Gas separation membrane and preparation method and application thereof

A technology of gas separation membrane and test method, which is applied in the field of gas separation membrane and can solve problems not related to separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

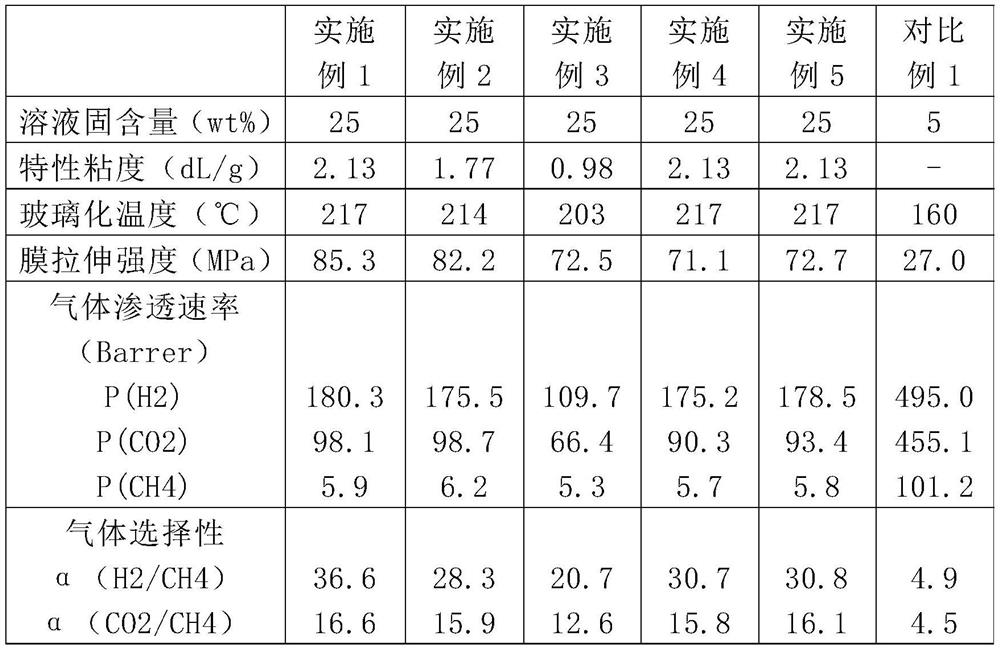

Embodiment 1

[0069] With 245g poly-α, β, β-trifluorostyrene resin (intrinsic viscosity is 2.13dL / g), 5g Permalyn 6110, dissolve in the N of 750g, N-dimethylacetamide, make solid content be 25 wt% solution. Coat the polytrifluorostyrene solution on a glass plate by a coating machine (TQC automatic film coating machine), and then put the coated film in an oven to dry, first bake at 140°C for 2 hours, then heat-treat at 180°C for 1 hour, and peel off A dense film was obtained. The film thickness after drying was measured by a thickness gauge (Metricon 2010) to be 30 microns.

Embodiment 2

[0071] 250g of poly-α, β, β-trifluorostyrene resin (intrinsic viscosity is 1.77dL / g) is dissolved in 750g of N,N-dimethylacetamide, making a solution with a solid content of 25wt%, No other additives are added. All the other operations are the same as in Example 1.

Embodiment 3

[0073] Poly-α,β,β-trifluorostyrene resin with an intrinsic viscosity of 0.98 dL / g was made into a dense film with a thickness of 30 μm. All the other operations are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com