Gas separation membrane containing MOF composite material, and preparation method thereof

A technology for gas separation membranes and composite materials, which is applied to gas separation membranes containing MOF composite materials and their preparation, and the field of membrane materials, which can solve the problems of low selectivity, limited practical application, and difficult accumulation of molecular chains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

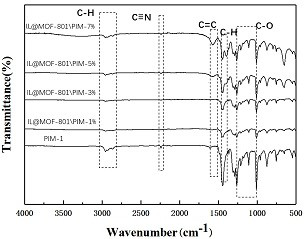

Method used

Image

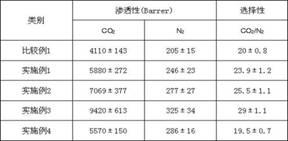

Examples

Embodiment 1

[0018] (1) Add 50mmol of fumaric acid and 50mmol of zirconium oxychloride octahydrate into the reaction kettle, and the solvent is a mixed solvent of N,N-dimethylformamide and formic acid (20:7 by volume). Then put the reaction kettle in an oven at 130°C for 6 hours. The resulting white precipitate was soaked in 100 ml of methanol for 72 hours, and then washed three times with an appropriate amount of N,N-dimethylformamide. Finally, the white precipitate was dried at 150 °C for 48 hours to obtain pure MOF-801 particles, and then MOF-801 was impregnated in IL methanol solution to prepare MOF-801\IL composites.

[0019] (2) Under nitrogen protection, add 0.005mol (1.702g) 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'- into the reaction vessel Spiral biindole, 0.005mol (1.005g) tetrafluoroterephthalonitrile, 1.658g anhydrous potassium carbonate, 7.5ml NMP, and 2.5ml toluene were mixed together, heated and stirred at 165°C for 4 hours to obtain the crude product, and re- Dis...

Embodiment 2

[0023] (1) Add 100mmol of fumaric acid and 100mmol of zirconium oxychloride octahydrate into the reaction kettle, and the solvent is a mixed solvent of N,N-dimethylformamide and formic acid (20:7 by volume). Then put the reaction kettle in an oven at 130°C for 6 hours. The resulting white precipitate was soaked in 200 ml of methanol for 72 hours, and then washed three times with an appropriate amount of N,N-dimethylformamide. Finally, the white precipitate was dried at 150 °C for 48 h to obtain pure MOF-801 particles, and then MOF-801 was impregnated in IL methanol solution to prepare MOF-801\IL composites.

[0024] (2) Under nitrogen protection, add 0.01mol (3.404g) 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'- into the reaction vessel Spiral biindole, 0.01mol (2.01g) tetrafluoroterephthalonitrile, 3.316g anhydrous potassium carbonate, 15ml NMP, and 5ml toluene were mixed together, heated and stirred at 165°C for 4 hours to obtain a crude product, which was redissolved ...

Embodiment 3

[0028] (1) Add 200mmol of fumaric acid and 200mmol of zirconium oxychloride octahydrate into the reactor, and the solvent is a mixed solvent of N,N-dimethylformamide and formic acid (20:7 by volume). Then put the reaction kettle in an oven at 130°C for 6 hours. The resulting white precipitate was soaked in 400 ml of methanol for 72 hours, and then washed three times with an appropriate amount of N,N-dimethylformamide. Finally, the white precipitate was dried at 150 °C for 48 h to obtain pure MOF-801 particles, and then MOF-801 was impregnated in IL methanol solution to prepare MOF-801\IL composites.

[0029] (2) Under nitrogen protection, add 0.02mol (6.808g) 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'- into the reaction vessel Spiral biindole, 0.02mol (4.02g) tetrafluoroterephthalonitrile, 6.632g anhydrous potassium carbonate, 30ml NMP, and 10ml toluene were mixed together, heated and stirred at 165°C for 4 hours to obtain a crude product, which was redissolved in Chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com