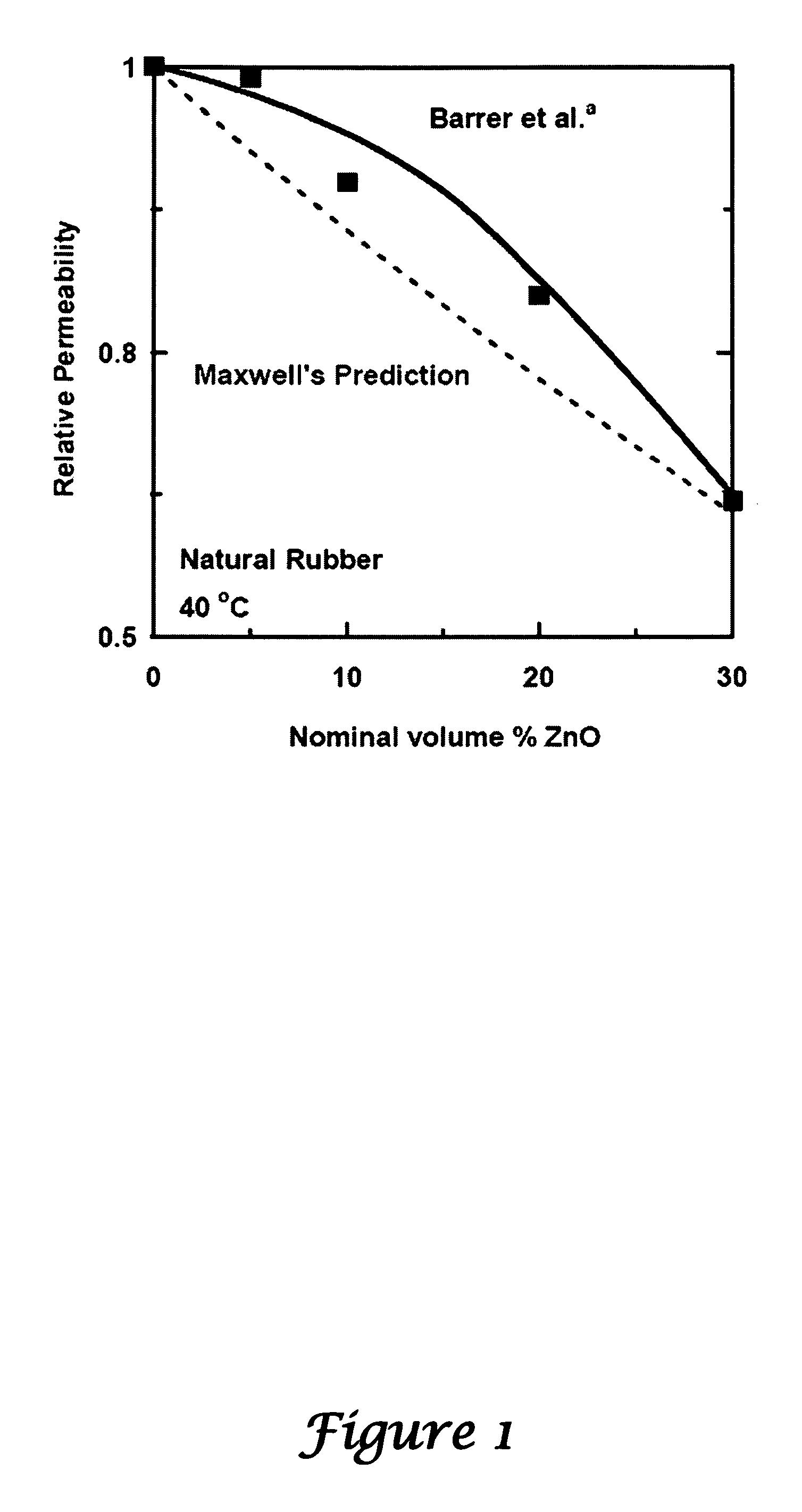

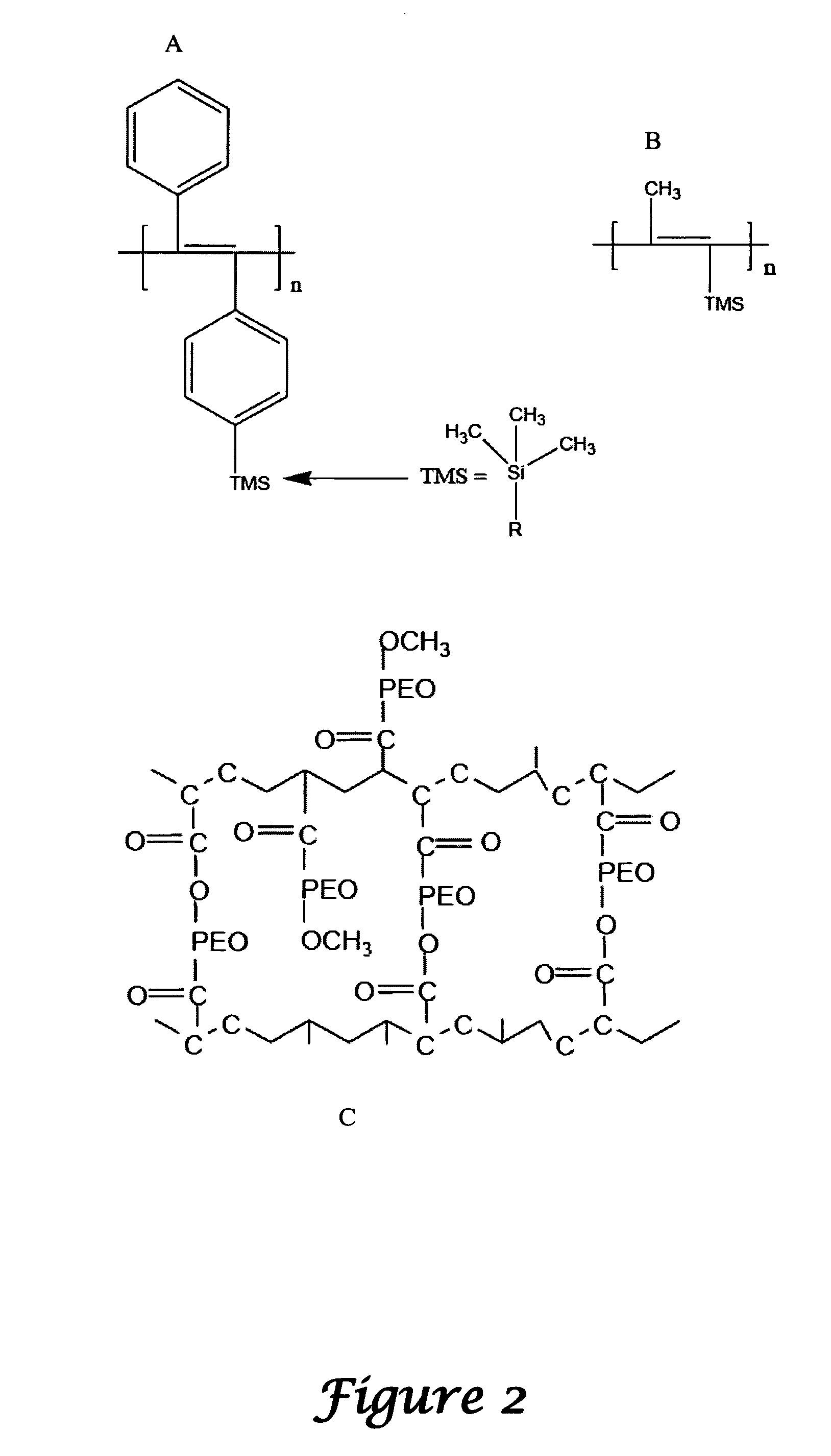

Metal oxide nanoparticle filled polymers

InactiveUS7510595B2Easy to separateImprove gas separation performanceMembranesSemi-permeable membranesMetal oxide nanoparticlesProduct gas

The present invention includes a method, composition and apparatus for forming a nanoparticle filled polymer having similar gas selectivity and greater gas permeability than the native polymer. The nanoparticle filled polymer includes one or more polymeric materials and one or more nanoparticles dispersed within the one or more polymeric materials that increasing the permeability of the nanoparticle filled polymers relative to the permeability of the native polymer membrane.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

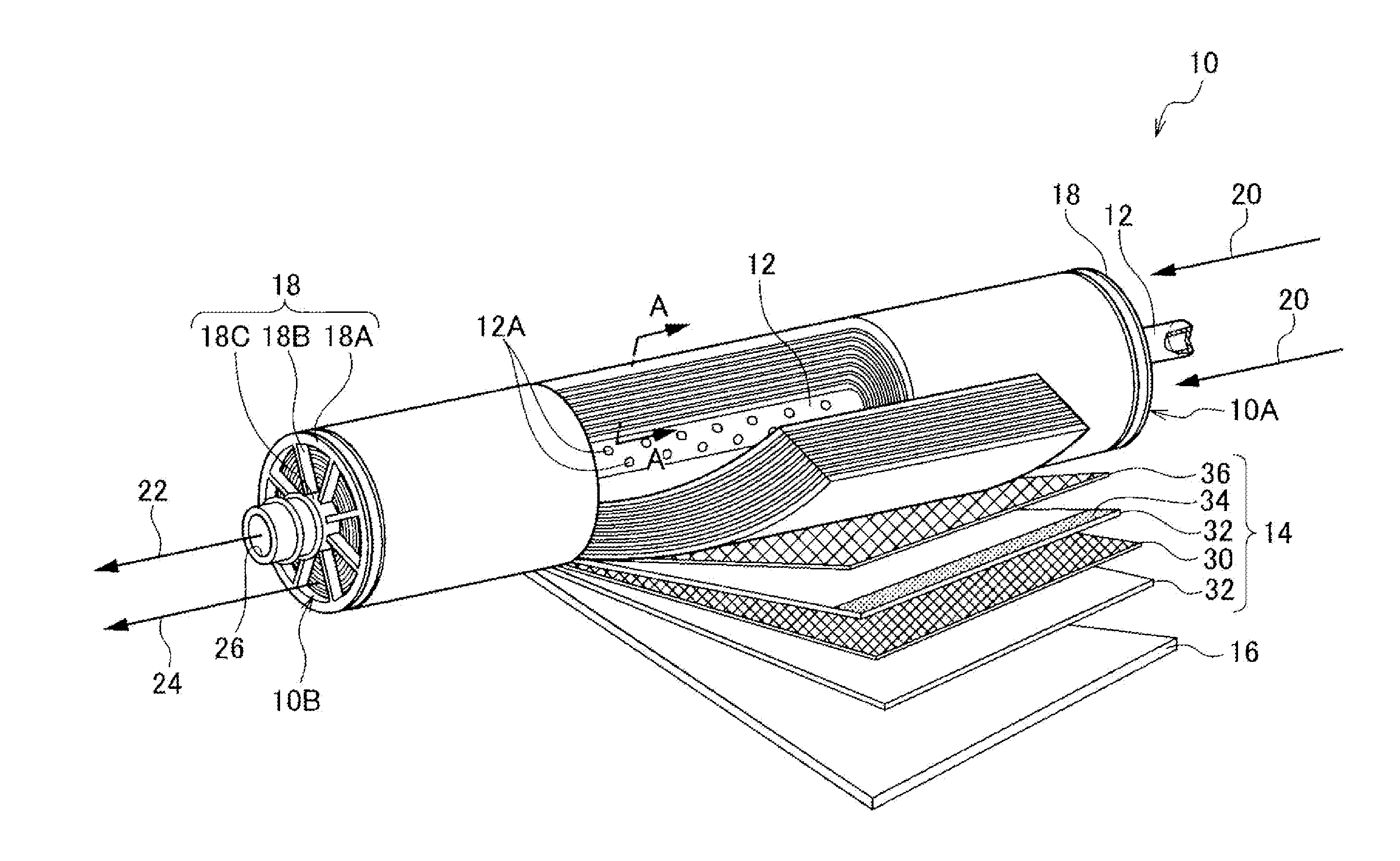

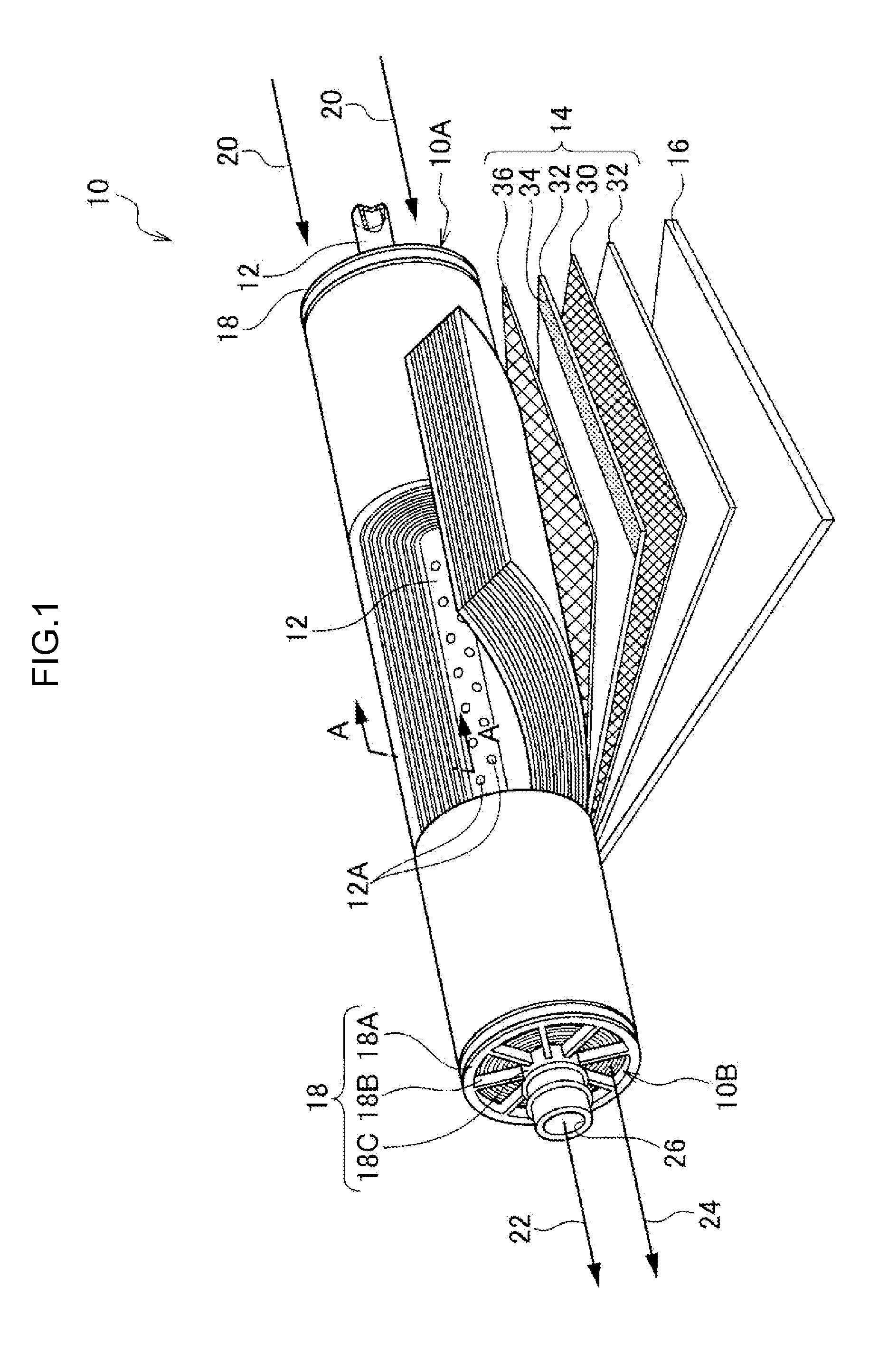

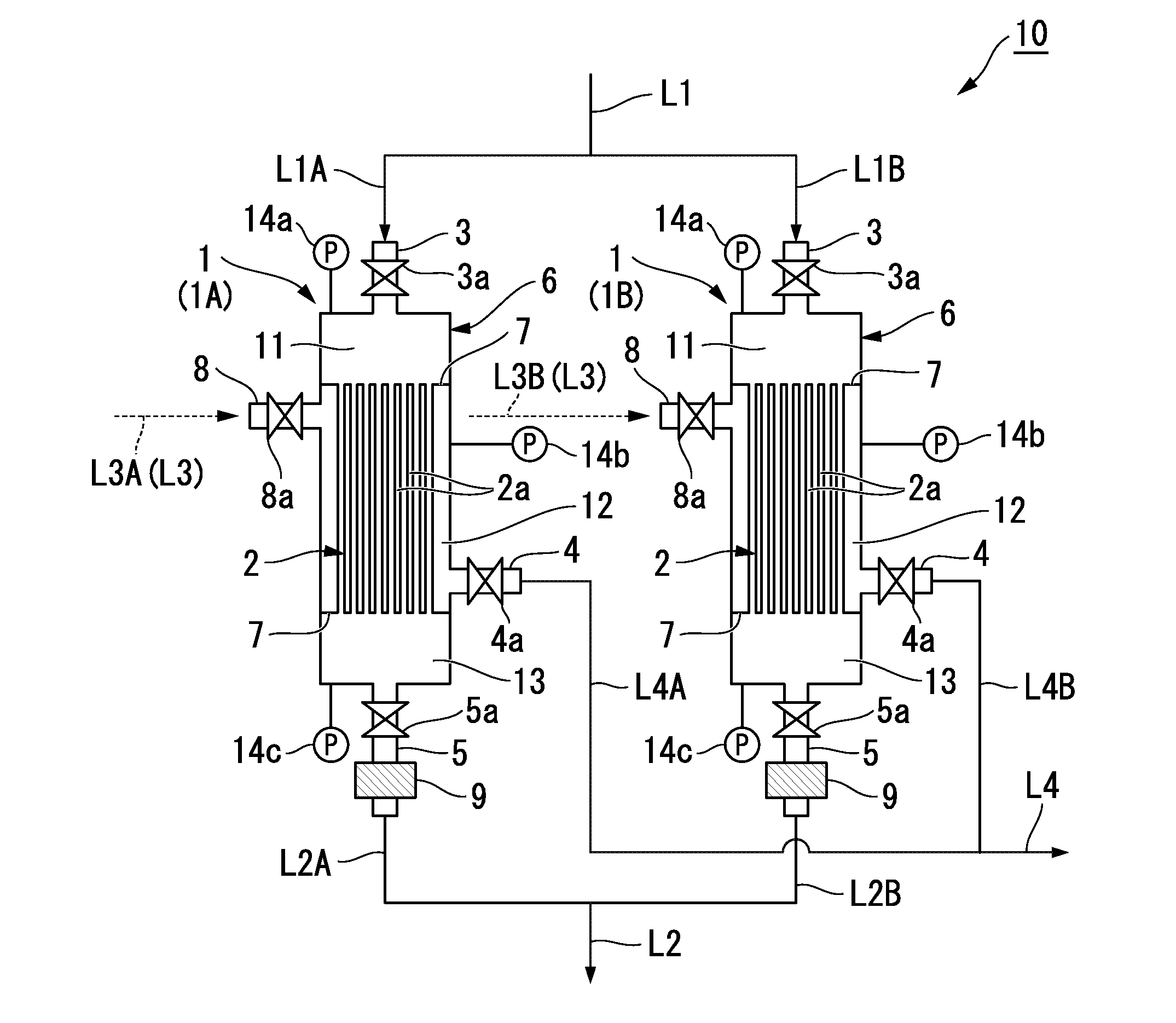

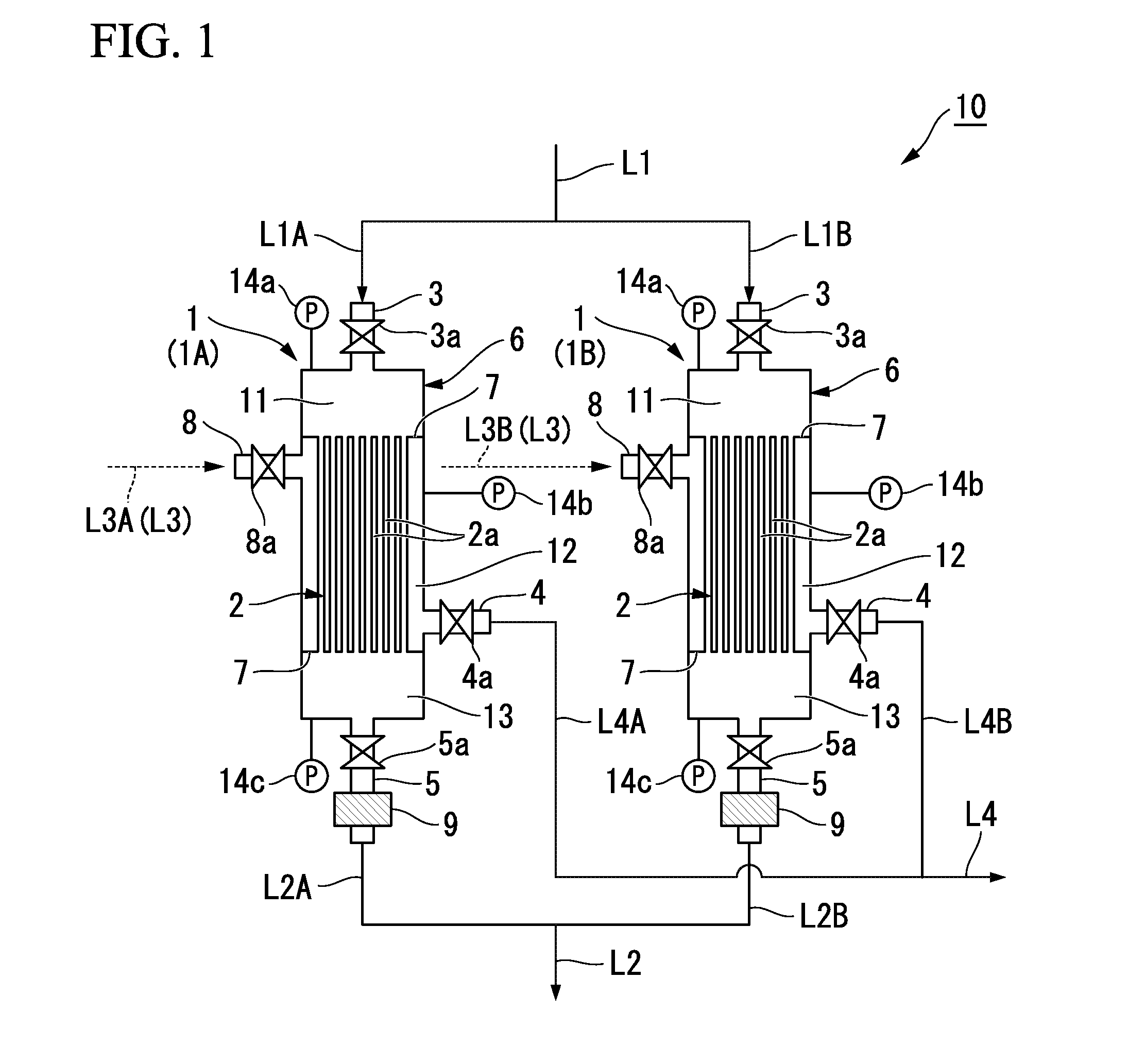

Acidic gas separation module and production method therefor, acidic gas separation layer, production method and facilitated transport membrane therefor, and acidic gas separation system

InactiveUS20150151244A1High acid gas separation efficiencyExcellent production suitability and usabilityMembranesSemi-permeable membranesChemistryGas separation

Provided is an acidic gas separation module 10 which contains: a permeated gas collection tube 12 having through-hole 12As formed on the wall thereof; a layered body 14 in which a feed gas flow path member 30 through which an acidic gas-containing source gas is fed, an acidic gas separation layer 32 that contains a carrier reacting with the acidic gas and a hydrophilic compound supporting the carrier, and a permeated gas flow path member 36 through which the acid gas that has reacted with the carrier and permeated through the acidic gas separation layer 32 flows toward the through-hole 12As are layered; and heat / moisture-resistant adhesive parts 34 and 40 which adhere the both side edges of the acidic gas separation layer 32 and the permeated gas flow path member 36 along the circumferential direction in a state where the layered body 14 is wound in layers on the permeated gas collection tube 12, the adhesive parts 34 and 40 also adhering the circumferential direction edges of the acidic gas separation layer 32 and the permeated gas flow path member 36.

Owner:FUJIFILM CORP

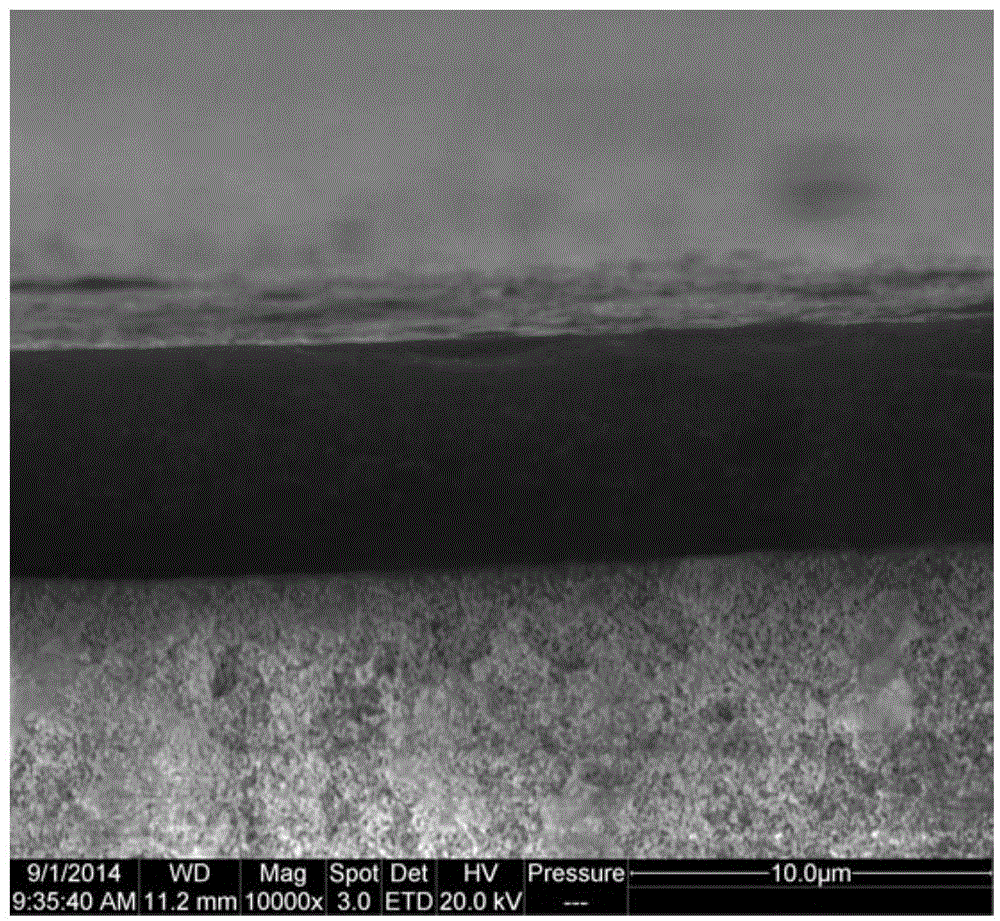

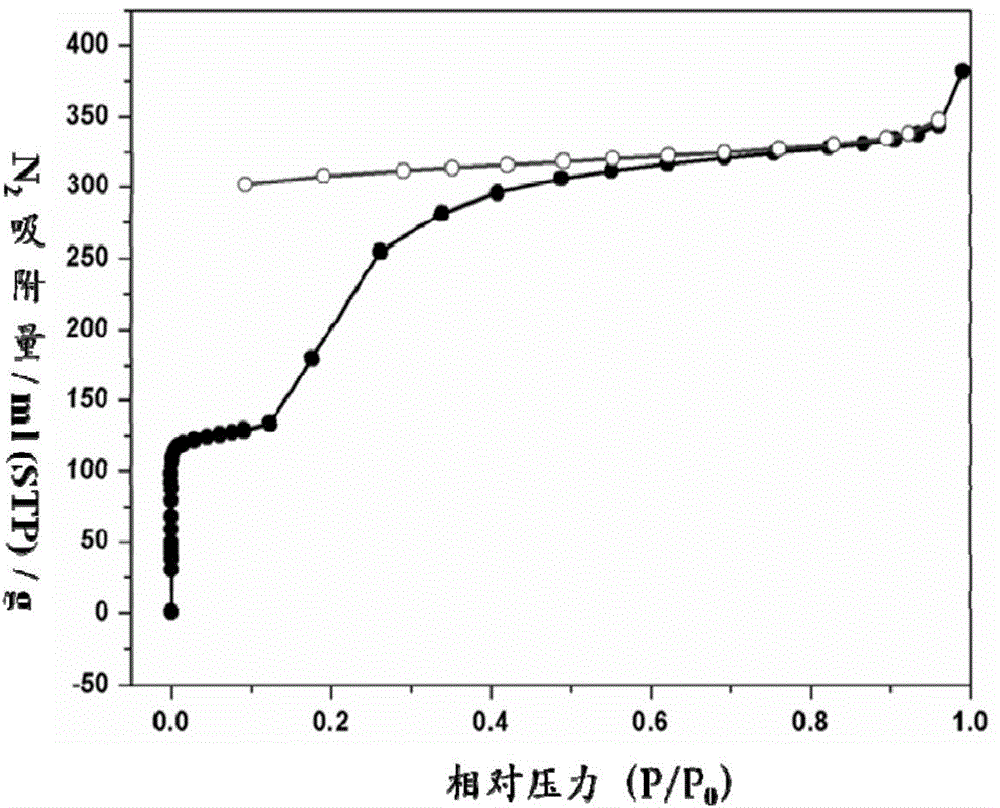

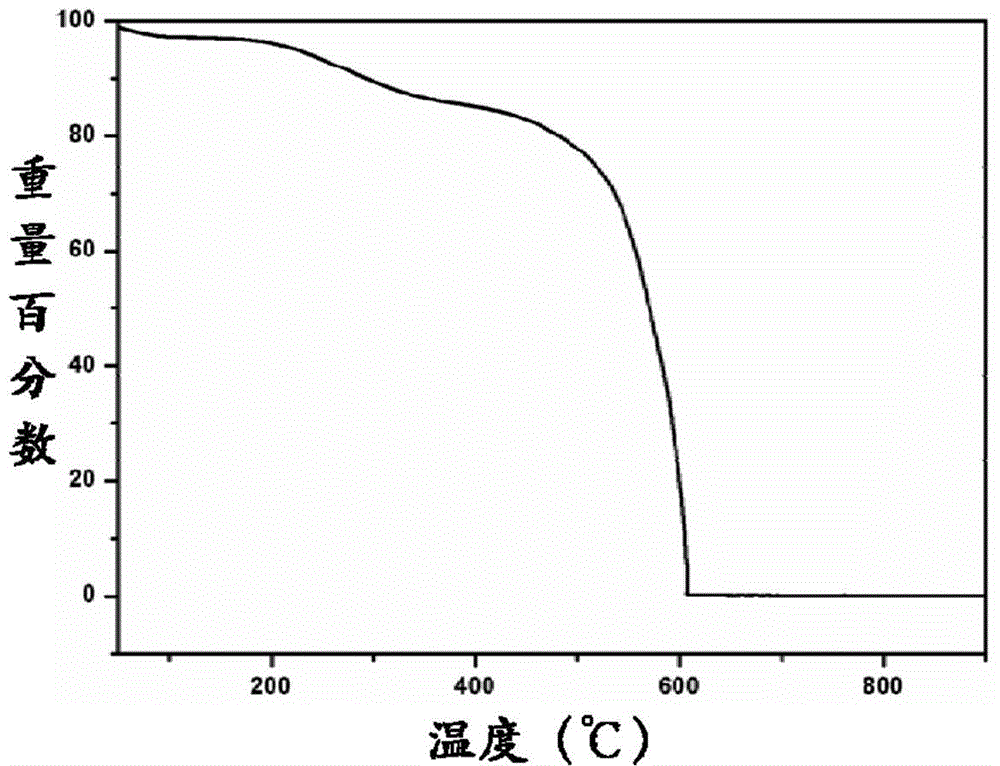

Supported composite carbon molecular sieve membrane

The invention discloses a supported composite carbon molecular sieve membrane. The supported composite carbon molecular sieve membrane is prepared by the following method: a. preparing a membrane-forming raw material: uniformly mixing a microporous material, a polymer material and a solvent; b. coating the surface of a carrier with the membrane-forming raw material prepared in the step a, and drying; and c. performing high-temperature carbonizing treatment. A certain metal element and a nitrogen-containing substance are introduced into the carbon molecular sieve membrane in a high-temperature pyrolysis process, so that permeability of the membrane is improved to a certain extent. The supported composite carbon molecular sieve membrane is high in preparation repeatability, and the prepared supported composite carbon molecular sieve membrane has excellent gas separation performance and has a wide application prospect in the field of gas separation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

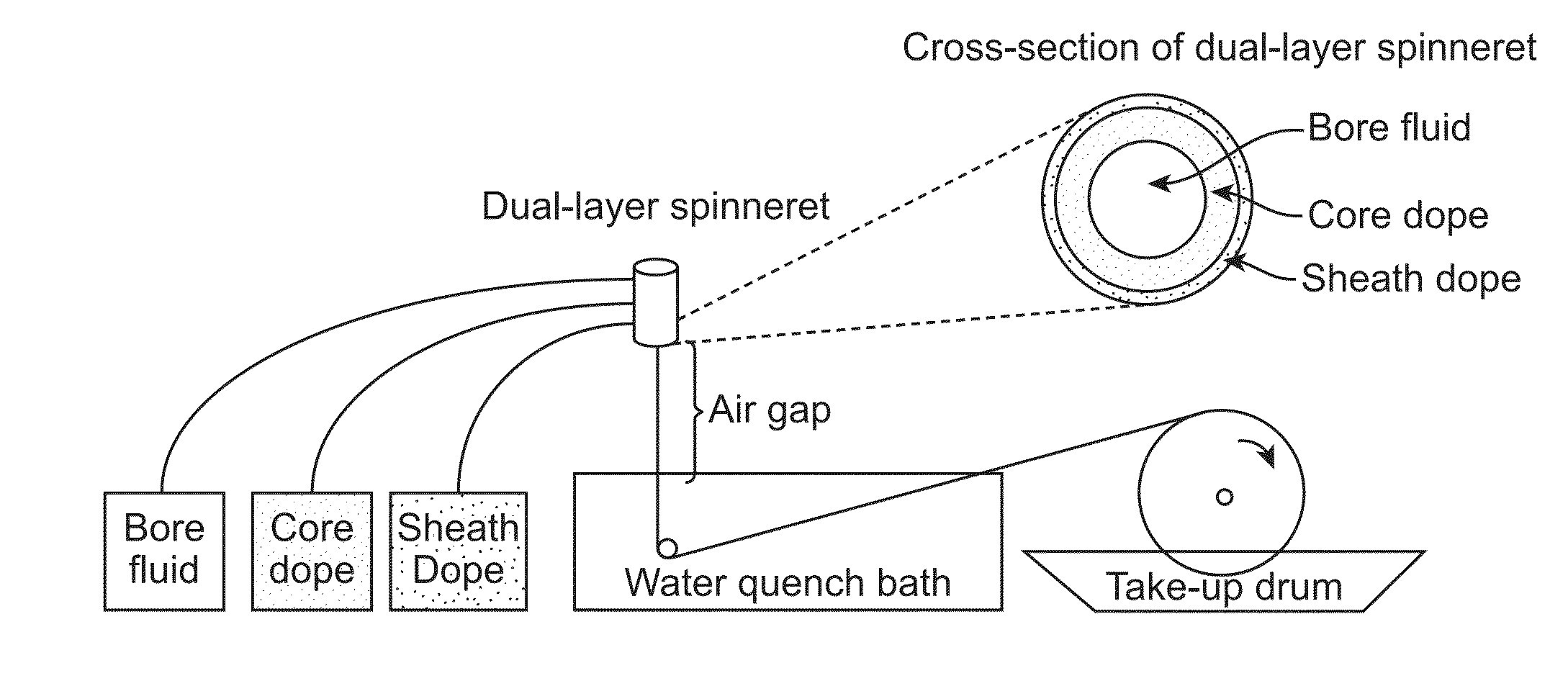

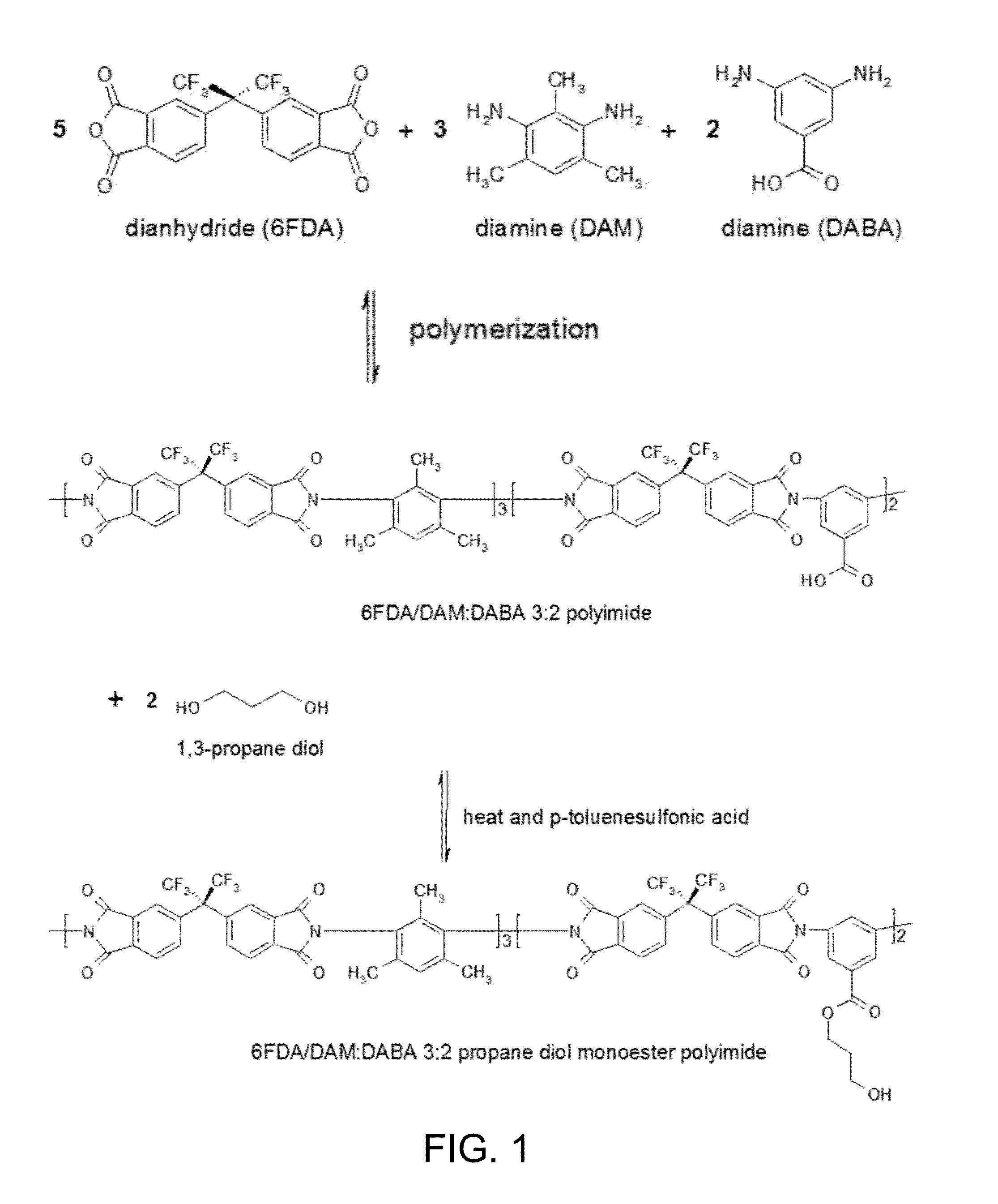

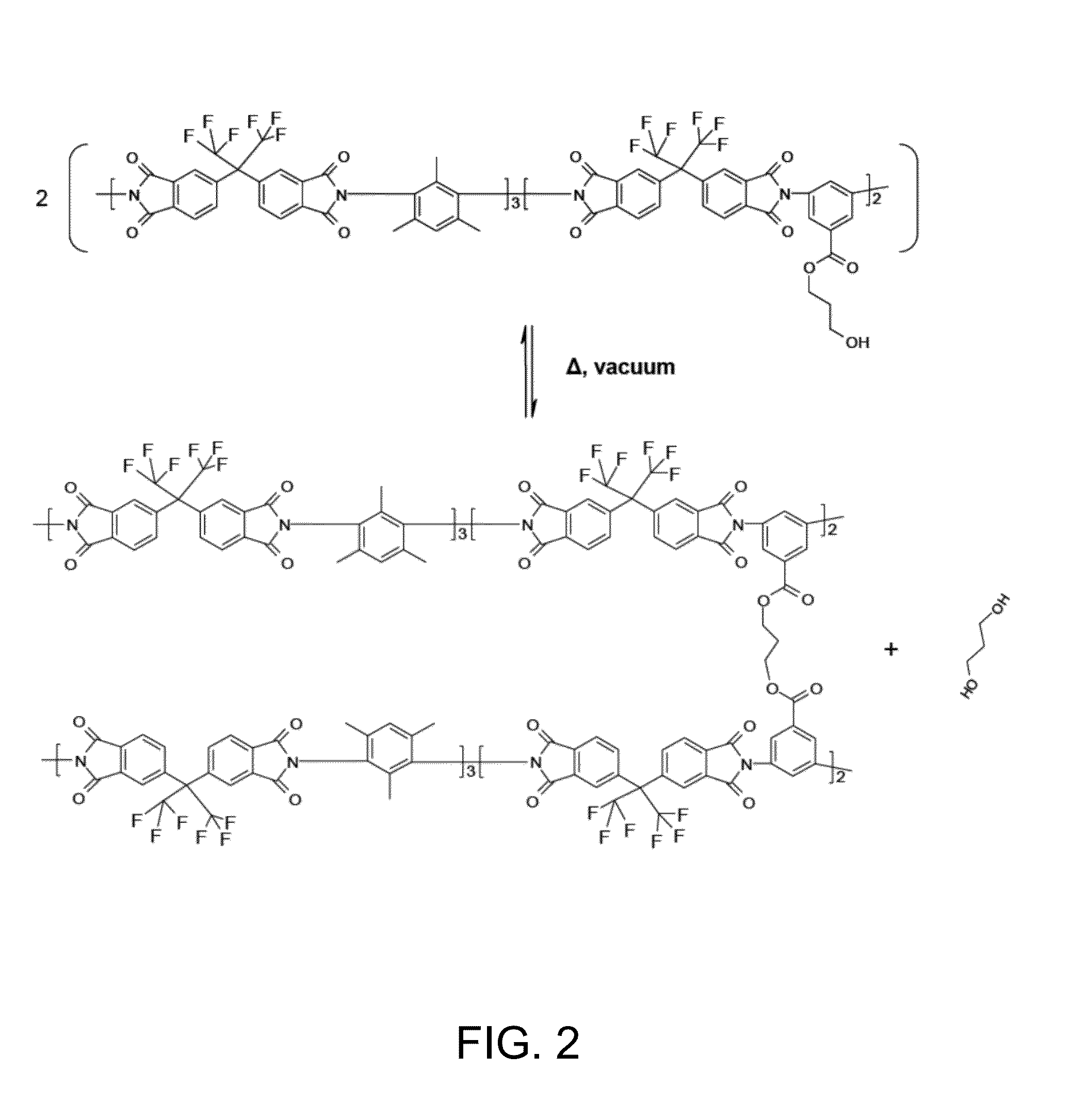

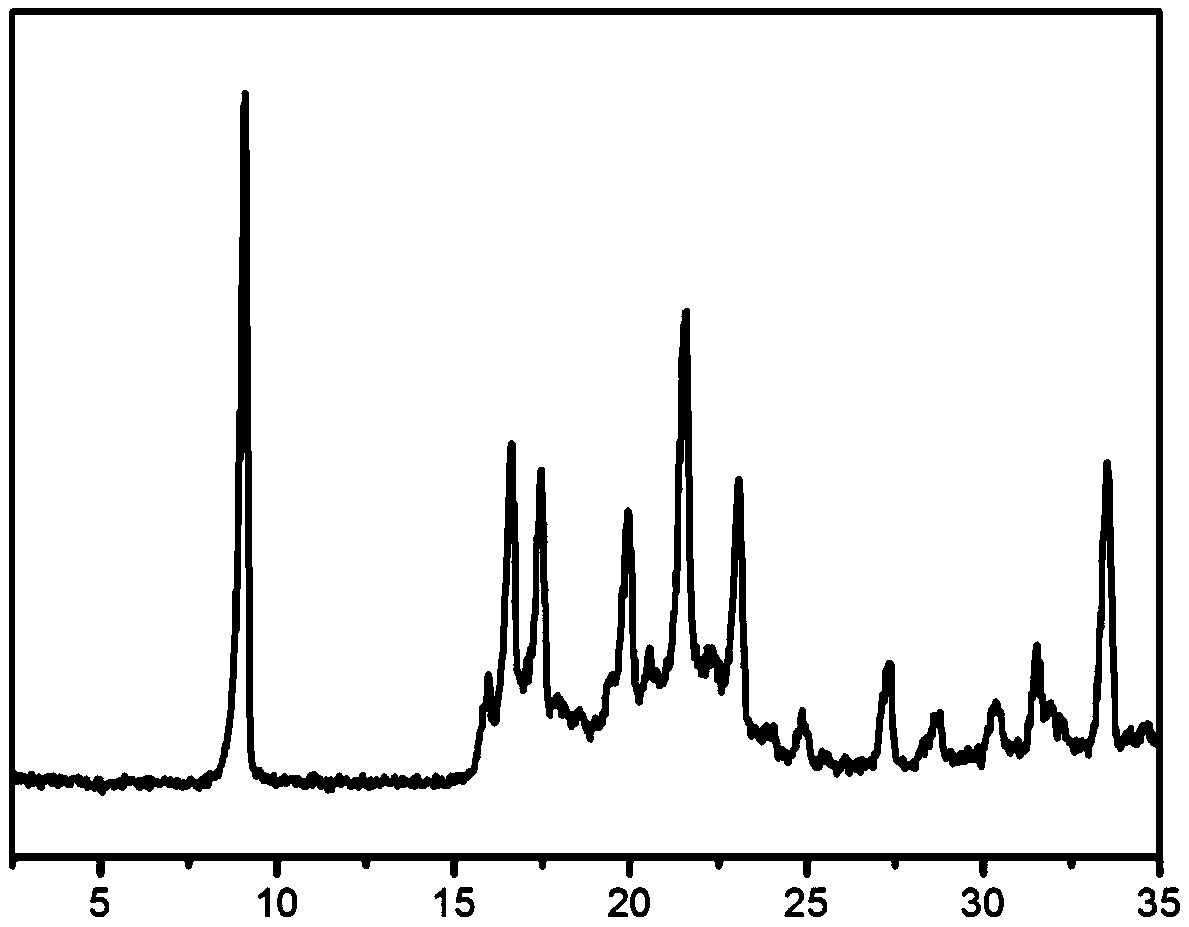

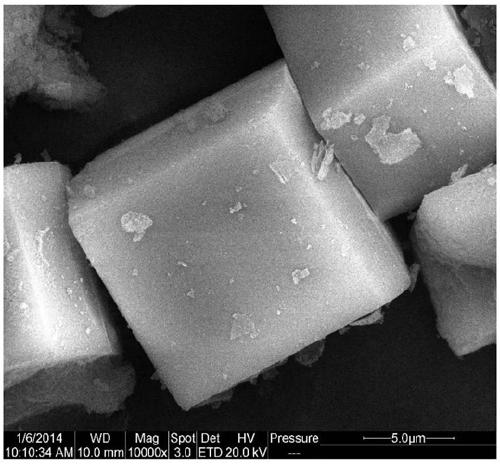

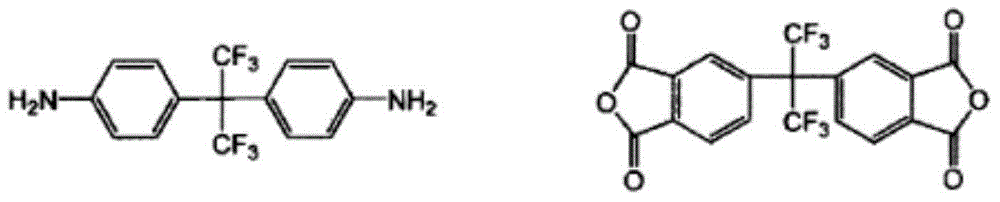

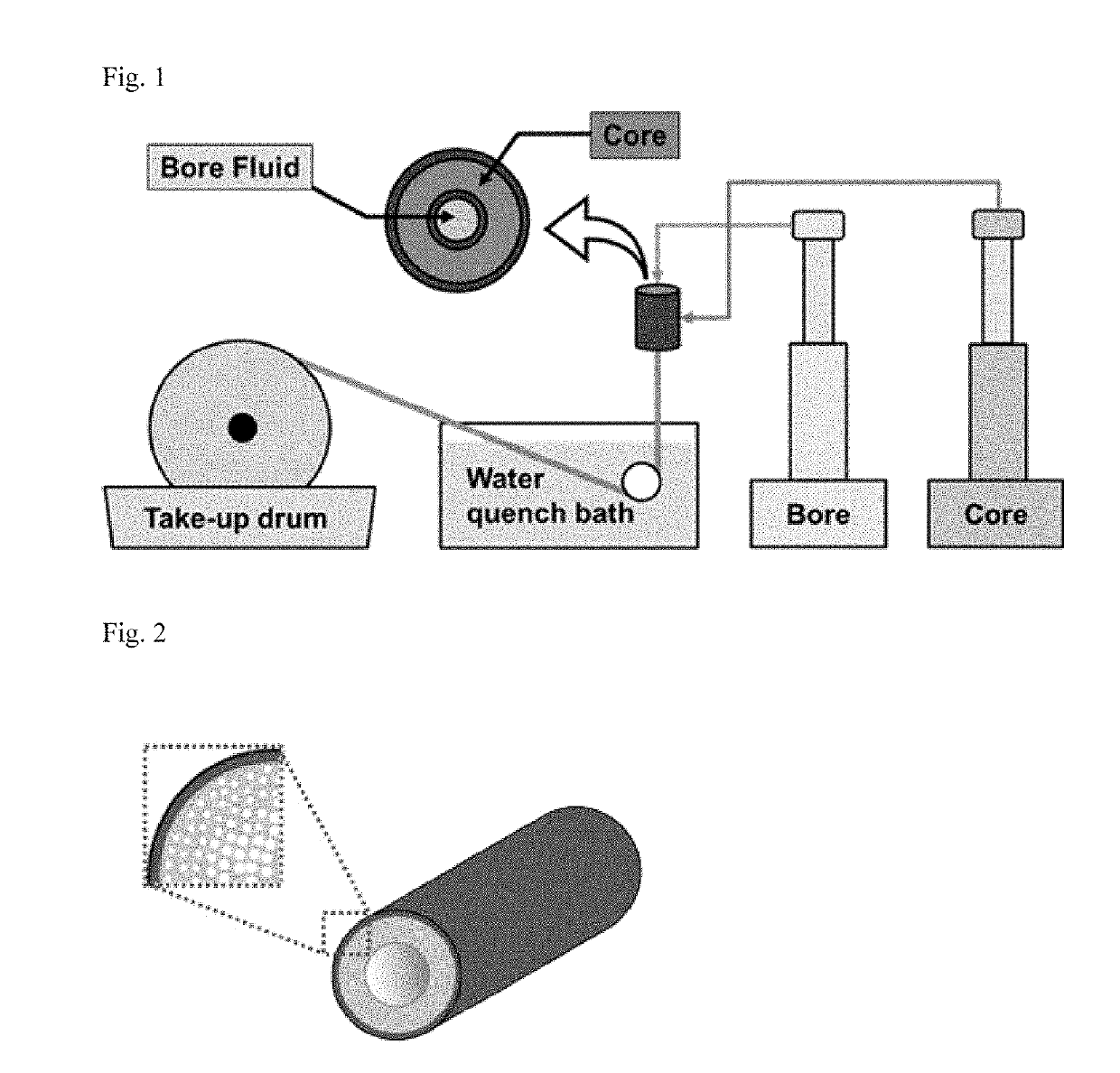

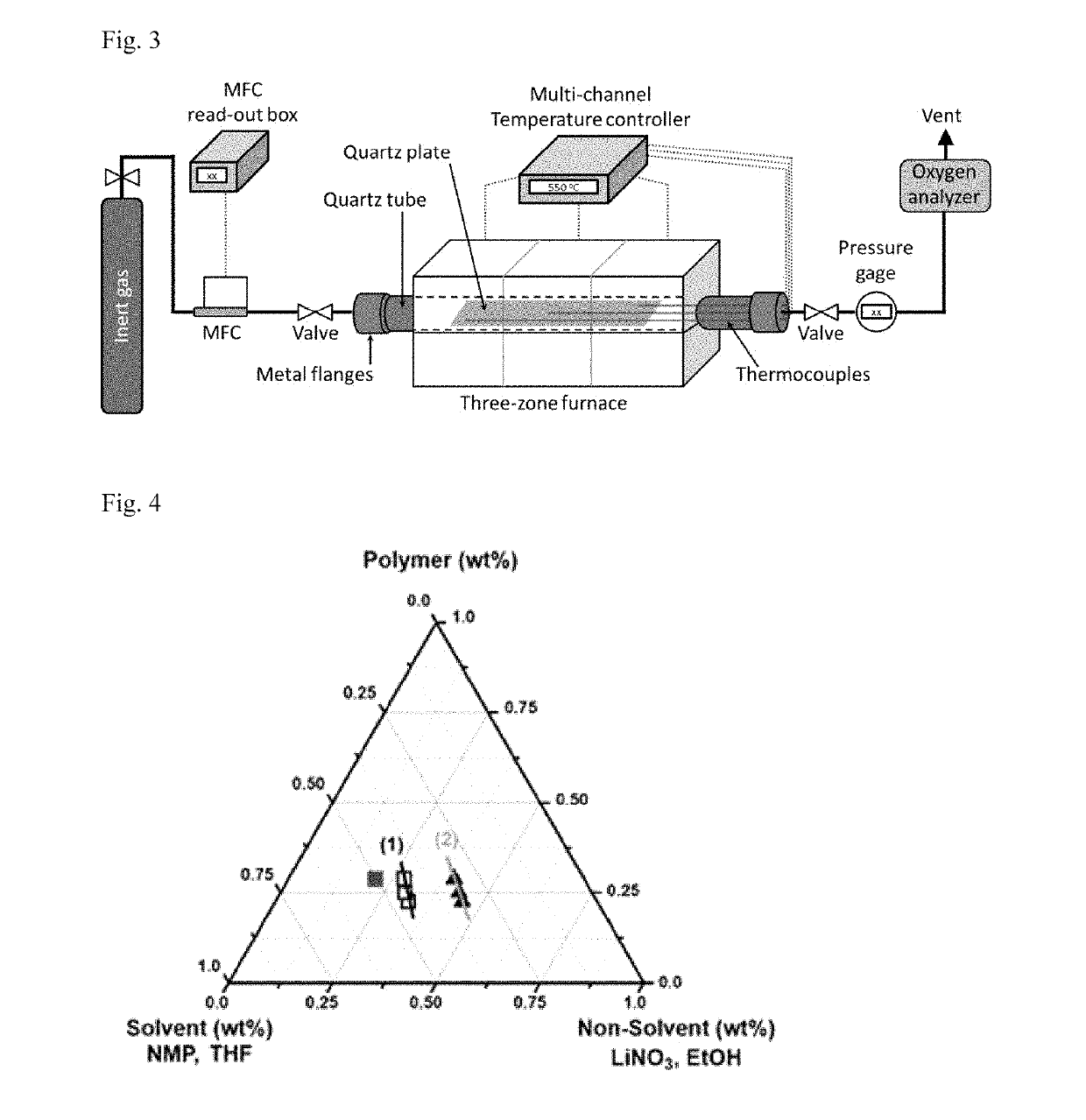

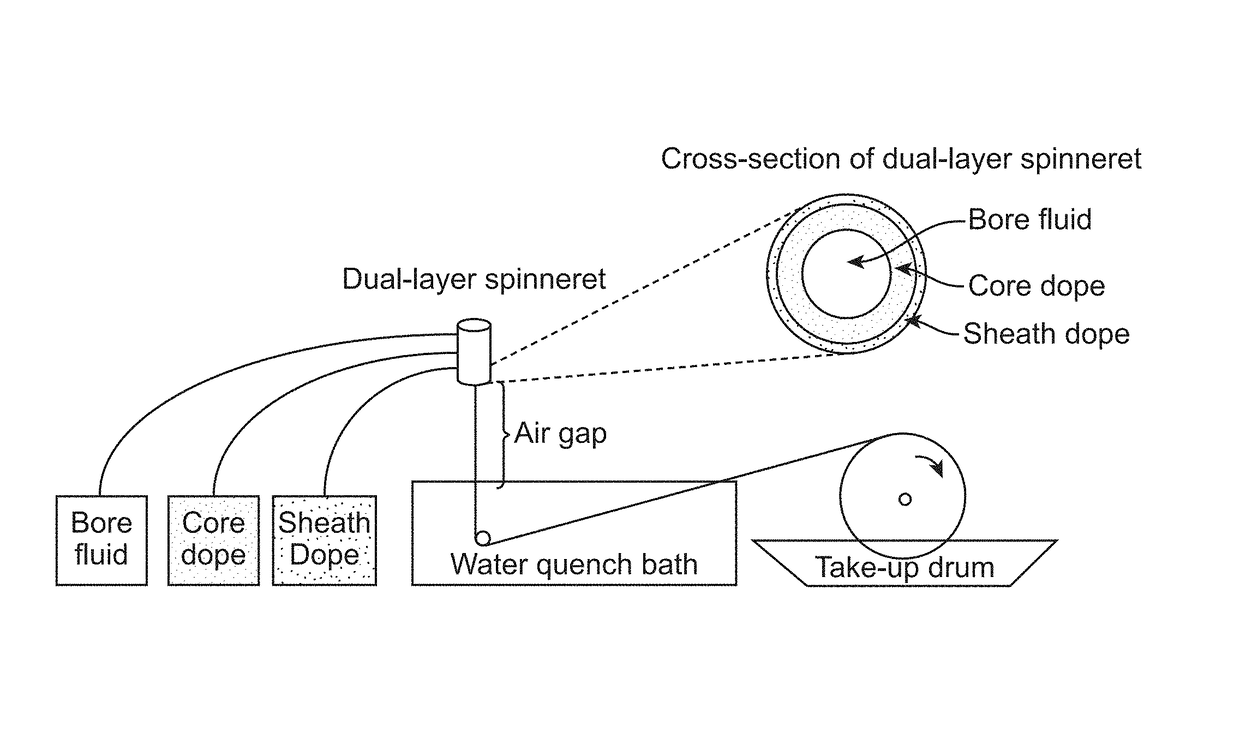

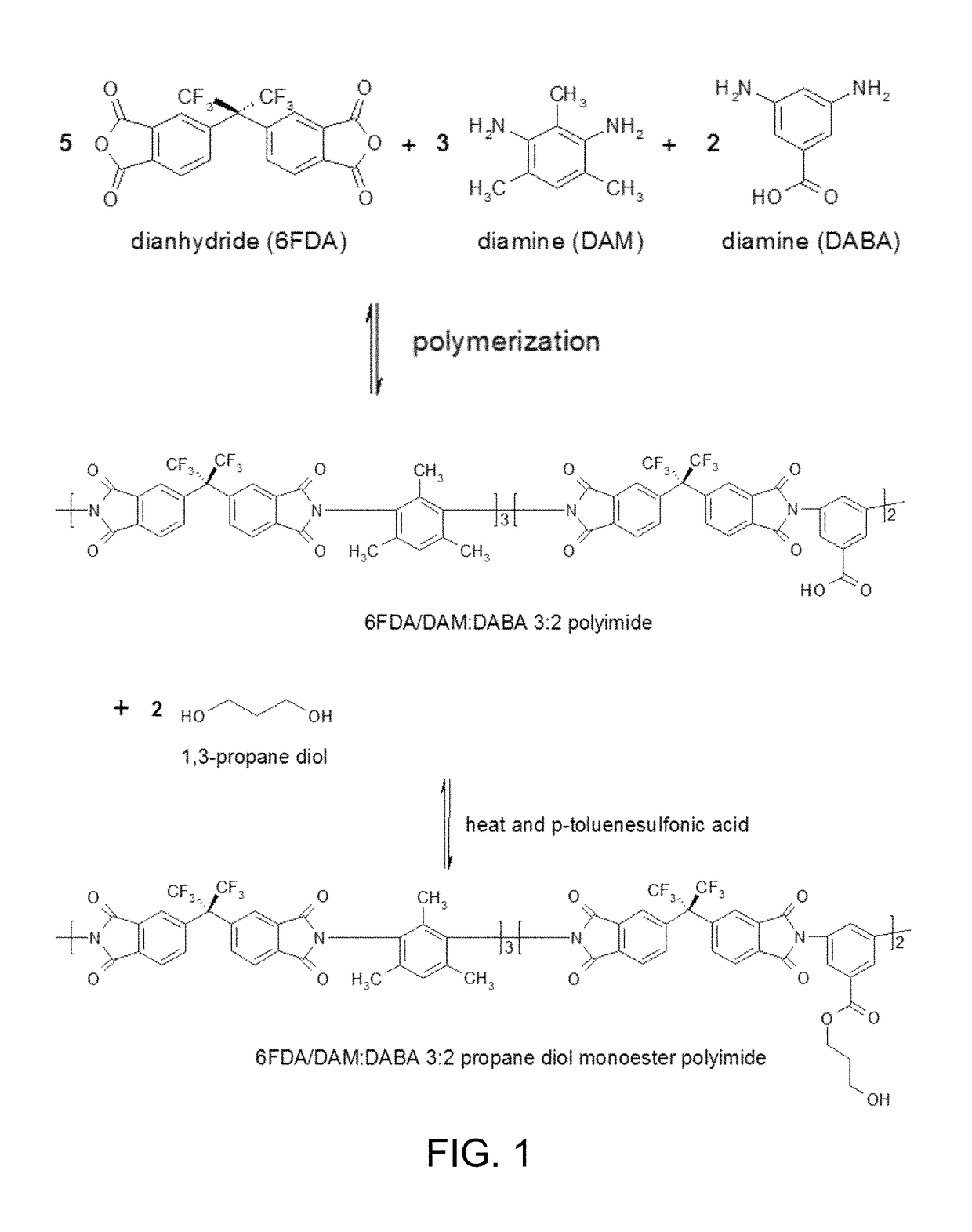

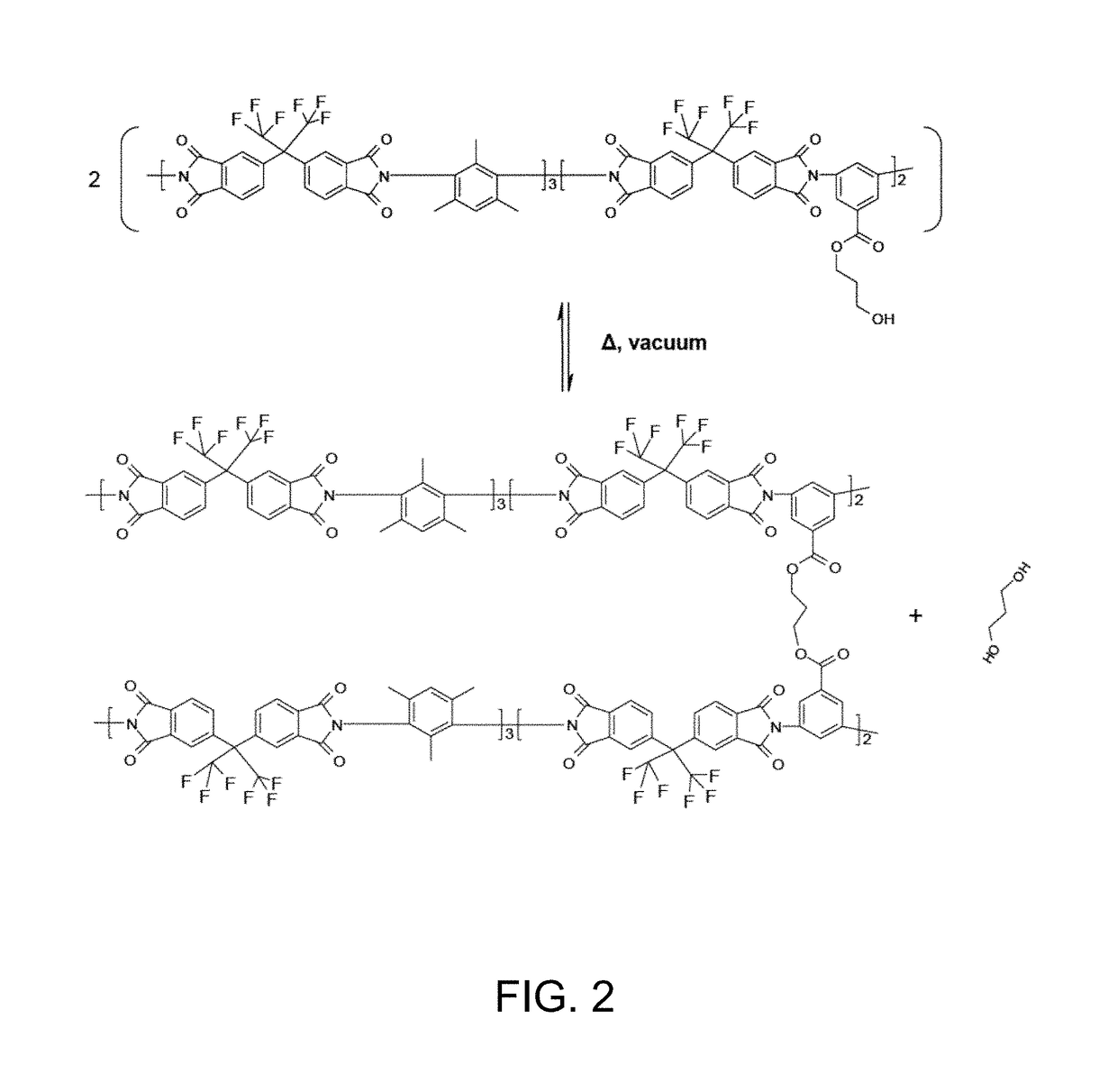

Composite hollow fiber membranes useful for co2 removal from natural gas

ActiveUS20150011815A1Excellent adhesionSuperior thermal stabilityMembranesSemi-permeable membranesHalogenPolyimide

Disclosed herein is a composite hollow fiber polymer membrane including a porous core layer and a selective sheath layer. The porous core layer includes a polyamide-imide polymer, or a polyetherimide polymer, and the selective sheath layer includes a polyimide polymer, which is prepared from monomers A, B, and C. The monomer A is a dianhydride of the formulawherein X1 and X2 are independently halogenated alkyl group, phenyl or halogen and R1, R2, R3, R4, R5, and R6 are independently H, alkyl, or halogen. The monomer B is a diamino cyclic compound without a carboxylic acid functionality and the monomer C is a diamino cyclic compound with a carboxylic acid functionality. The polyimide polymer further includes covalent ester crosslinks. Also disclosed herein is a method of making the composite polymer membrane and a process for purifying natural gas utilizing the composite polymer membrane.

Owner:GEORGIA TECH RES CORP

Preparation method of polyether sulphone ketone base gas separation carbon membrane

InactiveCN1830533ABroaden your optionsImprove gas separation performanceSemi-permeable membranesDispersed particle separationEtherKetone

Owner:DALIAN UNIV OF TECH

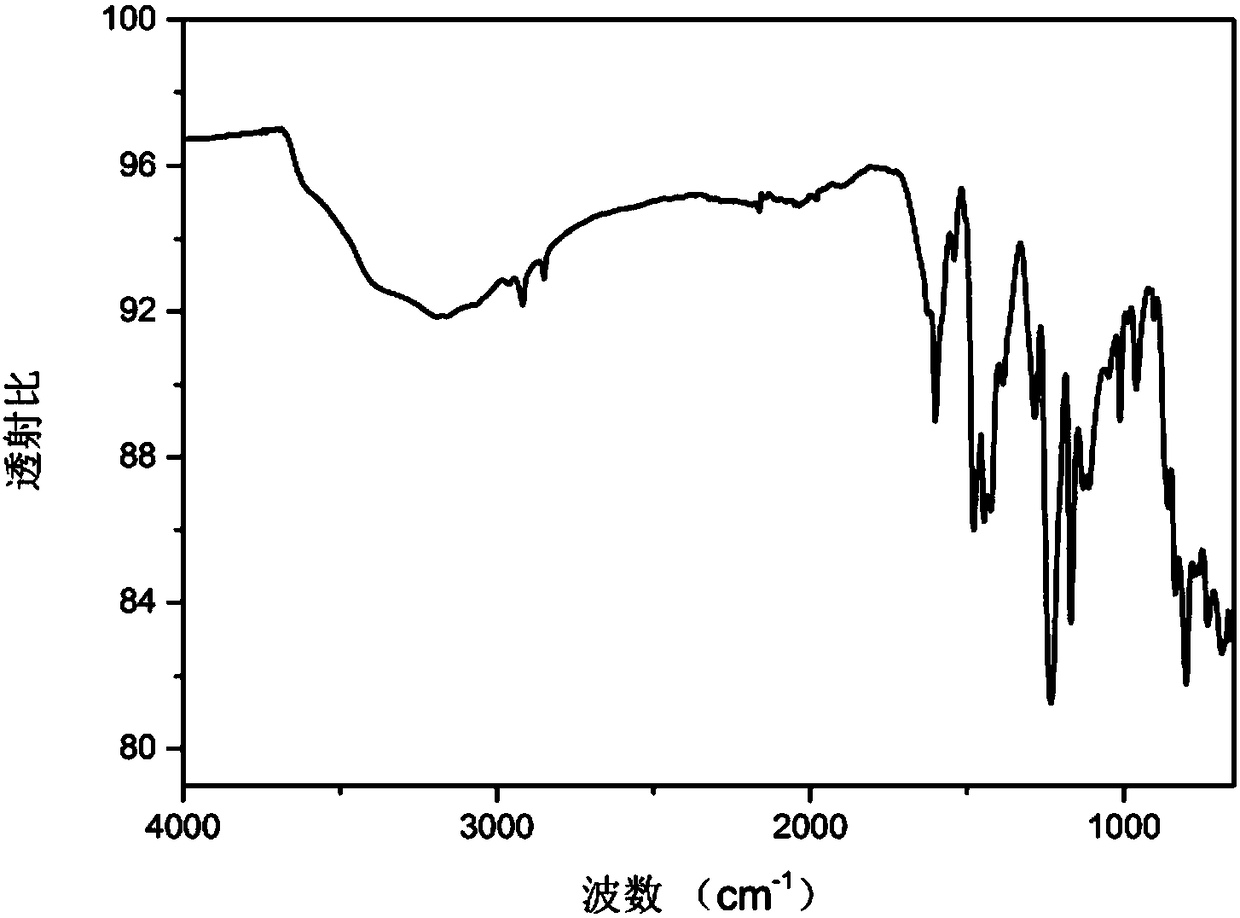

Modified metal organic framework nano-sheet and preparation method thereof

InactiveCN111282405AImprove gas separation performanceGood repeatabilitySemi-permeable membranesDispersed particle separationAlkanePhysical chemistry

The invention relates to a modified metal organic framework nano-sheet and a preparation method thereof, and belongs to the field of membrane separation. The preparation method disclosed by the invention comprises the following steps: mixing an organic matter for modifying a metal organic framework nano-sheet and a metal organic framework nano-sheet, wherein the organic matter is a long-chain alkane organic amine or imidazole compound, and the organic matter accounts for 0.002-50 wt% of the mixture of the organic matter and the metal organic framework nano-sheet; and reacting at a temperatureof room temperature to 100 DEG C to obtain the modified metal organic framework nano-sheet. The supported nano-sheet membrane prepared by the invention has high gas separation performance, high repeatability and good universality, and a modification strategy and a membrane preparation method can be applied to other two-dimensional nano-sheet materials.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

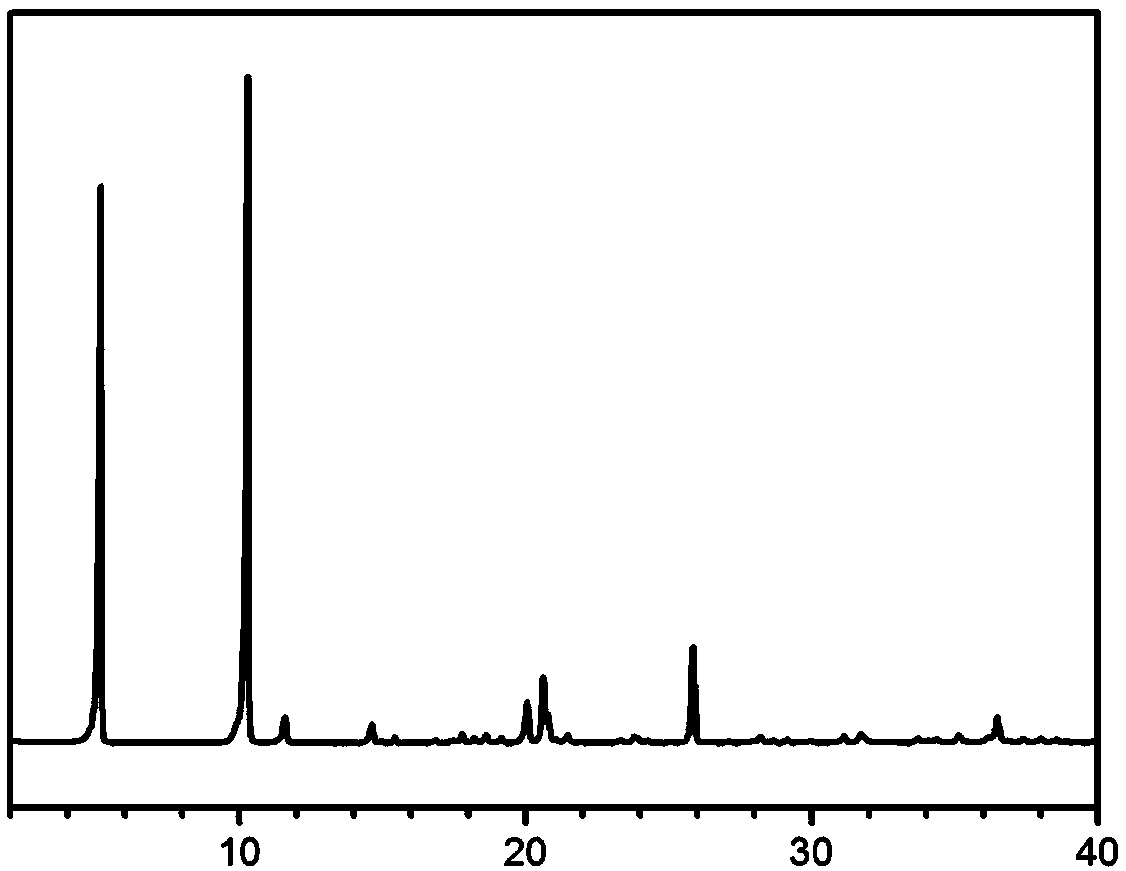

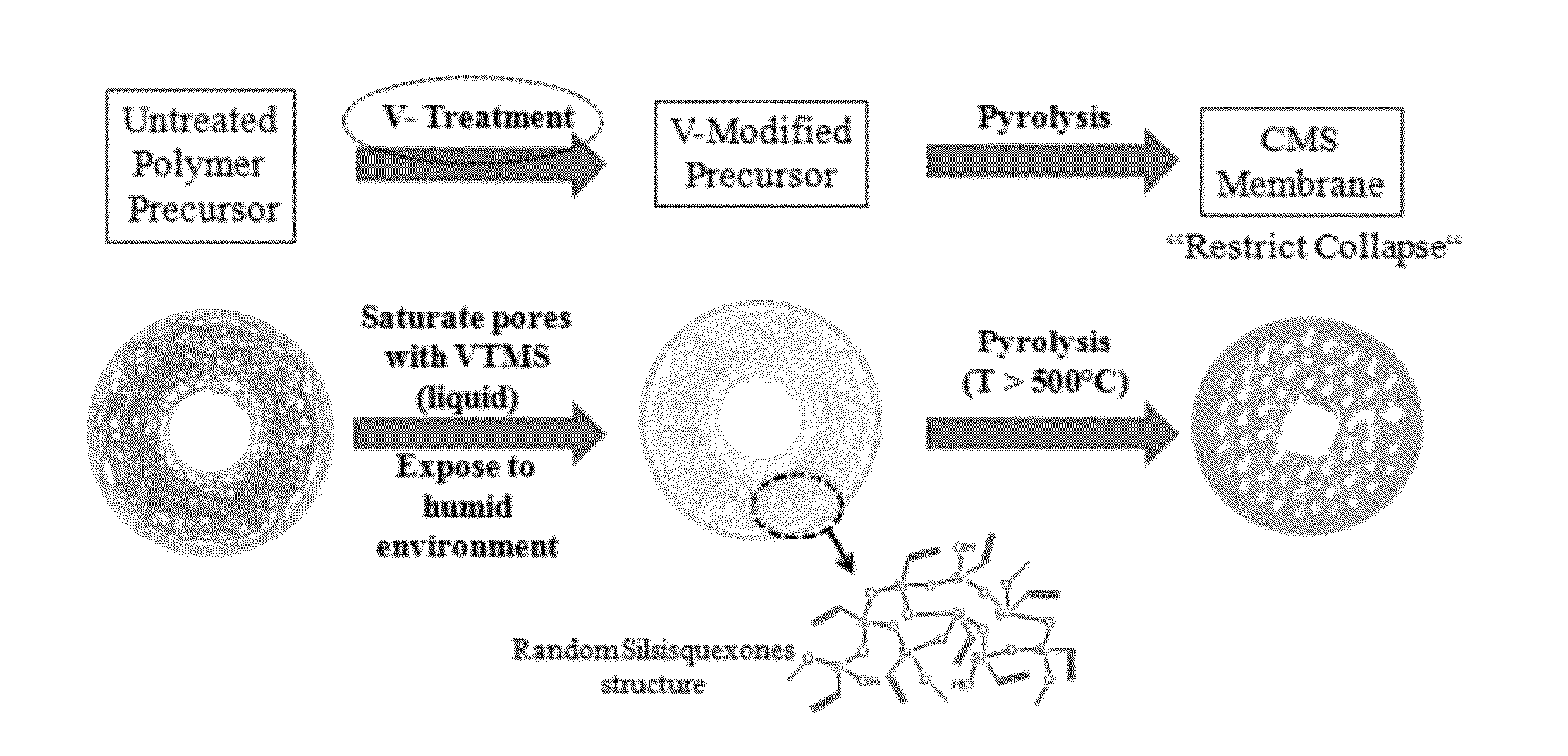

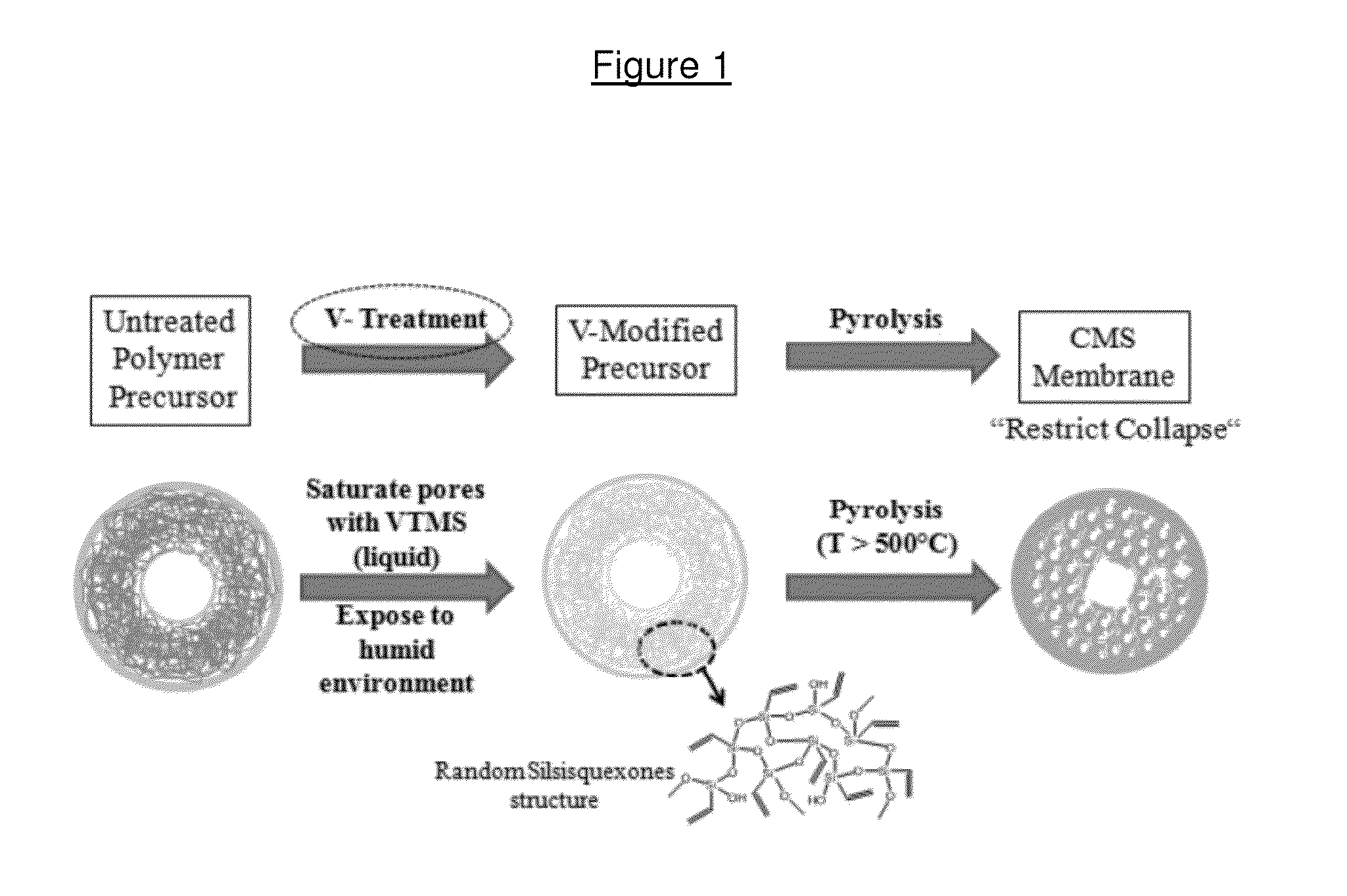

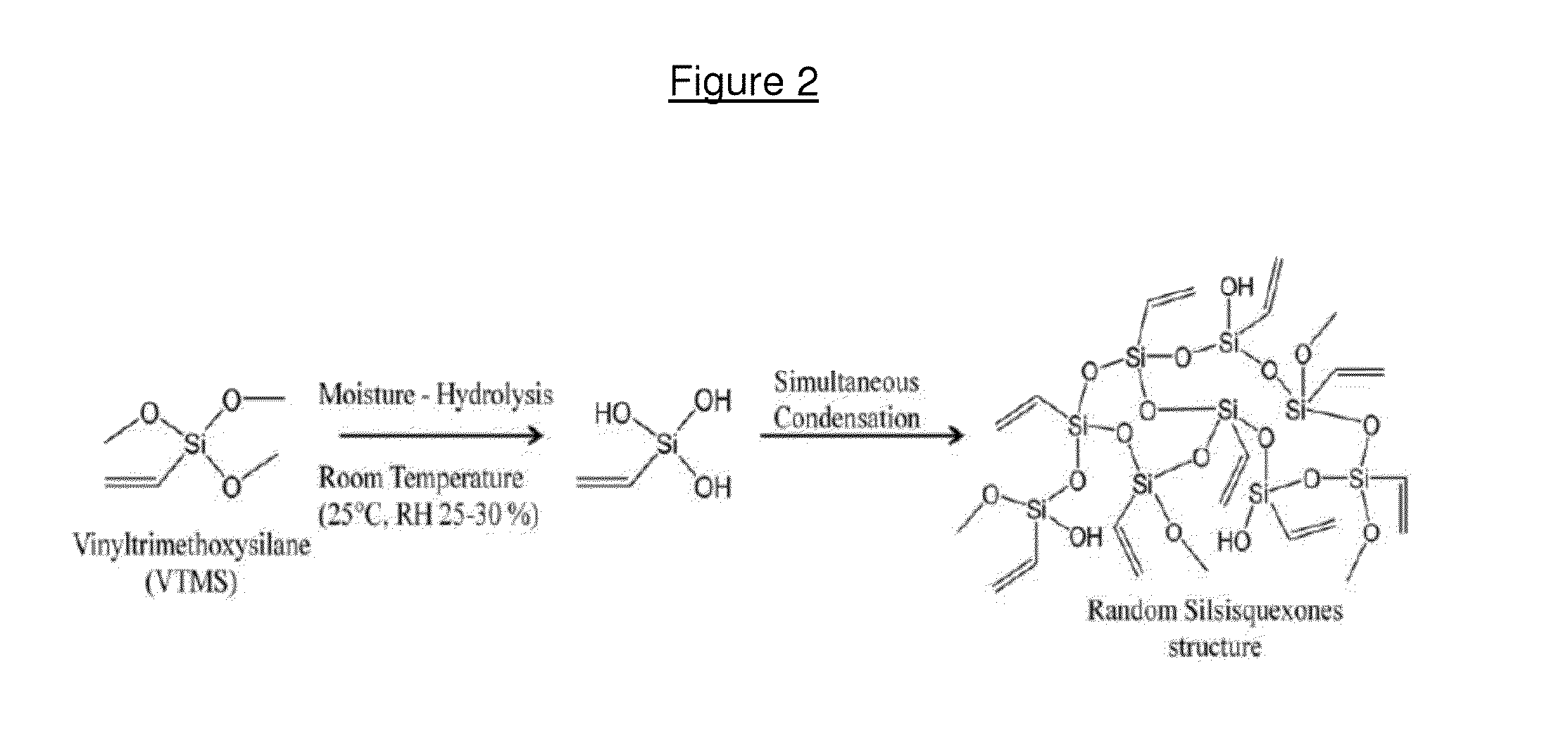

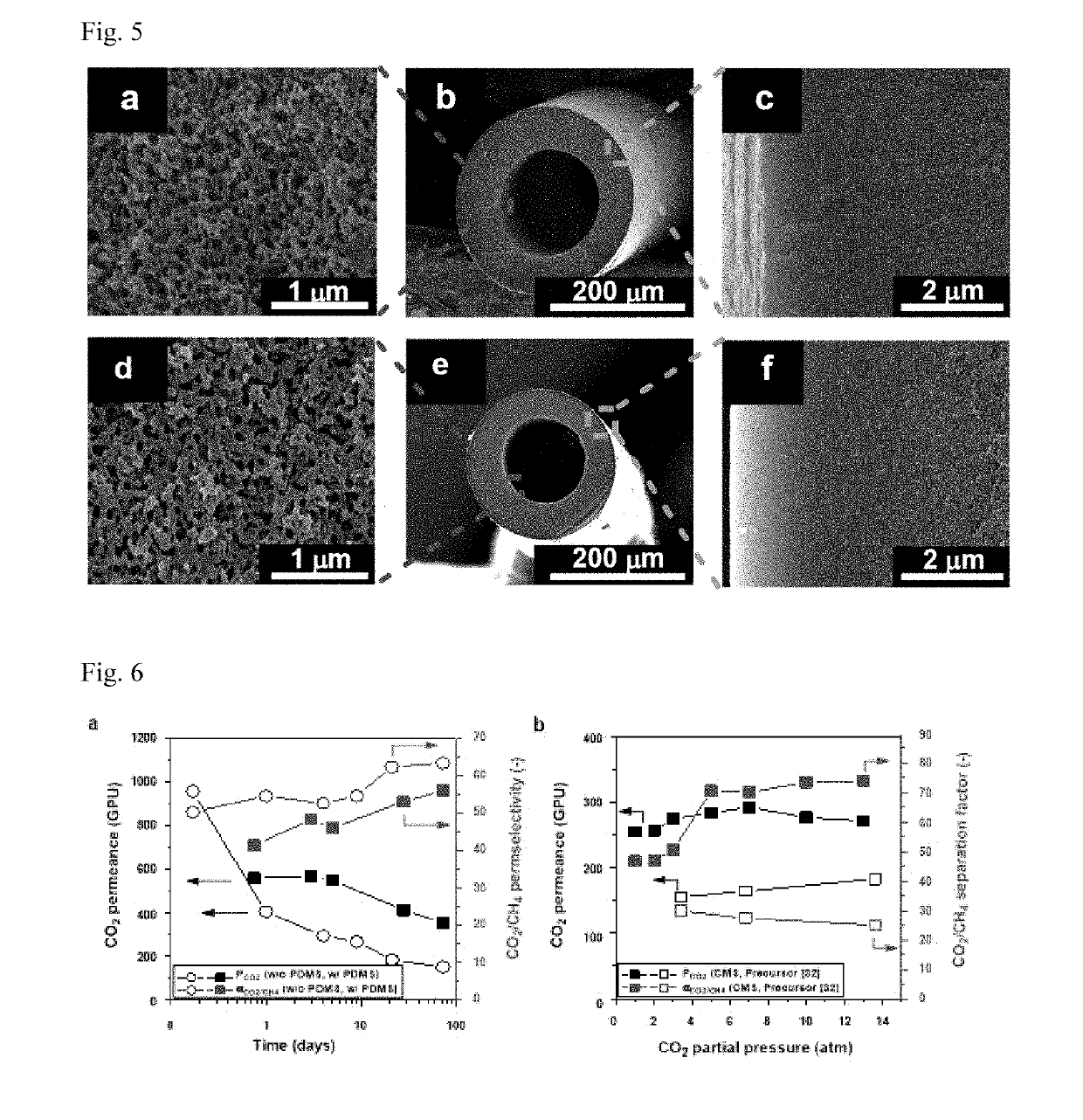

Asymmetric Modified Carbon Molecular Sieve Hollow Fiber Membranes Having Improved Permeance

ActiveUS20150094445A1Restrict collapseImprove gas separation performanceSemi-permeable membranesMembranesMolecular sievePermeance

The present invention provides an asymmetric modified CMS hollow fiber membrane having improved gas separation performance properties and a process for preparing an asymmetric modified CMS hollow fiber membrane having improved gas separation performance properties. The process comprises treating a polymeric precursor fiber with a solution containing a modifying agent prior to pyrolysis. The concentration of the modifying agent in the solution may be selected in order to obtain an asymmetric modified CMS hollow fiber membrane having a desired combination of gas permeance and selectivity properties. The treated precursor fiber is then pyrolyzed to form an asymmetric modified CMS hollow fiber membrane having improved gas permeance.

Owner:AIR LIQUIDE ADVANCED TECH U S +1

Sulfonated poly(ether ether ketone)-sulfonated silicon dioxide microsphere hybrid membrane, as well as preparation and application of membrane

InactiveCN104209023AHigh selectivityImprove permeabilitySemi-permeable membranesDispersed particle separationBenzeneMicrosphere

The invention discloses a sulfonated poly(ether ether ketone)-sulfonated silicon dioxide microsphere hybrid membrane which consists of sulfonated poly(ether ether ketone)-sulfonated silicon dioxide microspheres. The preparation process comprises the following steps of performing reaction on silicon dioxide microspheres synthesized by a Stober method and 3-(methacryloyl) trimethoxypropylsilane to obtain double-key modified silicon dioxide microspheres; then preparing sulfonated silicon dioxide microspheres from the double-key modified silicon dioxide microspheres and vinyl benzene sulfonic acid sodium salt under the action of an initiator; co-blending the sulfonated silicon dioxide microspheres and a sulfonated poly(ether ether ketone) solution to obtain membrane casting liquid; and preparing the hybrid membrane by a casting method. The sulfonated poly(ether ether ketone)-sulfonated silicon dioxide microsphere hybrid membrane has the advantages that the raw materials are readily available; the preparation process is simple and controllable; the prepared sulfonated poly(ether ether ketone)-sulfonated silicon dioxide microsphere hybrid membrane applied to CO2 / CH4 gas separation is relatively high in selectivity and permeability.

Owner:TIANJIN UNIV

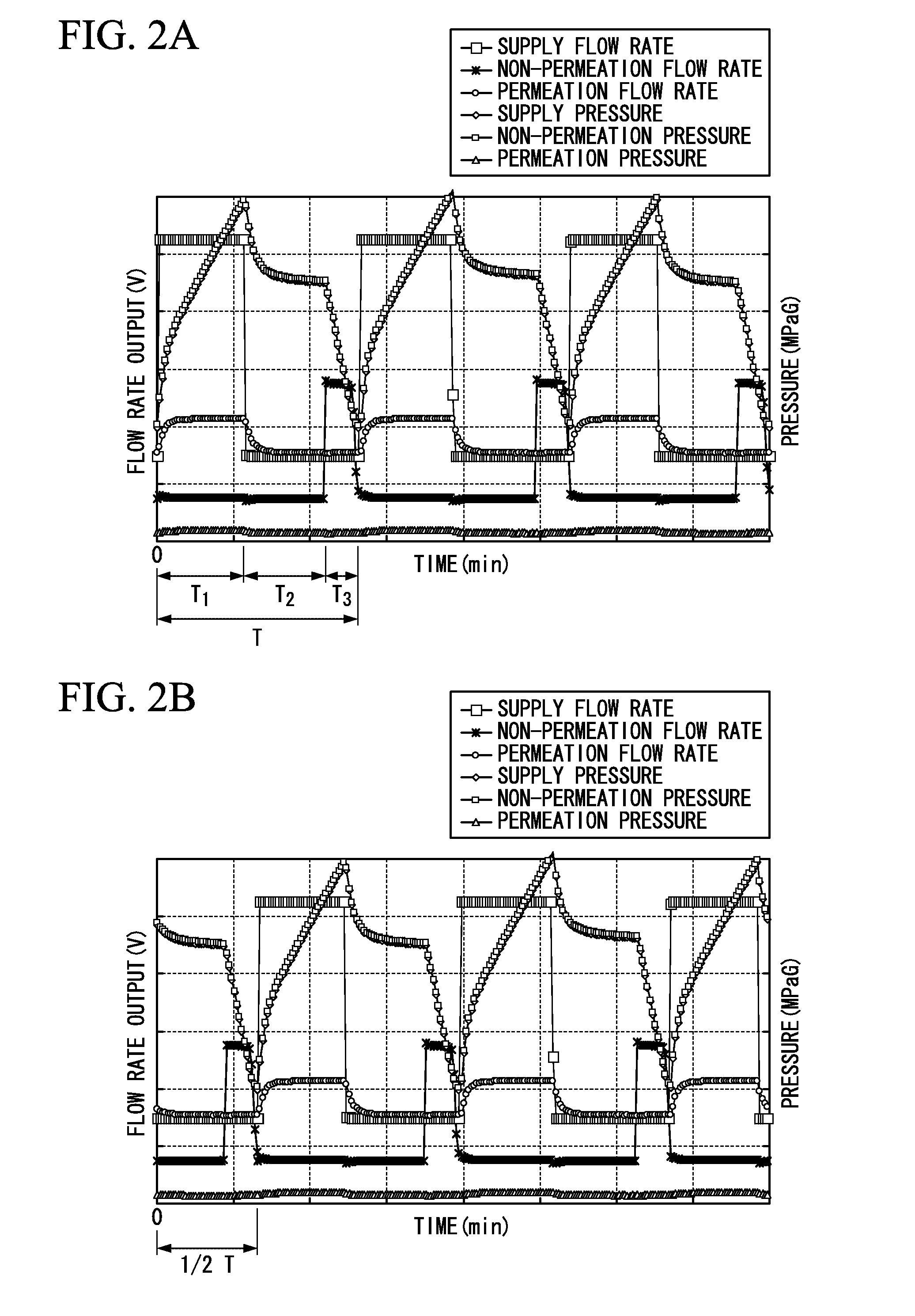

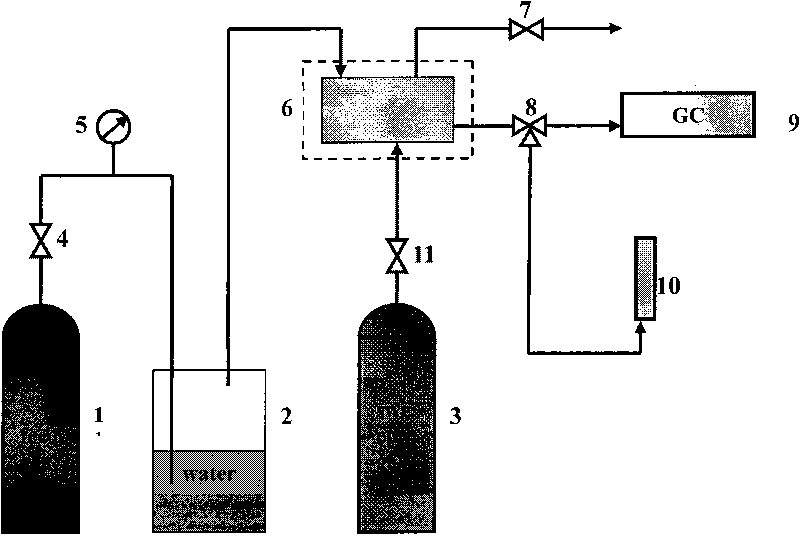

Method for operating gas separation device

InactiveUS20130032028A1Improve gas separation performanceEfficient separation and recoveryMembranesSemi-permeable membranesProduct gasMixed gas

Owner:NIPPON SANSO CORP +1

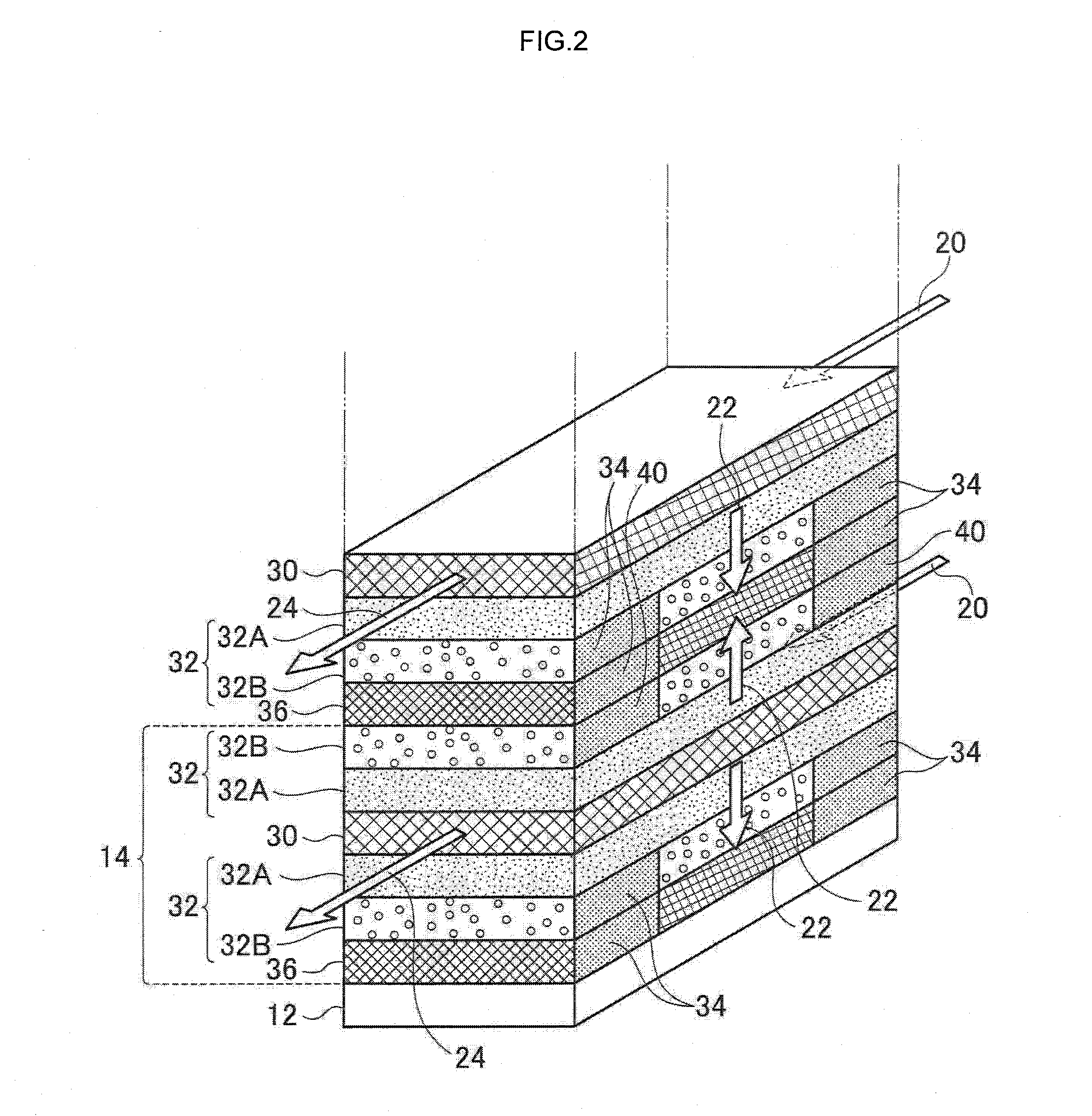

Method for preparing CO2 separation membrane material and composite membrane

InactiveCN101733029AEasy to separateFlux drop problem improvedProductsSemi-permeable membranesMembrane technologyRoom temperature

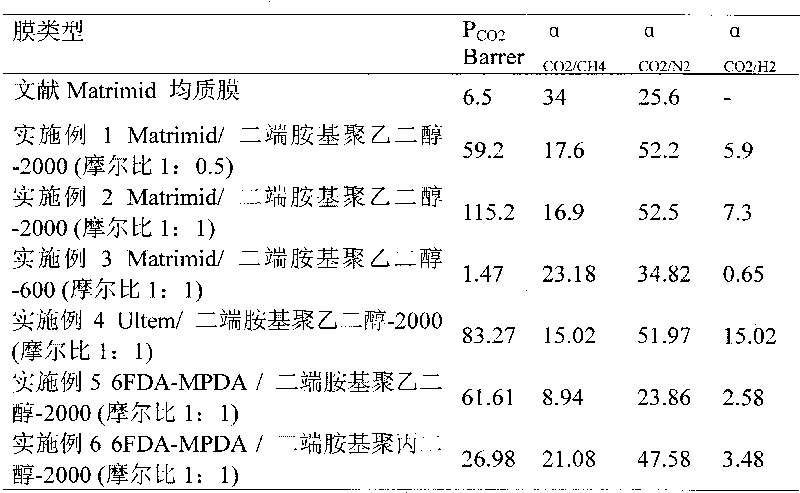

The invention relates to a macromolecule separation membrane technology, in particular to a method for preparing a CO2 separation membrane material and a composite membrane, comprising the following steps of: adding DM and PEGA to a tetrahydrofuran dissolvant, and then adding an initiator, wherein the total mass percent of the DM and the PEGA is 5-90 percent, and the mass percent of the initiator is 0.07-1 percent; then heating a 50-90 DEG C of oil bath for reflux; reacting for 10-30h; after the reaction, pouring into a stirring nonpolar dissolvant after the solution is cooled to the room temperature for settlement to obtain a white viscous polymer; and then baking for 20-30h in a vacuum baking oven at the temperature of 70-120 DEG C to obtain a light yellow transparent polymer PDM-PEGA. A composite plate prepared by the invention has good separating performance on CO1 / CH4, CO2 / Na and CO2 / H2.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing metal organic framework molecular sieve membrane by supercritical fluid technology

ActiveCN111589311ASustainable Manufacturing ProcessSustainable use of manufacturing processesSemi-permeable membranesDispersed particle separationMolecular sieveSupport matrix

The invention discloses a method for preparing a metal organic framework (MOF) molecular sieve membrane by a supercritical fluid technology. The method comprises the following steps: firstly, puttinga porous carrier (support matrix) modified with a compact metal precursor layer and a solid organic ligand powder into a reactor cavity in a supercritical kettle; under the action of a supercritical fluid (CO2), gradually dissolving the solid organic ligand in the cavity to form a homogeneous reaction system; and carrying out a coordination reaction on the homogeneous reaction system and the metalprecursor layer in an interface region to form a continuous MOF molecular sieve membrane layer having excellent gas separation performance. In addition, the method for preparing the molecular sieve membrane by the supercritical fluid technology realizes zero emission and green cyclic utilization of all chemical reagents. In conclusion, the MOF molecular sieve membrane is prepared by the supercritical fluid technology, and the environmental protection of a membrane preparation process and the excellent separation performance of the molecular sieve membrane can be considered at the same time, so that the molecular sieve membrane has a good industrial application prospect.

Owner:DALIAN UNIV OF TECH

Mixed matrix membranes incorporating surface-functionalized molecular sieve nanoparticles and methods for making the same

ActiveUS7846496B2Improve permeabilityHigh selectivitySemi-permeable membranesPretreated surfacesMolecular sieveNanoparticle

Owner:UOP LLC

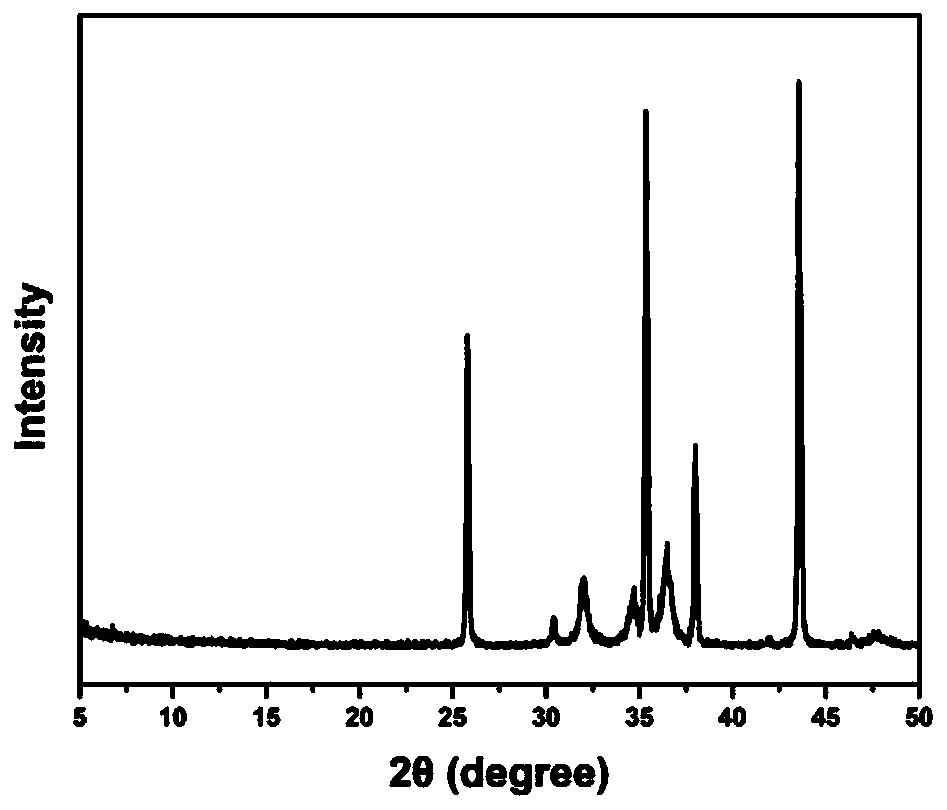

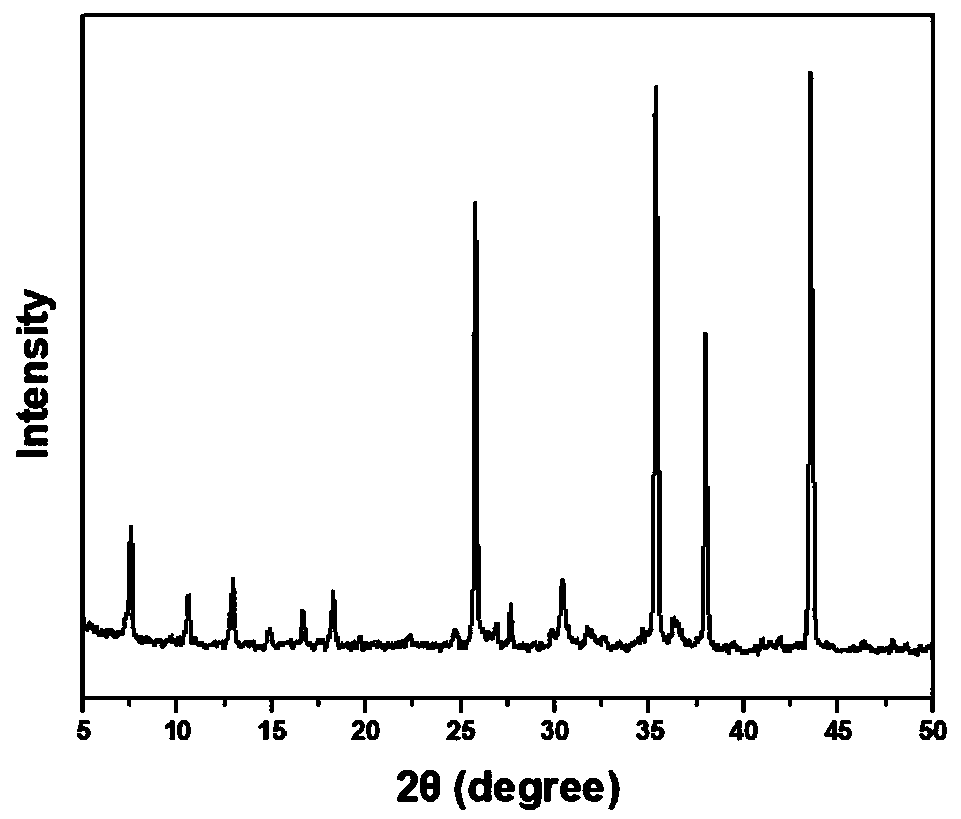

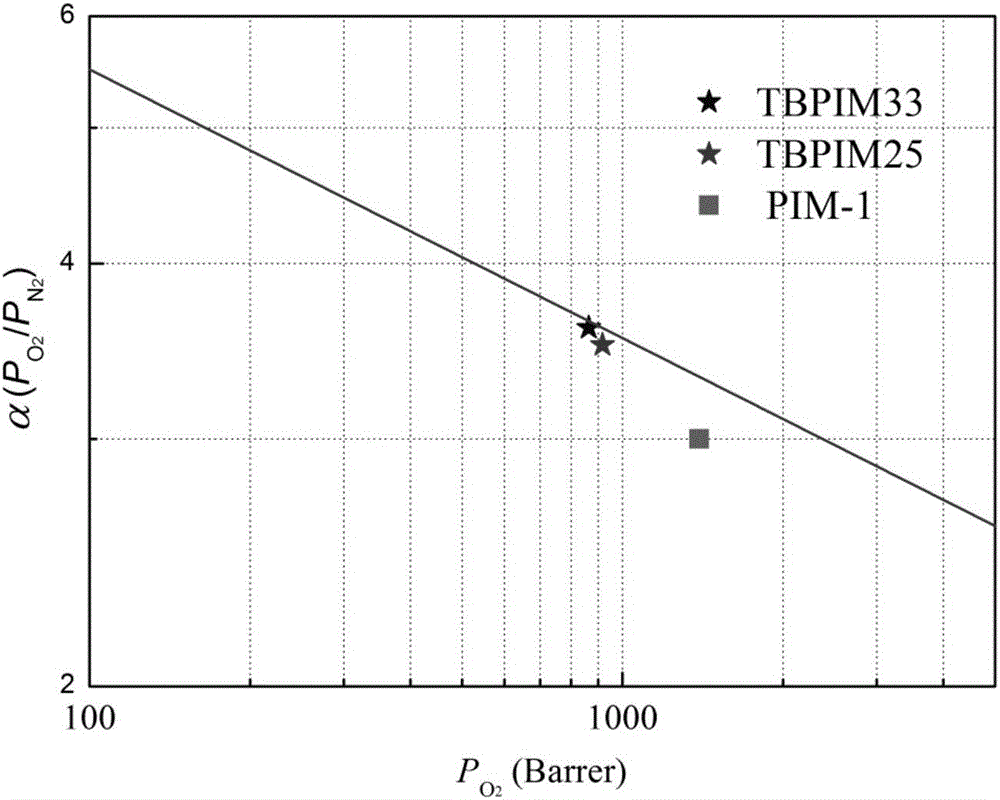

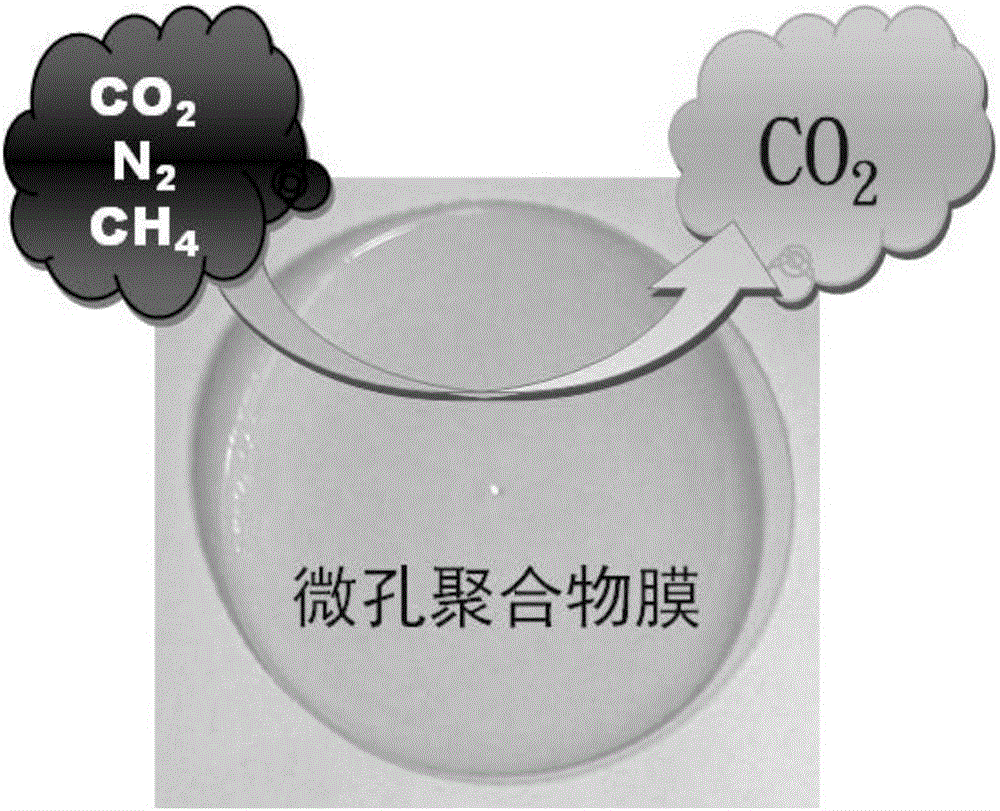

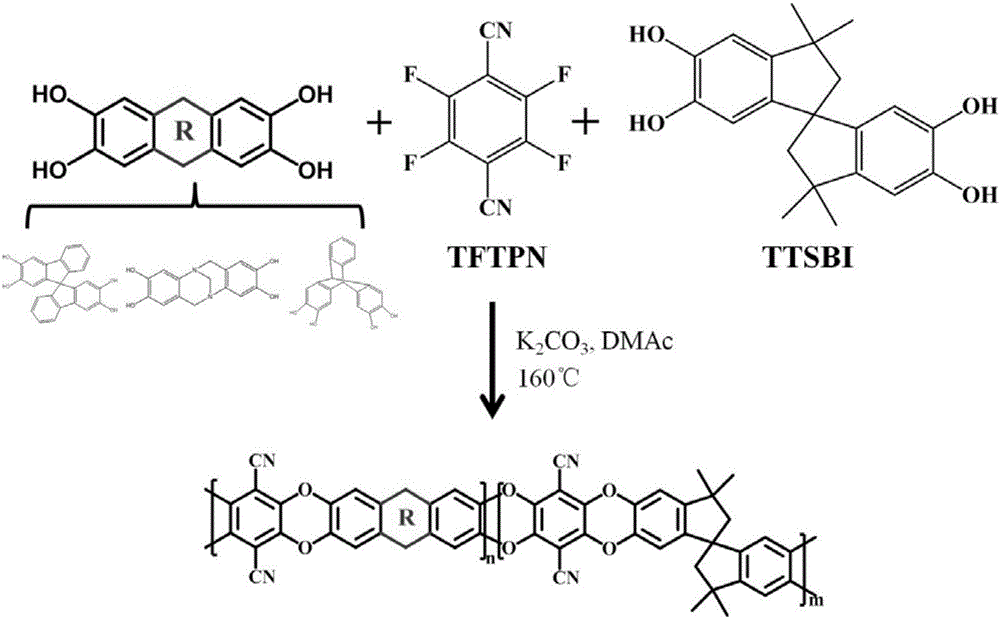

Copolymers of intrinsic microporosity, and preparation method and application thereof

ActiveCN106279672ALarge specific surface areaGood gas permeabilitySemi-permeable membranesMethane captureIndustrial gasOxygen

The invention discloses copolymers of intrinsic microporosity; the copolymers of intrinsic microporosity have the structure represented by the following formula described in the specification, wherein R is at least from substances represented by the following structural formulas, m and n are integers greater than or equal to 0 but are not 0 at the same time, and the ratio of n to m is (0-1) to (0-1). The copolymers are synthesized by a way of polycondensation with a Hitler alkali structure unit as a functional group. The copolymers have the characteristics of high specific surface area, high gas permeability rate, processable solvent and the like, and can be used for forming a test membrane material for a gas permeability rate test device; the membrane material has excellent gas separation performance, especially the separation performance of the oxygen / nitrogen gas pair is close to or beyond the Robeson upper limit updated in 2008, and the membrane material has wide prospect in industrial gas separation application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

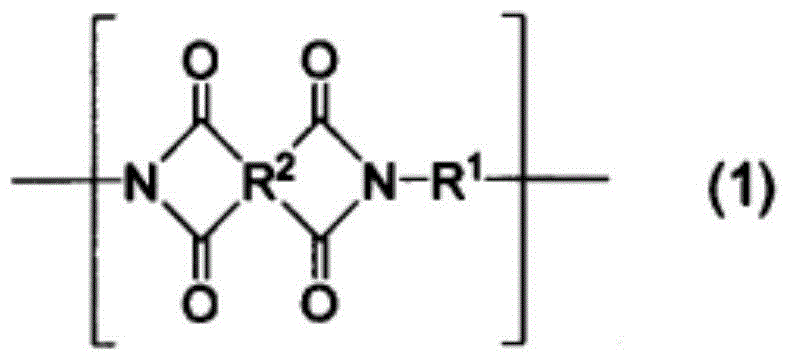

Gas separation membrane

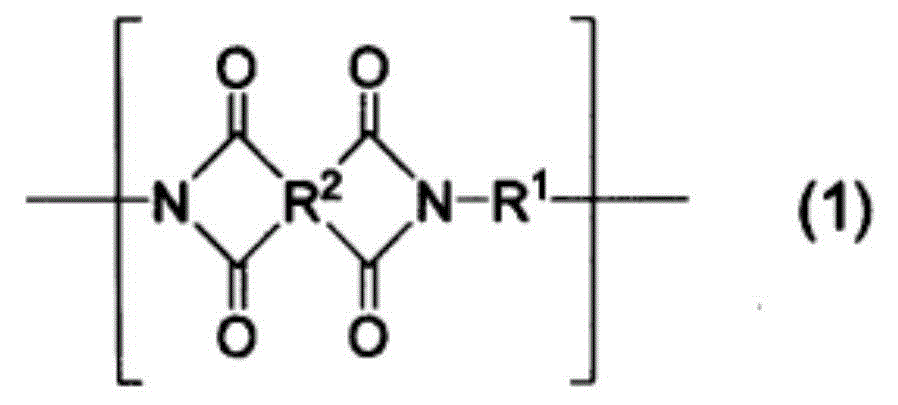

ActiveCN104822444AEasy to separateEasy to manufactureSemi-permeable membranesDispersed particle separationOrganic solventOrganic group

[Problem] The purpose of the present invention is to provide a gas separation membrane which dissolves in an organic solvent, exhibits excellent formability, and exhibits excellent gas-separation performance when used as a gas separation membrane. [Solution] A gas separation membrane having a polyimide structure having a repeating unit represented by general formula (1) (In the formula, R1 represents a bivalent organic group, and R2 represents a tetravalent organic group.), wherein R1 is a bivalent organic group represented by general formula (2) or a bivalent organic group represented by general formula (3).

Owner:CENT GLASS CO LTD

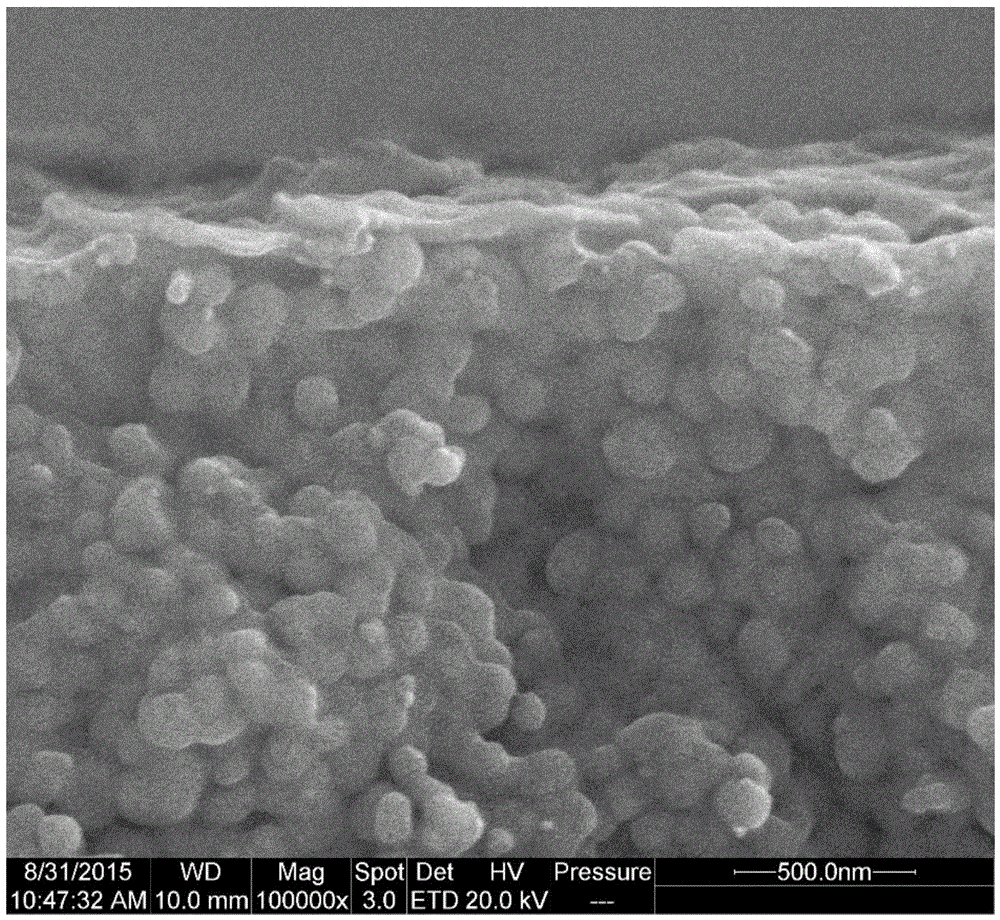

Ultrathin zeolite imidazate skeleton hybrid membrane, preparation method and application thereof

ActiveCN106823849AGood interface compatibilityGood gas separation performanceMembranesSemi-permeable membranesChemistryGas separation

The invention discloses an ultrathin zeolite imidazate skeleton hybrid membrane, a preparation method and application thereof. The hybrid membrane adopts ultrathin zeolite imidazate skeleton nanosheets to be dispersed into an organic solvent, a membrane is firstly formed on the surface of a carrier, and then a polymer membrane is formed on the membrane, so that the hybrid membrane is formed after 1 to 10 times of membrane formation. The ultrathin zeolite imidazate skeleton nanosheets in the zeolite imidazate skeleton hybrid membrane prepared in the invention and an organic polymer are of good interfacial compatibility, so that the hybrid membrane has extremely high gas separation performance. The hybrid membrane disclosed by the invention is simple in synthetic method and high in repeatability, and can be applied to various complex carriers.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

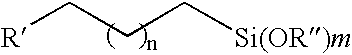

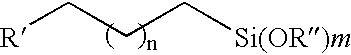

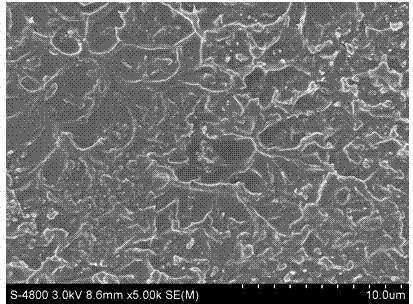

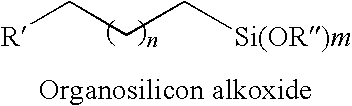

Crosslinked Organic-Inorganic Hybrid Membranes and Their Use in Gas Separation

InactiveUS20090299015A1Good chemical resistanceGuaranteed high pressure stabilitySemi-permeable membranesProductsCellulose acetateOrganic inorganic

The present invention is for crosslinked membranes and in particular for crosslinked poly(ethylene oxide)-cellulose acetate-silsesquioxane (PEO-CA-Si) organic-inorganic hybrid membranes and their use in gas separation. These crosslinked PEO-CA-Si membranes were prepared by in-situ sol-gel co-condensation of crosslinkable PEO-organotrialkoxysilane and CA-organotrialkoxysilane polymers in the presence of acetic acid catalyst during the formation of membranes. The crosslinkable PEO- and CA-organotrialkoxysilane polymers were synthesized via the reaction between the hydroxyl groups on PEO (or on CA) and the isocyanate on organotrialkoxysilane to form urethane linkages under mild conditions. The crosslinked PEO-CA-Si membranes exhibited both increased selectivity of CO2 / N2 and CO2 permeability as compared to a CA membrane, suggesting that these membranes are very promising for gas separations such as CO2 / N2 separation.

Owner:UOP LLC

Hydrogel microsphere-filled hybrid membrane capable of adjusting membrane water content as well as preparation and application thereof

InactiveCN103894080AExtended service lifeEvenly distributedProductsSemi-permeable membranesHydrogel microspheresPermeability coefficient

The invention discloses a hydrogel microsphere-filled hybrid membrane capable of adjusting membrane water content as well as preparation and application thereof. The hybrid membrane consists of hydrogel microspheres and polyimide resin. The preparation process of the hybrid membrane comprises the following steps: preparing the hydrogel microspheres; preparing a polyimide resin solution; feeding the hydrogel microspheres into the polyimide resin solution to prepare a casting membrane solution, and preparing the hybrid membrane. The hybrid membrane has the advantages that the preparation process is simple, and the membrane water content can be simply and conveniently adjusted; the prepared hydrogel microsphere-filled hybrid membrane is even in distribution in the membrane; the compatibility between filled particles and a polymer matrix is better; the water absorption of the hybrid membrane is improved and adjusted by the hydrogel microspheres in the hybrid membrane; the prepared hybrid membrane can be used for separating CO2 / CH4, and is better in separating property under the wet testing condition; the CO2 permeability coefficient is 270 barrer, and the CO2 / CH4 separation selectivity is 59.

Owner:TIANJIN UNIV

Gas separation membrane

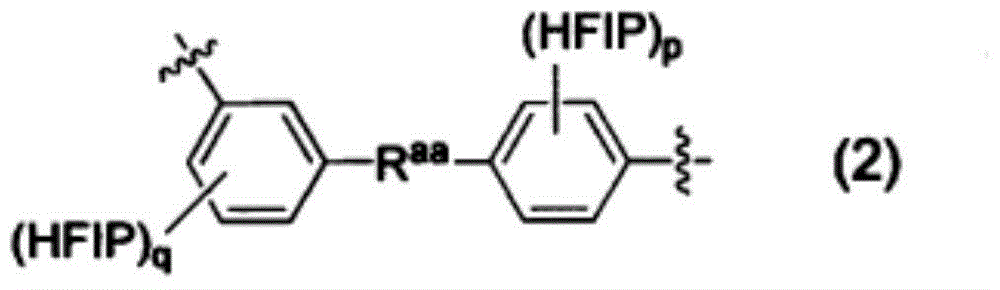

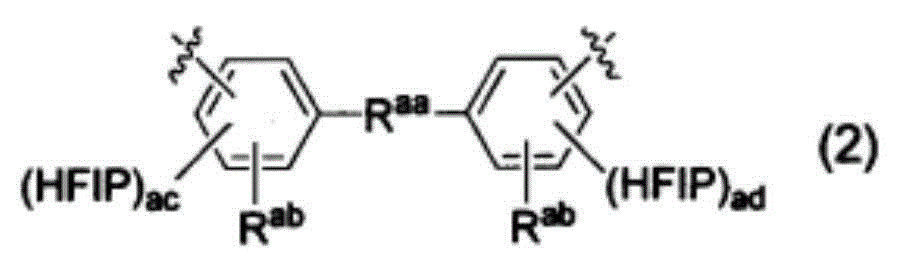

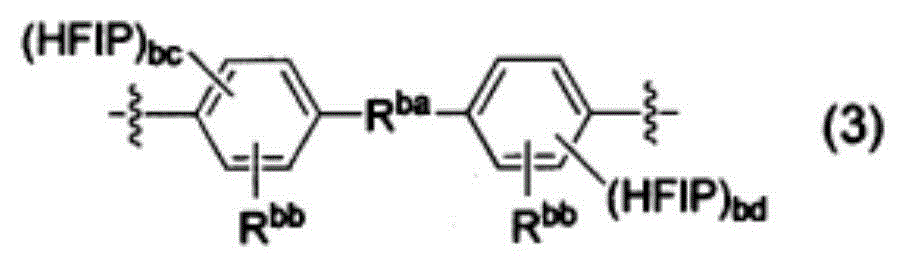

ActiveCN104822445AEasy to separateEasy to manufactureSemi-permeable membranesDispersed particle separationGas separationOrganic solvent

[Problem] To provide a gas separation membrane which dissolves in an organic solvent, exhibits excellent formability, and exhibits excellent gas-separation performance when used as a gas separation membrane. [Solution] A gas separation membrane having a polyimide structure containing a repeating unit represented by general formula (1) (In the formula, R1 represents a bivalent organic group, and R2 represents a tetravalent organic group.), wherein R1 is a bivalent organic group represented by general formula (2) (In the formula, Raa represents a single bond, a sulfur atom, -SO2-, -CH2-, -C(=O)-, -C(CH3)2-, -C(CH3)(CH2CH3)- or -C(CF3)2-, or a bivalent organic group obtained by separating two arbitrary hydrogen atoms from a C3-12 alicyclic hydrocarbon compound or from a C6-25 aromatic hydrocarbon compound. Rab is a C1-6 alkyl group. ac and ad each independently represent an integer of 0-2. 1≤ac+ad≤4. HFIP represents a -C(CF3)2OH group. The line segments intersecting the wavy lines represent the locations of bonds.)

Owner:CENT GLASS CO LTD

Method for preparing polyoxyethylene-introduced cross-linked modified polyimide gas separation membrane

InactiveCN101733026AImprove gas separation performanceImprove throughputSemi-permeable membranesCross-linkPolymer science

The invention relates to polymer separation membrane technology, in particular to a method for preparing a polyoxyethylene-introduced cross-linked modified polyimide gas separation membrane. The method comprises the steps of: 1) performing a cross-linking reaction, namely dissolving polyimide and a cross-linking agent, namely polyether amine into a solvent respectively until a polymer and the cross-linking agent are completely dissolved, mixing two solutions, and then stirring the obtained solution for 5 to 30h to react; and 2) preparing a homogeneous membrane, namely dumping the solution on a polyethylene plate after a complete mixed reaction of the solution, performing drying and film formation at the temperature of between 25 and 60 DEG C, placing the obtained homogeneous membrane into water for 1 to 5 days to remove the unreacted cross-linking agent in the homogeneous membrane, and then placing the membrane into a vacuum baking oven to bake at the temperature of between 50 and 120 DEG C for 5 to 24h, wherein the obtained membrane thickness is between 50 and 150mu m. The method uses the special cross-linking agent, namely the polyether amine to perform comprehensive cross-linking modification on the polyimide, and obtains the homogeneous membrane with excellent CO2 gas separation performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Facilitated transport membrane based on amino acid ionic liquid and preparation method and application of facilitated transport membrane

ActiveCN107875867AEasy to prepareImprove gas separation performanceSemi-permeable membranesGas treatmentIonPolyamide

The invention discloses a facilitated transport membrane based on amino acid ionic liquid and a preparation method and application of the facilitated transport membrane. The facilitated transport membrane based on the amino acid ionic liquid is characterized by adopting a polyether-polyamide block copolymer as a membrane substrate, and 1-hexyl-3-methylimidazole glycinate is added into the membranesubstrate. The facilitated transport membrane has a simple preparation process, and due to 1-hexyl-3-methylimidazole glycinate which is contained in the facilitated transport membrane and provided with an amino group and a carboxyl functional group, the gas separation performance of the facilitated transport membrane can be improved.

Owner:SHIHEZI UNIVERSITY

Hybrid polymeric hollow fiber membrane, hybrid carbon molecular sieve hollow fiber membrane, and processes for preparing the same

ActiveUS20190176090A1Improve gas separation performanceImprove throughputMembranesSemi-permeable membranesMolecular sievePolymer science

The present invention relates to a polymeric hollow fiber membrane and a carbon molecular sieve hollow fiber membrane, both of which have excellent gas separation performance, and processes for preparing the same. Specifically, the present invention relates to a hybrid polymeric hollow fiber membrane that comprises a glassy polymer containing fluorine and a ladder-structured polysilsesquioxane, a hybrid carbon molecular sieve hollow fiber membrane prepared by pyrolysis thereof, and processes for preparing the same. The hybrid polymeric hollow fiber membrane and the hybrid carbon molecular sieve hollow fiber membrane according to the embodiments of the present invention are excellent in gas flux and selectivity and can have a large surface area per unit volume. Thus, they can be advantageously used for separating gases with a high energy efficiency on a large scale.

Owner:SOGANG UNIV RES & BUSINESS DEV FOUND

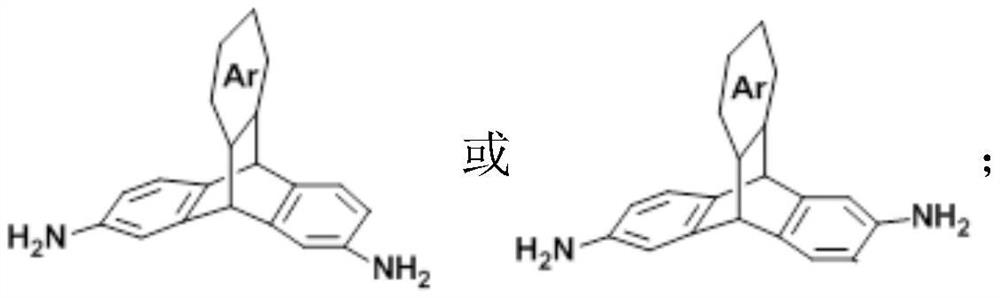

Polyimide for gas separation prepared based on diaminotriptycene and derivatives thereof and preparation method thereof

PendingCN112574412AImprove gas separation performanceGood gas permeabilityProductsReagentsPolymer scienceCarboxylic acid

The invention discloses polyimide prepared based on diaminotriptycene and derivatives thereof and used for gas separation and a preparation method thereof. The polyimide is a copolymer formed by polymerizing one or two diaminotriptycene and one or two tetracarboxylic dianhydrides, or is a copolymer formed by polymerizing one or two diaminotriptycene derivatives and one or two tetracarboxylic dianhydrides, wherein the value range of the polymerization degree of the copolymer is 1-10000. The polyimide has excellent gas separation performance, and can be used as a gas separation film to effectively separate CH4 from a gas mixture of CH4 and CO2 in biogas separation application after being prepared into a film; therefore, a membrane material prepared from the polymer has huge application valuein the field of gas separation. For example, N2 and O2 can be separated from the air. The CO2 is removed in the purification process of natural gas and high-purity CH4 is obtained, so that the polyimide can be used for H2 recovery in the field of ammonia synthesis.

Owner:TIANJIN POLYTECHNIC UNIV

Crosslinked organic-inorganic hybrid membranes and their use in gas separation

InactiveUS7790803B2Improve gas separation performanceInherent disadvantageProductsSemi-permeable membranesAcetic acidCellulose acetate

The present invention is for crosslinked membranes and in particular for crosslinked poly(ethylene oxide)-cellulose acetate-silsesquioxane (PEO-CA-Si) organic-inorganic hybrid membranes and their use in gas separation. These crosslinked PEO-CA-Si membranes were prepared by in-situ sol-gel co-condensation of crosslinkable PEO-organotrialkoxysilane and CA-organotrialkoxysilane polymers in the presence of acetic acid catalyst during the formation of membranes. The crosslinkable PEO- and CA-organotrialkoxysilane polymers were synthesized via the reaction between the hydroxyl groups on PEO (or on CA) and the isocyanate on organotrialkoxysilane to form urethane linkages under mild conditions. The crosslinked PEO-CA-Si membranes exhibited both increased selectivity of CO2 / N2 and CO2 permeability as compared to a CA membrane, suggesting that these membranes are very promising for gas separations such as CO2 / N2 separation.

Owner:UOP LLC

Composite hollow fiber membranes useful for CO2 removal from natural gas

ActiveUS9718031B2Improve adhesionImprove thermal stabilityMembranesSemi-permeable membranesHollow fibreImide

Disclosed herein is a composite hollow fiber polymer membrane including a porous core layer and a selective sheath layer. The porous core layer includes a polyamide-imide polymer, or a polyetherimide polymer, and the selective sheath layer includes a polyimide polymer, which is prepared from monomers A, B, and C. The monomer A is a dianhydride of the formulawherein X1 and X2 are independently halogenated alkyl group, phenyl or halogen and R1, R2, R3, R4, R5, and R6 are independently H, alkyl, or halogen. The monomer B is a diamino cyclic compound without a carboxylic acid functionality and the monomer C is a diamino cyclic compound with a carboxylic acid functionality. The polyimide polymer further includes covalent ester crosslinks. Also disclosed herein is a method of making the composite polymer membrane and a process for purifying natural gas utilizing the composite polymer membrane.

Owner:GEORGIA TECH RES CORP

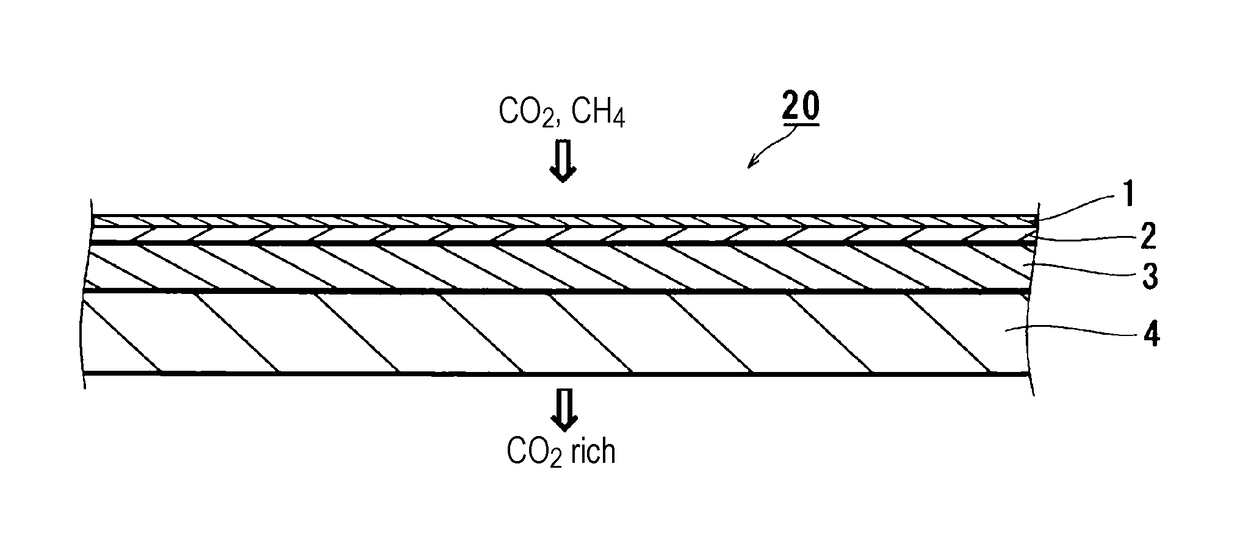

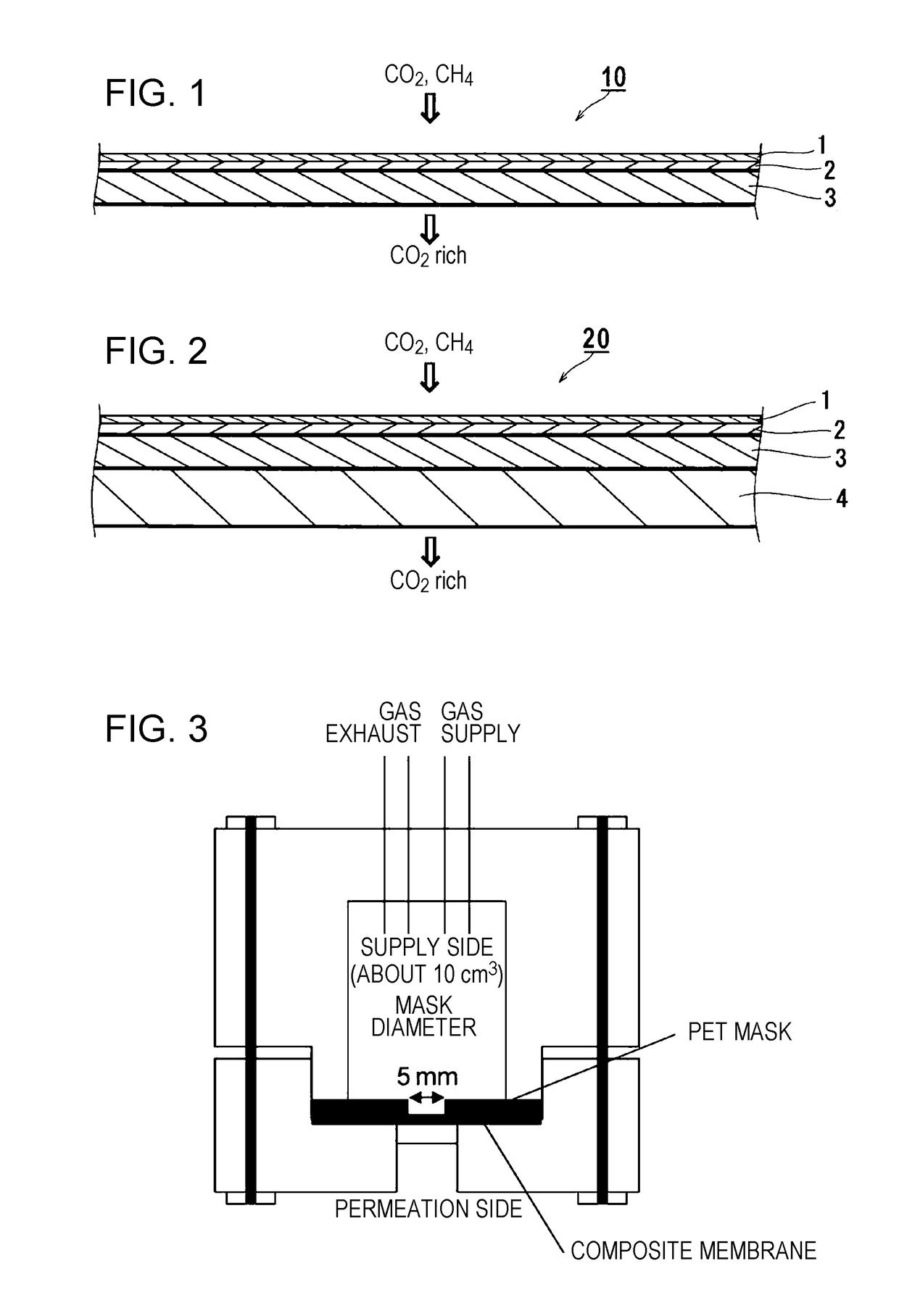

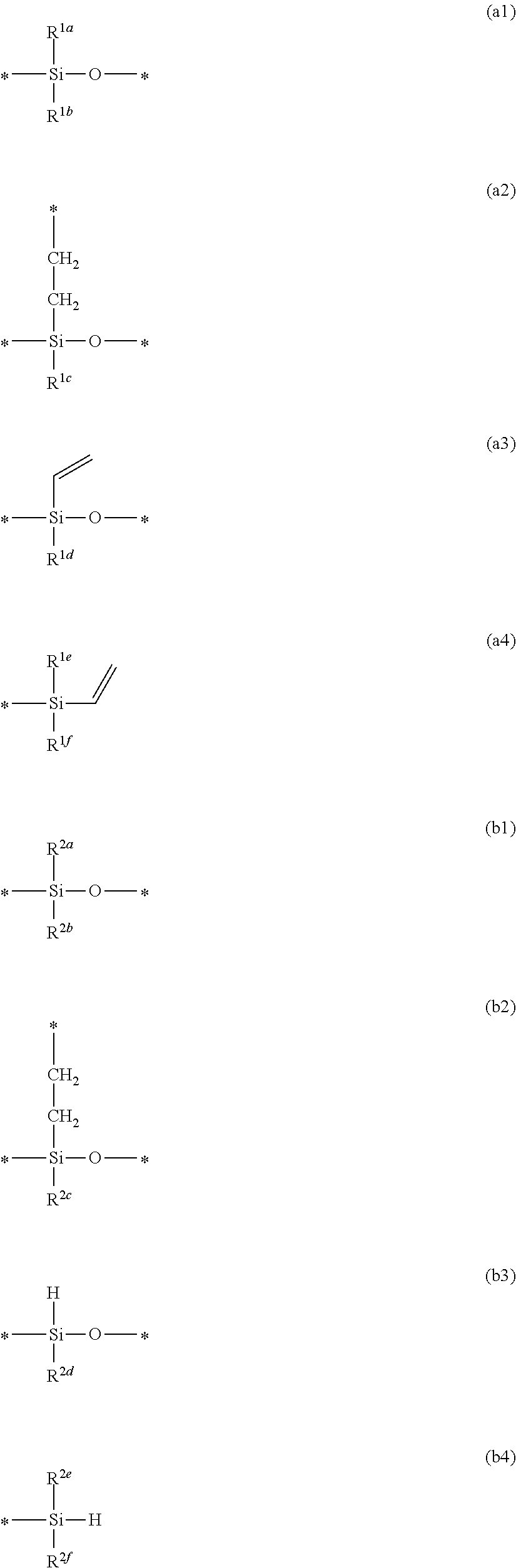

Method for producing gas separation composite membrane, liquid composition, gas separation composite membrane, gas separation module, gas separation apparatus, and gas separation method

ActiveUS20180147546A1High yieldLow sample error percentageSemi-permeable membranesMembranesStructural unitLiquid composition

The method for producing a gas separation composite membrane includes applying a mixed liquid containing compounds (a) and (b) below onto a porous support to form a coating film and curing the coating film to form a crosslinked polysiloxane compound layer:(a) a particular crosslinkable polysiloxane compound having a structural unit (a1), a structural unit (a2), and a structural unit (a3) or (a4), and(b) a particular crosslinkable polysiloxane compound having a structural unit (b1), a structural unit (b2), and a structural unit (b3) or (b4),where R1a to R1f and R2a to R2f represent a particular group and * represents a particular linking site.

Owner:FUJIFILM CORP

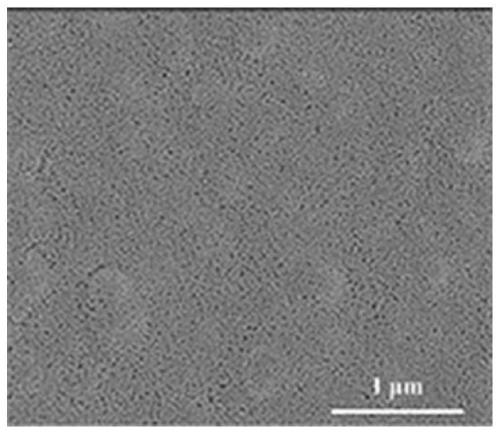

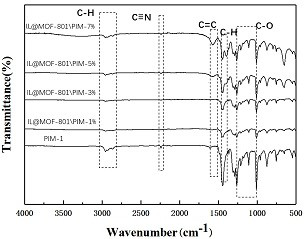

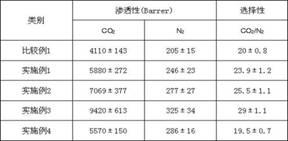

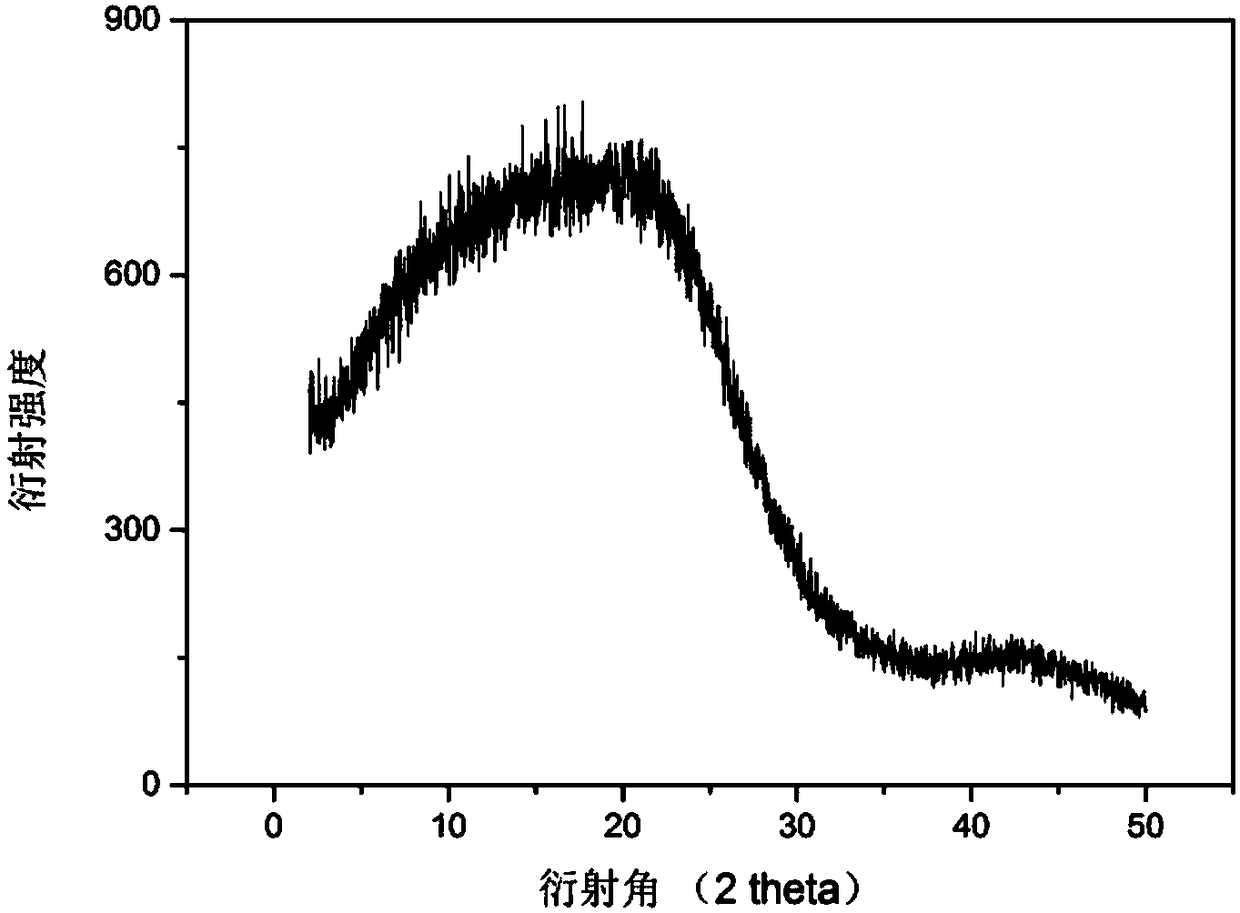

Gas separation membrane containing MOF composite material, and preparation method thereof

InactiveCN112007527AImprove gas permeabilityImprove permeabilitySemi-permeable membranesGas treatmentGas separationCompositermes

The invention relates to a mixed matrix gas separation membrane material and a preparation method thereof. The mixed matrix gas separation membrane is composed of a metal-organic framework composite material and a polymer matrix, wherein a filler is an MOF-801\IL composite material with a three-dimensional structure, the polymer matrix is a microporous polymer PIM-1 with high permeability, and themass percent of the MOF-801\IL composite material with the microporous structure in the mixed matrix gas separation membrane material is 1-7%. The MOF-801\IL composite material has good affinity to CO2, and the three-dimensional porous structure of the MOF-801\IL composite material provides a selective rapid transportation channel for the passage of CO2. Meanwhile, the self-microporous polymer PIM-1 also has relatively good air permeability, and the two components are mixed to synergistically adjust gas permeability and selectivity, so the prepared novel PIM-1 mixed matrix gas separation membrane containing the MOF-801\IL composite material has relatively good gas permeability and separation performance, has good thermal stability and physical aging resistance, and has a wide applicationprospect.

Owner:CHANGCHUN UNIV OF TECH

Metal organic framework film with polymer as ligand

InactiveCN108114696ALow costImprove solubilitySemi-permeable membranesGas treatmentPolymer scienceMetal framework

The invention discloses a metal organic framework film with a polymer as a ligand. A reaction is carried out on film-forming raw materials obtained by mixing metal ions, polymer ligands and a solvent,and then the formed film is dried to obtain the metal organic framework film, wherein the film-forming raw material is a uniform mixture of the metal ions, the polymer ligands and the solvent. According to the metal organic framework film with the polymer as the ligand, the advantages of a conventional organic metal framework material and a polymer material are sufficiently combined. The metal organic framework film provided by the invention has high preparation repeatability, and the prepared product film has excellent gas separation performance, and has a wide application prospect in the field of gas separation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

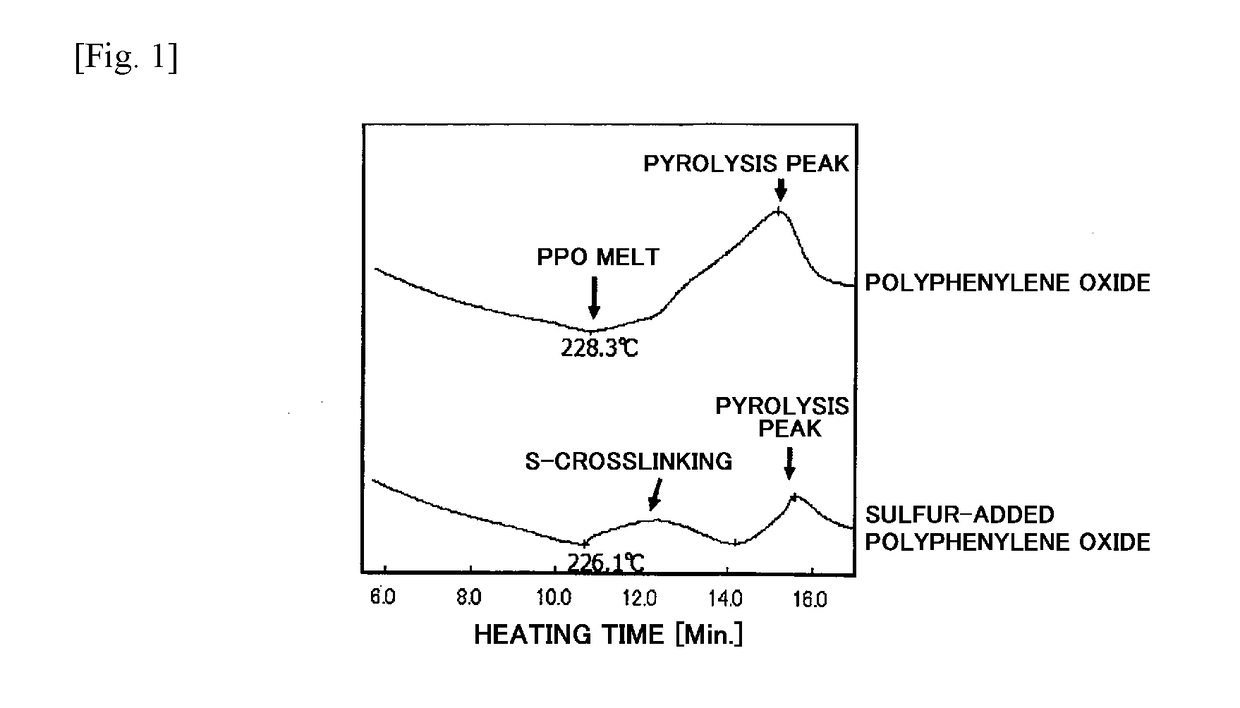

Method for producing a carbon hollow fiber membrane

ActiveUS20170320020A1Good effectImprove gas separation performanceSemi-permeable membranesLiquid surface applicatorsNon solventHollow fibre membrane

A hollow fiber carbon membrane is produced by preparing a membrane-forming dope for carbon membranes by dissolving polyphenylene oxide in an amount giving a concentration of 15 to 40 wt. % in the membrane-forming dope, and sulfur in an amount giving a ratio of 0.2 to 3.0 wt. % based on the polyphenylene oxide, in a solvent capable of dissolving these components; preparing the membrane-forming dope for carbon membranes into a hollow shape by means of a spinning method in accordance with a non-solvent induced separation method using a double annular nozzle; performing a crosslinking treatment at 200 to 240° C. in the air; then performing an infusibilization treatment by heating at 250 to 350° C.; and further performing a carbonization treatment by heating at 450 to 850° C. in an inert atmosphere or under vacuum.

Owner:NOK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com