Silicone hydrogel contact lenses having non-uniform morphology

A contact lens and silicone technology, applied in home appliances, other home appliances, glasses/goggles, etc., can solve problems such as excessive eye deposits and reduced visual acuity, reduce costs, and simplify the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 9

[0384] A reactive monomer mixture was prepared consisting of 77% by weight of the formulation listed in Table 1 and 23% by weight of diluent D3O. Filter the reactive monomer mixture separately through a 3 μm filter using a stainless steel syringe. Then, at the time of use, about 0.074 grams of AIBN (thermal initiator) was dissolved in 20.0000 grams of RMM. The weight percent of AIBN in the final RMM was about 0.37% by weight.

[0385] The RMM with AIBN was degassed at ambient temperature by applying vacuum (40 Torr) for at least 20 minutes. Then, about 75 μL to 80 μL of the reactive mixture was dosed with an Eppendorf pipette into the FC made of Zeonor at room temperature in a glove box with a nitrogen atmosphere and less than about 0.2% oxygen. A BC made of a 55:45 (w / w) Z:PP blend was then placed onto the FC. The molds were allowed to equilibrate in the glove box for a minimum of twelve hours prior to batching. Approximately 20 pallets each comprising eight mold assembli...

Embodiment 8 to 11

[0410] A reactive monomer mixture was prepared consisting of 77% by weight of the formulation listed in Table 5 and 23% by weight of diluent D3O. PVMA from Preparation 1 was used. Filter the reactive monomer mixture separately through a 3 μm filter using a stainless steel syringe. Then, at the time of use, about 0.037 grams of AIBN (thermal initiator) was dissolved in 10.0000 grams of RMM. The weight percent of AIBN in the final RMM was about 0.37% by weight.

[0411] The RMM with AIBN was degassed at ambient temperature by applying vacuum (40 Torr) for at least 20 minutes. Then, about 70 μL to 75 μL of the reactive mixture was dosed with an Eppendorf pipette into the FC made of Zeonor at room temperature in a glove box with a nitrogen atmosphere and less than about 0.2% oxygen. A BC made of a 55:45 (w / w) Z:PP blend was then placed onto the FC. The molds were allowed to equilibrate in the glove box for a minimum of twelve hours prior to batching. Approximately 20 pallets ...

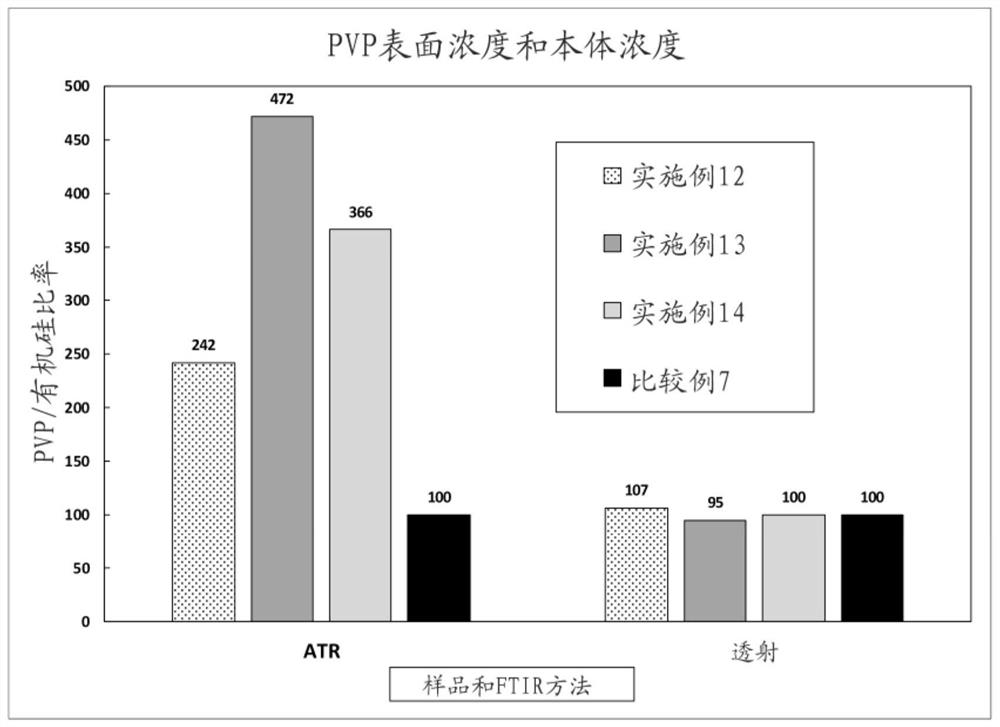

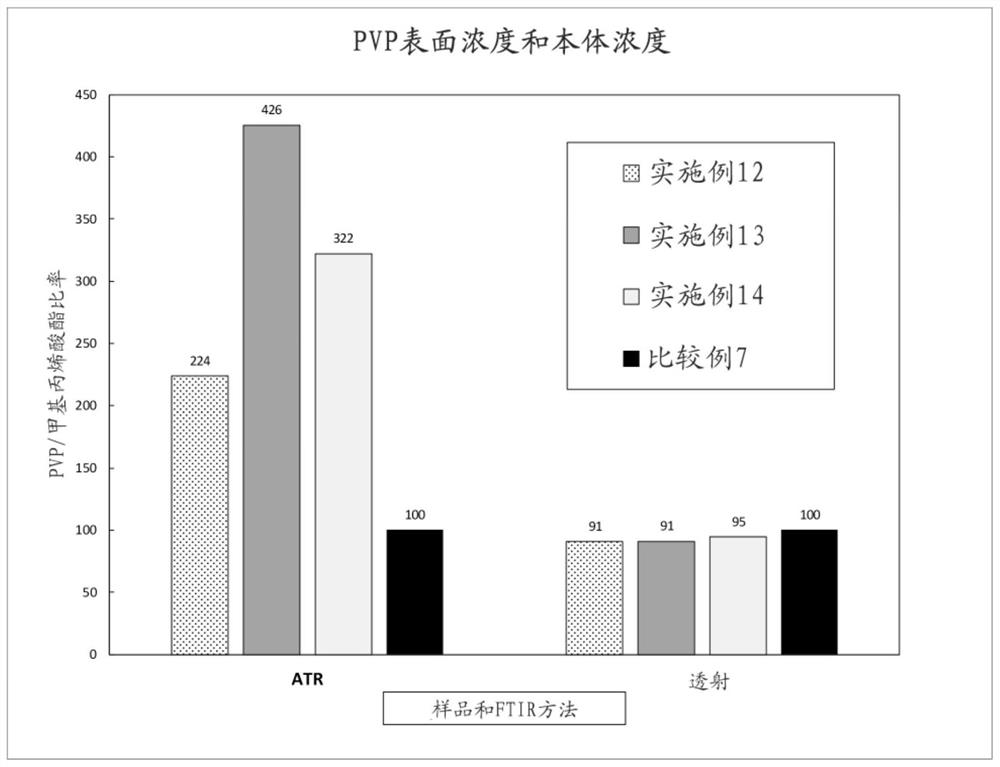

Embodiment 12 to 14

[0431] A reactive monomer mixture was prepared consisting of 77% by weight of the formulation listed in Table 9 and 23% by weight of diluent D3O. Filter the reactive monomer mixture separately through a 3 μm filter using a stainless steel syringe. Then, at the time of use, about 0.0285 grams of AIBN (Thermal Initiator) was dissolved in 10.0000 grams of RMM. The weight percent of AIBN in the final RMM was about 0.28% by weight.

[0432] The RMM with AIBN was degassed at ambient temperature by applying vacuum (40 Torr) for at least 20 minutes. Then, about 75 μL of the reactive mixture was dosed with an Eppendorf pipette into the FC made of Zeonor at room temperature in a glove box with a nitrogen atmosphere and less than about 0.1% to 0.2% oxygen. Then, place the BC, also made of Zeonor, onto the FC. The molds were allowed to equilibrate in the glove box for a minimum of twelve hours prior to batching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com