Patents

Literature

32 results about "Barrer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barrer is a non-SI unit of gas permeability (specifically, gas permeability) used in the membrane technology and contact lens industry. It is named after Richard Barrer.

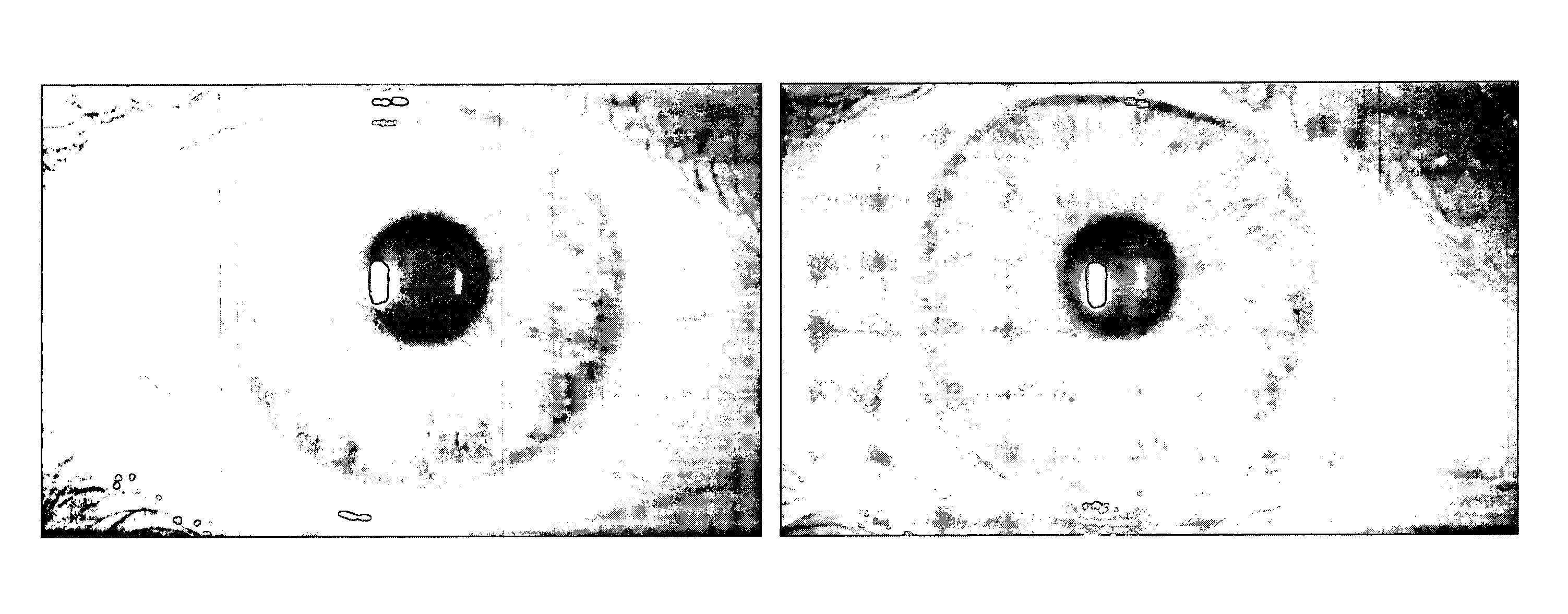

Soft contact lenses displaying superior on-eye comfort

The present invention relates to soft contact lenses having an overall comfort preference of at least about 2 to 1 as compared to an Acuvue® contact lens and measured after one week of daily wear. The present invention further relates to a soft contact lens comprising an oxygen transmissibility greater than about 70 barrers / mm and physical properties suitable to provide wearer comfort over at least about 9 hours in at least about 80% of wearers, as measured in a randomized, double masked clinical study.

Owner:JOHNSON & JOHNSON VISION CARE INC

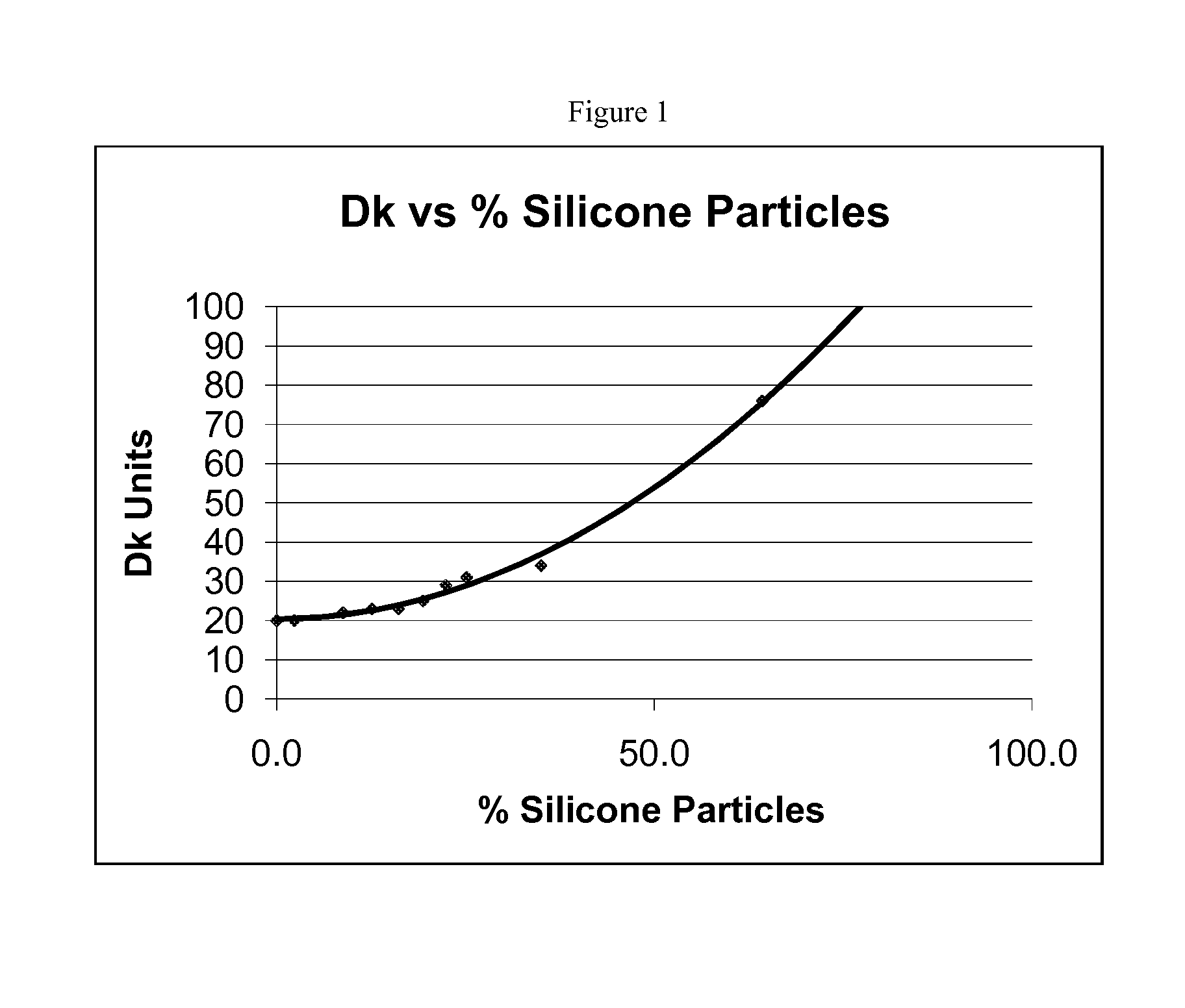

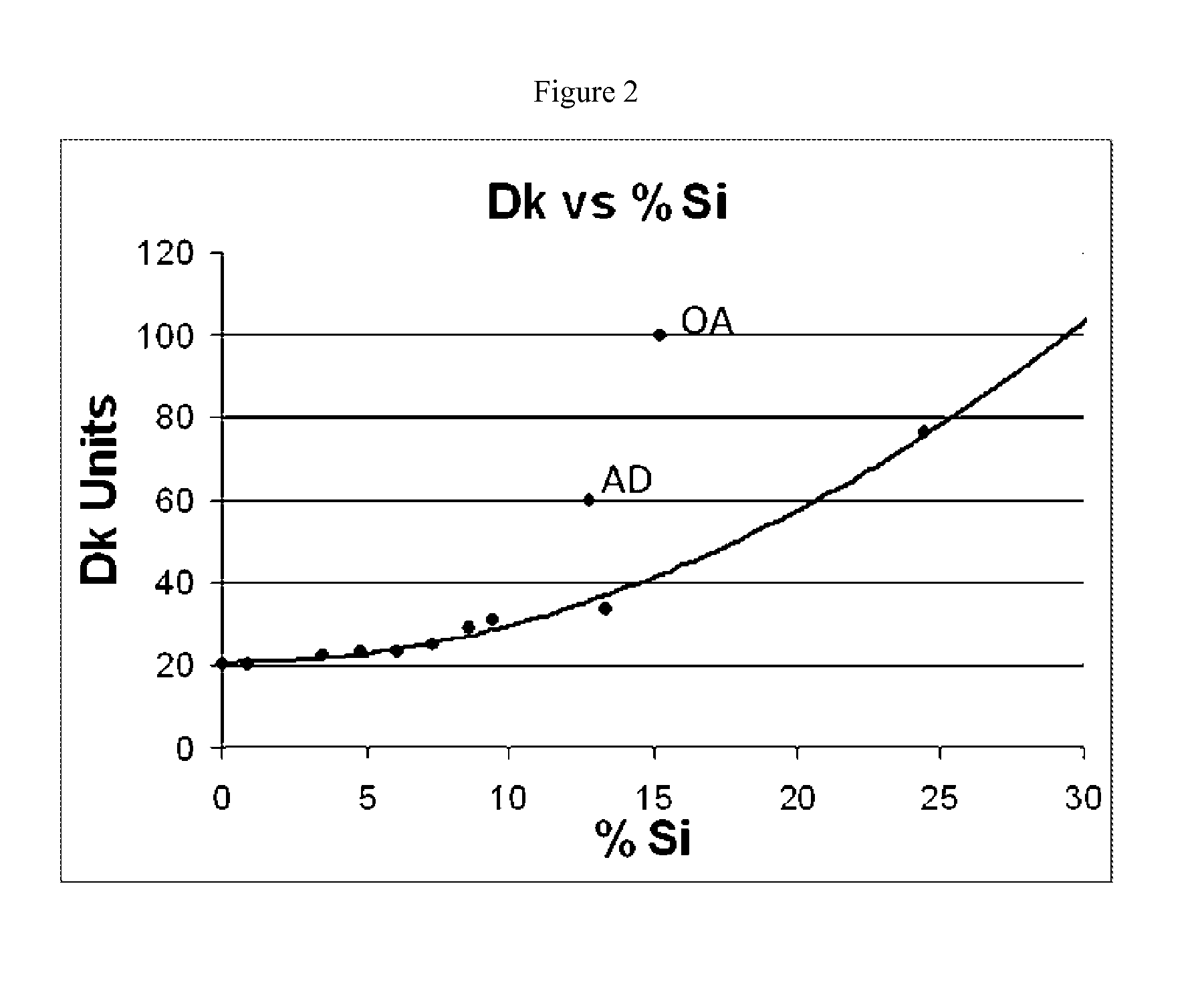

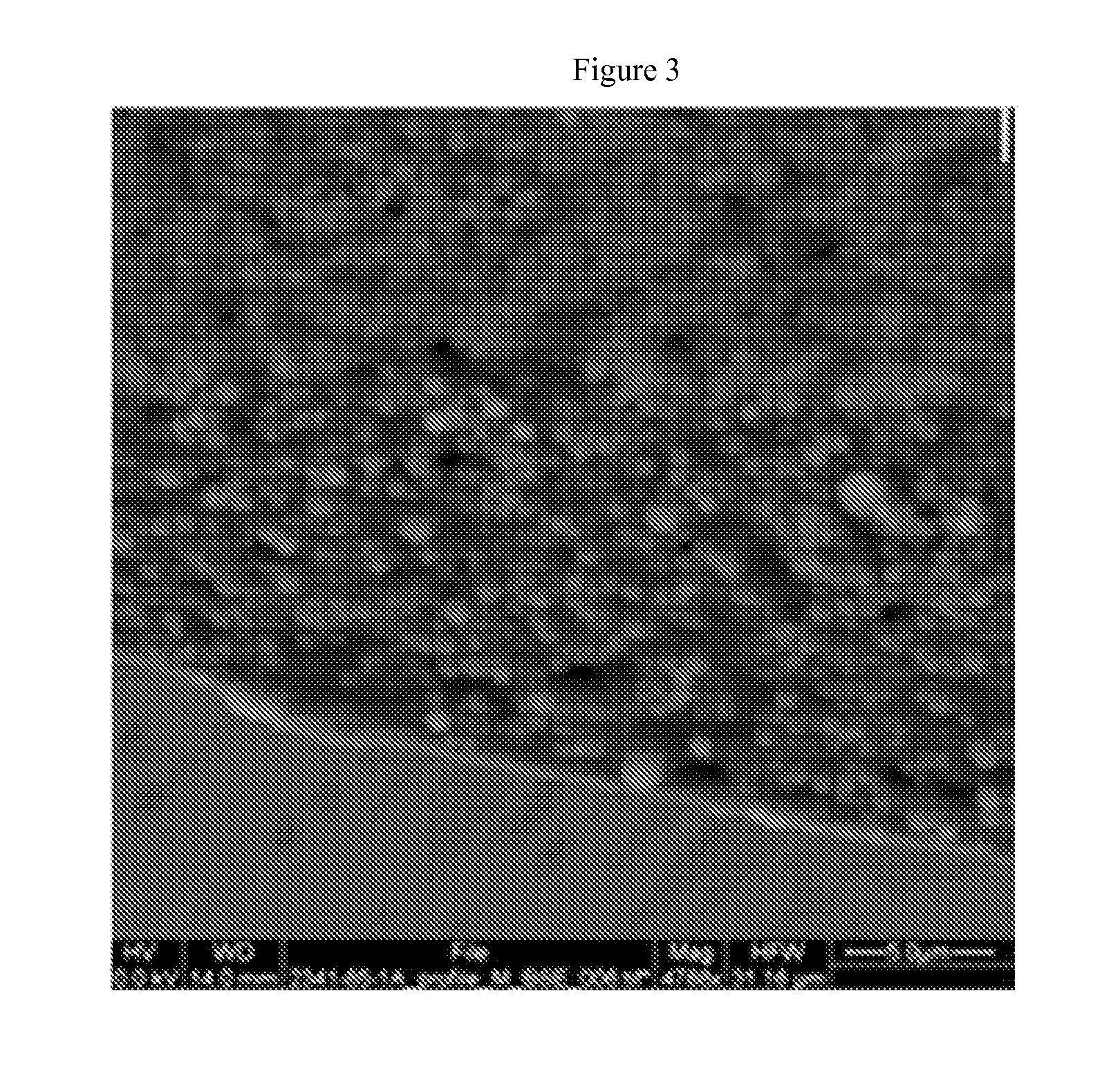

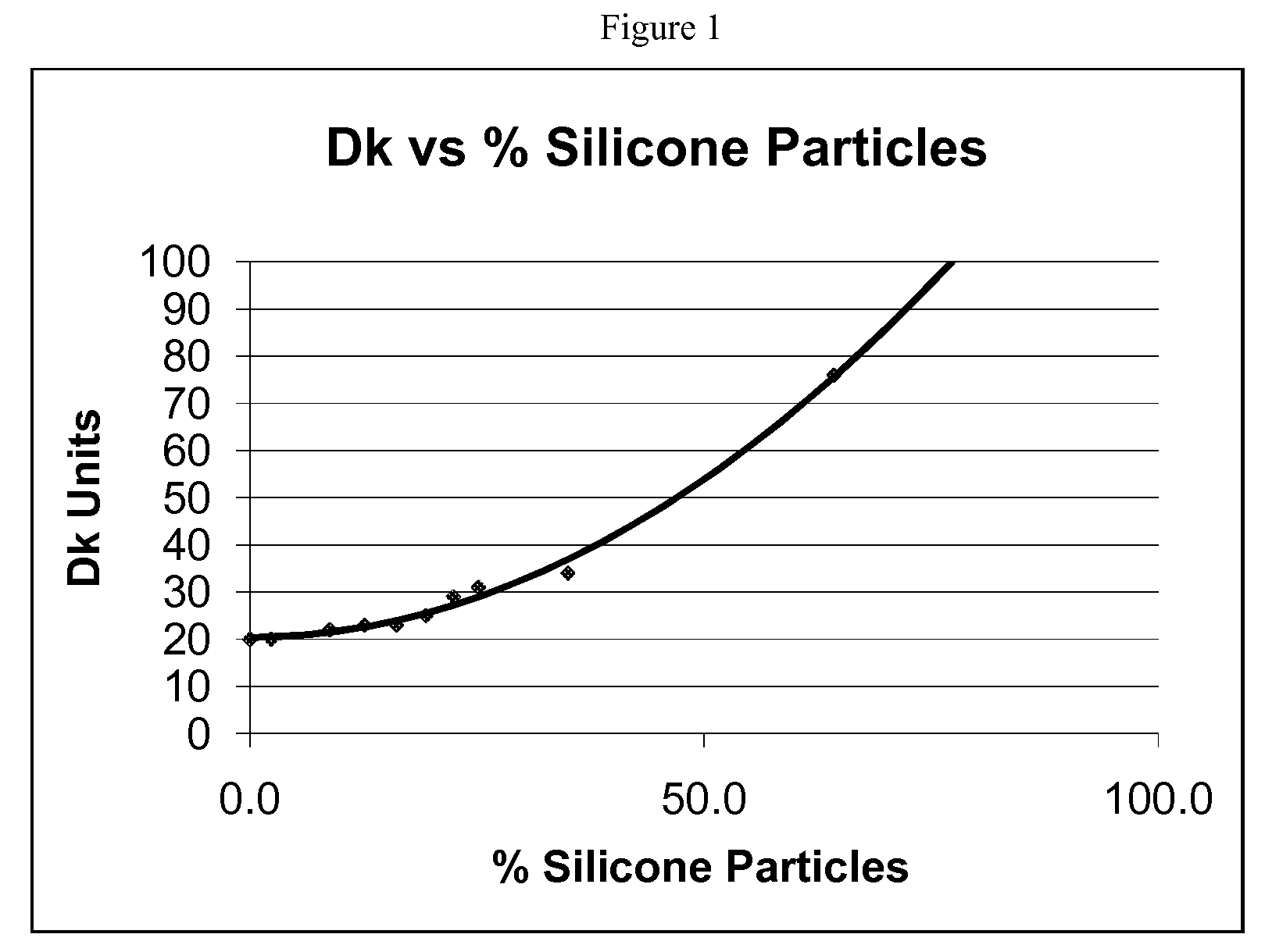

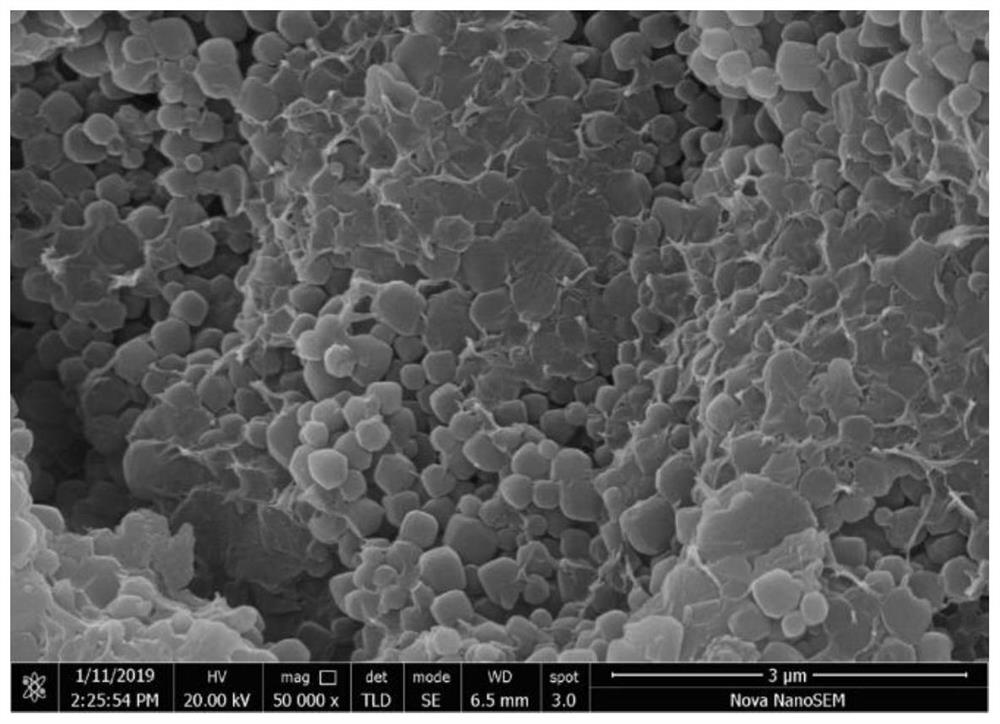

Polymeric articles comprising oxygen permeability enhancing particles

InactiveUS20100249273A1Increasing the thicknessPaper coatingCoatingsOxygen enhancedOxygen permeability

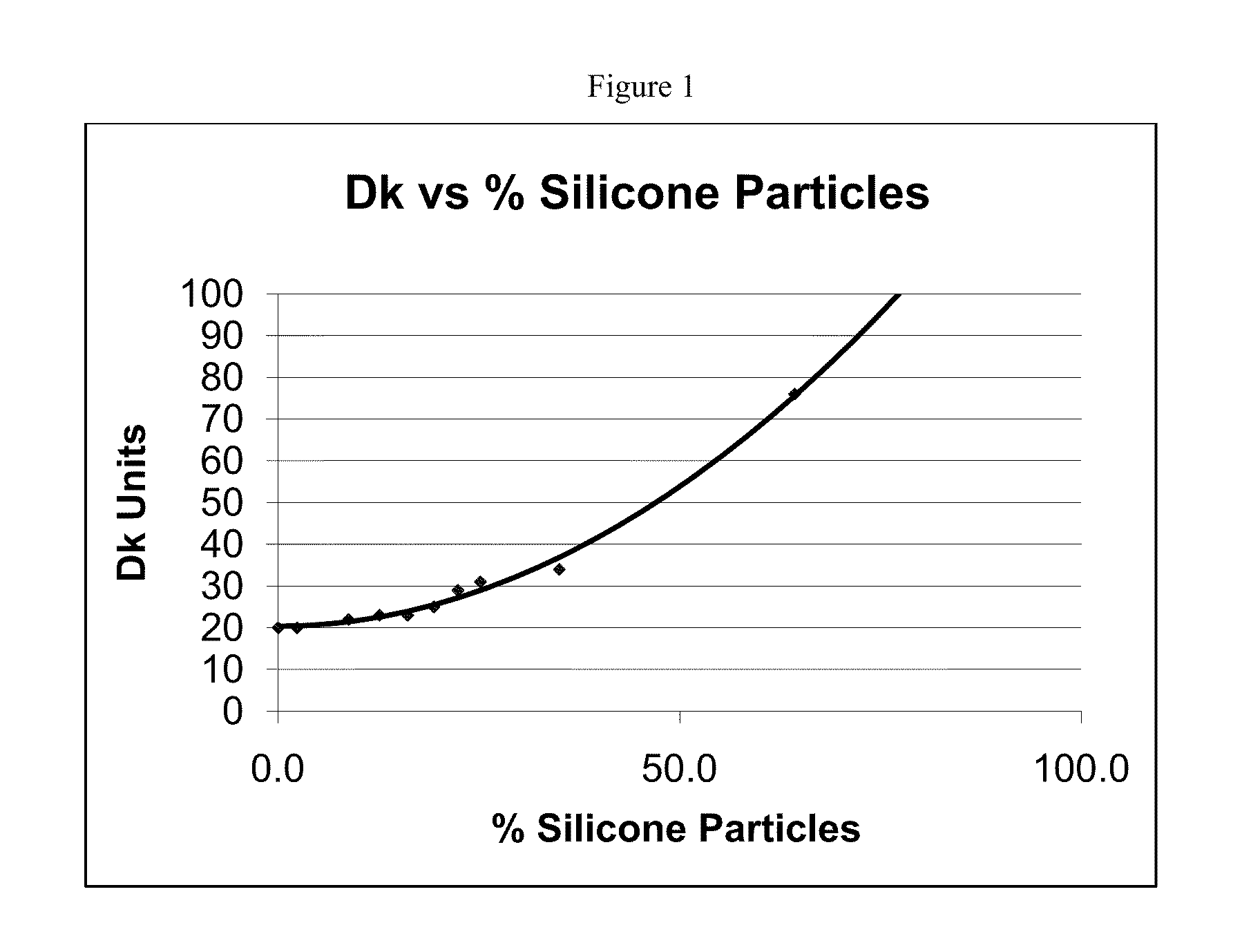

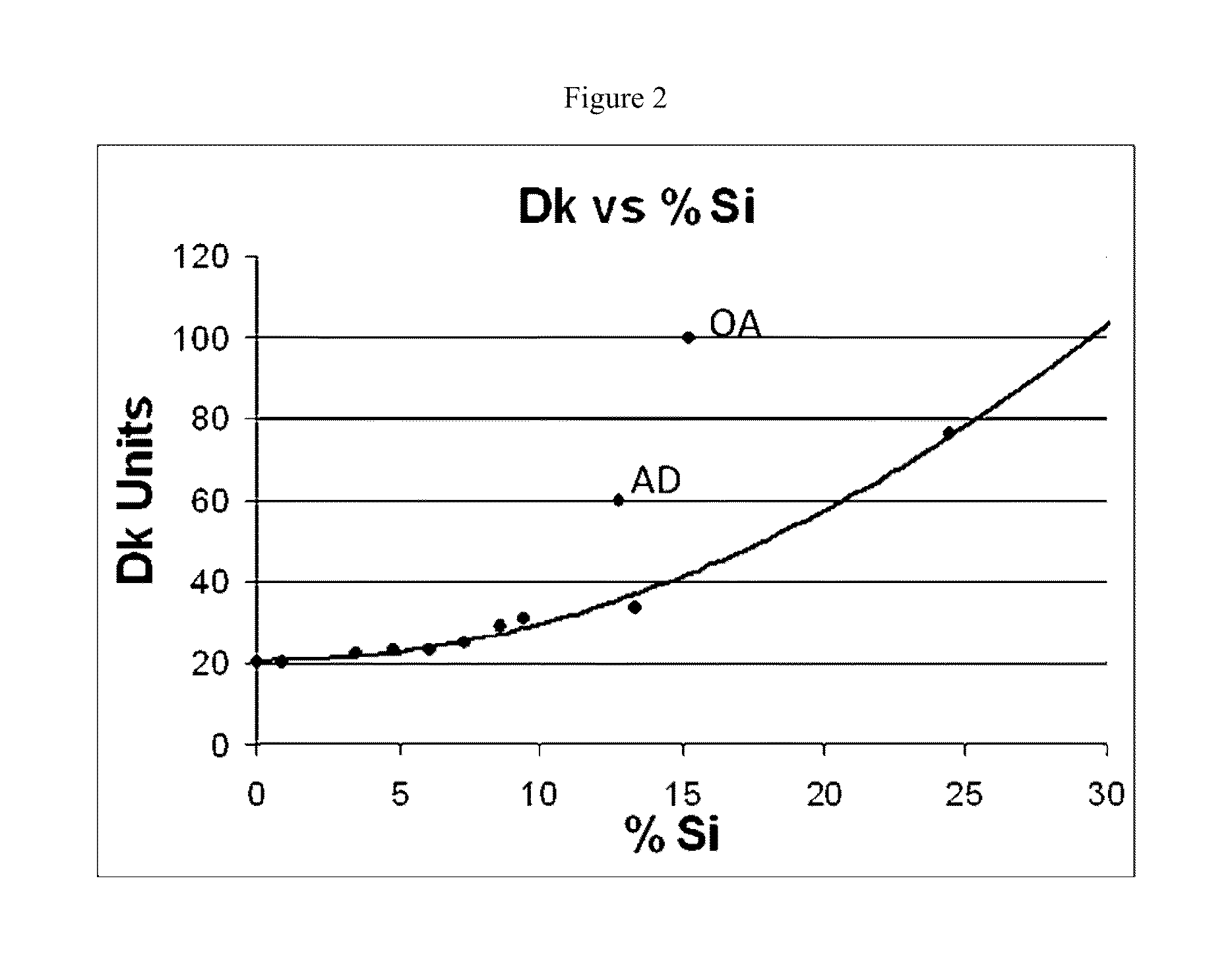

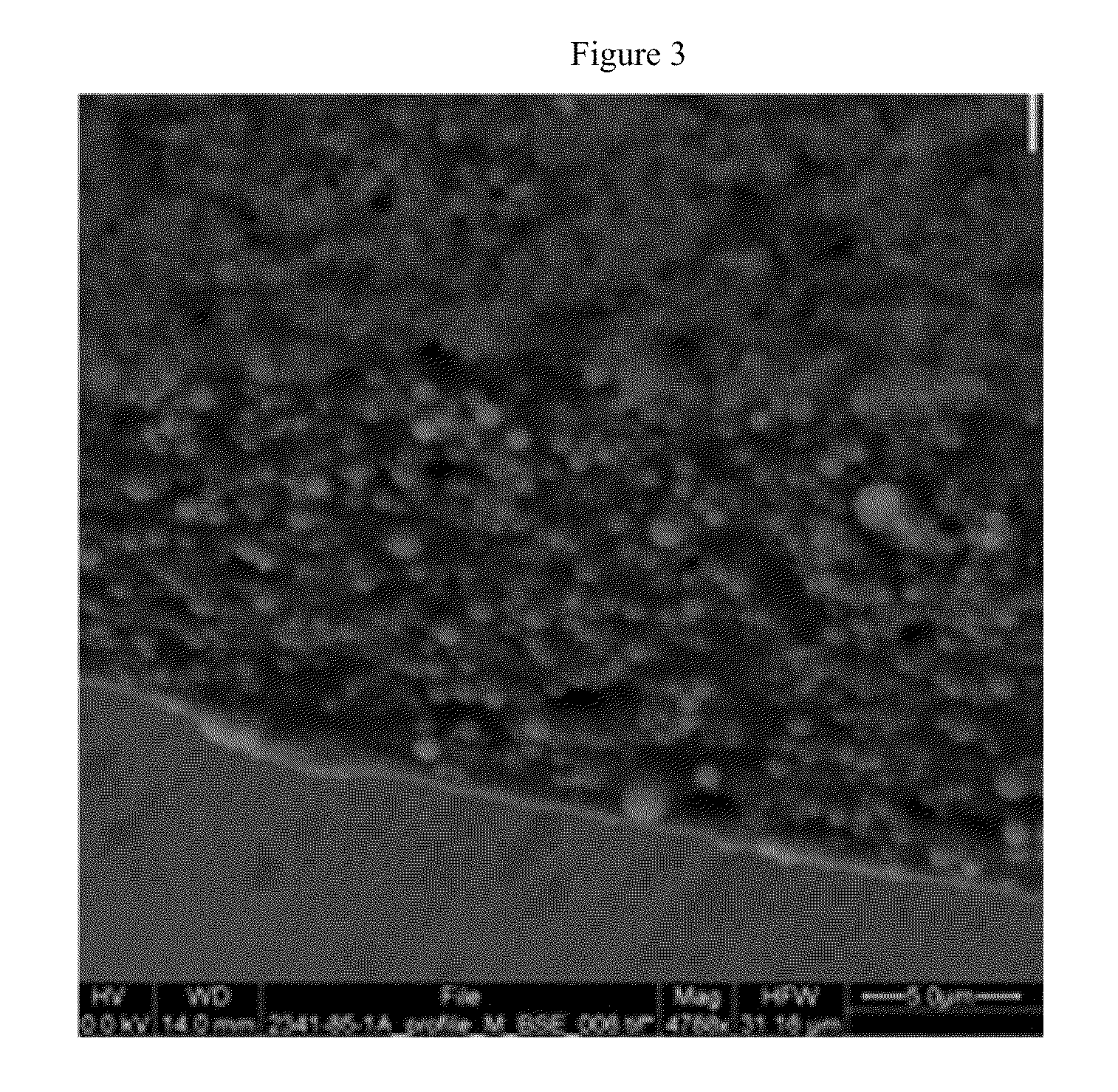

The present invention relates to a composition comprising a hydrogel polymer having less than 100% haze, and distributed therein an oxygen enhancing effective amount of oxygen permeable particles having an oxygen permeability of at least about 100 barrer, average particle size less than about 5000 nm.

Owner:JOHNSON & JOHNSON VISION CARE INC

Soft contact lenses displaying superior on-eye comfort

The present invention relates to soft contact lenses having an overall comfort preference of at least about 2 to 1 as compared to an Acuvue® contact lens and measured after one week of daily wear. The present invention further relates to a soft contact lens comprising an oxygen transmissibility greater than about 70 barrers / mm and physical properties suitable to provide wearer comfort over at least about 9 hours in at least about 80% of wearers, as measured in a randomized, double masked clinical study.

Owner:JOHNSON & JOHNSON VISION CARE INC

Polymeric articles comprising oxygen permeability enhancing particles

The present invention relates to a composition comprising a hydrogel polymer having less than 100% haze, and distributed therein an oxygen enhancing effective amount of oxygen permeable particles having an oxygen permeability of at least about 100 barrer, average particle size less than about 5000 nm.

Owner:JOHNSON & JOHNSON VISION CARE INC

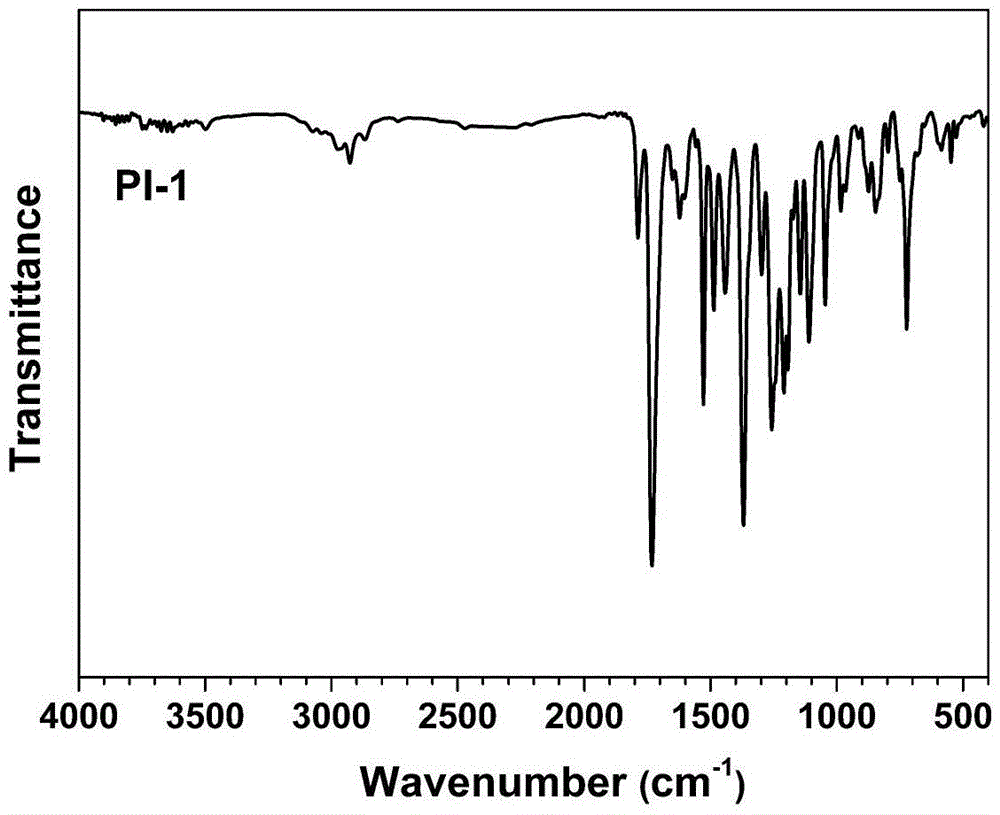

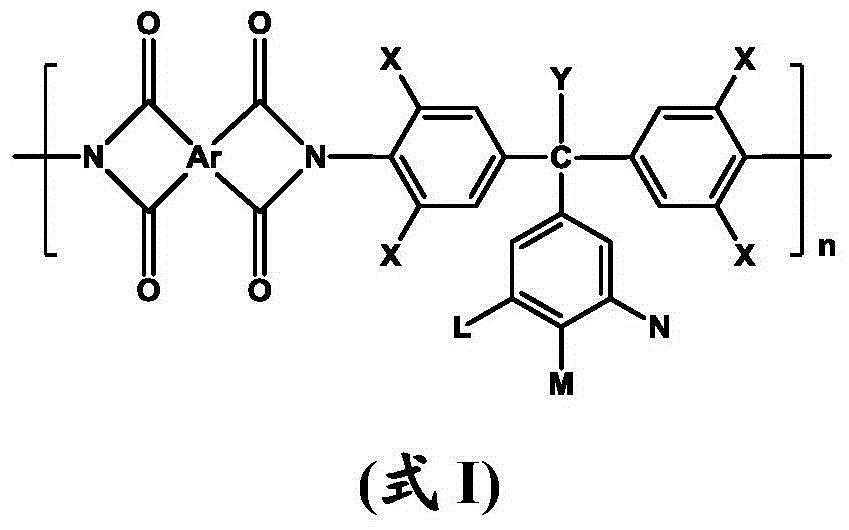

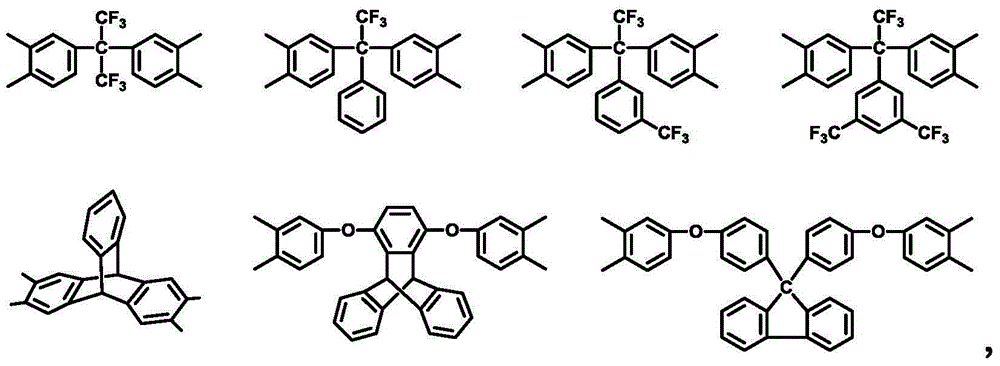

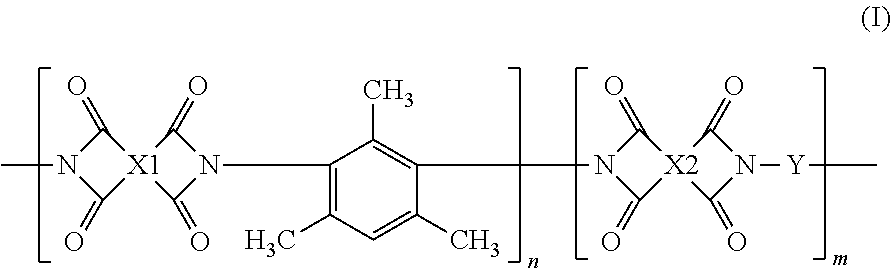

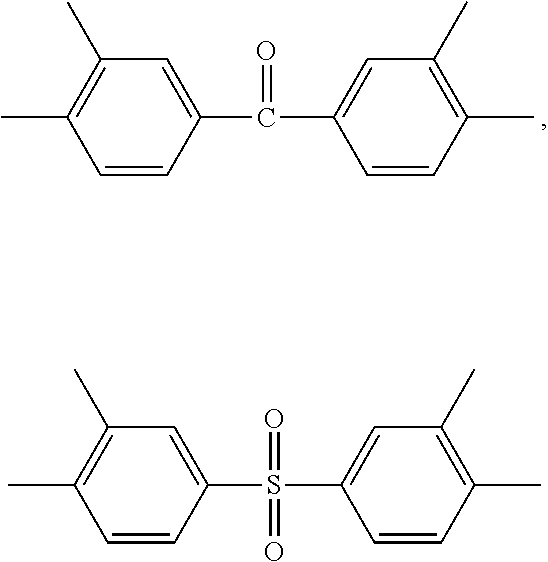

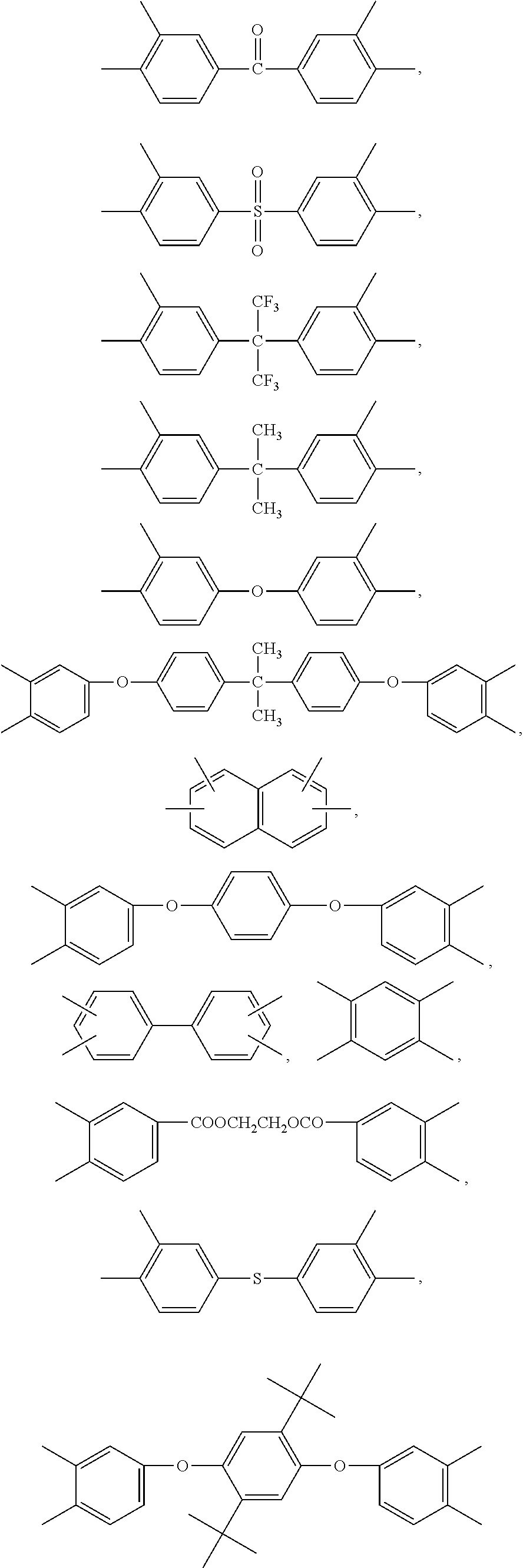

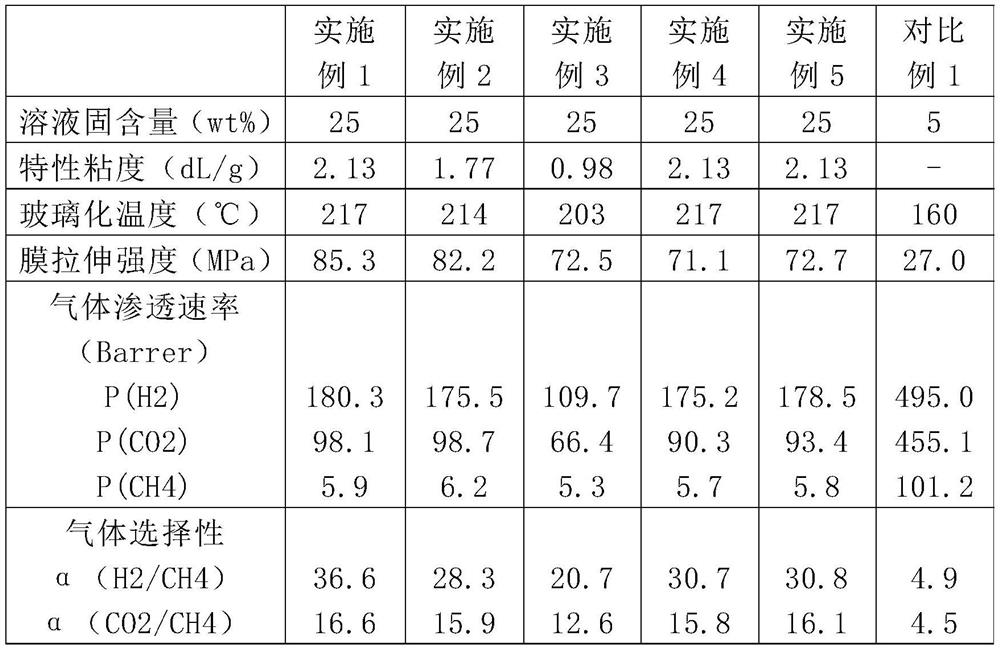

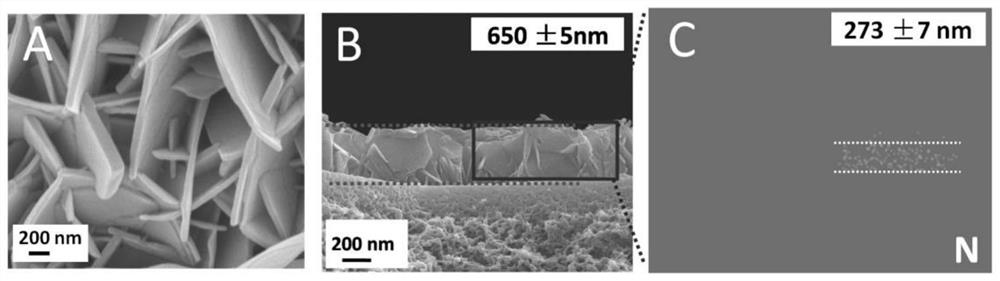

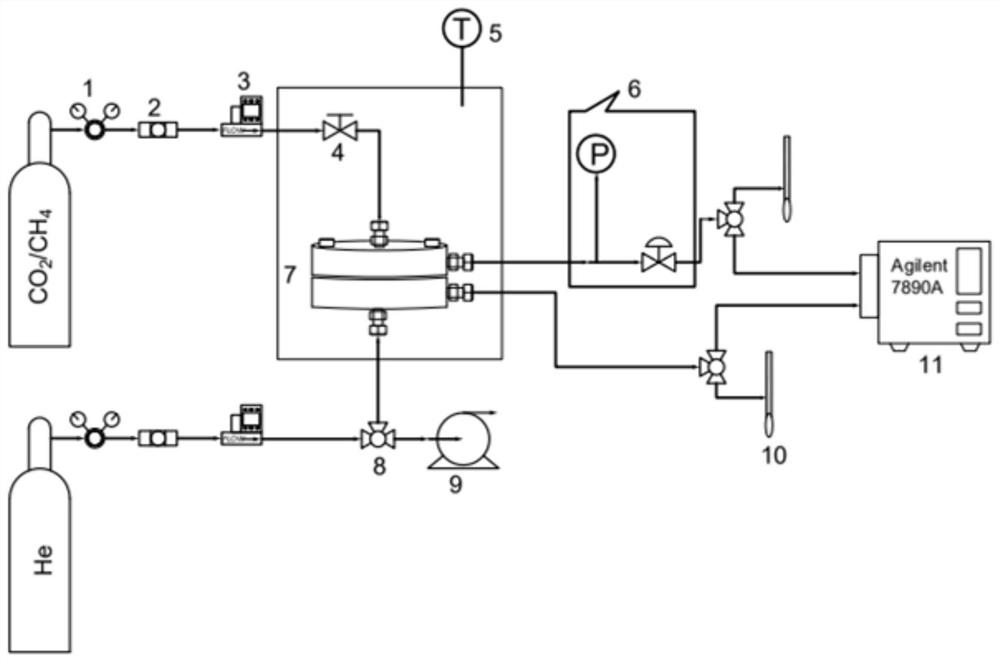

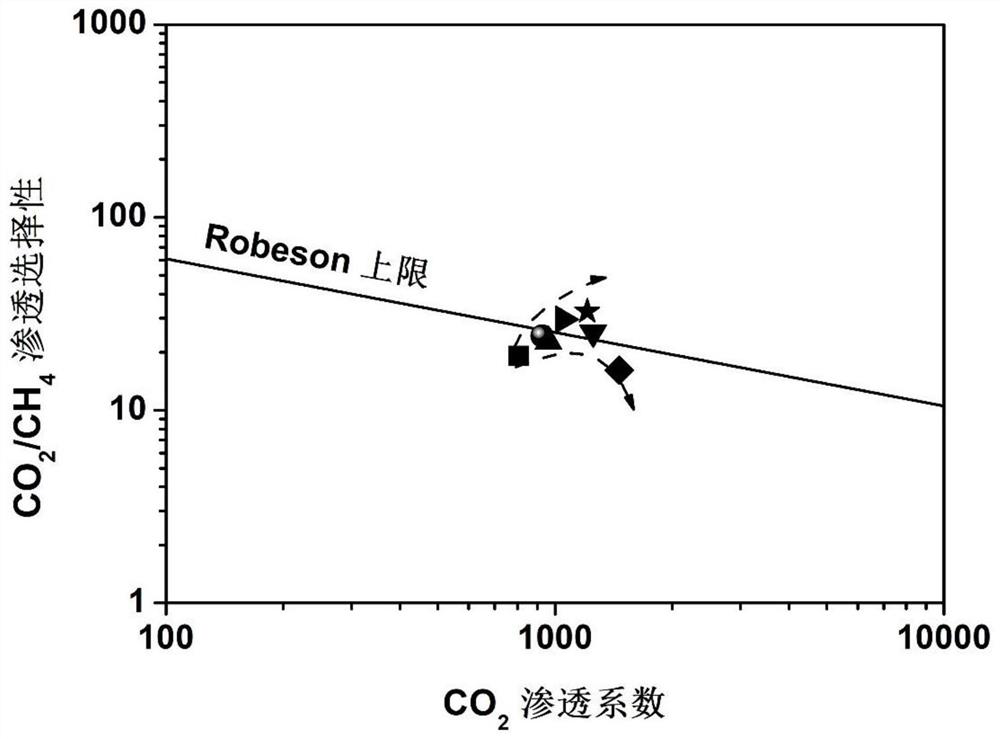

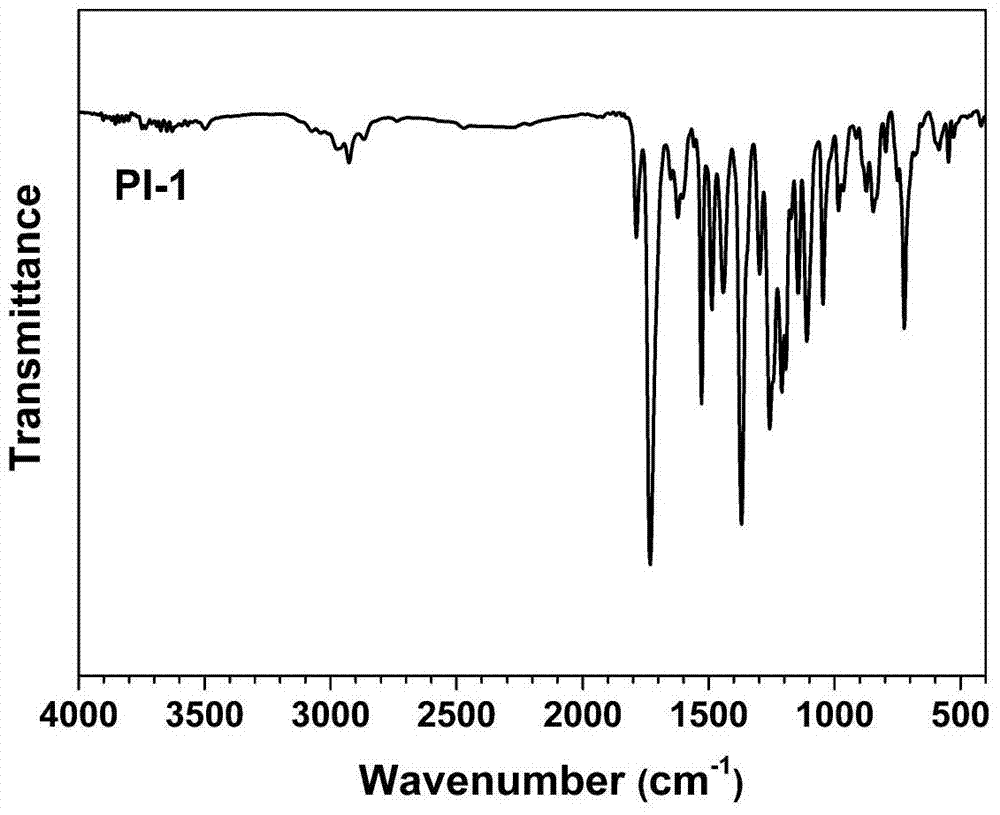

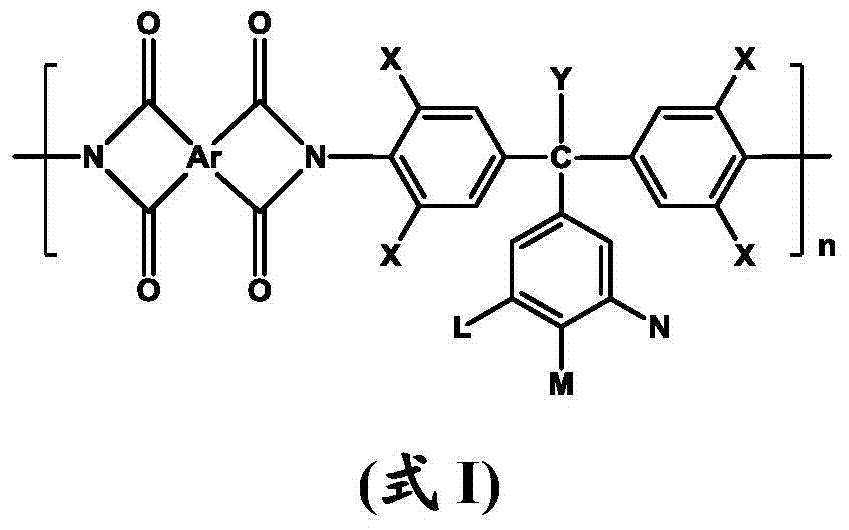

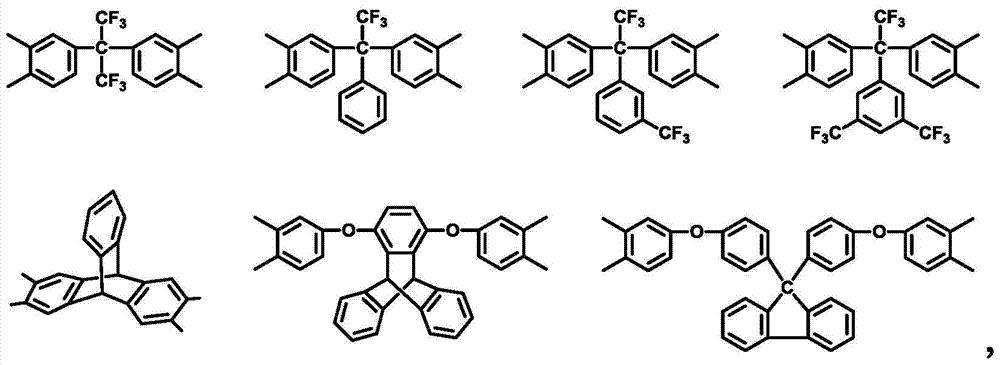

Polyimide gas separation membrane as well as preparation method and applications thereof

ActiveCN104829853AImprove permeabilityHigh selectivityProductsSemi-permeable membranesHeat resistancePermeability coefficient

The invention discloses a polyimide gas separation membrane as well as a preparation method and applications thereof. The separation membrane is made of a polyimide resin which is shown in a formula I and has a fluorobenzene side group containing structure. The polyimide gas separation membrane has the characteristics of high permeability and high selectivity, the permeability coefficient to CO2 is greater than or equal to 180 barrer, the selective coefficient to CO2 / CH4 is greater than 30, and the separation membrane shows excellent heat resistance and mechanical properties. The gas separation membrane has an important application value in various CO2-related separation and recovery applications such as the separation of carbon dioxide and methane in biological gas, the removal of acid gases such as carbon dioxide and the like, the recovery of carbon dioxide in tertiary oil recovery of oil fields, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polymeric articles comprising oxygen permeability enhancing particles

The present invention relates to a composition comprising a hydrogel polymer having less than 100% haze, and distributed therein an oxygen enhancing effective amount of oxygen permeable particles having an oxygen permeability of at least about 100 barrer, average particle size less than about 5000 nm.

Owner:JOHNSON & JOHNSON VISION CARE INC

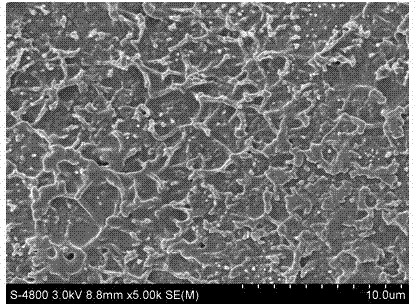

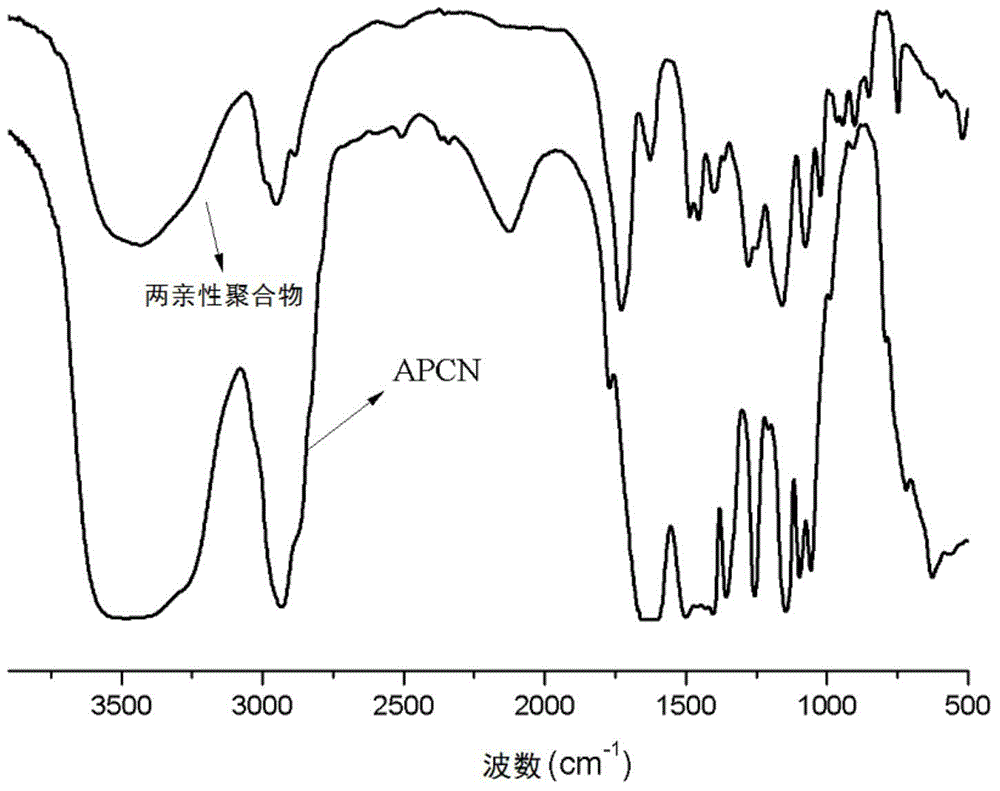

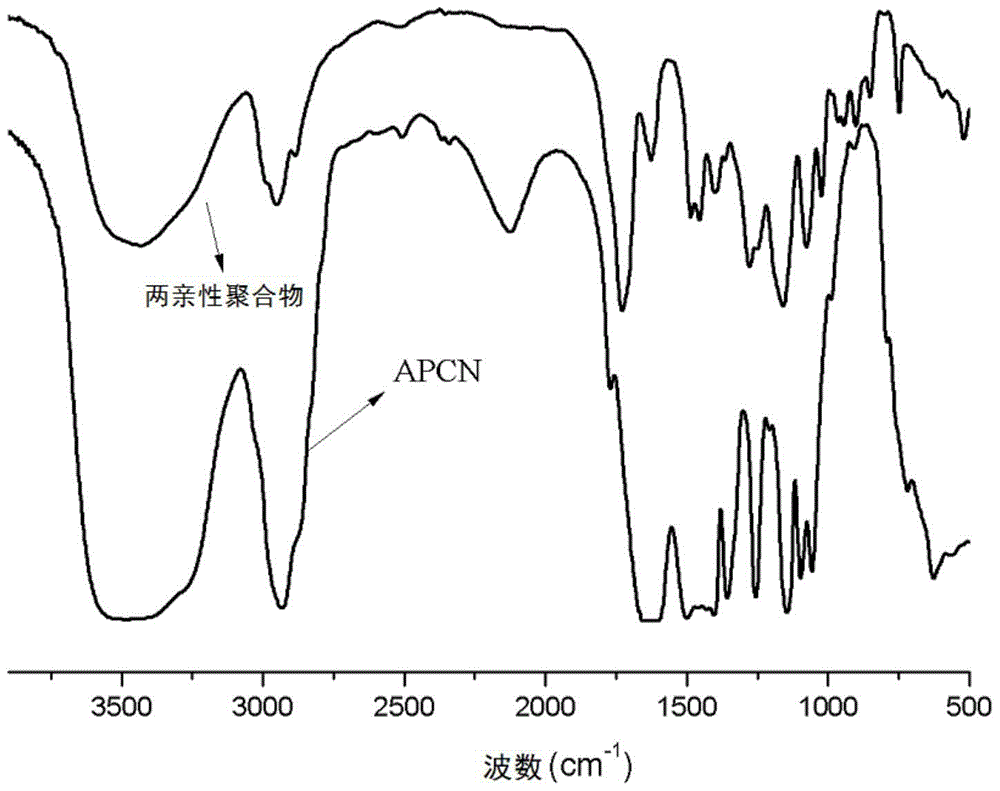

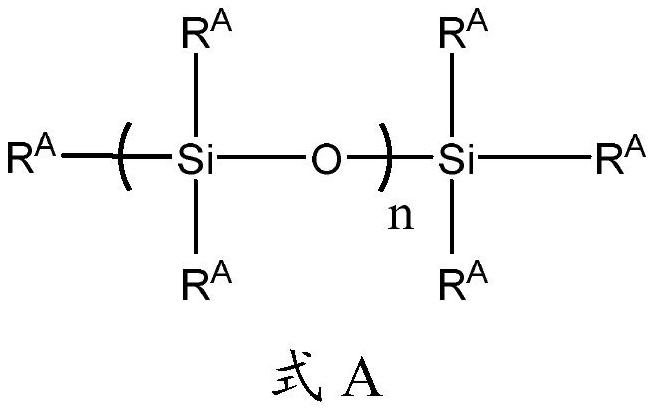

Amphiprotic co-continuous polymer network, preparation method and application thereof

InactiveCN101293963AIncrease temperaturePharmaceutical non-active ingredientsProsthesisControlled releasePolymer network

The invention relates to an amphoteric co-continuous polymer network. The amphoteric co-continuous polymer network is prepared through chemical crosslinking reaction by using an organic siloxane polymer as a raw material and N-isopropyl acrylamide as a reactant monomer to generate a graft copolymer. The gel dissolving rate in water is in the range of 0-10%, the swelling rate in water is in the range of 20-50%, and the oxygen transmissibility is in the range of 150-600 barrers. The invention also relates to a method for producing the amphoteric co-continuous polymer network. The method comprises the following steps: (1) synthesis of methacrylic acid-3-(1,1,3,3-tetramethyldisiloxane)propyl ester; (2) preparation of a modified unsaturated organic siloxane polymer mixture; (3) synthesis of the graft copolymer; and (4) preparation of amphoteric co-continuous network. The amphoteric co-continuous polymer network is used for biomedical materials, including contact lens, artificial organs, controlled-release drug carriers etc.

Owner:DONGHUA UNIV

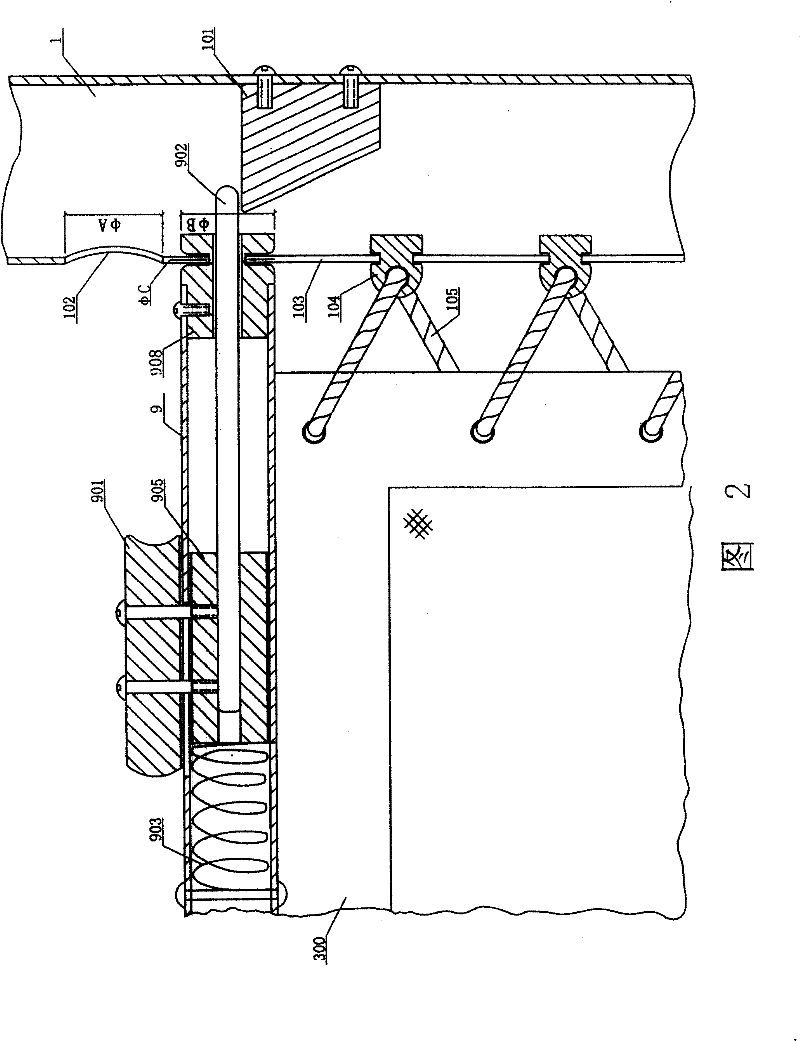

Hydrogel microsphere-filled hybrid membrane capable of adjusting membrane water content as well as preparation and application thereof

InactiveCN103894080AExtended service lifeEvenly distributedProductsSemi-permeable membranesHydrogel microspheresPermeability coefficient

The invention discloses a hydrogel microsphere-filled hybrid membrane capable of adjusting membrane water content as well as preparation and application thereof. The hybrid membrane consists of hydrogel microspheres and polyimide resin. The preparation process of the hybrid membrane comprises the following steps: preparing the hydrogel microspheres; preparing a polyimide resin solution; feeding the hydrogel microspheres into the polyimide resin solution to prepare a casting membrane solution, and preparing the hybrid membrane. The hybrid membrane has the advantages that the preparation process is simple, and the membrane water content can be simply and conveniently adjusted; the prepared hydrogel microsphere-filled hybrid membrane is even in distribution in the membrane; the compatibility between filled particles and a polymer matrix is better; the water absorption of the hybrid membrane is improved and adjusted by the hydrogel microspheres in the hybrid membrane; the prepared hybrid membrane can be used for separating CO2 / CH4, and is better in separating property under the wet testing condition; the CO2 permeability coefficient is 270 barrer, and the CO2 / CH4 separation selectivity is 59.

Owner:TIANJIN UNIV

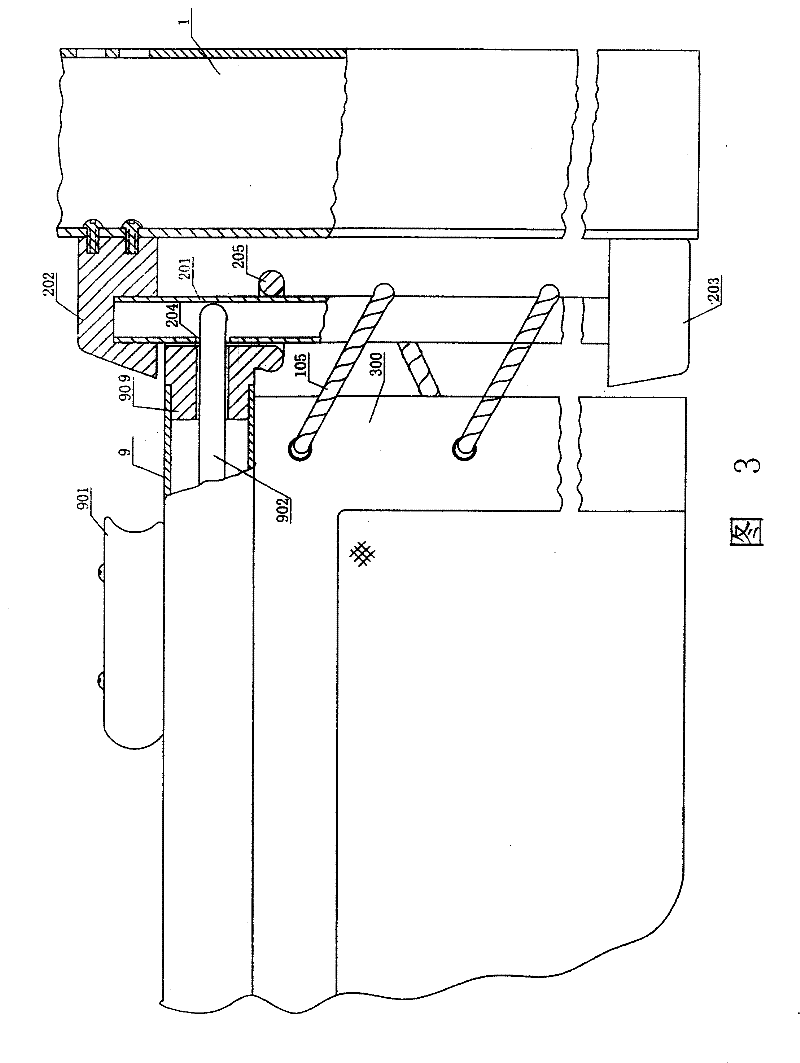

Polyimide-zinc organic framework loaded graphene oxide hybrid membrane as well as preparation and application

ActiveCN107866154AEasy to prepareProcess controllableProductsSemi-permeable membranesGas separationHummers' method

The invention discloses a polyimide-zinc organic framework loaded graphene oxide hybrid membrane. A preparation process comprises the following steps: preparing graphene oxide by adopting a Hummer method, preparing dispersing liquid with a mass ratio of methanol to water of (1 to 4) to 1, and performing ultrasonic dispersion; adding the graphene oxide and the dispersing liquid into a mixed solution of zinc nitrate hexahydrate and 2-methylimidazole, and performing a stirring reaction at room temperature, thus preparing a zinc organic framework loaded graphene oxide compound nanosheet; and blending the zinc organic framework loaded graphene oxide compound nanosheet and a polyimide solution to prepare a membrane casting solution, and preparing the hybrid membrane through a tape casting method. The polyimide-zinc organic framework loaded graphene oxide hybrid membrane disclosed by the invention has the advantages that the raw materials of the hybrid membrane are easy to obtain, and the preparation process is simple and controllable; and the prepared compound membrane is used for gas separation, and has excellent separation performance. Particularly, under a humidification condition, the permeability of CO2 pure gas is 238 barrer, and the CO2 / N2 selectivity is 65.

Owner:TIANJIN POLYTECHNIC UNIV

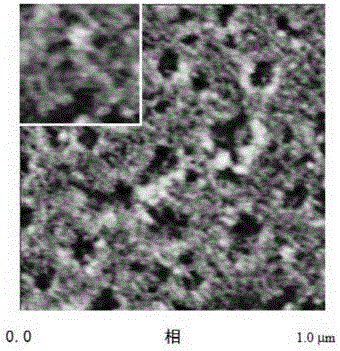

Amphiphilic copolymer network and preparation method thereof

The invention discloses an amphiphilic copolymer network, which is composed of a star amphiphilic copolymer and a hydrosilation crosslinking agent by crosslinking, wherein the star amphiphilic copolymer is prepared by carrying out chemical reaction on a star amphiphilic homopolymer and a suspension alkynyl containing hydrophobic segmented copolymer; and the swelling degree of the amphiphilic copolymer network in n-hexane is 20-150%, the swelling degree of the amphiphilic copolymer network in water is 50-800%, the swelling degree of the amphiphilic copolymer network in ethanol is 400-1000%, and the oxygen transmittance is 500-1600 Barrers. The amphiphilic copolymer network can be used as a medical polymer material. The invention also discloses a preparation method of the amphiphilic copolymer network.

Owner:DONGHUA UNIV

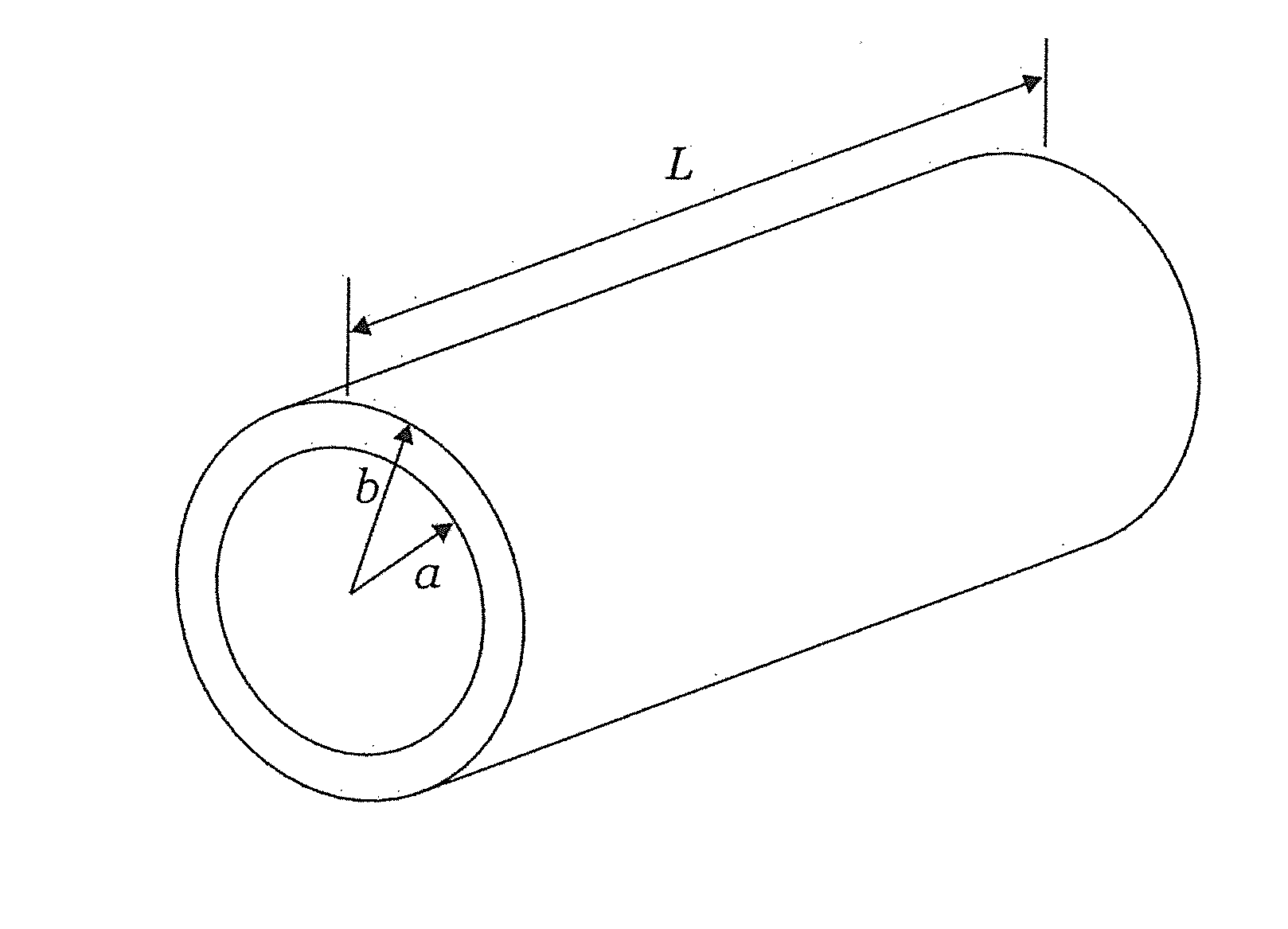

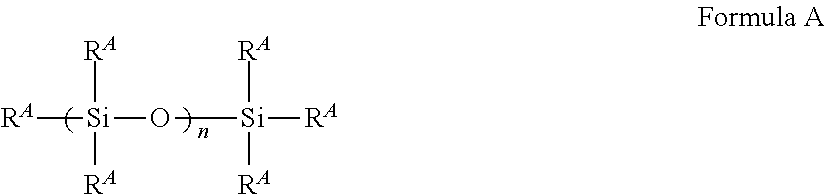

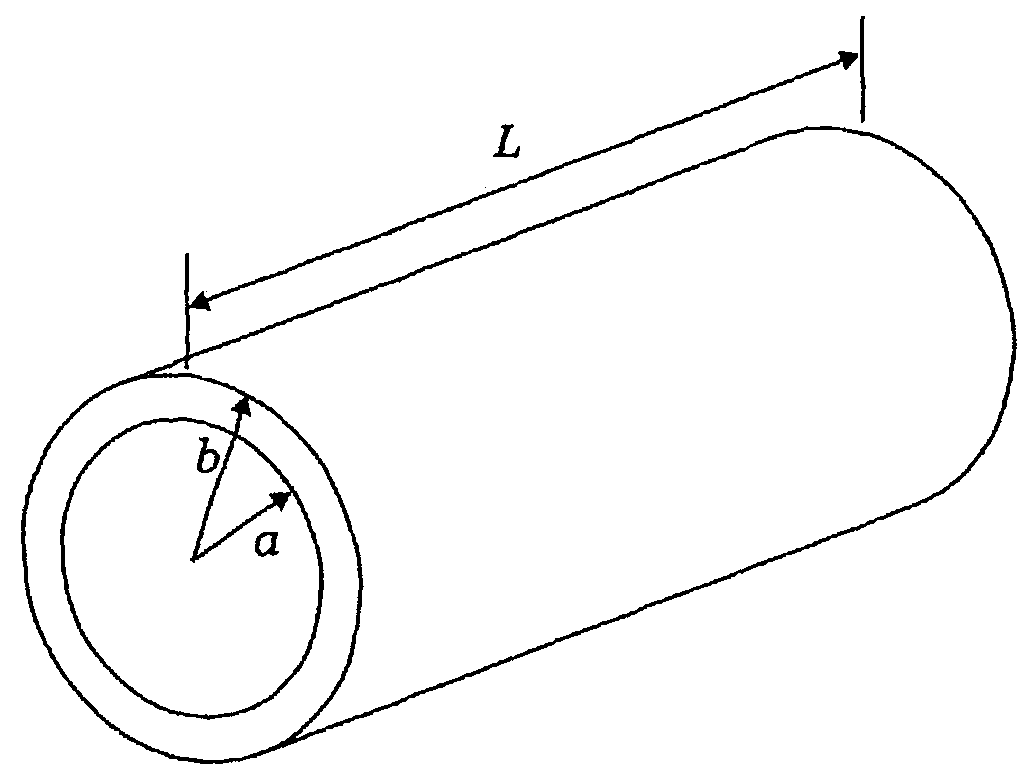

Siloxane based hollow fibers

ActiveUS20140220344A1Group 4/14 element organic compoundsFilament/thread formingFiberPolymer science

The present invention provides inventive hollow fibers having defined gas permability characteristics. Hollow fibers of the present invention are characterized by a PMPCO2 greater than 30,000 Barrer*MPa. Curable compositions and silicone elastomers produced by curing the curable compositions are provided by the present invention. Compositions and methods for making the hollow fibers and devices incorporating them are provided by the present invention.

Owner:MEDARRAY

Polyimide gas separation membranes

The present invention discloses a new type of polyimide membrane with high permeances and high selectivities for gas separations and particularly for CO2 / CH4 and H2 / CH4 separations. The polyimide membranes have CO2 permeability of 50 Barrers or higher and single-gas selectivity for CO2 / CH4 of 15 or higher at 50° C. under 791 kPa for CO2 / CH4 separation. The polyimide membranes have UV cross-linkable functional groups and can be used for the preparation of UV cross-linked polyimide membranes having CO2 permeability of 20 Barrers or higher and single-gas selectivity for CO2 / CH4 of 35 or higher at 50° C. under 791 kPa for CO2 / CH4 separation.

Owner:UOP LLC

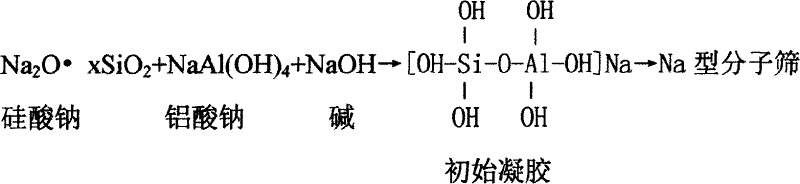

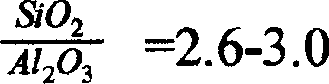

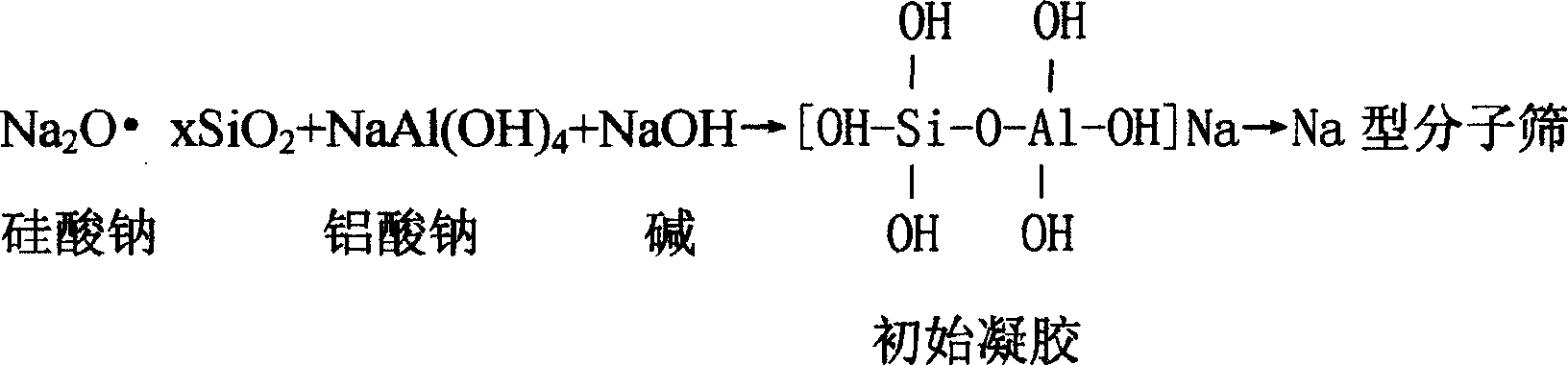

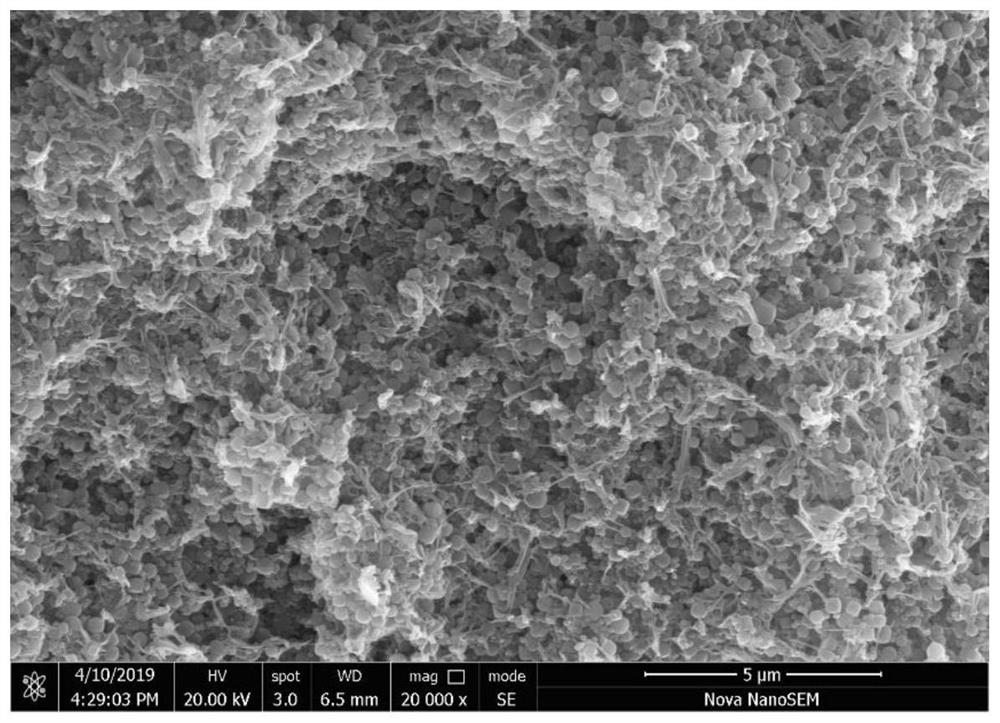

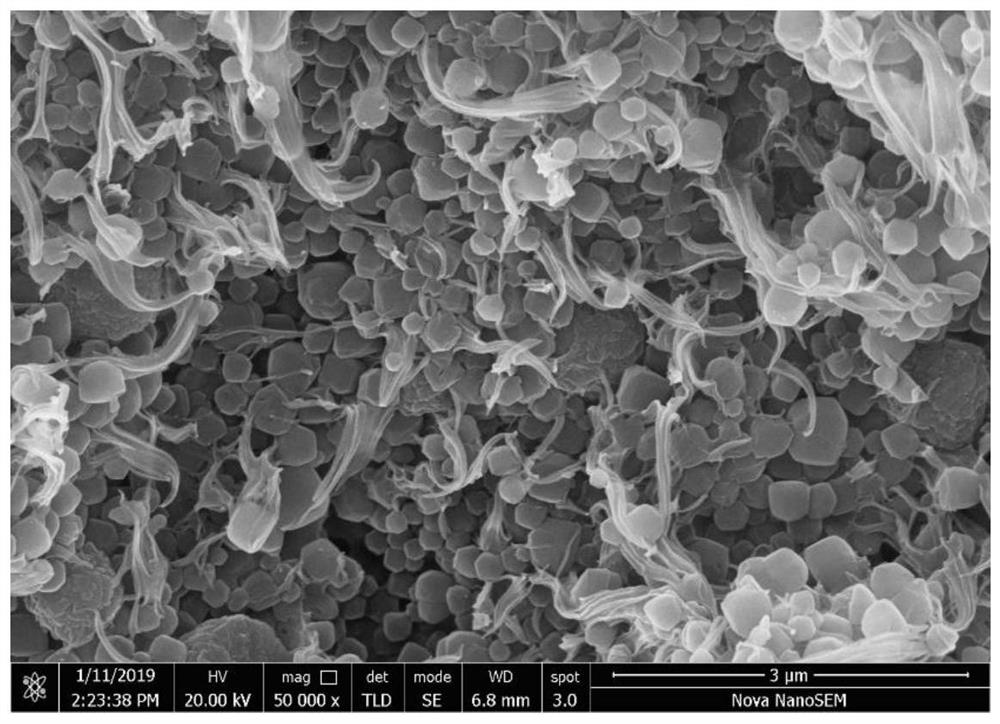

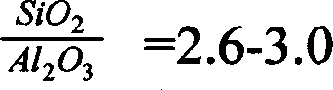

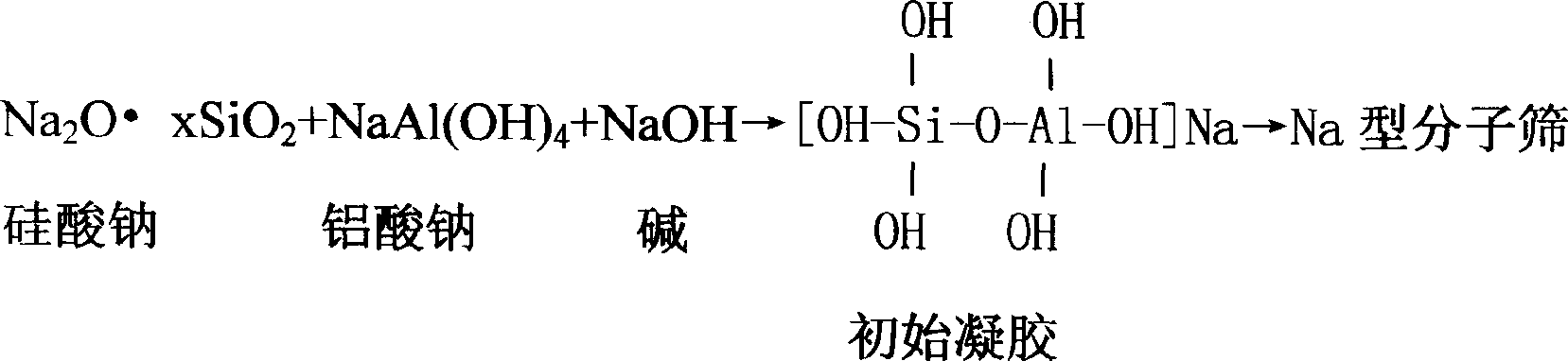

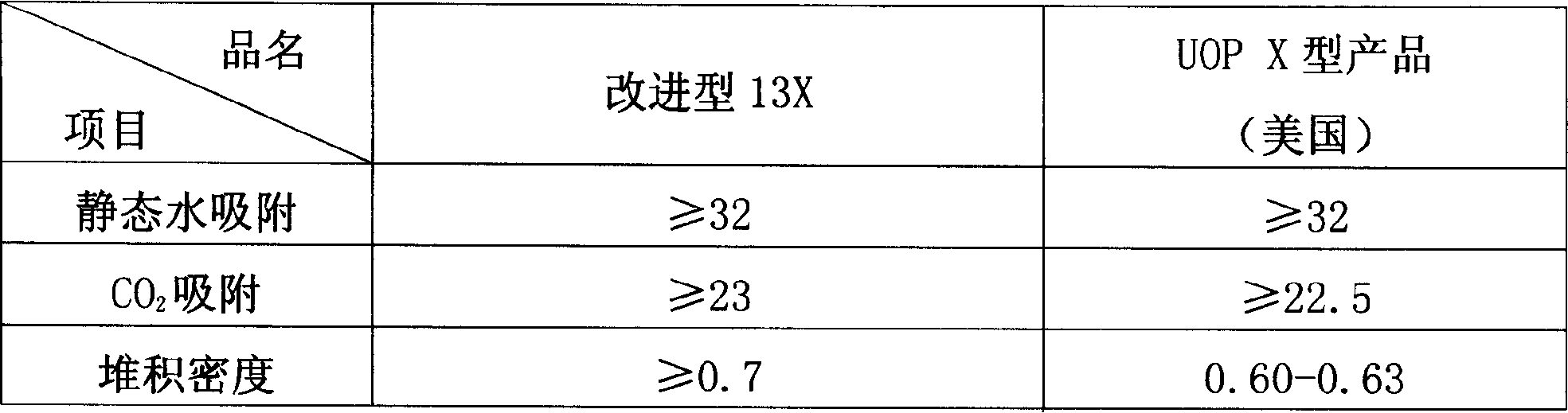

Process method of improved 13X molecular screen

InactiveCN1736865ASolve concentrationAddress key issues of compositionOther chemical processesFaujasite aluminosilicate zeoliteMolecular sieveSodium aluminate

The disclosed preparation method with hydrothermal and Barrer non-equilibrium synthesis techniques is for improved 13X molecular sieve. Wherein, the said sieve is metastable phase; when using sodium silicate and sodium aluminate as silicon source and aluminium source separately, the silicate radical has different polymerization states, the aluminate radical and aluminosilicate radical have different structures and states; in alkaline condition, the silicate and aluminate polymerize and form crystallized glue and obtain the said sieve; wherein, the mole ratio of indredients is: Na2O / Al2O3: 3.0-4.0, SiO2 / Al2O3: 2.5-3.2, H2O / Al2O3: 30-40.

Owner:LUOYANG JALON MICRO NANO NEW MATERIALS CO LTD

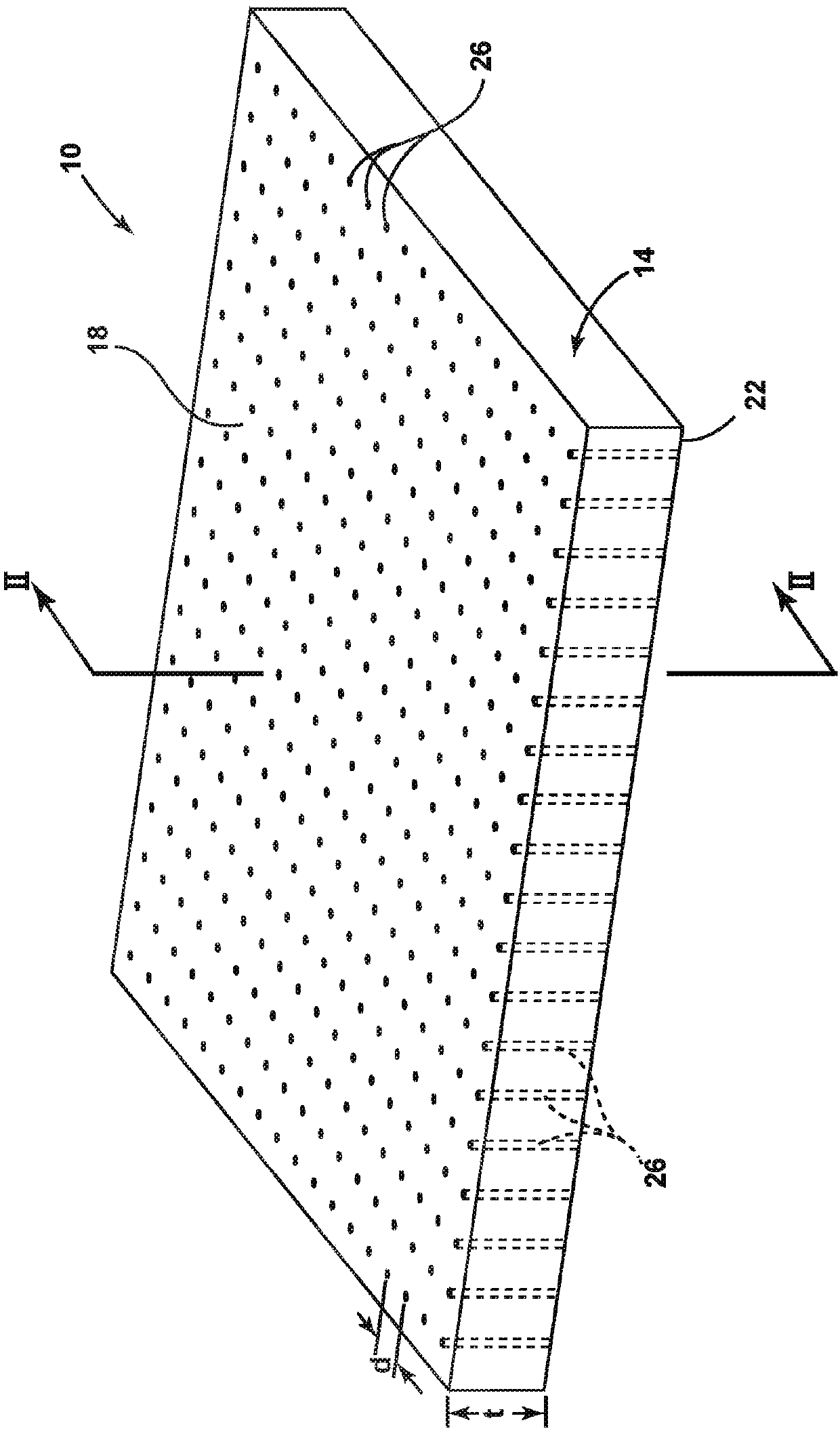

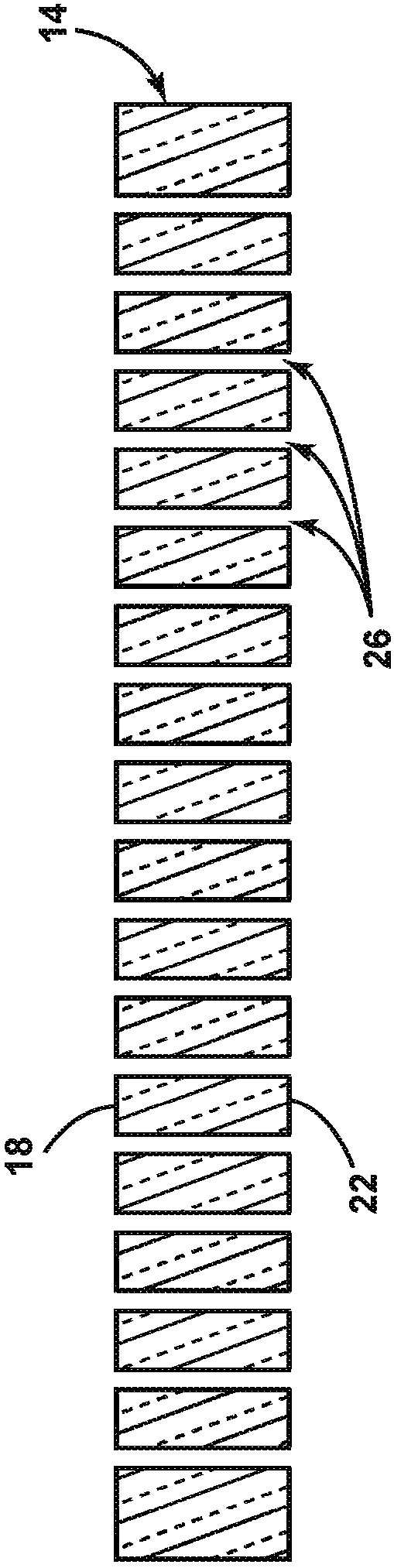

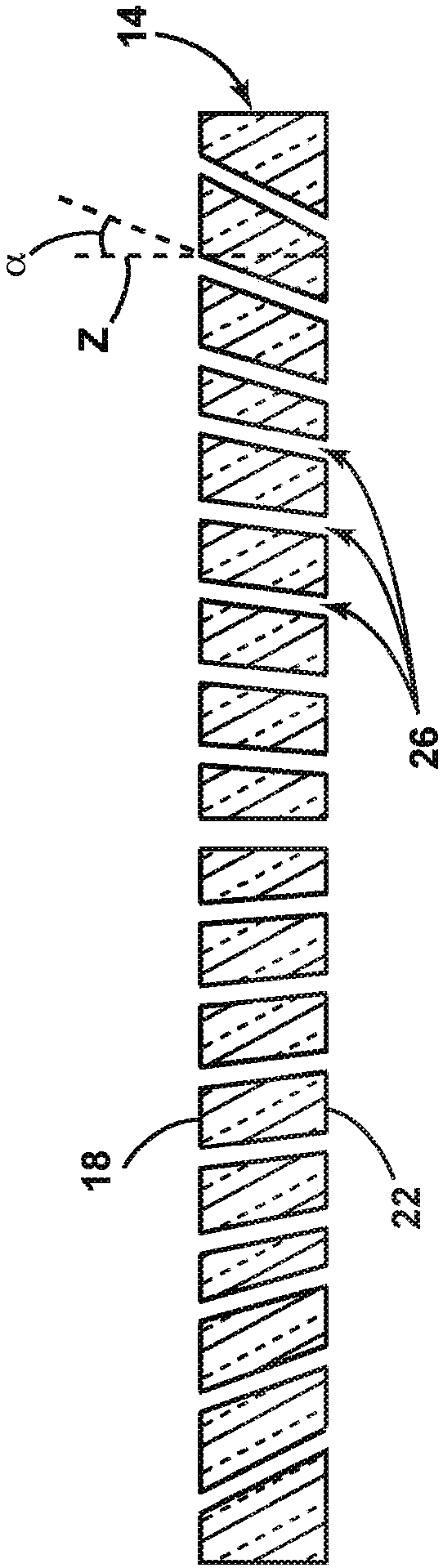

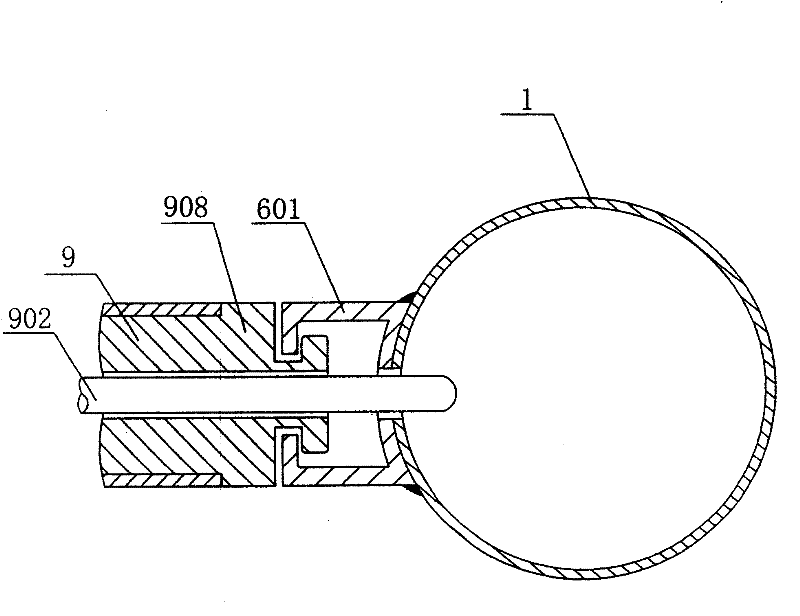

Gas permeable window and method of fabricating the same

InactiveCN107666983AManufacturing platforms/substratesLamination ancillary operationsEngineeringMaterials science

A gas permeable glass window, suitable for use with liquid interface additive manufacturing, has an optically transparent glass article greater than about 0.5 millimeters in thickness defining a firstsurface and a second surface. A plurality of gas channels are disposed through the article from the first surface to the second surface. The gas channels occupy less than about 1.0% of a surface areaof the article and are configured such that the article has a gas permeability between about 10 barrers and about 2000 barrers.

Owner:CORNING INC

Gas separation membrane and preparation method and application thereof

ActiveCN113786743AImproved Separation FactorImprove mechanical propertiesProductsSemi-permeable membranesPhysical chemistryIntrinsic viscosity

The invention discloses a gas separation membrane, and a preparation method and application thereof. The gas separation membrane comprising 60-100 mol% of monomeric units derived from alpha,beta,beta-trifluorostyrene, has an intrinsic viscosity of 0.5-5.0 dL / g, a tensile strength of at least 50 MPa, and a hydrogen permeability coefficient of at least 100 barrer according to a test result of the GB / T 1038-2000 test method.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS +2

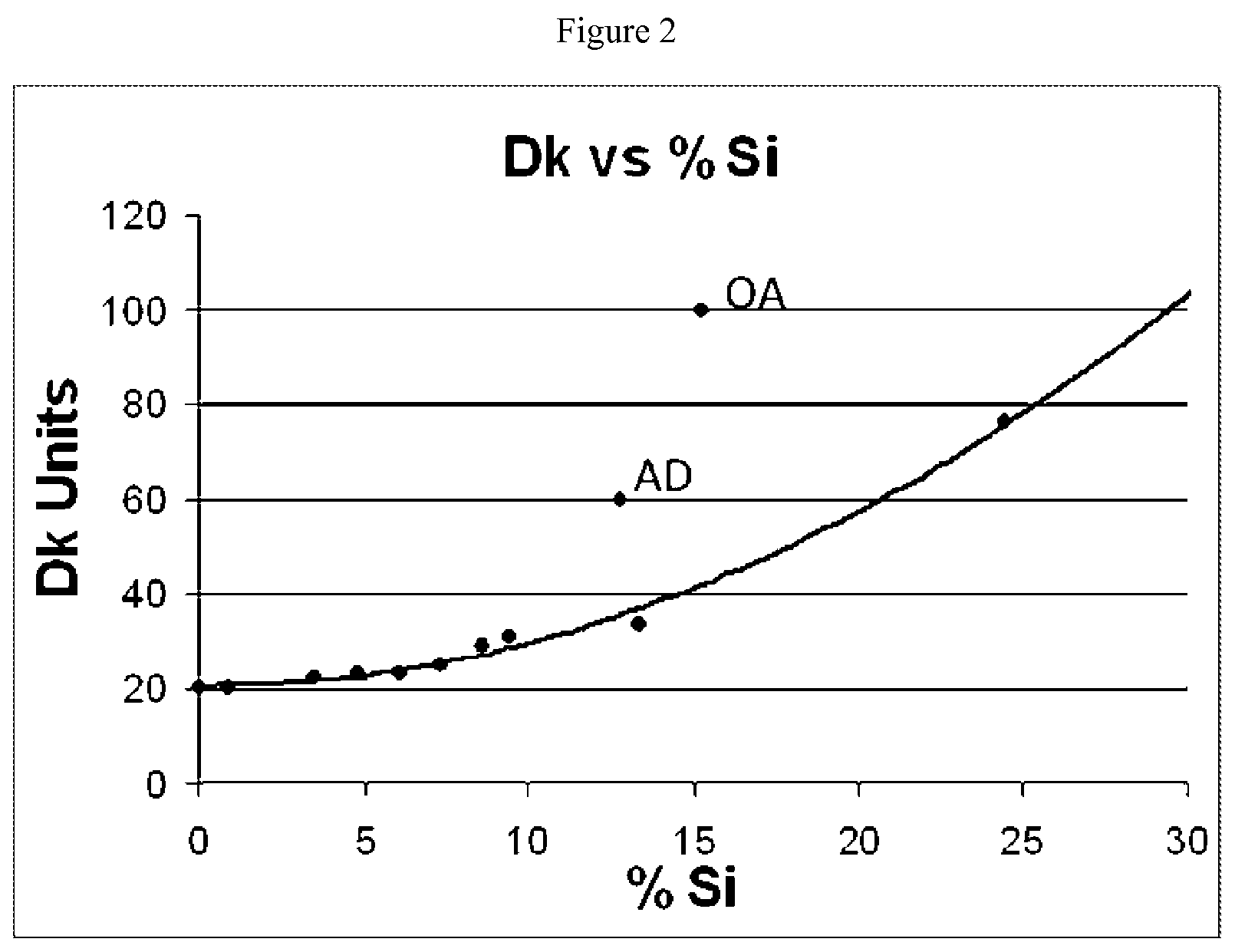

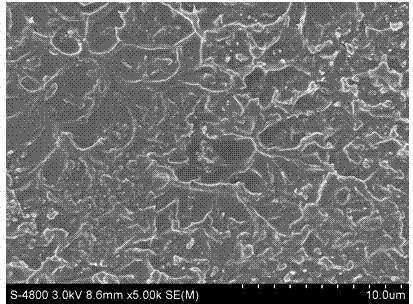

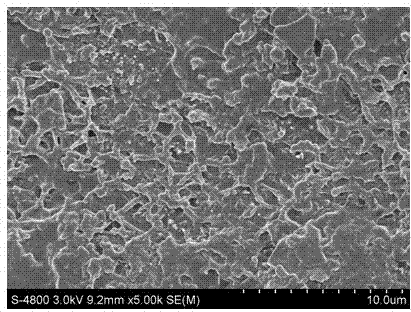

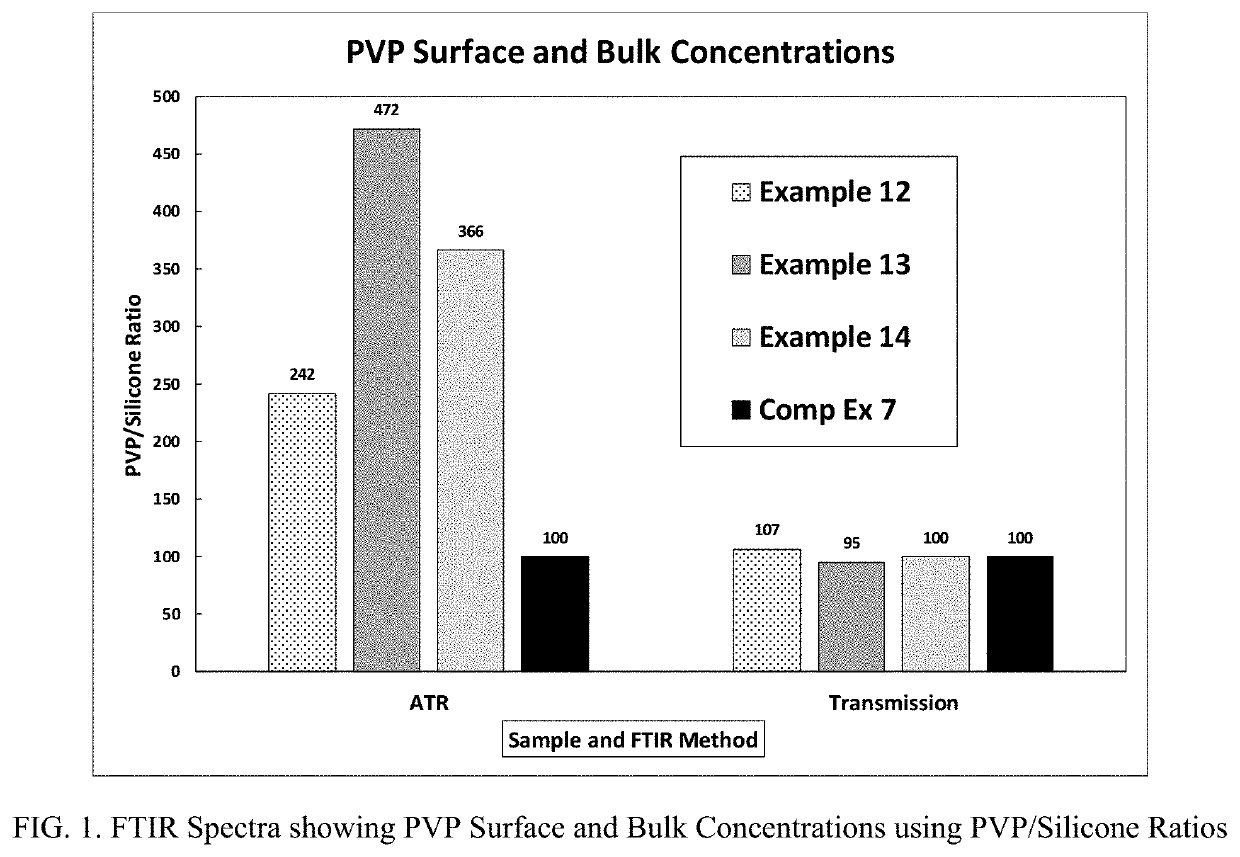

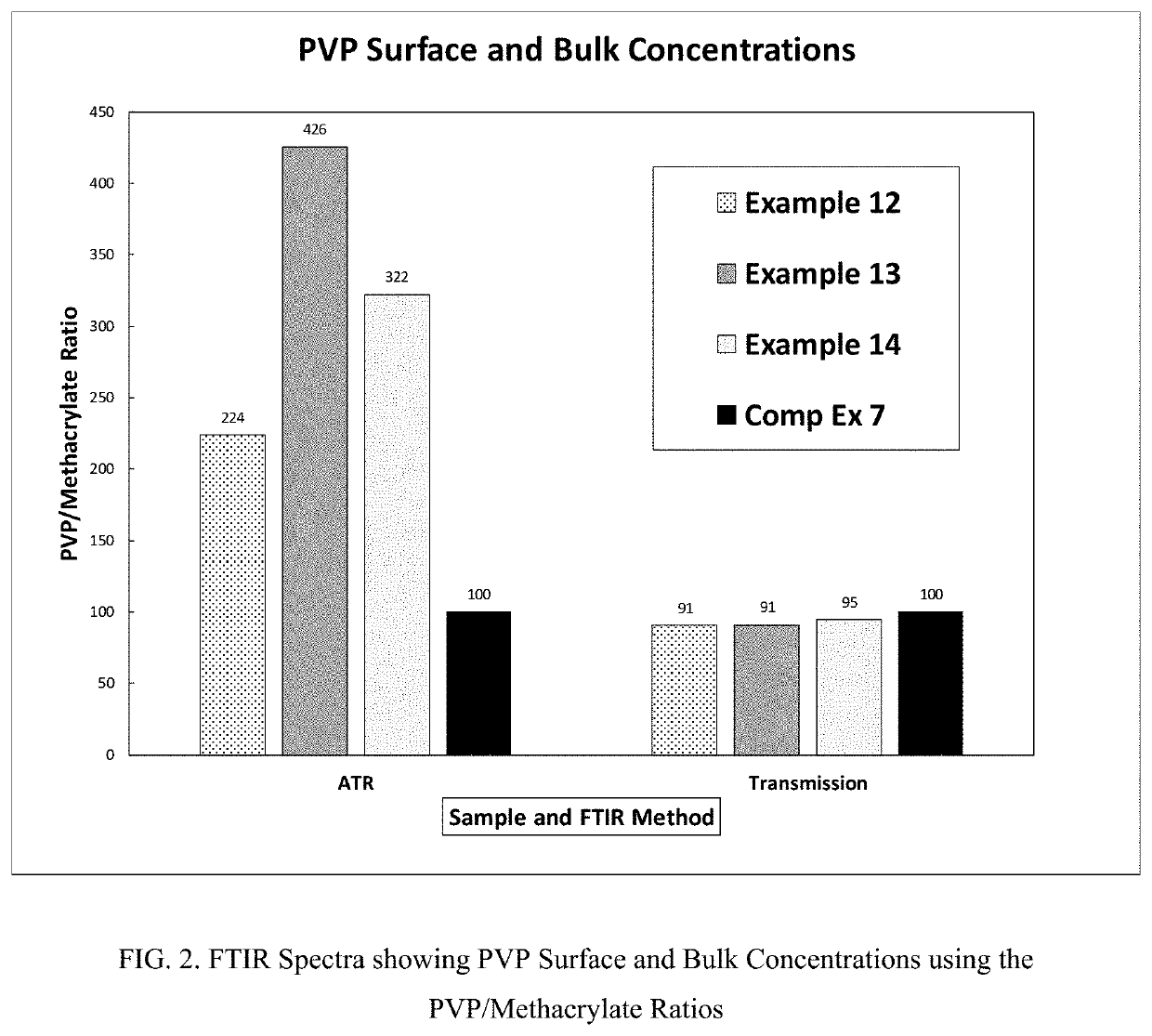

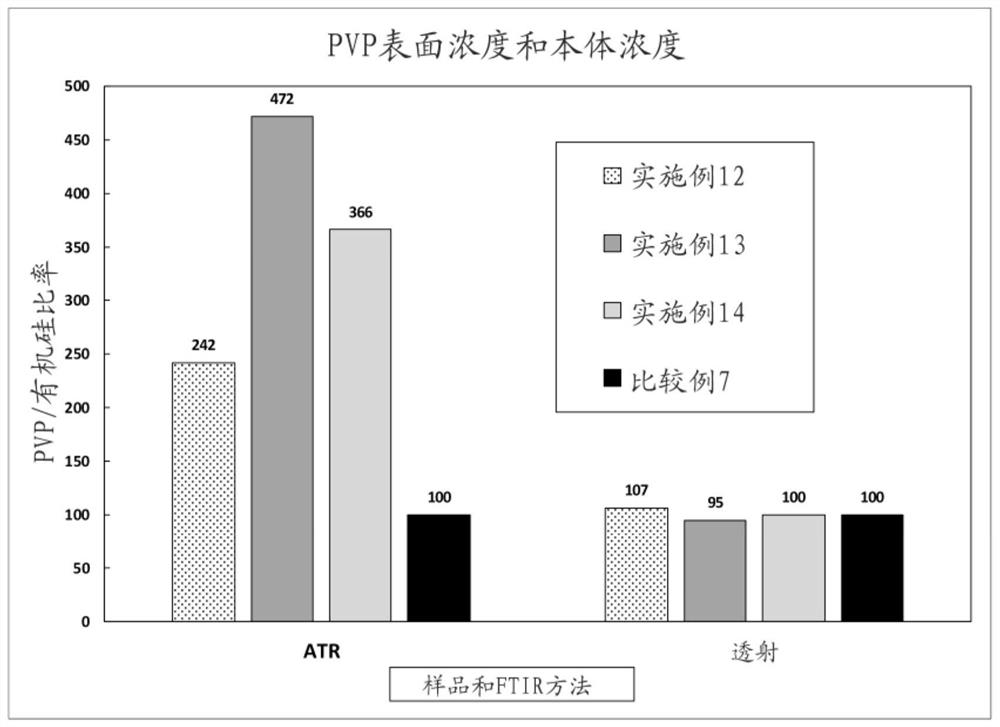

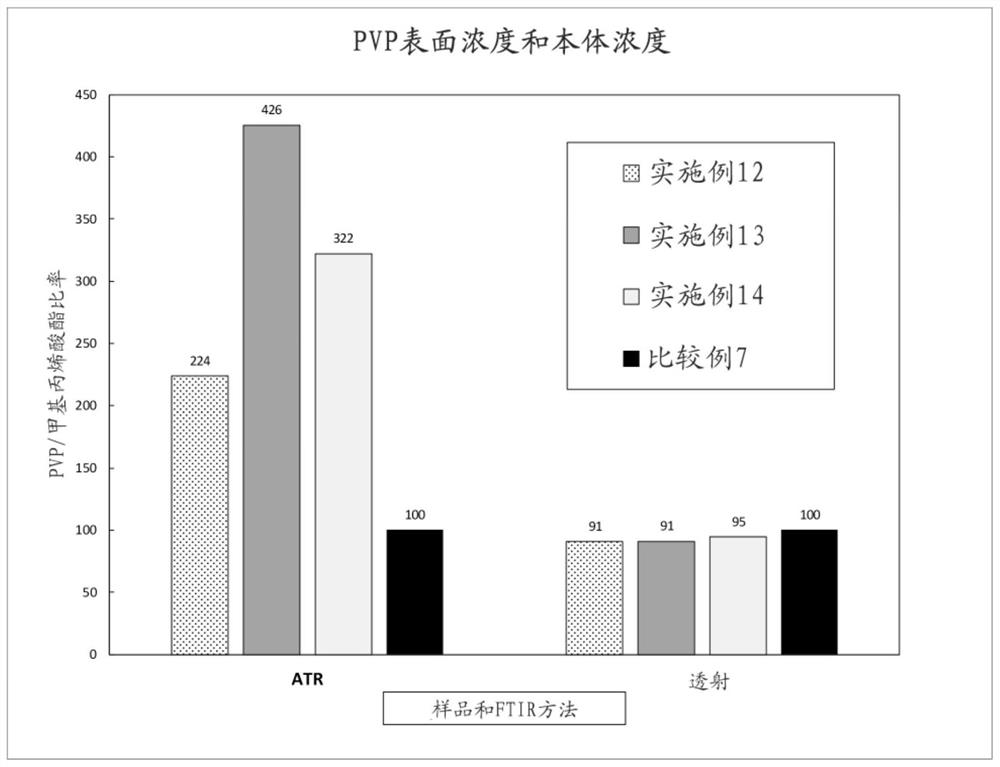

Silicone hydrogel contact lenses having non-uniform morphology

ActiveUS20200399429A1More efficientImprove surface wettabilityOptical articlesOptical partsPolymer sciencePolymer chemistry

Described is a silicone hydrogel contact lens having non-uniform morphology. The contact lens may be made from a reactive mixture comprising: a silicone-containing component; a hydrophilic component; a non-reactive polymeric internal wetting agent; and a polymerization initiator, the contact lens having an oxygen permeability of at least about 60 barrers, and wherein the molar ratio in the lens of the polymeric non-reactive internal wetting agent to silicone, without a surface treatment, is greater in the lens's surface than in its bulk.

Owner:JOHNSON & JOHNSON VISION CARE INC

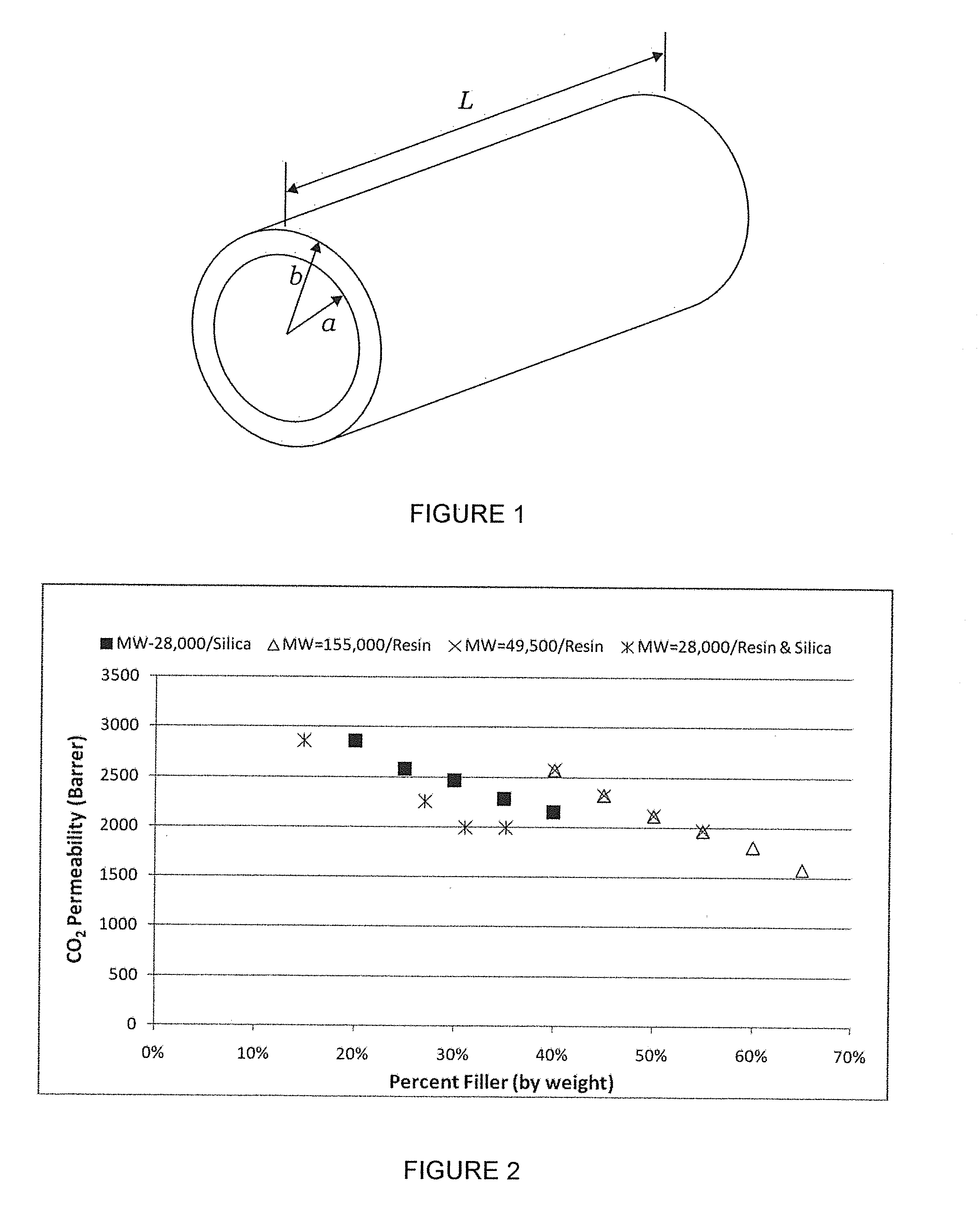

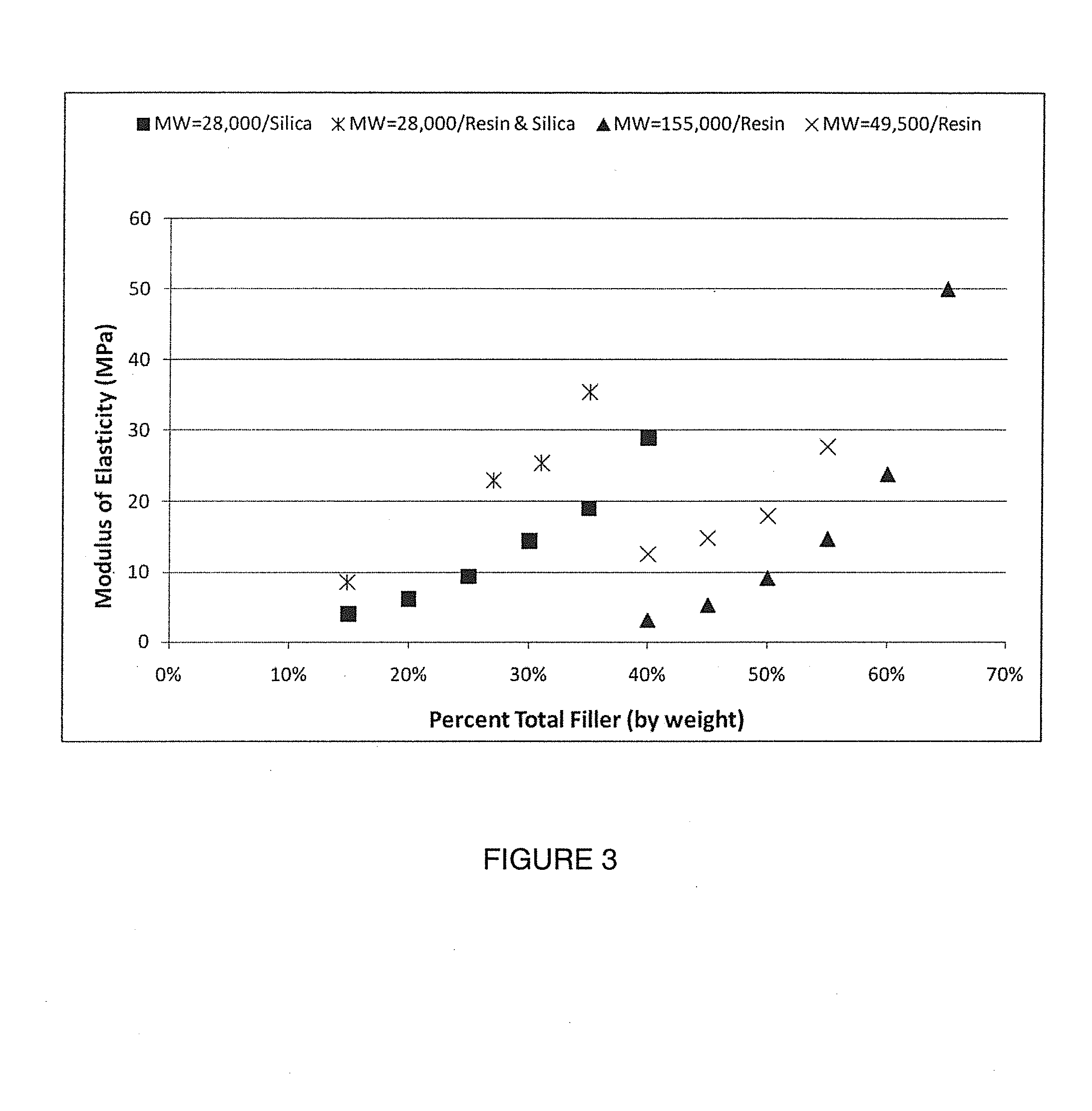

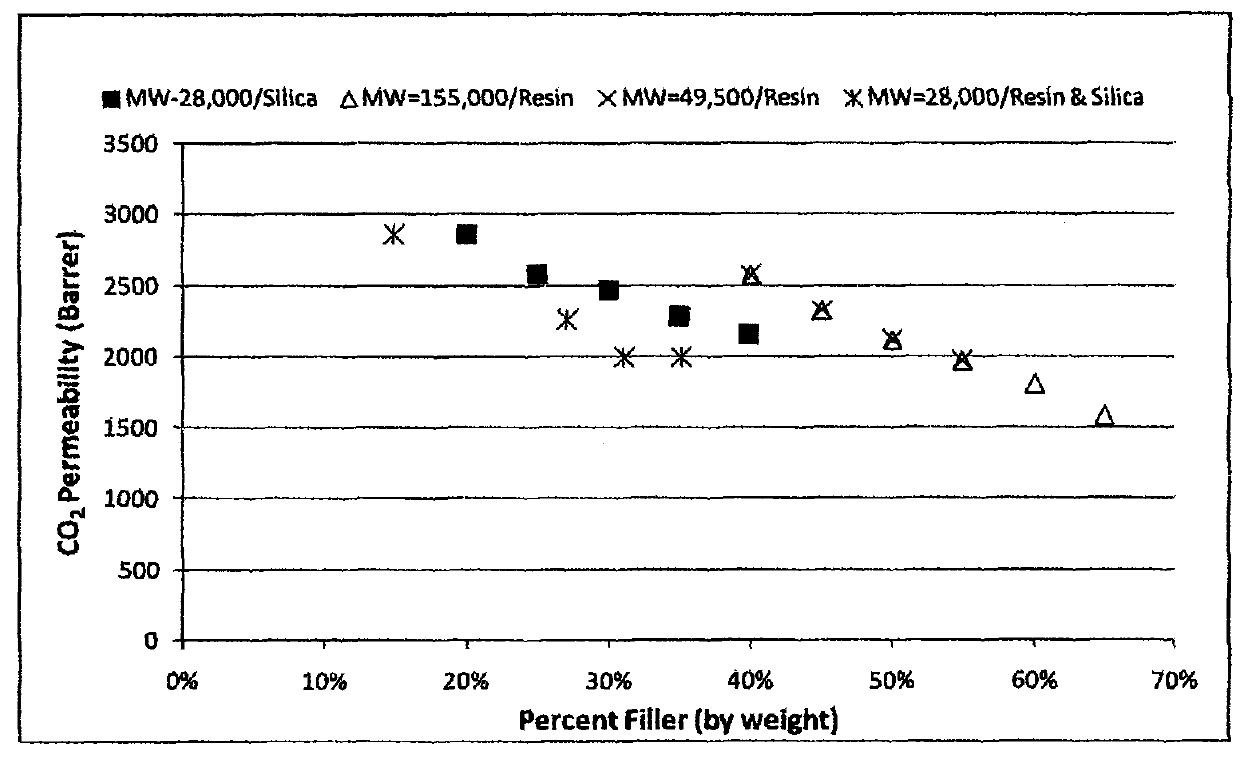

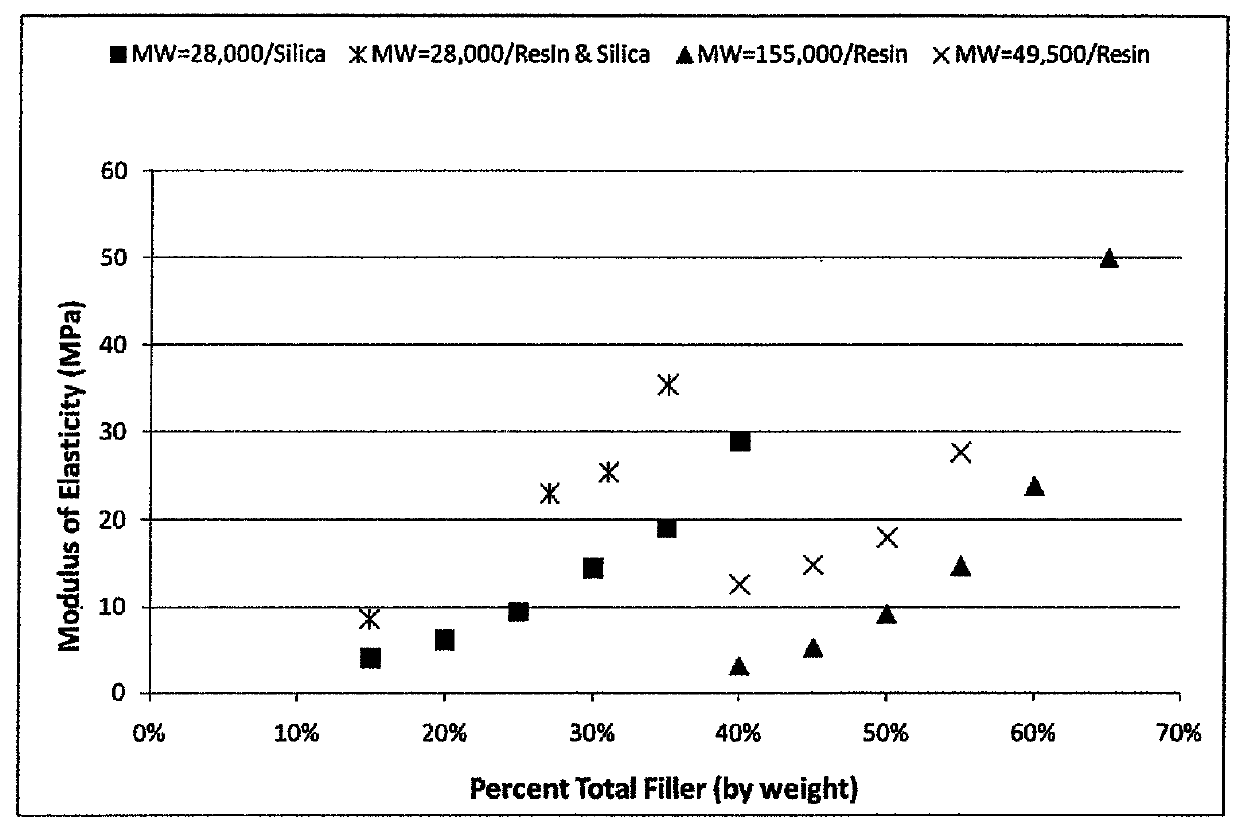

A kind of preparation method of gas separation membrane with high MOF filler content

ActiveCN110639374BSemi-permeable membranesDispersed particle separationPhysical chemistryPolymer solution

The invention discloses a method for preparing a gas separation membrane with high MOF filler content, and belongs to the technical field of membrane separation. Disperse MOF particles in a solvent to prepare MOF "ink", and then mix the "ink" with the polymer solution in a water bath and ultrasonically make the two compatible. The film solution obtained after the solvent evaporated was poured on a glass plate and scraped to remove the solvent to obtain a film with a high MOF filler content. Finally, the obtained membrane is immersed in an appropriate amount of polymer solution, and the solvent is completely volatilized to obtain a high-MOF filler gas separation membrane with high gas separation performance. The membrane can avoid the problem of agglomeration caused by excessive filler content in traditional mixed matrix membranes, which leads to the degradation of separation performance. Its MOF filler content can reach up to 70%, and it shows the 2 / N 2 , CO 2 / CH 4 、H 2 / N 2 、H 2 / CO 2 With moderate selectivity for such gas pairs, the gas permeability coefficient can reach thousands of barrers, which is expected to meet the requirements of practical industrial applications.

Owner:DALIAN UNIV OF TECH

Process method of improved 13X molecular screen

InactiveCN1323944CChange compositionStable productionOther chemical processesFaujasite aluminosilicate zeoliteMolecular sieveSodium aluminate

The disclosed preparation method with hydrothermal and Barrer non-equilibrium synthesis techniques is for improved 13X molecular sieve. Wherein, the said sieve is metastable phase; when using sodium silicate and sodium aluminate as silicon source and aluminium source separately, the silicate radical has different polymerization states, the aluminate radical and aluminosilicate radical have different structures and states; in alkaline condition, the silicate and aluminate polymerize and form crystallized glue and obtain the said sieve; wherein, the mole ratio of indredients is: Na2O / Al2O3: 3.0-4.0, SiO2 / Al2O3: 2.5-3.2, H2O / Al2O3: 30-40.

Owner:LUOYANG JALON MICRO NANO NEW MATERIALS CO LTD

Siloxane based hollow fibers

The present invention provides inventive hollow fibers having defined gas permability characteristics. Hollow fibers of the present invention are characterized by a PMPCO2 greater than 30,000 Barrer*MPa. Curable compositions and silicone elastomers produced by curing the curable compositions are provided by the present invention. Compositions and methods for making the hollow fibers and devices incorporating them are provided by the present invention.

Owner:MEDARRAY

A kind of amphiphilic copolymer network and preparation method thereof

The invention discloses an amphiphilic copolymer network, which is composed of a star amphiphilic copolymer and a hydrosilation crosslinking agent by crosslinking, wherein the star amphiphilic copolymer is prepared by carrying out chemical reaction on a star amphiphilic homopolymer and a suspension alkynyl containing hydrophobic segmented copolymer; and the swelling degree of the amphiphilic copolymer network in n-hexane is 20-150%, the swelling degree of the amphiphilic copolymer network in water is 50-800%, the swelling degree of the amphiphilic copolymer network in ethanol is 400-1000%, and the oxygen transmittance is 500-1600 Barrers. The amphiphilic copolymer network can be used as a medical polymer material. The invention also discloses a preparation method of the amphiphilic copolymer network.

Owner:DONGHUA UNIV

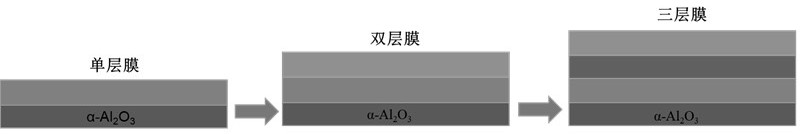

A kind of preparation method of multi-layer il@mof composite film

Owner:BEIJING UNIV OF CHEM TECH

A mixed matrix membrane with highly selective gas channels and its preparation method

ActiveCN111744375BAddressing the Effects of Gas Separation PerformanceImprove permeabilitySemi-permeable membranesGas treatmentHydrophilic polymersPolyvinyl alcohol

The application discloses a mixed matrix membrane with a highly selective gas channel and a preparation method thereof, belonging to the technical field of membrane separation. The preparation process is to first coat polydimethylsiloxane and polyvinyl alcohol on the surface of polysulfone to prepare a hydrophilic modified polysulfone membrane, and then adopt low-temperature solid-phase synthesis method, using metal salt and ligand In-situ synthesis of metal composite hydrophobic filler particles on the surface of the obtained hydrophilic modified polysulfone membrane to obtain a hydrophobic HMP / MPSf membrane, and finally coating the hydrophilic polymer polyvinylamine on the surface of the hydrophobic HMP / MPSf membrane After interfacial self-assembly and drying, a mixed matrix membrane with highly selective gas channels was obtained, and its CO 2 The penetration rate is 1800‑3400GPU, CO 2 The permeability coefficient is 490‑995 Barrer, CO 2 / N 2 The selectivity is preferably 65-70, especially suitable for the separation of mixed gases containing carbon dioxide.

Owner:中恒新材料科技(山东)有限责任公司

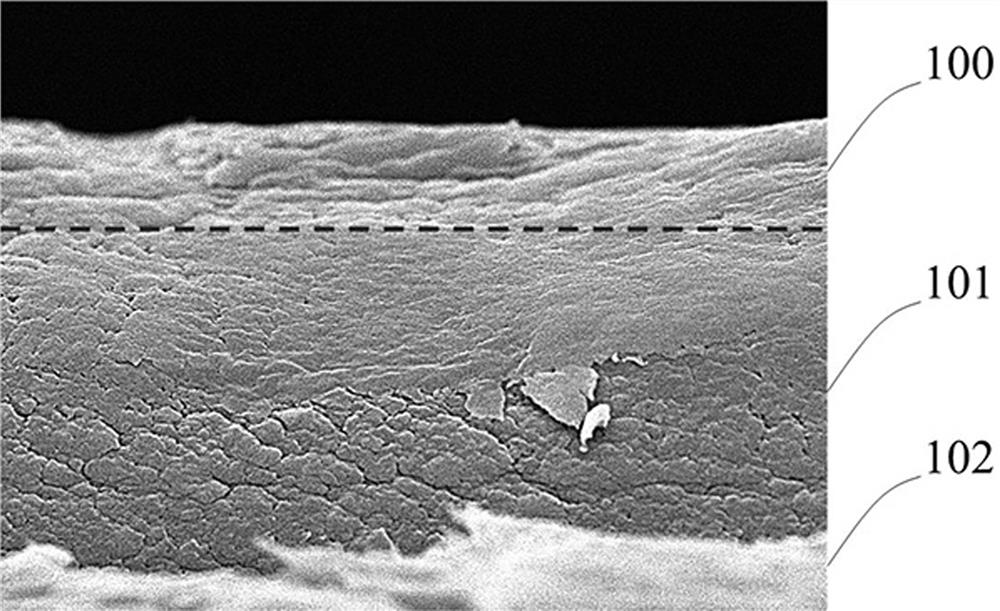

A carbon dioxide separation membrane and its application

ActiveCN113663540BHigh selectivityImprove permeabilitySemi-permeable membranesDispersed particle separationNanoparticles dispersionNanoparti cles

The invention discloses a carbon dioxide separation membrane and its application. The carbon dioxide separation membrane comprises a support layer, a nanoparticle composite layer and a polymer layer arranged in sequence; the carbon dioxide permeability of the carbon dioxide separation membrane is greater than 3400 Barrer, CO 2 / N 2 The selection factor is greater than 45. The carbon dioxide separation membrane prepared by the present invention has a three-layer structure, and the nanoparticle composite layer is formed by combining nanoparticles and the first polymer to solve the defect problem caused by uneven dispersion or agglomeration of nanoparticles in the mixed matrix membrane in the related art; At the same time, it also solves the problem of selectivity loss caused by the mismatch between the polymer component and the inorganic nanoparticle phase interface in the traditional mixed matrix membrane. The carbon dioxide separation membrane of the present invention has high selectivity to carbon dioxide and high permeability.

Owner:湖南叶之能科技有限公司

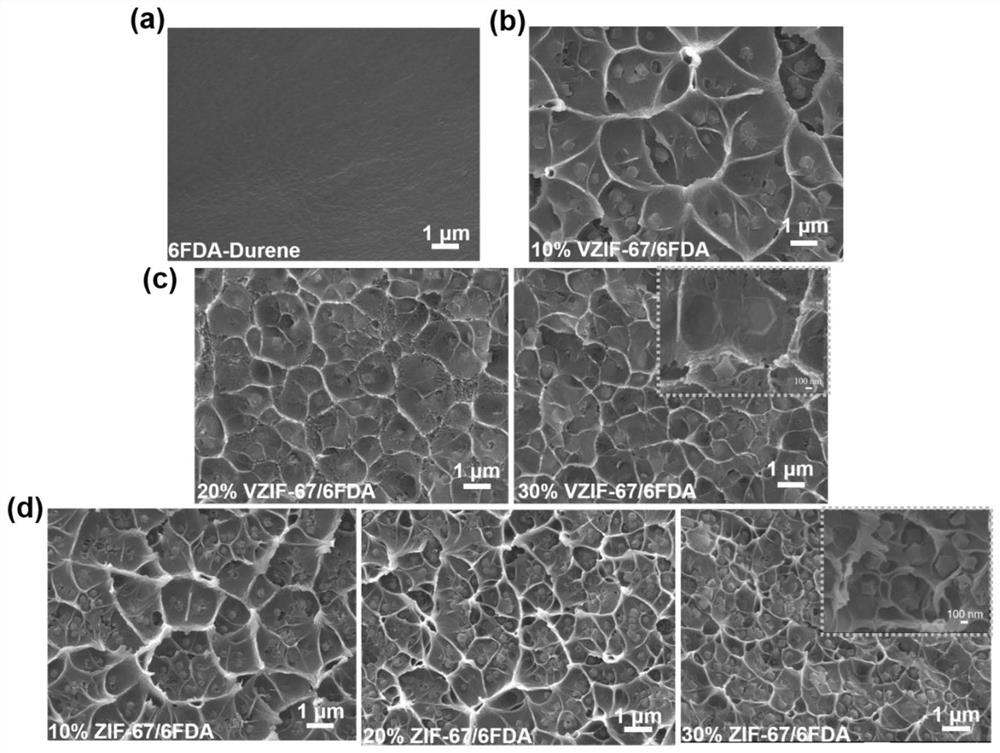

vzif-67/zif-67-polyimide mixed matrix film, preparation method and application thereof

ActiveCN113413777BAchieve selective separationEasy to separateProductsSemi-permeable membranesPolymer sciencePolyimide membrane

The invention discloses a VZIF-67 / ZIF-67-polyimide mixed matrix film, a preparation method and an application. The material of the matrix film is polyimide 6FDA-Durene, the filler is VZIF-67 or ZIF-67, and the filler is The mass fraction in the mixed matrix film is 10-30%, and the rest is polyimide 6FDA-Durene. VZIF-67 is uniformly dispersed in the matrix film solution by ultrasonic dispersion, and the solution casting method is used to prepare the described VZIF‑67 / polyimide mixed matrix membrane. The mixed matrix membrane pair separates CO 2 / CH 4 The mixed gas has remarkable separation performance (PCO 2 >1210 Barrer, αCO 2 / CH 4 >32.5), with higher CO compared to pure polyimide membrane 2 The gas permeability and separation selectivity can be applied to the purification of natural gas.

Owner:NANJING UNIV OF SCI & TECH

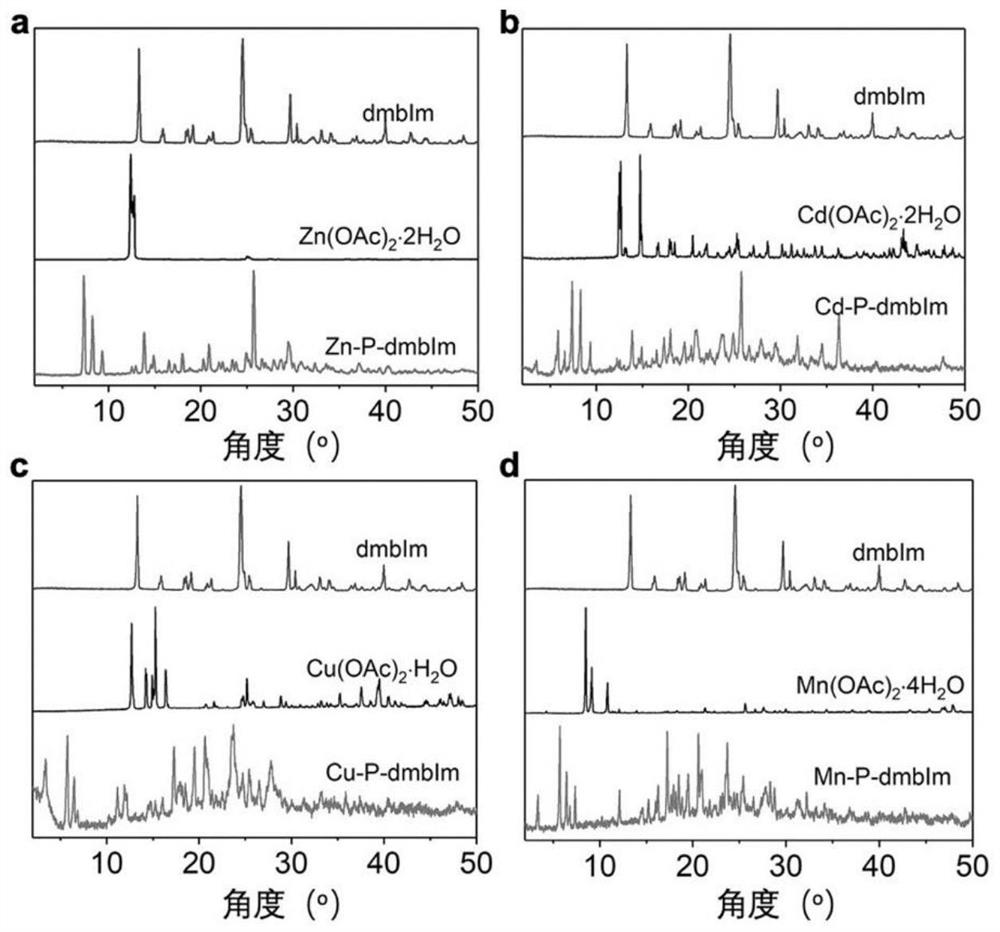

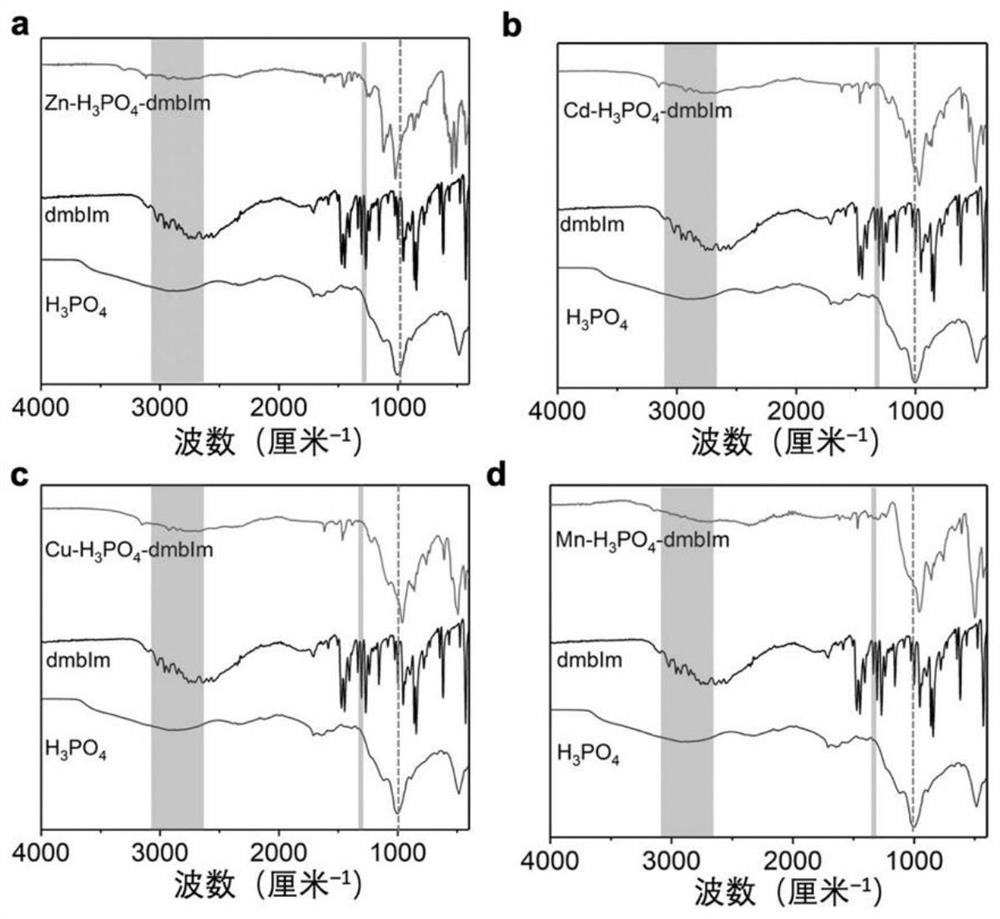

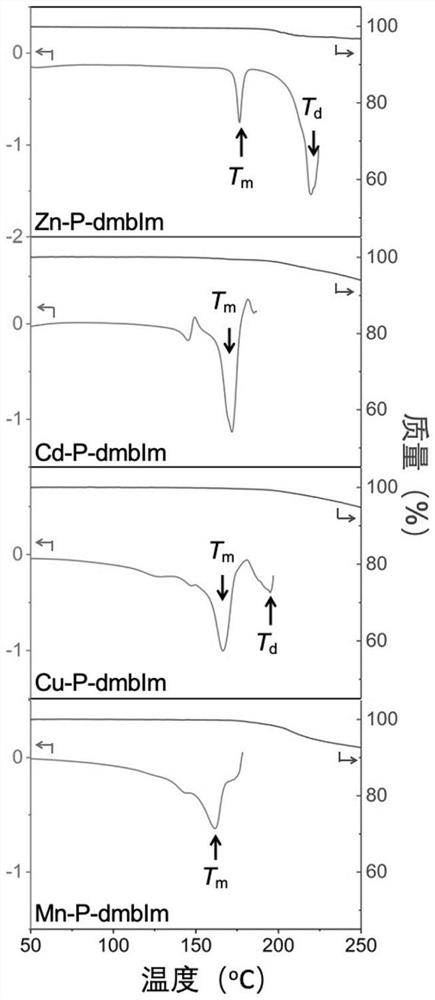

A class of glassy MOF membrane material with hydrogen separation properties and preparation method thereof

A class of glassy MOF membrane materials with hydrogen separation properties of the present invention is obtained by pressing the obtained MOFs powder material into tablets-melting-cooling or hot pressing on a substrate to prepare a glassy MOF with hydrogen separation properties The membrane material method is characterized in that: the steps are as follows: MOFs powder material preparation method: mix the materials in 2 or 3, add ethanol to grind, wash and dry the solid to obtain the target product, this kind of glassy MOFs membrane material It is synthesized by melting-cooling method for MOFs materials with glass transition behavior. This method is universal, easy to operate, low in raw material cost, large-scale processability, and different selectivities can be obtained by adjusting different metal salts The separation membrane material, the prepared glass MOF membrane H 2 / CO 2 The highest separation ratio can reach 92.7, and it has a hydrogen flux of 230.4 Barrer.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation and application of an ionic liquid blend membrane

InactiveCN105749769BIncrease penetration rateImprove performanceSemi-permeable membranesDispersed particle separationLoss rateRoom temperature

The invention discloses a preparation method and application of an ionic liquid blended membrane and belongs to the technical field of gas separating membranes.The preparation method includes: preparing a polyoxyethylene-polycaprolactam segmented copolymer solution, and adding imidazole type room-temperature ionic liquid into the solution to obtain membrane casting liquid; drying at room temperature, and further drying under a vacuum condition to obtain the ionic liquid blended membrane.The preparation method and the application have the advantages that the preparation method is simple, and the ionic liquid is fixed in macromolecular chains, thereby being low in loss rate; the composite membrane prepared by the method has excellent comprehensive performance when being used for gas separation; especially, the blanded membrane filled with 1-butyl-2, 3-dimethyl imidazole hexafluorophosphate of 40% in mass percentage has high CO2 seepage velocity and CO2 / CH4 and CO2 / N2 selectivity, CO2 seepage coefficient in a pure gas test under a humidifying condition can reach 695 Barrer, CO2 / CH4 selectivity is 35, and CO2 / N4 selectivity is 42.

Owner:TIANJIN UNIV

A kind of polyimide gas separation membrane and its preparation method and application

ActiveCN104829853BImprove permeabilityHigh selectivityProductsSemi-permeable membranesHeat resistanceProduct gas

The invention discloses a polyimide gas separation membrane as well as a preparation method and applications thereof. The separation membrane is made of a polyimide resin which is shown in a formula I and has a fluorobenzene side group containing structure. The polyimide gas separation membrane has the characteristics of high permeability and high selectivity, the permeability coefficient to CO2 is greater than or equal to 180 barrer, the selective coefficient to CO2 / CH4 is greater than 30, and the separation membrane shows excellent heat resistance and mechanical properties. The gas separation membrane has an important application value in various CO2-related separation and recovery applications such as the separation of carbon dioxide and methane in biological gas, the removal of acid gases such as carbon dioxide and the like, the recovery of carbon dioxide in tertiary oil recovery of oil fields, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Amphiprotic co-continuous polymer network, preparation method and application thereof

InactiveCN101293963BIncrease temperaturePharmaceutical non-active ingredientsProsthesisPolymer scienceMeth-

The invention relates to an amphoteric co-continuous polymer network. The amphoteric co-continuous polymer network is prepared through chemical crosslinking reaction by using an organic siloxane polymer as a raw material and N-isopropyl acrylamide as a reactant monomer to generate a graft copolymer. The gel dissolving rate in water is in the range of 0-10%, the swelling rate in water is in the range of 20-50%, and the oxygen transmissibility is in the range of 150-600 barrers. The invention also relates to a method for producing the amphoteric co-continuous polymer network. The method comprises the following steps: (1) synthesis of methacrylic acid-3-(1,1,3,3-tetramethyldisiloxane)propyl ester; (2) preparation of a modified unsaturated organic siloxane polymer mixture; (3) synthesis of the graft copolymer; and (4) preparation of amphoteric co-continuous network. The amphoteric co-continuous polymer network is used for biomedical materials, including contact lens, artificial organs, controlled-release drug carriers etc.

Owner:DONGHUA UNIV

Silicone hydrogel contact lenses having non-uniform morphology

PendingCN112437889AEasy to useImprove surface wettabilityOptical articlesOptical partsPolymer scienceOxygen permeability

Described is a silicone hydrogel contact lens having non-uniform morphology. The contact lens may be made from a reactive mixture comprising: a silicone-containing component; a hydrophilic component;a non-reactive polymeric internal wetting agent; and a polymerization initiator, the contact lens having an oxygen permeability of at least about 60 barrers, and wherein the molar ratio in the lens ofthe polymeric non-reactive internal wetting agent to silicone, without a surface treatment, is greater in the lens's surface than in its bulk.

Owner:强生视力健公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com