Method for preparing polyoxyethylene-introduced cross-linked modified polyimide gas separation membrane

A technology of gas separation membrane and polyimide, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of difficult to improve gas separation performance and decrease of polymer sieving ability, and achieve excellent CO2 gas separation performance, effect of separation performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

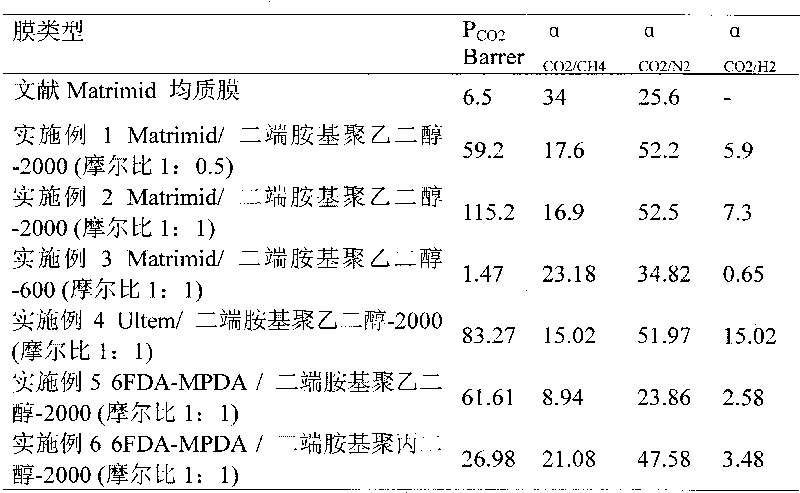

Embodiment 1

[0017] Take 1g of Matrimid and 1.185g of two-terminal amino polyethylene glycol molecular weight (2000) and add them to about 5g of THF respectively. After the two solutions are completely dissolved, mix and stir for 24 hours. The solution is cast on a flat plate and dried at 25°C. The film was placed in water for 2 days to remove unreacted cross-linking agent, and then baked in a vacuum oven at 100°C for 24 hours. The membrane was stored in a desiccator at room temperature, and the thickness of the obtained membrane was ~100 μm.

[0018] Test gas separation performance:

[0019] P CO2 = 59.2 Barrer

[0020] (1Barrer=10 -10 cm 3 (STP)cm / (cm 2 scmHg))

[0021] alpha CO2 / CH4 =17.6α CO2 / N2 =52.2α CO2 / H2 =5.9

Embodiment 2

[0023] Take 1g of Matrimid and 3.63g of two-terminal amino polyethylene glycol molecular weight (2000) and add them to about 10g of THF respectively. After the two solutions are completely dissolved, mix and stir for 24 hours. The film was placed in water for 2 days to remove unreacted cross-linking agent, and then baked in a vacuum oven at 100°C for 24 hours. The membrane was stored in a desiccator at room temperature, and the thickness of the obtained membrane was ~100 μm.

[0024] Test gas separation performance:

[0025] P CO2 = 115.2 Barrer

[0026] alpha CO2 / CH4 =16.9α CO2 / N2 =52.5α CO2 / H2 =7.3

Embodiment 3

[0028] Take 1g of Matrimid and 1.089g of two-terminal amino polyethylene glycol (molecular weight: 600) and add them to about 10g of THF respectively. After the two solutions are completely dissolved, mix and stir for 24 hours. The solution is cast on a flat plate and dried at 25°C. The film was placed in water for 2 days to remove unreacted cross-linking agent, and then baked in a vacuum oven at 100°C for 24 hours. The membrane was stored in a desiccator at room temperature, and the thickness of the obtained membrane was ~100 μm.

[0029] Test gas separation performance:

[0030] P CO2 = 1.47 Barrer

[0031] alpha CO2 / CH4 =23.18α CO2 / N2 =34.82α CO2 / H2 =0.65

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com