Process method of improved 13X molecular screen

A manufacturing process and molecular sieve technology, which is applied in the chemical industry, can solve the problem of low bulk density of molecular sieves, and achieve the effects of improving product performance and efficiency, stable production, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

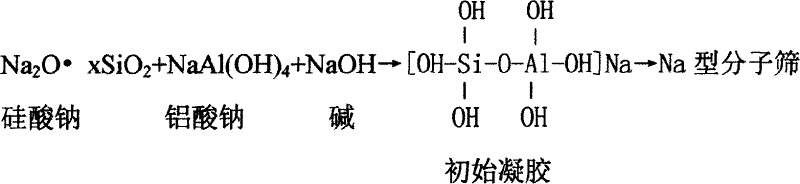

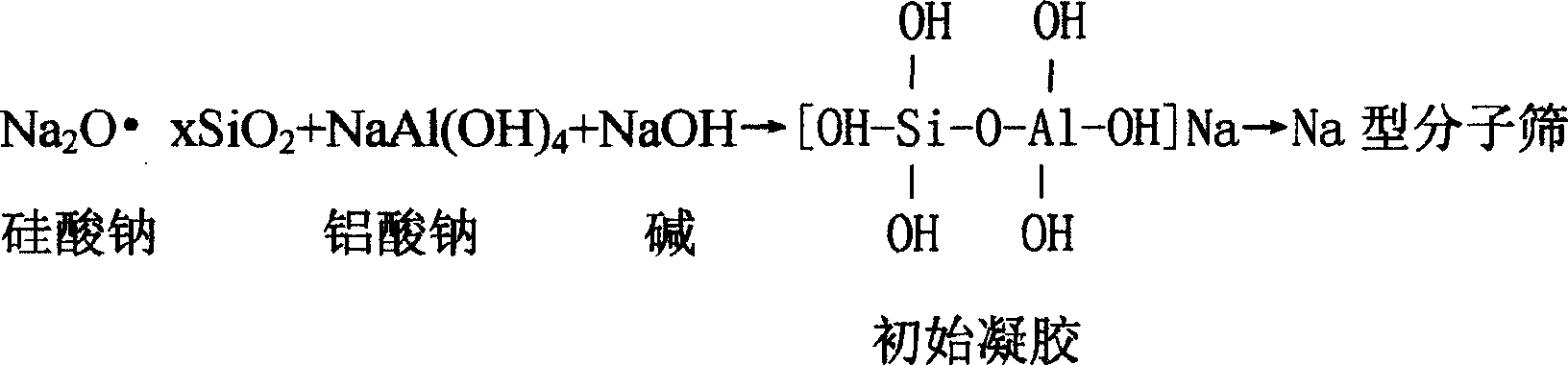

[0041] According to the ratio of ingredients: (molar ratio)

[0042] Take Na 2 O / Al 2 o 3 3.0~4.0

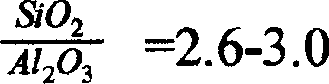

[0043] SiO 2 / Al 2 o 3 2.5~3.0

[0044] h 2 O / Al 2 o 3 30~40

[0045] Synthesis: aging and crystallization According to the given process formula and process conditions, calculate the dosage of various materials, according to the order of feeding, after feeding into gel, transfer to the crystallization tank for aging, after aging, heat up and crystallize , according to the specified crystallization time, after the crystallization is completed, the material is discharged;

[0046] Filtration: Filter the synthesized slurry through a plate-and-frame filter to achieve solid-liquid separation, and recycle the remaining NaOH mother liquor, then wash with water to PH10-11, wind pressure drainage, and discharge;

[0047] Drying: Add the air-pressed filter cake to the flash drying equipment to dry and remove the wet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com