Online hydrogen production method and equipment with methanol oxidation and steam reforming segmental combined

A methanol oxidation and water vapor technology, applied in chemical instruments and methods, hydrogen/syngas production, hydrogen and other directions, can solve the problems of inevitable local overheating and bed overheating, affecting hydrogen online production, poor thermal stability of catalysts, etc. , to achieve the effect of low cost, fast reaction start and high hydrogen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

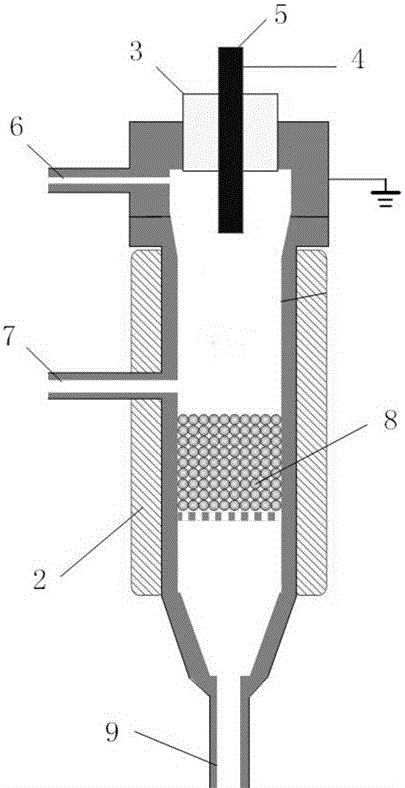

[0015] Equipment used such as figure 1 As shown: there is a stainless steel cylindrical reactor 1, and the outer side of the cylindrical reactor 1 has an insulating layer 2 to insulate the cylindrical reactor 1. The top of the cylindrical reactor 1 has a ceramic insulating cover 3, which is in phase with the high-voltage power supply 4. The connected discharge electrode 5 (sliding arc discharge high-voltage electrode) vertically passes through the axis of the cover 3, and a section of gas inlet 6 is provided on the cylindrical reactor 1 above the end of the discharge electrode 5, and a gas inlet 6 is provided in the cylindrical reactor 1. Catalyst bed 8 is arranged, and the distance between described discharge electrode 5 ends and catalyst bed 8 is 8 cm, is provided with the second stage gas between discharge electrode 5 ends and catalyst bed 8 on cylinder reactor 1 Inlet 7, below the catalyst bed 8 is a gas outlet 9. The high-voltage power supply 4 can be a DC high-voltage p...

Embodiment 2

[0033] Equipment used such as figure 1 As shown, except that the distance between the end of the discharge electrode 5 and the catalyst bed 8 is 15 cm, the other structures are the same as those in Example 1. What this embodiment 2 adopted is commercial copper-based catalyst (Cu / ZnO / Al 2 o 3 ), the space velocity is 8000 ml / g h.

[0034] The method is to follow the steps as follows:

[0035] a. Mix water and methanol at a molar ratio of 0.5:1, vaporize or atomize to obtain methanol and water mixed steam A, mix methanol and water mixed steam A with air to obtain a mixed gas, in which methanol and water The molar ratio of oxygen is 1:0.3;

[0036] b. Make the resulting mixed gas tangentially enter the reactor 1 through a section of gas inlet 6 to carry out the sliding arc discharge plasma oxidation reforming reaction to obtain the reforming hot gas, and the specific energy input of the plasma (the ratio of the input power to the total flow rate of methanol ) is 0.34 kW: 1kg...

Embodiment 3

[0049] Equipment used such as figure 1 As shown, except that the distance between the end of the discharge electrode 5 and the catalyst bed 8 is 20 cm, the other structures are the same as those in Example 1. What this embodiment 3 adopted is commercial copper-based catalyst (Cu / ZnO / Al 2 o 3 ), the space velocity is 6000 ml / g h.

[0050] The method is to follow the steps as follows:

[0051] a. Mix water and methanol at a molar ratio of 0.5:1, vaporize or atomize to obtain methanol and water mixed steam A, mix methanol and water mixed steam A with air to obtain a mixed gas, and in the mixed gas, methanol and The molar ratio of oxygen is 1:0.3;

[0052] b. Make the resulting mixed gas tangentially enter the reactor 1 through a section of gas inlet 6 to carry out the sliding arc discharge plasma oxidation reforming reaction to obtain reforming hot gas, and the specific energy input of the plasma (the ratio of the input power to the total flow rate of methanol ) is 0.44 kW: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com