Modified metal organic framework nano-sheet and preparation method thereof

A metal-organic framework and organic framework technology, applied in the field of membrane separation, can solve the problems of macromolecular gas diffusion, gas separation selectivity decline, layer gap increase, etc., to achieve high gas separation performance, good universality, and repeatability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Zn 2 (bim) 4 Preparation of layered precursors

[0050] Dissolve 0.612 g of zinc chloride in 23 ml of N,N-dimethylformamide and stir for 20 minutes;

[0051] Dissolve 0.354 g of benzimidazole in a mixture of 23 ml of N,N-dimethylformamide and 0.22 g of diethylamine, and stir for 20 minutes;

[0052] Pour the latter solution into the former solution, stir for 5 minutes, Zn 2+ , The molar ratio of benzimidazole, diethylamine and N,N-dimethylformamide is 1.5:1:1:200;

[0053] The mixed solution was transferred to a reaction kettle, reacted at 130°C for 42 hours, centrifuged to obtain the reaction product, dispersed with methanol several times, centrifuged, and dried overnight at 60°C.

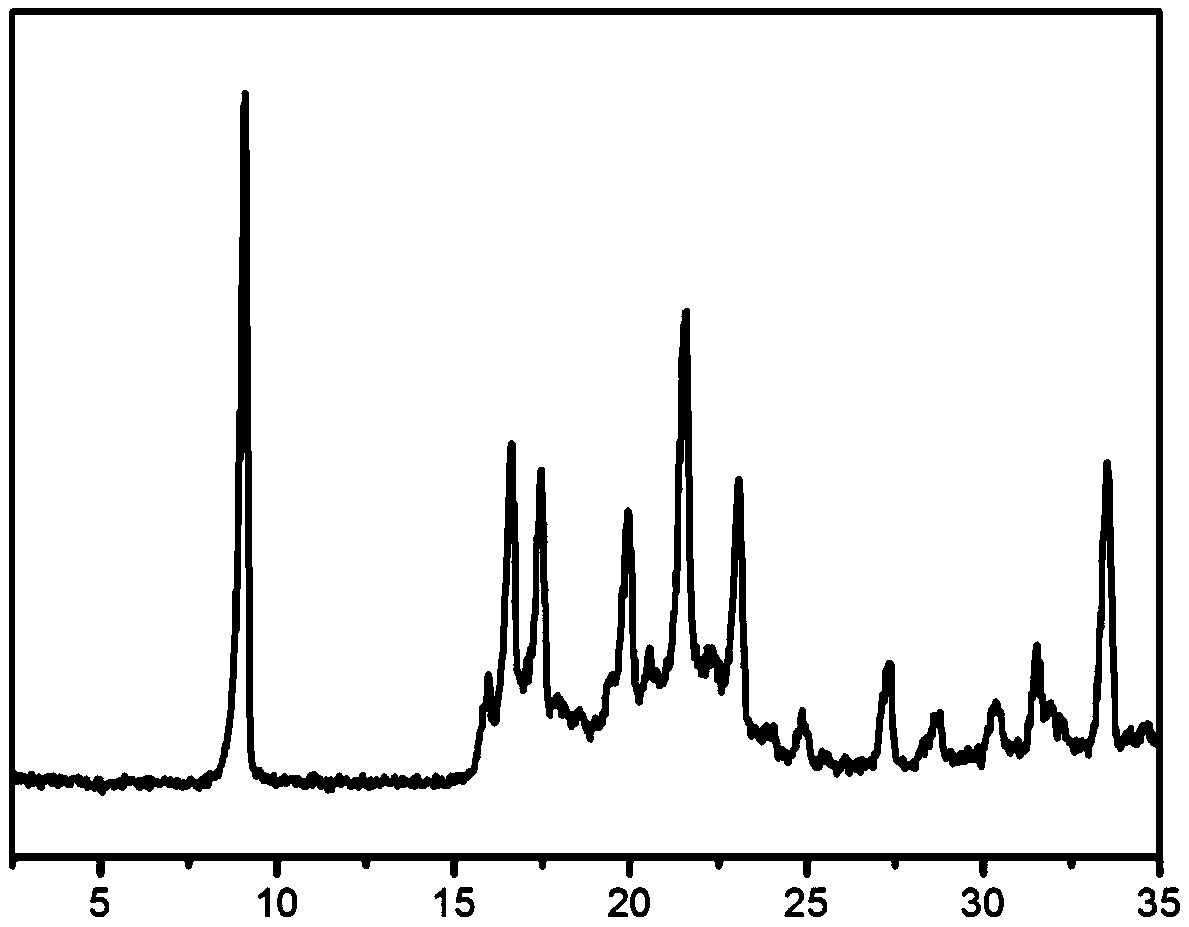

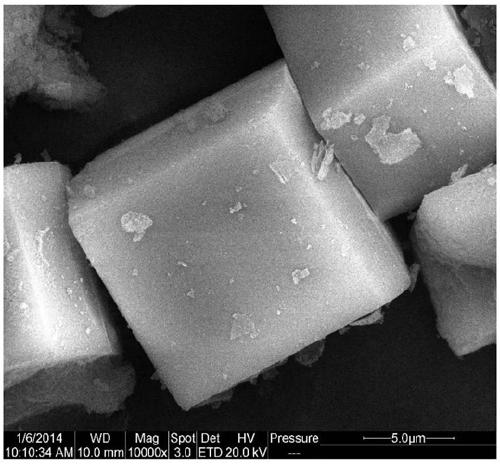

[0054] X-ray diffraction confirms that the product has a c-axis orientation stacked layered structure (see figure 1 ), and its (002) characteristic peak appears near 9°; scanning electron microscope pictures show that the particle size of the product is micron order, with obvious shar...

Embodiment 2

[0056] Zn 2 (Bim) 3 preparation of

[0057] Mix 3 grams of zinc nitrate hexahydrate and 0.6 grams of benzimidazole and add them to 90 milliliters of N,N-dimethylformamide, dissolve them evenly in a water bath with ultrasonic waves, transfer them to a reaction kettle, and react at 100 degrees Celsius for 72 hours. After repeated centrifugation and washing with methanol, the product was first dried at 60°C overnight, and then dried in a vacuum oven at 150°C for 24 hours.

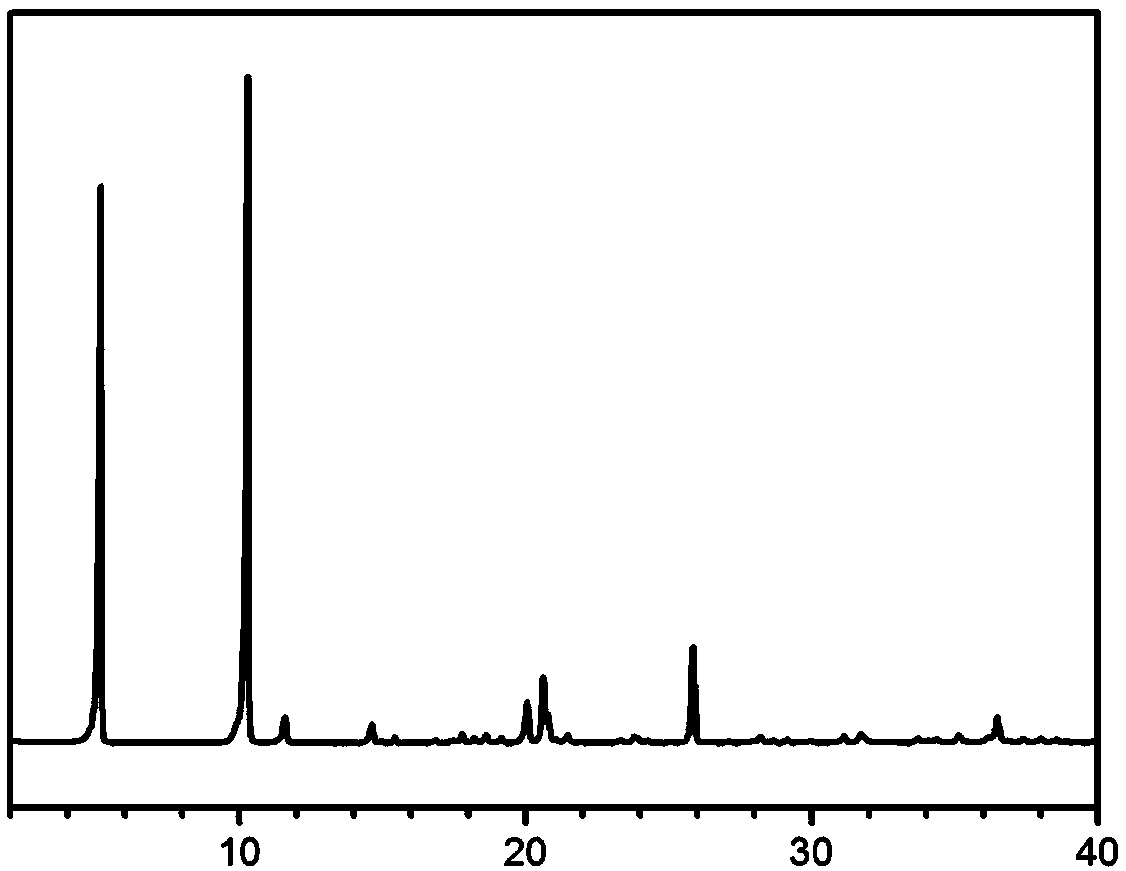

[0058] X-ray diffraction showed that the product had a layered crystal structure (see image 3 ), the scanning electron microscope photo shows that the Zn 2 (bim) 3 The particles are diamond-like in shape, with obvious layered structure (see Figure 4 ).

Embodiment 3

[0060] Two-dimensional Zn 2 (bim) 4 Preparation of nanosheets

[0061] Take by weighing 0.025 gram of embodiment 1 gained Zn 2 (bim) 4 Add 10 milliliters of methanol to the powder before layering, dilute to 250 milliliters with methanol after grinding at 60 rpm for 1 hour, and ultrasonicate in a circulating water bath at 600 watts for 30 minutes to obtain Zn 2 (bim) 4 The nanosheet dispersion before layering was left to stand for a week to precipitate unexfoliated blocky large particles.

[0062] Atomic force microscope pictures show that the thickness of nanosheets is 1-4 nm, and it is 1-4 layers of nanosheets (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com