Facilitated transport membrane based on amino acid ionic liquid and preparation method and application of facilitated transport membrane

A technology that promotes the transfer of membranes and ionic liquids, applied in the field of membrane separation, can solve problems such as limiting the application field of FTMs, and achieve the effect of improving gas separation performance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare a facilitated transport membrane based on amino acid ionic liquid, the thickness of the facilitated transport membrane is 110 μm, the facilitated transport membrane uses polyether-polyamide block copolymer as the membrane matrix, and 1-hexyl 3-methanol is added to the membrane matrix Glycine salt of imidazole, wherein, the mass ratio of polyether-polyamide block copolymer to 1-hexyl 3-methylimidazole glycinate is 1:0.2, and the specific preparation method is as follows:

[0021] Step 1, take by weighing 0.5g polyether-polyamide block copolymer (trade name is 1657) was dissolved in 12 g of a 70% ethanol aqueous solution, stirred at 80° C. for 24 h, so that the polyether-polyamide block copolymer was completely dissolved, and the prepared polyether-polyamide block copolymer was 4% in mass fraction solution, set aside.

[0022] Step 2. Weigh 0.1 g of 1-hexyl 3-methylimidazolium glycinate and add it to the 4% polyether-polyamide block copolymer solution obtained i...

Embodiment 2

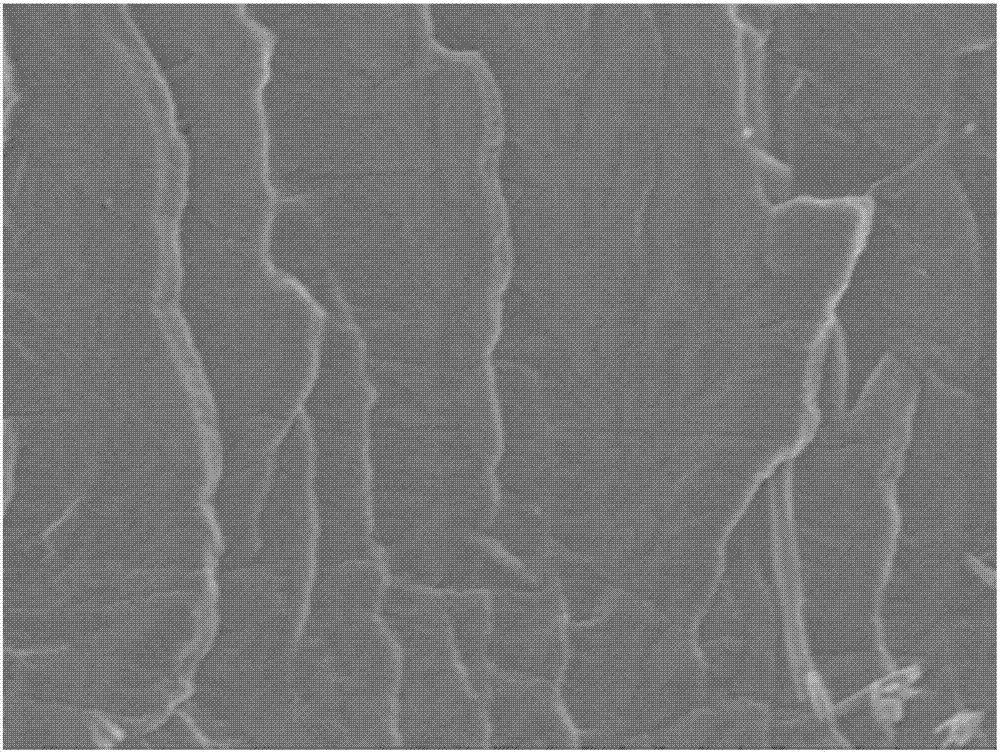

[0025] Prepare a kind of facilitated transport membrane based on amino acid ionic liquid, the difference with embodiment 1 facilitated transport membrane is: the thickness of membrane is 120 μ m, wherein, polyether-polyamide block copolymer and 1-hexyl 3-methylimidazole The mass ratio of glycine salt is 1:0.4, the difference between the preparation of this facilitated transport membrane and the preparation method of Example 1 is that in step 1, 0.1 g of 1-hexyl 3-methylimidazolium glycinate is replaced by 0.2 g of 1-hexyl 3-methylimidazolium glycinate; a facilitated transport membrane with a thickness of 120 μm was finally obtained. figure 2 It is the scanning electron microscope sectional view of the polyether-polyamide block copolymer-1-hexyl 3-methylimidazolium glycinate facilitated transport membrane prepared in Example 2.

[0026] At room temperature and 2bar conditions, the facilitated transport membrane prepared in Example 2 was used to separate CO 2 10% CO by volume ...

Embodiment 3

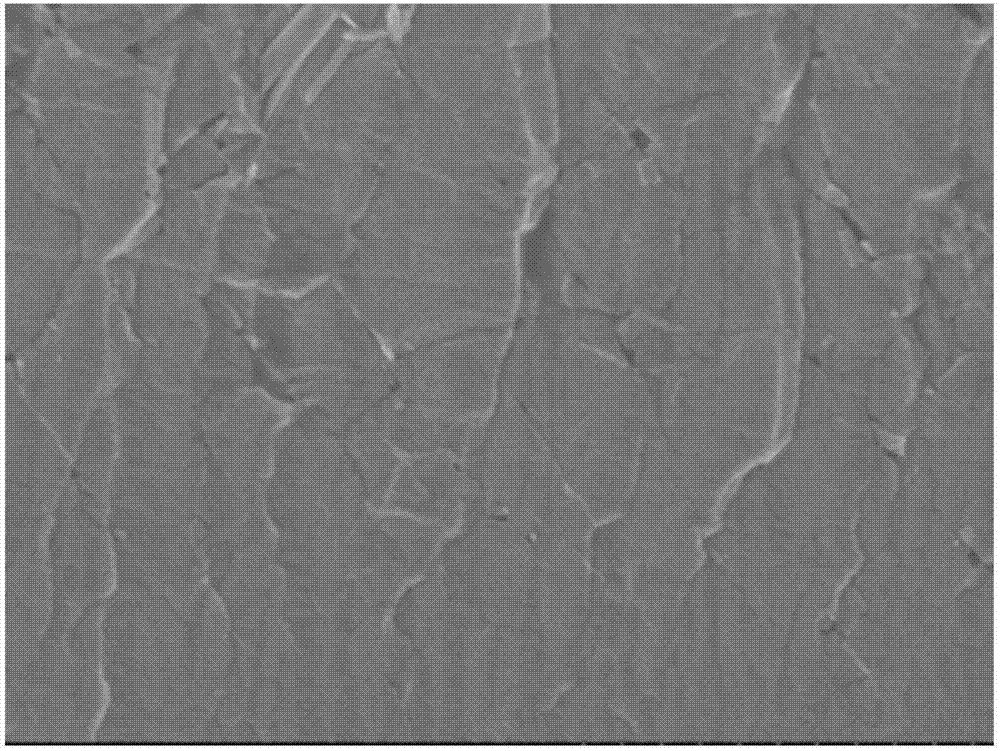

[0028] Prepare a kind of facilitated transport membrane based on amino acid ionic liquid, the difference with embodiment 1 facilitated transport membrane is: the thickness of membrane is 138 μ m, wherein, polyether-polyamide block copolymer and 1-hexyl 3-methylimidazole The mass ratio of glycinate is 1:0.6. The difference between the preparation of this facilitated transport membrane and the preparation method of Example 1 is that in step 1, 0.1 g of 1-hexyl 3-methylimidazolium glycinate is replaced by 0.3 g of 1-hexyl 3-methylimidazolium glycinate; finally a facilitated transport membrane with a thickness of 138 μm was obtained. image 3 It is the scanning electron microscope sectional view of the polyether-polyamide block copolymer-1-hexyl 3-methylimidazolium glycinate facilitated transport membrane prepared in Example 3.

[0029] At room temperature and 2bar conditions, the facilitated transport membrane prepared in Example 2 was used to separate CO 2 10% CO by volume 2 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com