Metal organic framework film with polymer as ligand

A metal-organic framework and polymer technology, applied in the field of membrane separation, can solve the problems of limited industrial application, unstable cost of metal-organic framework membrane materials, etc., and achieve the effects of low cost, easy amplification and good solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation of film-forming raw materials:

[0038] Weigh 1.8378 grams of zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) was dissolved in 10 ml of dimethyl sulfoxide (DMSO), and 0.9 g of polybenzimidazole was dissolved in 10 ml of DMSO. Add the former to the latter and mix under airtight condition and stir at room temperature for 1 hour to obtain a film-forming raw material solution.

[0039] 2. Film forming reaction:

[0040] The raw material solution prepared in step 1 was sealed and placed in a blast drying oven to naturally raise the temperature to 100° C. and react for 72 hours to obtain a film-forming solution.

[0041] 3. Squeeze coating and dry to form a film:

[0042] The surface of the film scraping machine is naturally heated to 80°C, the scraper is set to 250 microns, and the scraping speed is set to 50 mm / s. Gently push the side with glass to the other side to prepare a film, and dry it with the surface of the film scraping machine at 80°C for 24 hours. A...

Embodiment 2

[0046] 1. Weigh 0.332 gram of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) was dissolved in 10 ml of dimethyl sulfoxide (DMSO), and 0.9 g of polybenzimidazole was dissolved in 10 ml of DMSO. Add the former to the latter and mix under airtight condition and stir at room temperature for 1 hour to obtain a film-forming raw material solution. Then, according to the method of Steps 2-3 of Example 1, the metal-organic framework membrane product B using the polymer as a ligand was prepared.

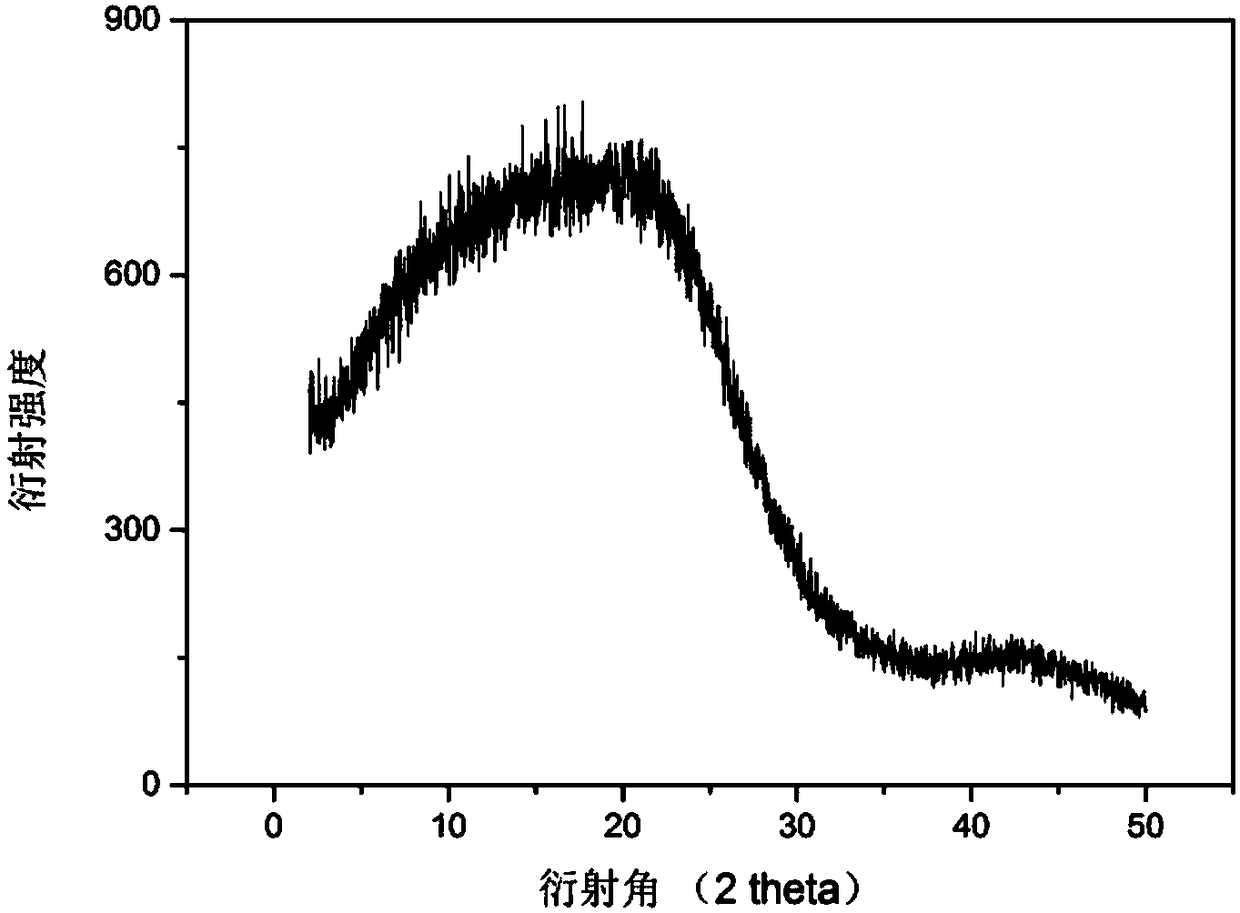

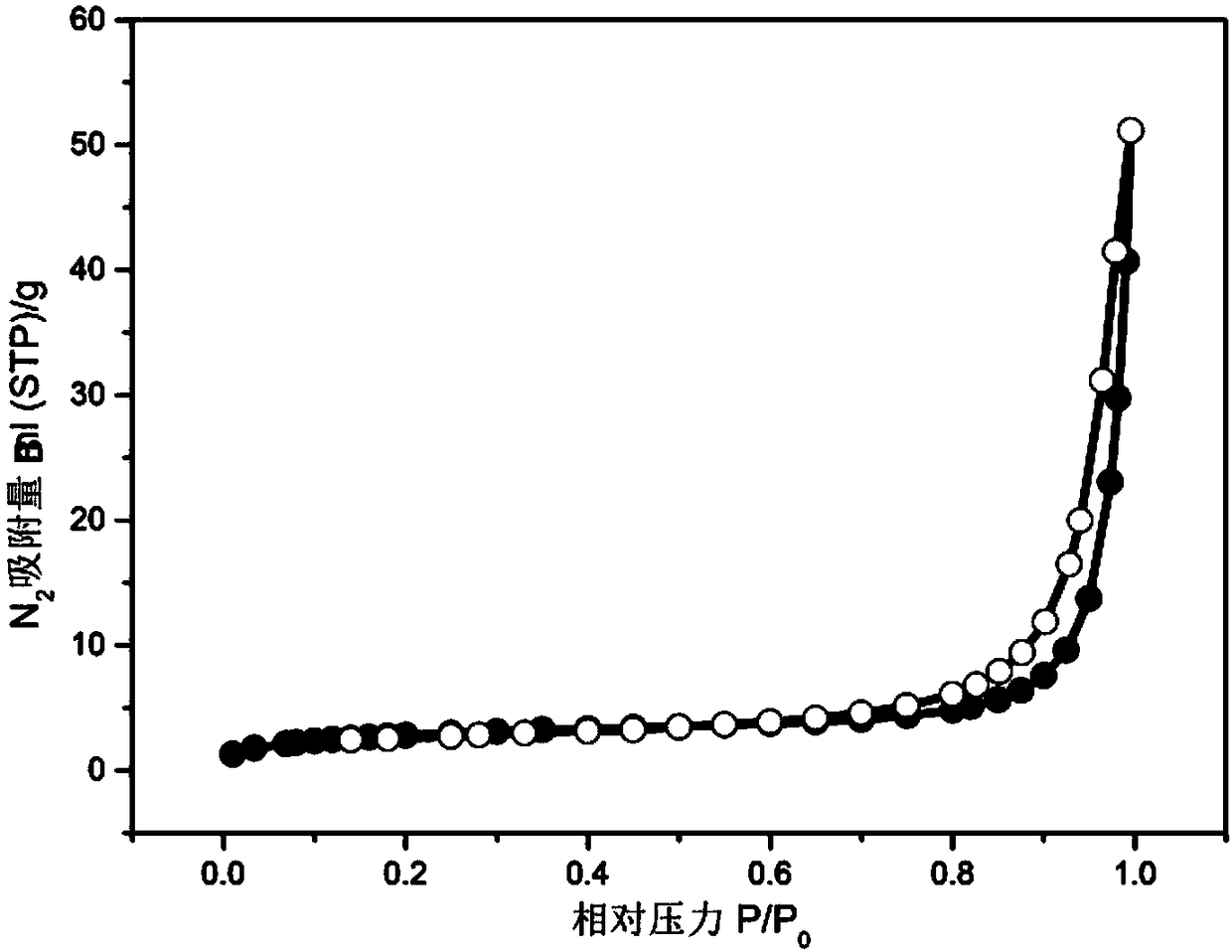

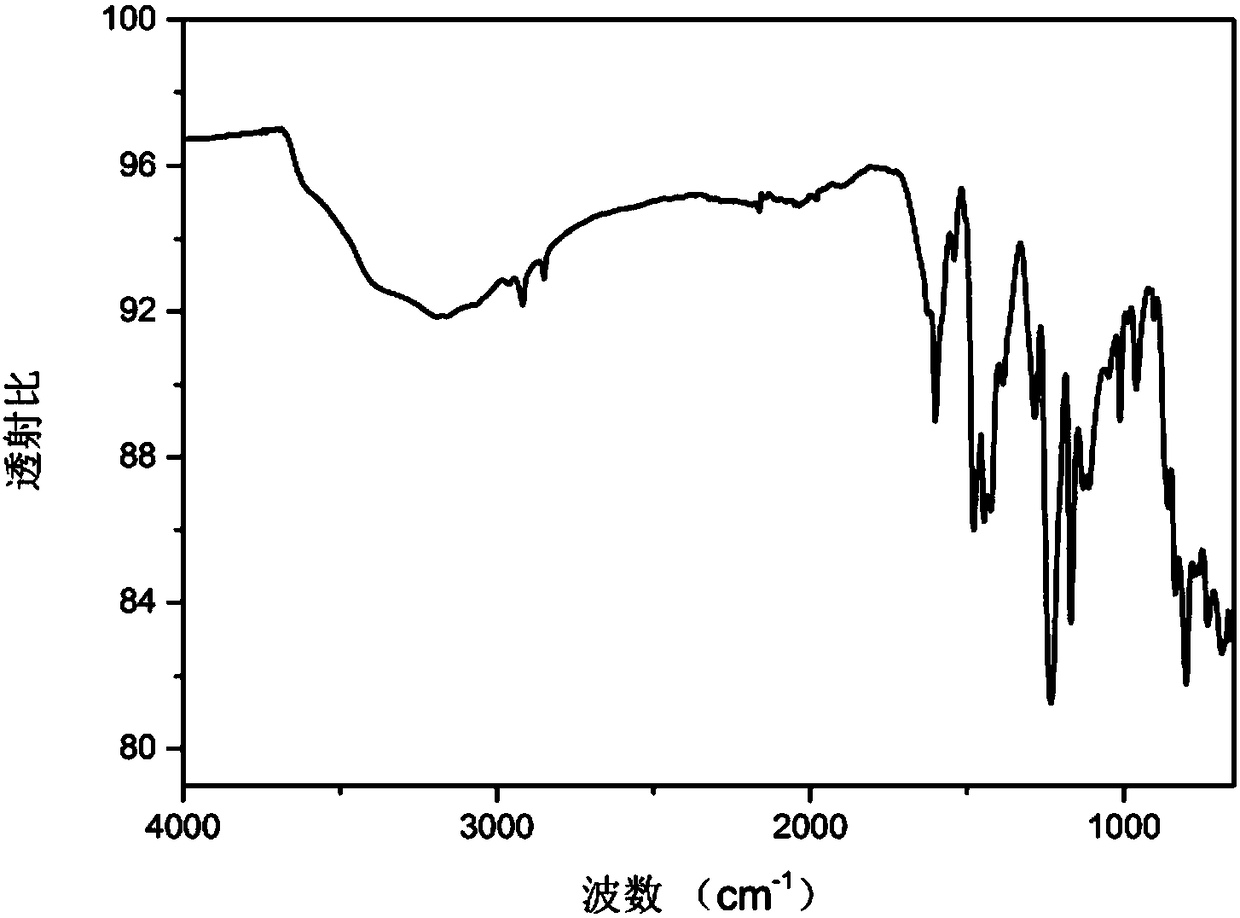

[0047] The X-ray diffraction pattern of the prepared product B is as follows Figure 7 As shown, with the polymer polybenzimidazole ligand (such as figure 1 ) shows that there are obvious diffraction peaks at about 10 degrees, and new peaks appear, which proves that a new substance has been formed, and the crystal form of the substance is inconsistent with polybenzimidazole itself, so it can be judged that a new Metal-organic framework membrane materials. N of product B 2 The results o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com