Sulfonated poly(ether ether ketone)-sulfonated silicon dioxide microsphere hybrid membrane, as well as preparation and application of membrane

A technology of sulfonated polyether ether ketone and sulfonated silica, which is applied in the field of sulfonated polyetheretherketone-sulfonated silica microsphere hybrid membrane and its preparation and application, can solve the problem of gas separation and has not been reported in the literature and other problems, to achieve excellent gas separation performance, increased strength, and the effect of simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of a sulfonated polyether ether ketone-sulfonated silica microsphere hybrid membrane with a thickness of about 60 μm

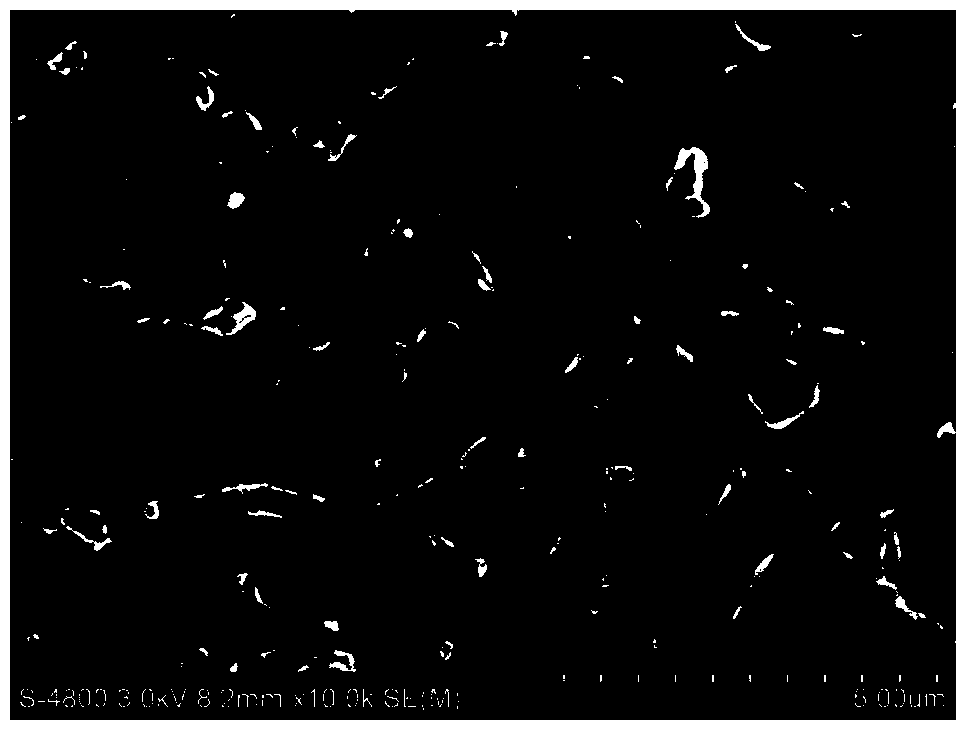

[0035] (1) Preparation of sulfonated silica microspheres

[0036] first use Methods Synthesis of silica spheres with a diameter of about 300nm: Disperse 12mL of TEOS and 20mL of ammonia water with a mass fraction of 25% in 200mL of absolute ethanol, and stir at room temperature for 24h. Then 1.0 mL of 3-(trimethoxysilyl)propyl-2-methyl-2-acrylate was added to the above solution, and stirring was continued at room temperature for 24 h. Centrifuge, wash with water three times and ethanol once, and dry to obtain double bond-modified silica microspheres.

[0037] Sulfonated silica microspheres were prepared by precipitation co-distillation method, and the specific process was as follows: 0.30 g of the double bond-modified silica microspheres obtained above, 0.40 g of sodium styrene sulfonate, 0.40 mL of styrene and 2,2 - Disperse ...

Embodiment 2

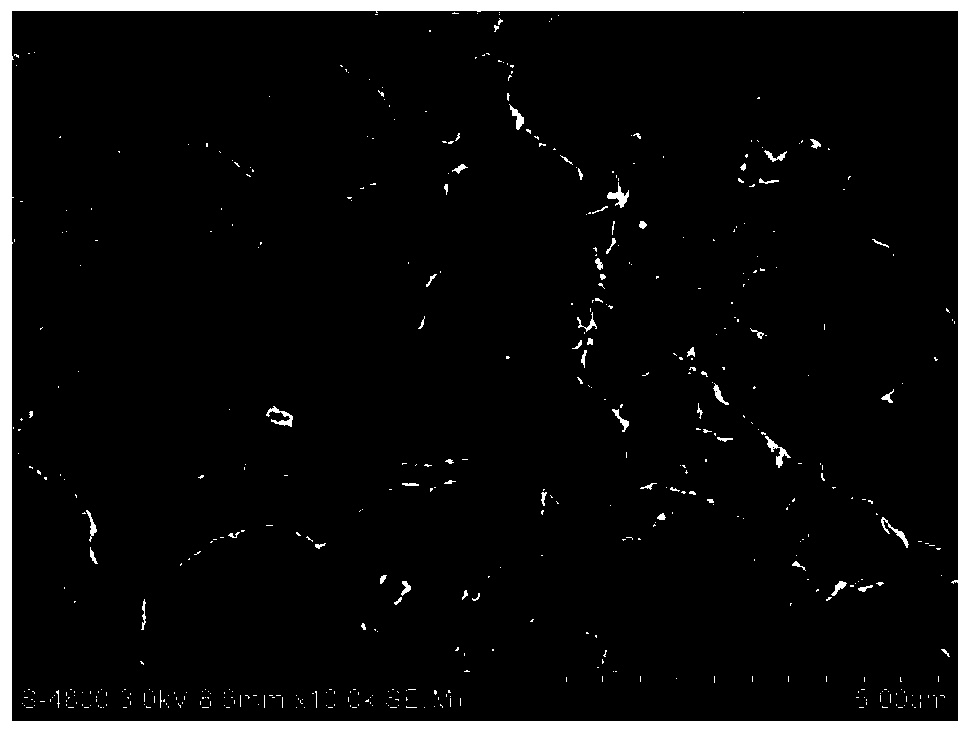

[0045] Example 2: Preparation of a sulfonated polyether ether ketone-sulfonated silica microsphere hybrid membrane with a thickness of about 65 μm

[0046] Weigh 0.6 g of sulfonated polyether ether ketone and 6 g of N,N-dimethylacetamide with a sulfonation degree of 65%, and stir at room temperature for 12 hours under magnetic stirring at 500 r / min to dissolve all the polymers to obtain sulfonated polyether ether ketone solution. Add 0.06 g of the aminated silica microspheres prepared in Example 1, add 4 g of DMAc, ultrasonicate for 24 h, add to the above sulfonated polyether ether ketone solution, stop stirring after 12 h, filter with a copper mesh, and let stand for 2 h to remove Soak the sulfonated polyether ether ketone-sulfonated silicon micro-casting solution, pour the casting solution into a clean glass Petri dish (Φ100mm), place it in an oven, and dry it at 60°C and 80°C for 12 hours respectively , to obtain a homogeneous sulfonated polyether ether ketone-sulfonated s...

Embodiment 3

[0051] Example 3: Preparation of a sulfonated polyether ether ketone-sulfonated silica microsphere hybrid membrane with a thickness of about 70 μm

[0052] Weigh 0.6 g of sulfonated polyether ether ketone and 6 g of N,N-dimethylacetamide with a sulfonation degree of 65%, and stir at room temperature for 12 h under magnetic stirring at 500 r / min to dissolve the polymer completely. Add 0.09 g of the aminated silica microspheres prepared in Example 1, add 4 g of DMAc, ultrasonicate for 24 h, add to the above sulfonated polyether ether ketone solution, stop stirring after 12 h, filter with a copper mesh, and let stand for 2 h to remove Soak the sulfonated polyether ether ketone-sulfonated silicon micro-casting solution, pour the casting solution into a clean glass Petri dish (Φ100mm), place it in an oven, and dry it at 60°C and 80°C for 12 hours respectively , to obtain a homogeneous sulfonated polyether ether ketone-sulfonated silica microsphere hybrid membrane with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com