Patents

Literature

155 results about "Durene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

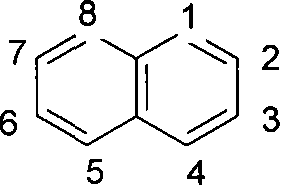

Durene, or 1,2,4,5-tetramethylbenzene, is an organic compound with the formula C₆H₂(CH₃)₄. It is a colourless solid with a sweet odor. The compound is classified as an alkylbenzene. It is one of three isomers of tetramethylbenzene, the other two being prehnitene (1,2,3,4-tetramethylbenzene, m.p. −6.2 °C) and isodurene (1,2,3,5-tetramethylbenzene, m.p. −23.7 °C). Durene has an unusually high melting point (79.2 °C), reflecting its high molecular symmetry.

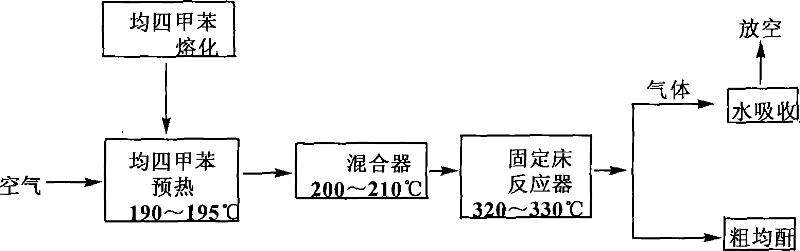

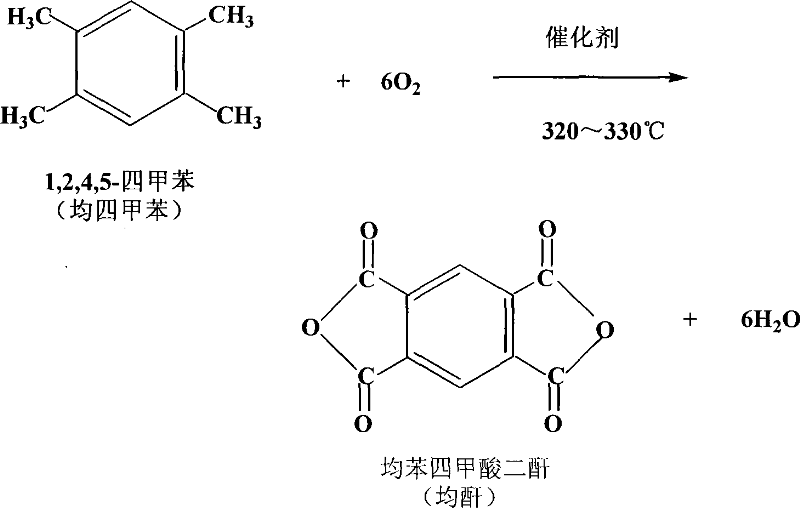

Production technique of benzenetetracarboxylic dianhydride by catalyzing carrier-type polyoxometalates

InactiveCN101037439AOvercome the difficulties, high production costs and other shortcomingsEasy to recycleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFixed bedIndustrial equipment

The invention discloses a craft for producing pyromellitic dianhydride catalyzed by a carrier-type poly-oxometalate, including melting the pyromellitic dianhydride by the groove, feeding to the mixing machine for evapouration after pre-heating with a feed concentration of 15.0-19.5g / m3, mixing with the air, entering into the fixed bed reactor for a oxidation, oxidating with an airspeed of 4500-6500 h-1, cooling the produced air, then condensing in the collector, getting coarse pyromellitic dianhydride. At 300-340 DEG C, the catalyzer is mostly poly-oxometalate which is fixed on the catalyst bed after loading. The mass ratio of the catalyzer to pyromellitic dianhydride is 0.2-1%. The invention has the durene in the C10 heavy aromatics as raw material, produces the pyromellitic dianhydride by oxidation in air, makes the C10 heavy aromatics be with a higher added value, uses the current resource and industrial equipments as more as possible, exploits the catalysis and synthesis path of the pyromellitic dianhydride. The invention has a low pollution and production cost, a wide development prospect and is suitable for commercial process.

Owner:NORTHEAST NORMAL UNIVERSITY

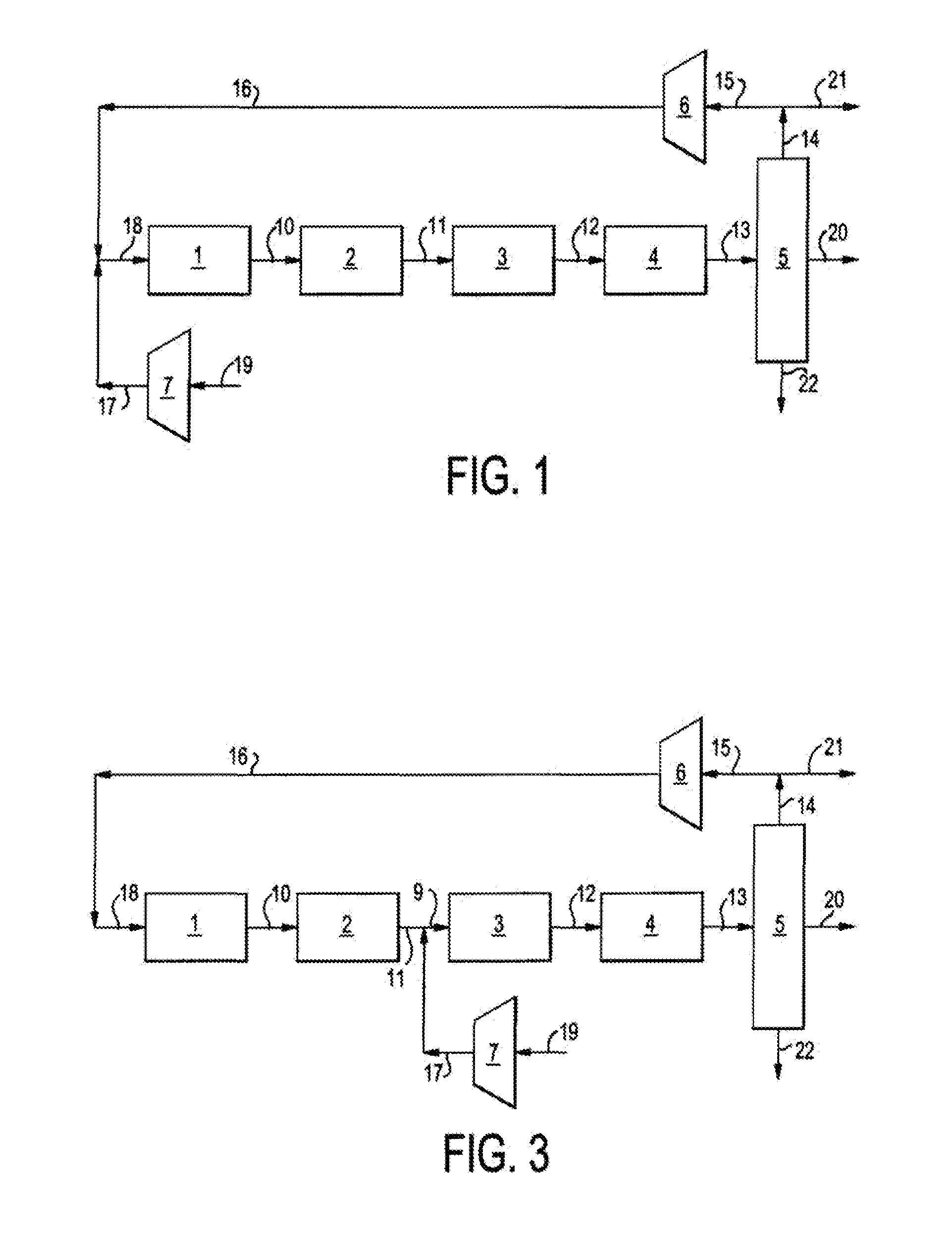

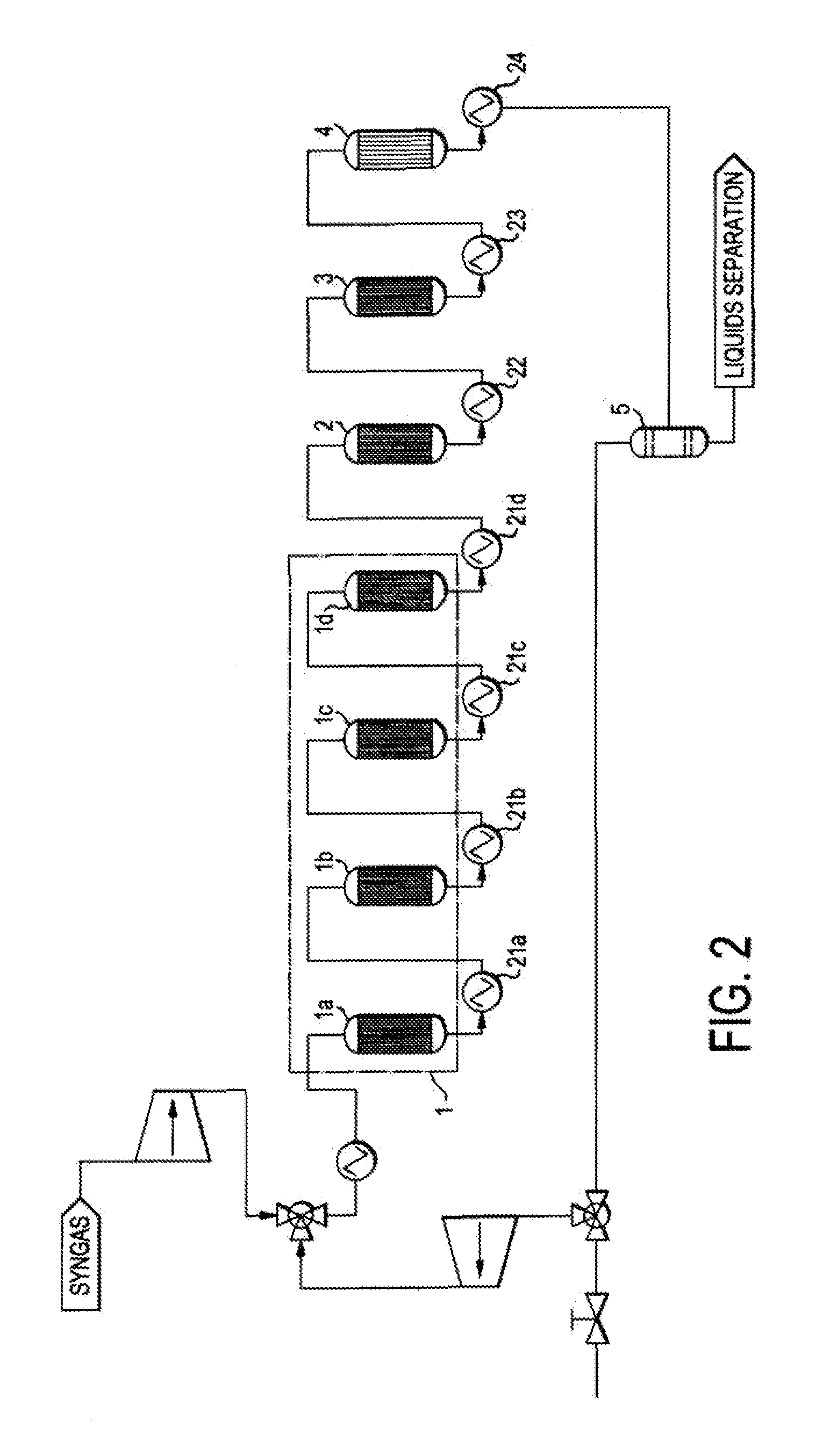

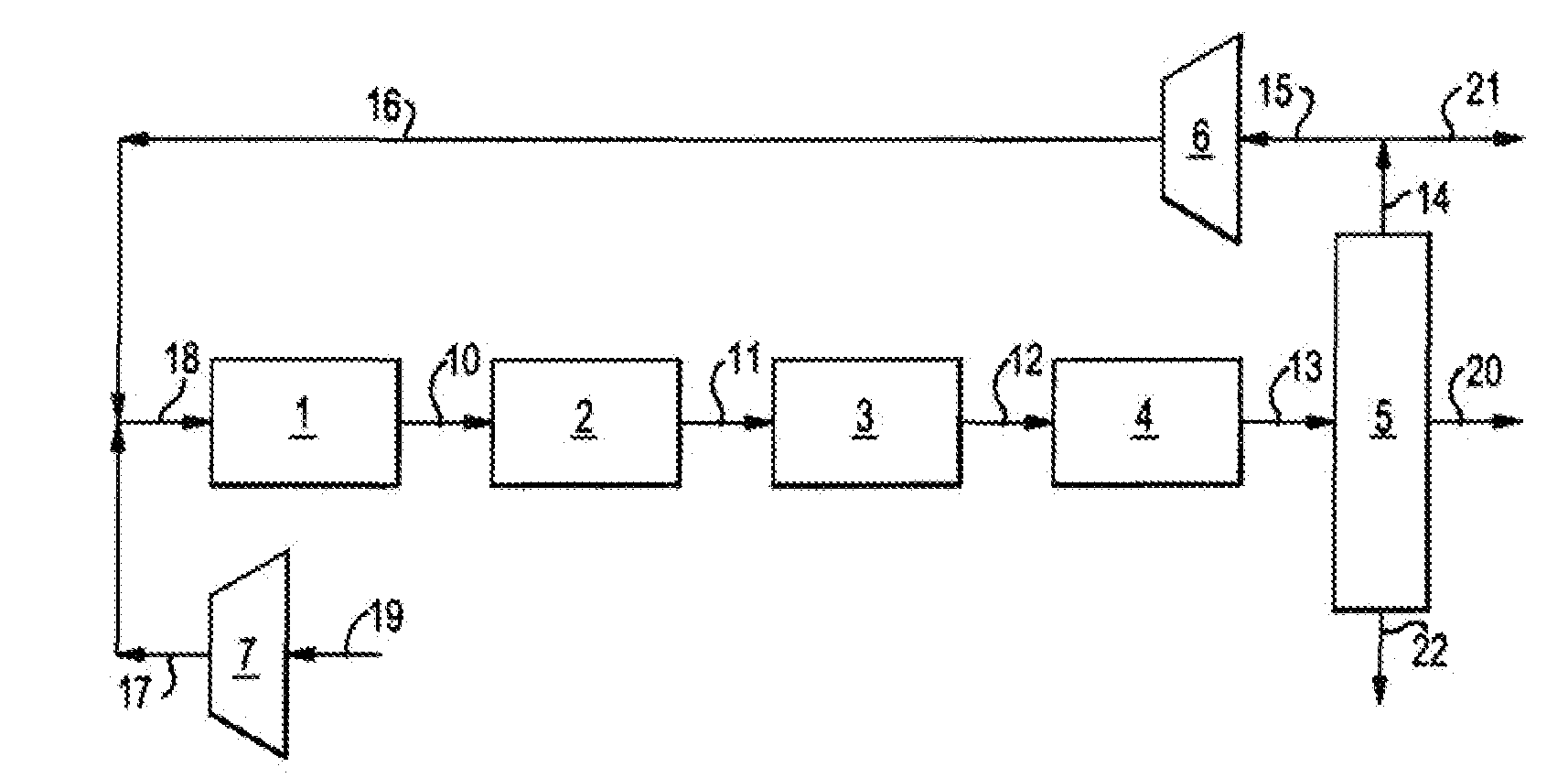

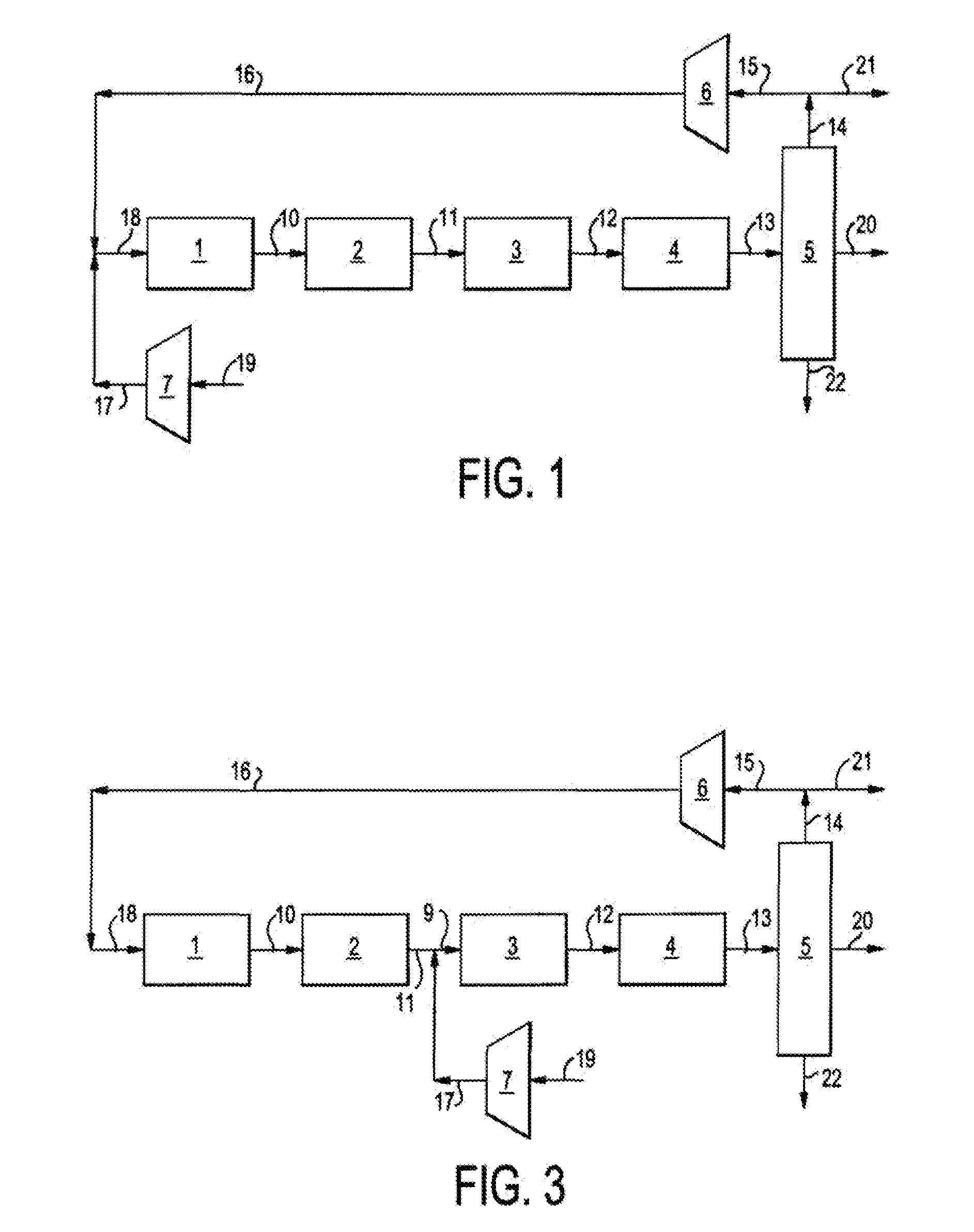

Single loop multistage fuel production

ActiveUS20120116137A1Speed up the conversion processImprove utilization efficiencyRefining to change hydrocarbon structural skeletonHydroxy compound preparationLiquid fuelHigh pressure

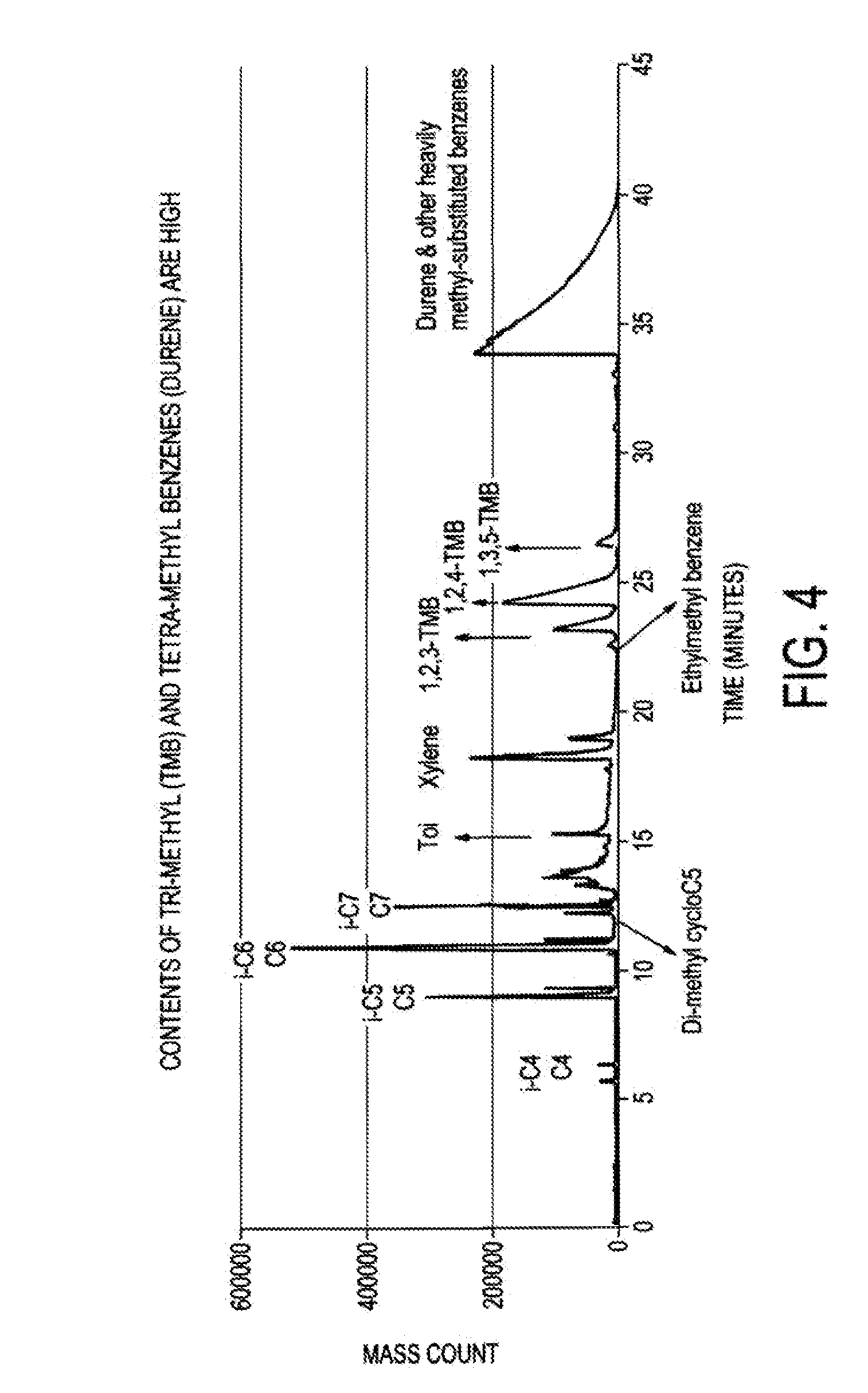

Synthetic fuels are produced from synthesis gas in a four-stage reactor system with a single recycle loop providing the requisite thermal capacity to moderate the high heat release of the reactions and to provide the reactants and reaction environments for the efficient operation of the process. The first stage converts a portion of the synthesis gas to methanol, the second stage converts the methanol to dimethylether, the third stage converts the methanol and dimethylether to fuel and the fourth stage converts the high melting point component, durene, and other low volatility aromatic components such as tri- andtetra-methylbenzenes to high octane branched paraffins. The four-stage catalyst used for hydrotreating is resistant to CO poisoning. The reactions i produce water as a side product that is carried through to a high pressure separator after the fourth stage. The streams from the separator are a liquid fuel stream, a water stream and a gaseous stream that contains light hydrocarbon gases and the unreacted synthesis gas. The larger part of this gas stream is recycled to the inlet of the first stage and mixed with the fresh synthesis gas stream. Alternatively, the fresh synthetic gas stream is mixed with the product of the second stage. The smaller part of the gas stream from the separator is sent to hydrocarbon recovery and to fuel gas used for providing preheat of various streams. The liquid fuel is sent for blending into fuel products, such as gasoline, jet fuel, or diesel, and the water stream can be sent, for example, to the synthesis gas producing plant for steam generation.

Owner:BLUESCAPE CLEAN FUELS LLC

Process for joint production of aromatic solvent, stone oil naphthalin and durene line products with C10 heavy aromatic raw material

ActiveCN101318874ATake advantage ofSave resourcesDistillation purification/separationCrystallisation purification/separationAromatic solventGas phase

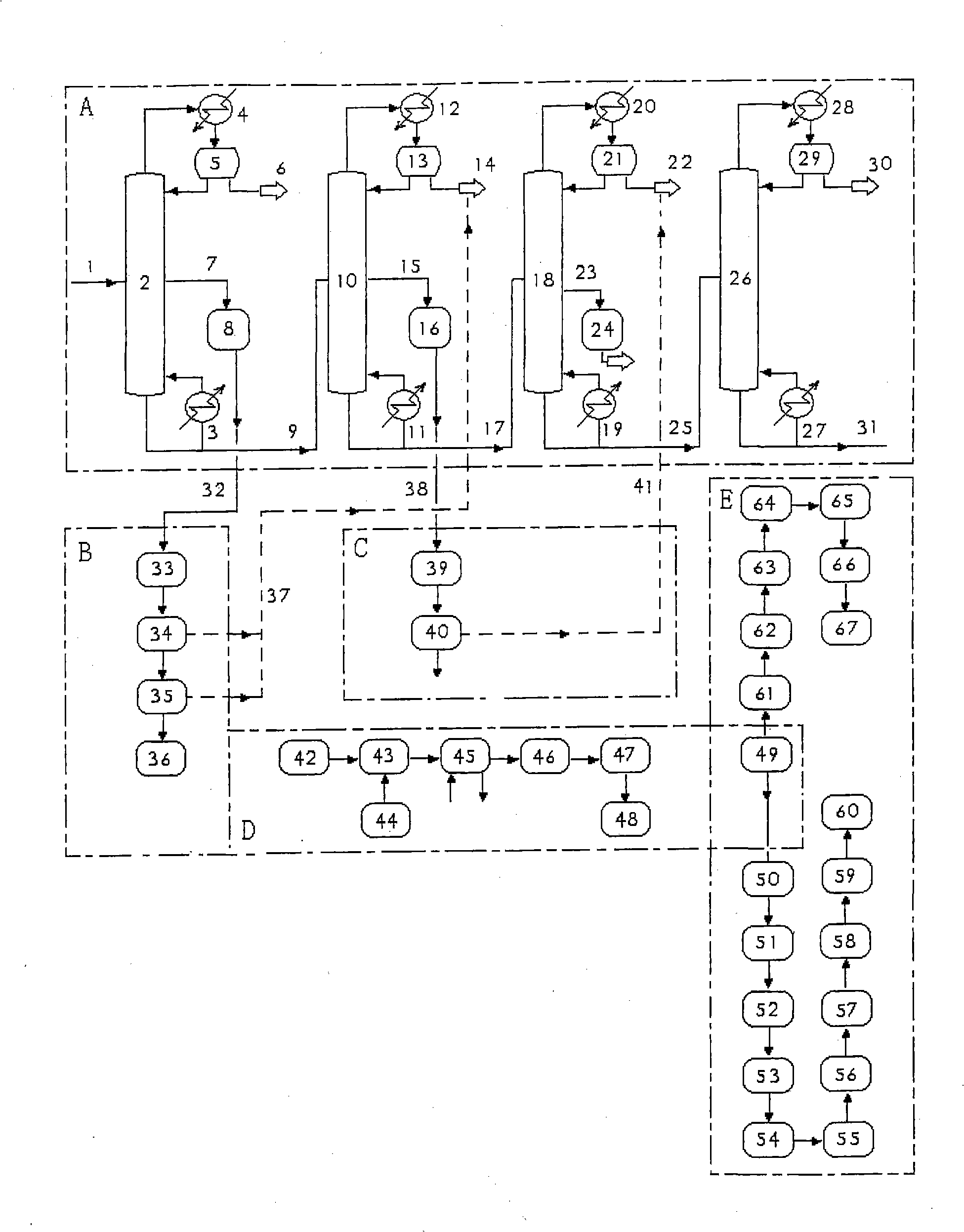

The present invention discloses a method for jointly preparing a series of products of an aromatic solvent, petronaphthalene and durene from a C10 heavy aromatics material, belonging to the C10 heavy aromatics complex utilization technical field. The method comprises the following steps of: A) separating the C10 heavy aromatics material; B)refrigerating and crystallizing an enrichment solution of durene; C)refrigerating and crystallizing an enrichment solution of naphthalene; D) gas phase catalytically oxidizing durene; and E) preparing technical grade PMA, technical grade PMDA and electronic grade PMDA from a crude product. The method has the advantages that the method can carry out joint production to obtain the series of products of aromatic solvent, petronaphthalene and durene by the C10 heavy aromatics material so that the C10 heavy aromatics material obtains sufficient utilization, thereby contributing to resource economizing.

Owner:常熟华虞环境科技有限公司

Molecular sieve catalyst for synthesizing methanol into durene and its prepn and application

InactiveCN1421271ASimple manufacturing methodHigh selectivityMolecular sieve catalystsCatalyst activation/preparationHydrogenToluene

The molecular sieve catalyst for synthesizing methanol into durene is ZSM-5 type with molar Si / Al ratio of 13-50, strong / weak acid ratio of 1.03-1.30, adsorption amount to cyclohexane of 5.95-6.25 wt%, said adsorption amount to n-hexane of 8.95-9.15 wt%. The hydrogen-type molecular sieve, assistant and nitric acid are mixed and kneaded, and the mixture is formed, stoved, crushed, roasted, soakingin acid solution, stoved and roasted to obtain the catalyst. The present invention has the advantages of simple preparation process, high selectivity of the catalyst, and the durene content in the product as high as 20%.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Catalyst and preparation method and application thereof, and preparation method for durene

ActiveCN106076404ASimple ingredientsEasy to manufactureMolecular sieve catalystsMolecular sieve catalystRare-earth elementMolecular sieve

The invention provides a catalyst and a preparation method and application thereof, and a preparation method for durene. The catalyst is mainly prepared from the following components by weight: 45 to 85% of a beta-molecular sieve, 10 to 55% of a binder and 0 to 10% of a modified element, wherein the binder is one or more selected from a group consisting of alumina, alumina sol and silica sol, and the modified element is one or more selected from a group consisting of zinc, iron, magnesium, calcium and rare earth elements. The catalyst has high catalytic activity to alkylation and can substantially improve the conversion rate of pseudocumene in preparation of durene from pseudocumene and methanol.

Owner:SINOPEC ENG GRP CO LTD

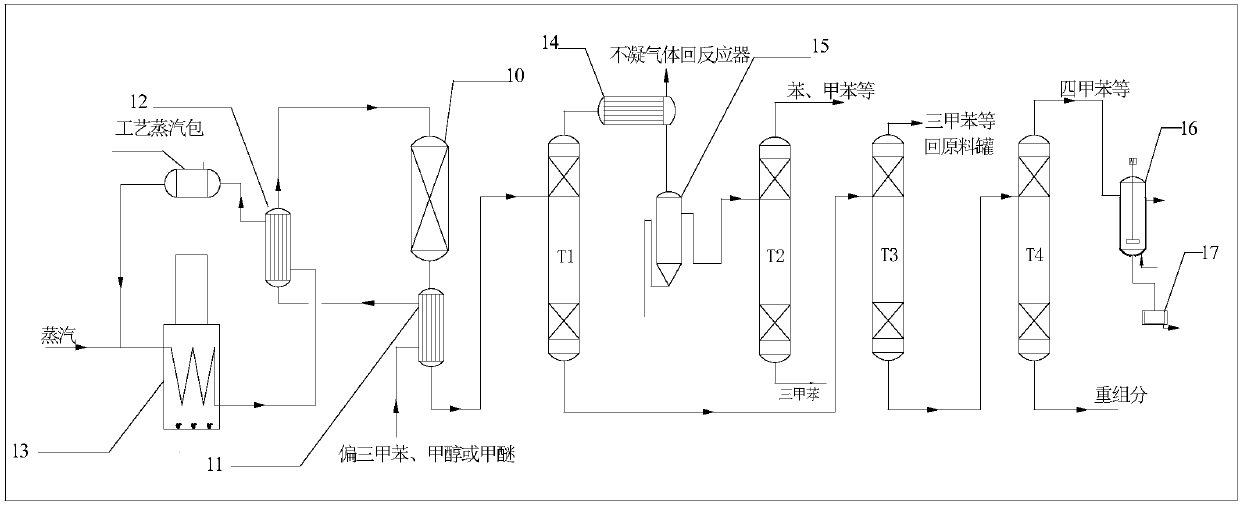

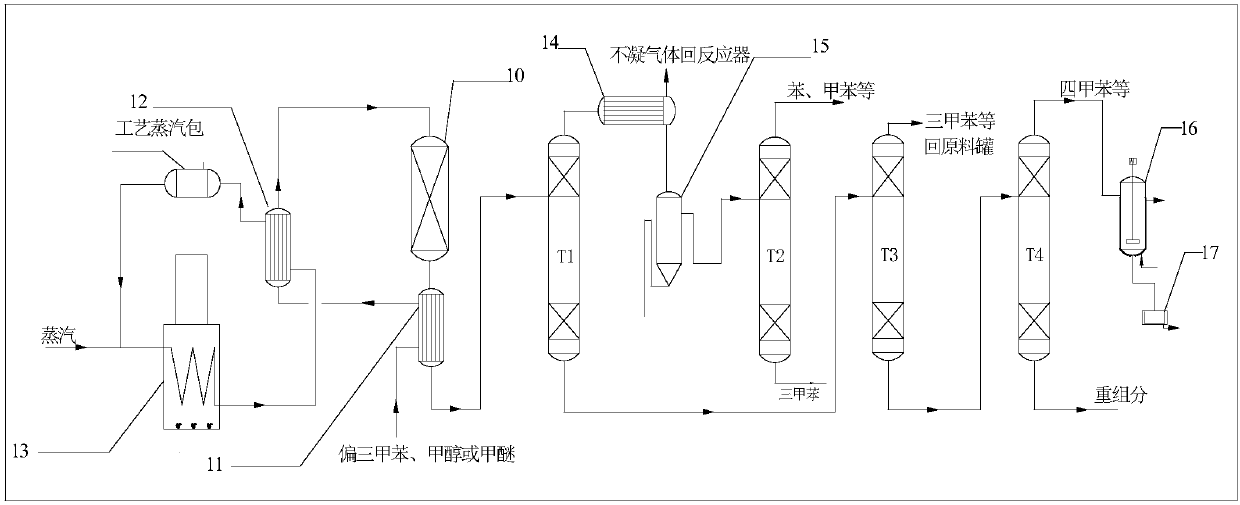

Technological process for preparing durene with reformed C10 aromatic

InactiveCN101279886AEmission reductionIncrease freezing temperatureHydrocarbon by isomerisationChemical industryBoiling pointFiltration

Owner:天津市兴源化工有限公司

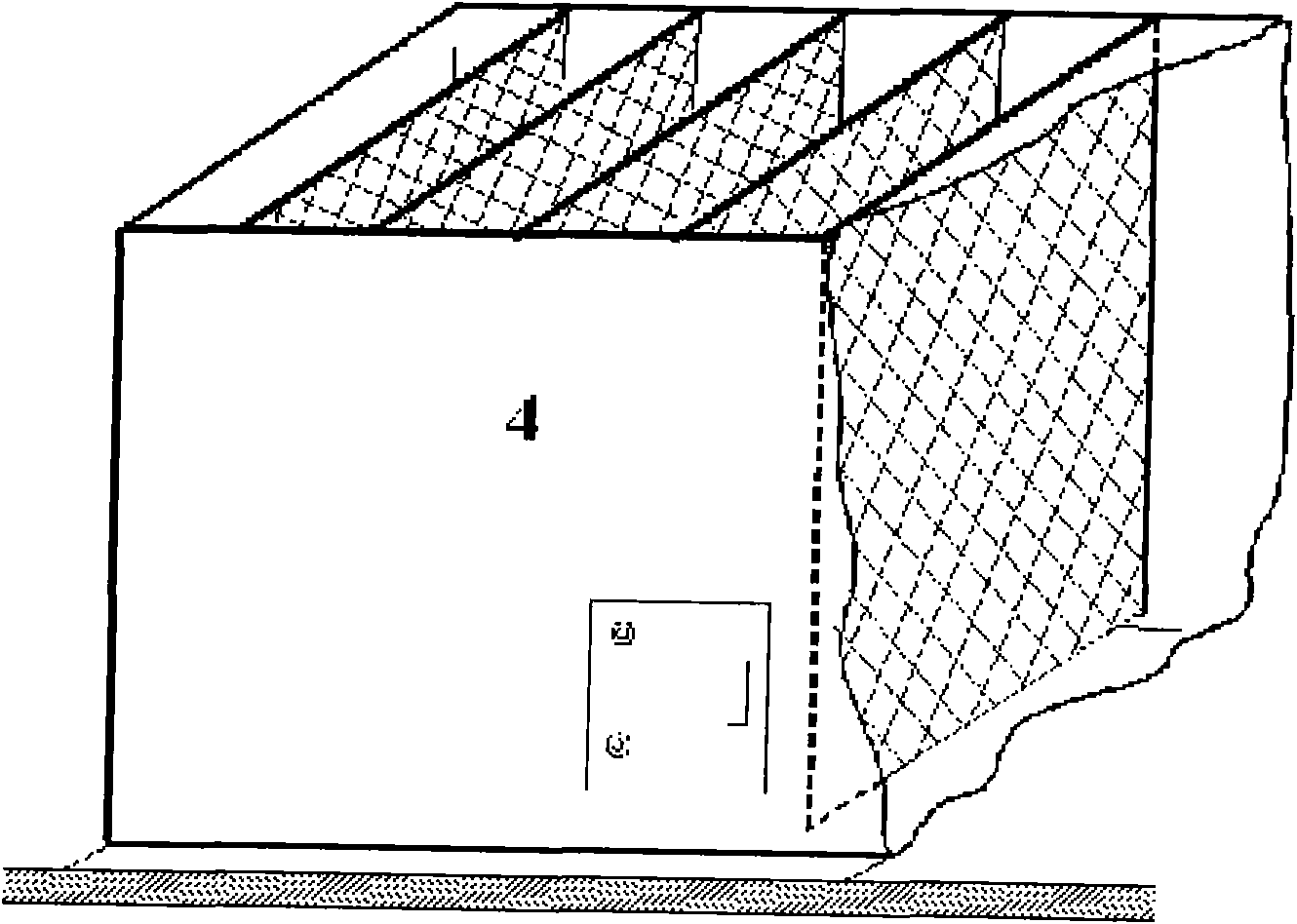

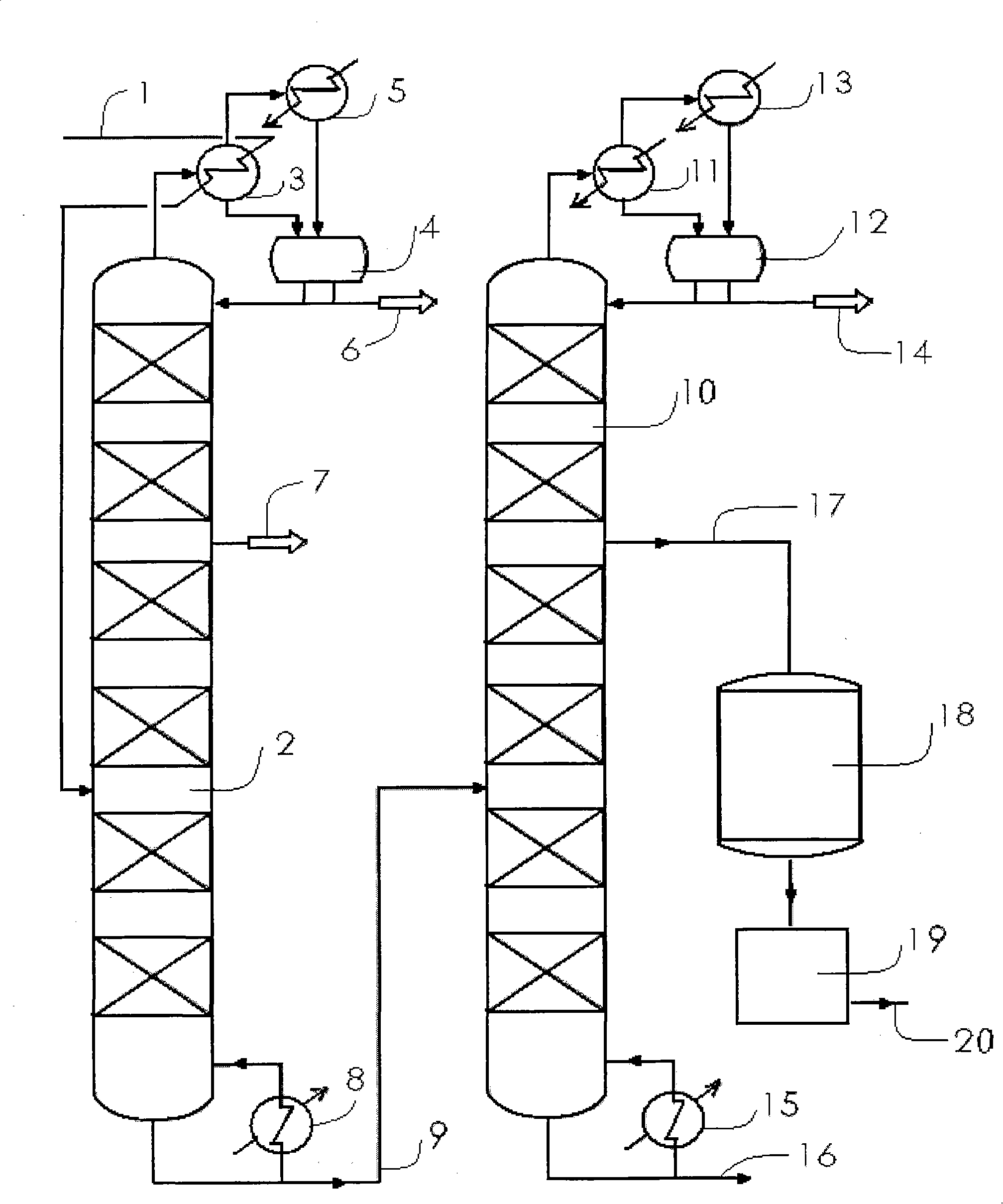

Method and device for extracting durene from methanol synthetic oil

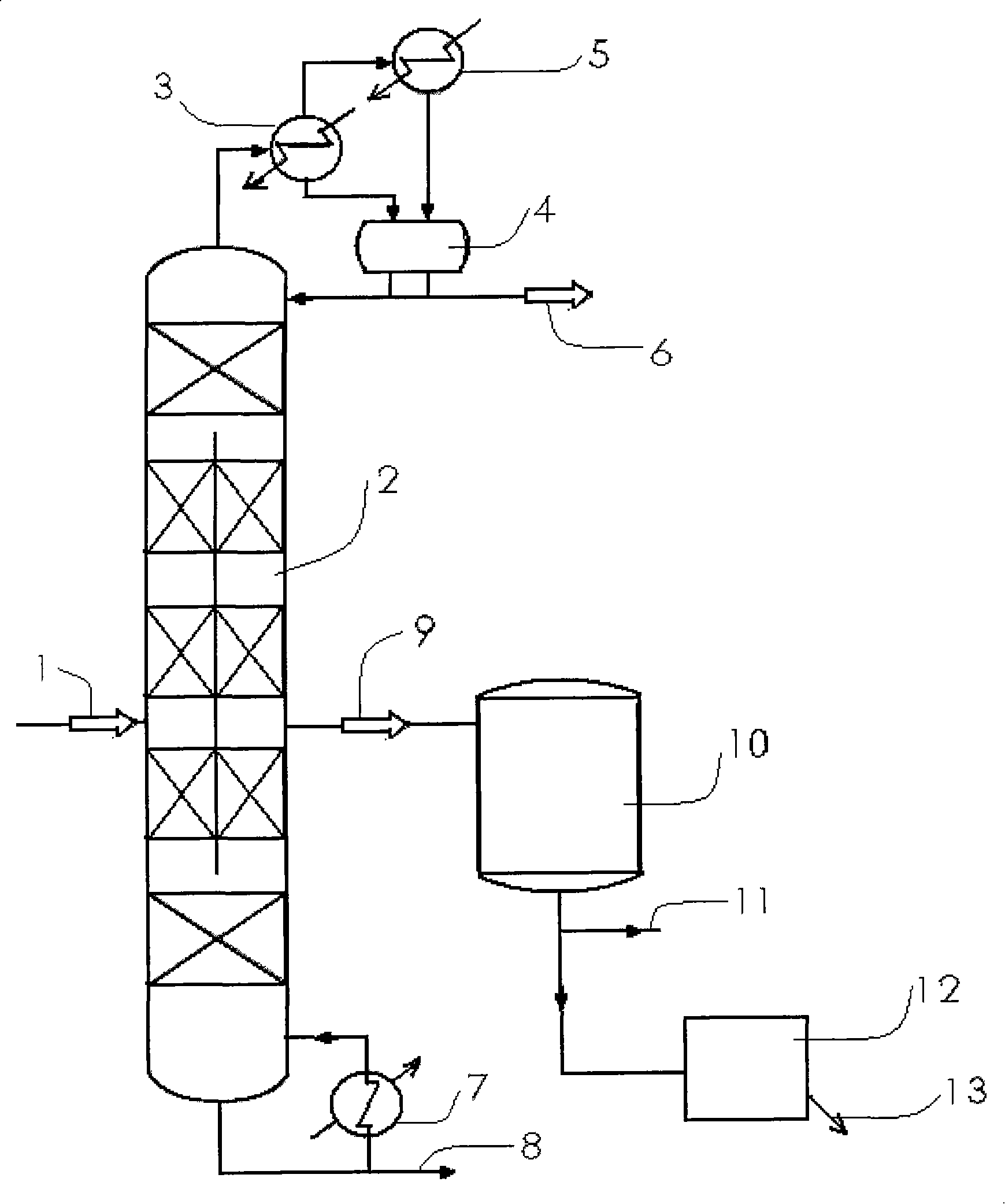

ActiveCN104058913AIncrease added valueReduce energy consumptionDistillation purification/separationTreatment with plural serial refining stagesReboilerEngineering

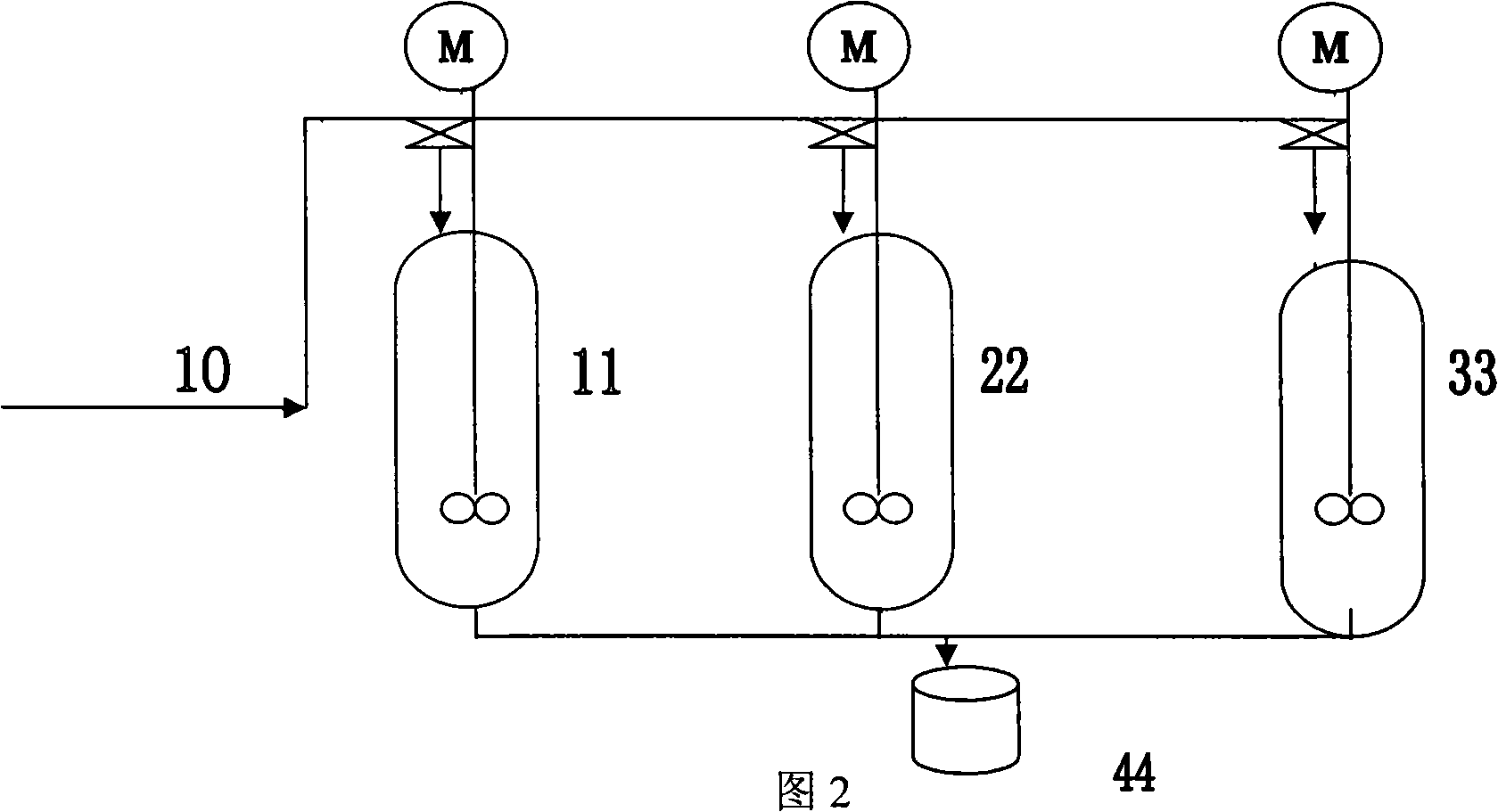

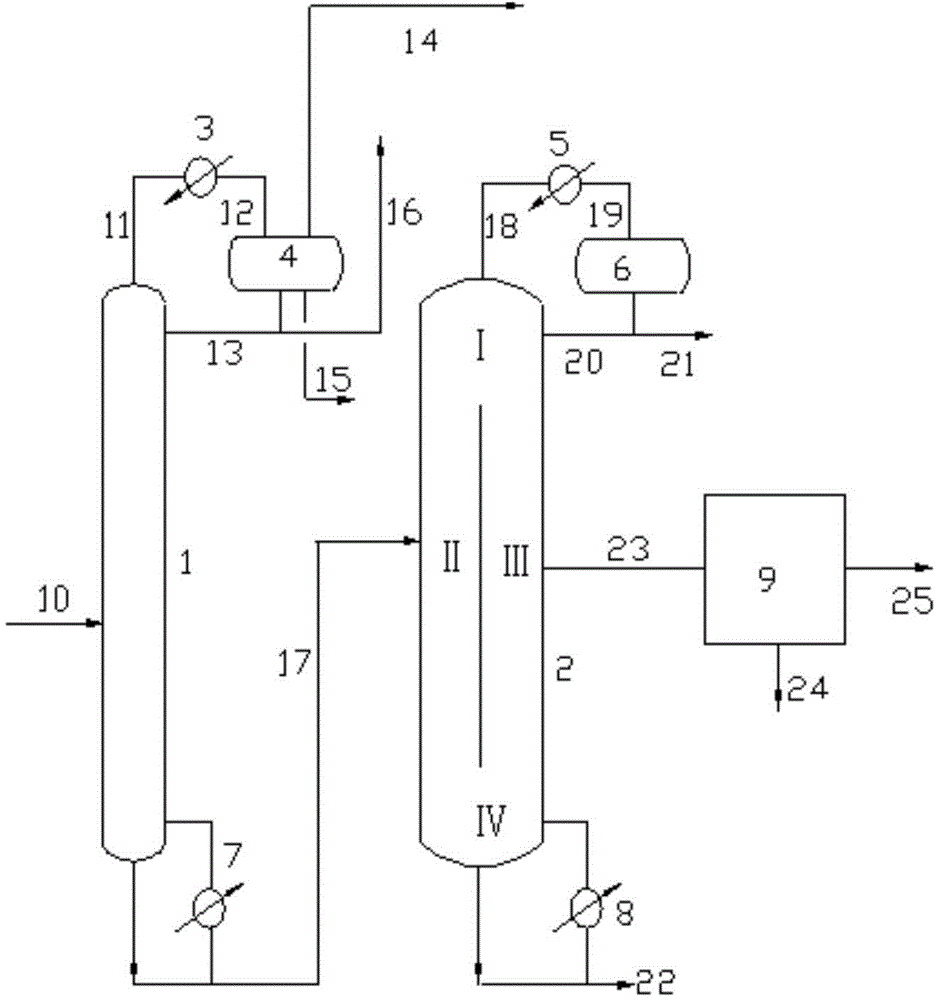

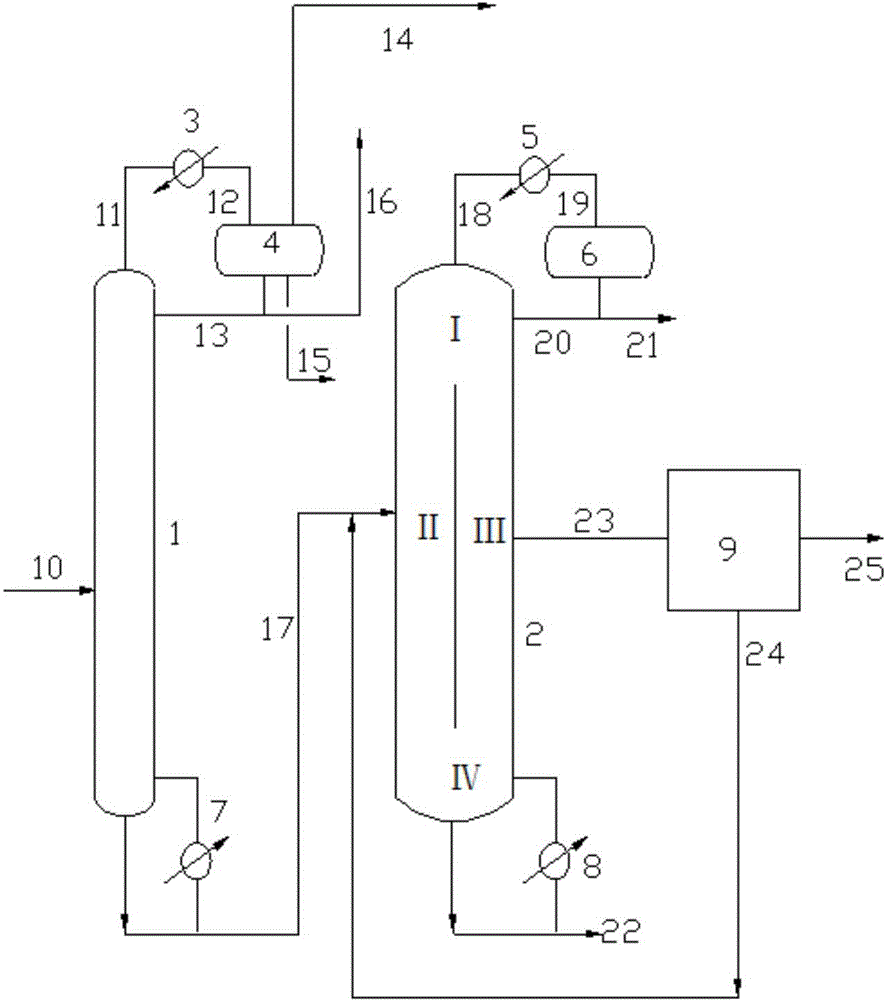

The invention relates to a method and a device for extracting durene from methanol synthetic oil. The device comprises a fractionating tower, a dividing wall tower crystallization system and a plurality of pumps, wherein condensers and return tanks are arranged at the tops of the fractionating tower and the dividing wall tower; reboilers are arranged at the bottoms of the towers; a partition plate is arranged inside the dividing wall tower; the dividing wall tower is partitioned into a distillation zone I, a feeding zone II, an intermediate product zone III and an extraction zone IV; a raw material enters the fractionating tower, and is connected to a dividing wall tower feeding zone II from a discharge pipeline at the bottom of the fractionating tower; the intermediate product zone III of the dividing wall tower is arranged in an opening of a dividing wall tower discharge pipe; and the opening of the dividing wall tower discharge pipe is connected to the inlet of the crystallization system by adopting a production line. The functions of lightly cutting, heavily cutting and gathering and refining the durene are integrated into the dividing wall tower to achieve after naphtha and the like in the synthetic oil are removed, and the equipment such as a rectifying tower, attached condensers and reboilers thereof and the like can be removed. Thus, energy consumption and equipment investment in the process are reduced, and the energy consumption in the process can be reduced by over 10% by adopting the dividing wall tower technology.

Owner:TIANJIN UNIV +1

Process for converting an oxygenated feed to high octane gasoline

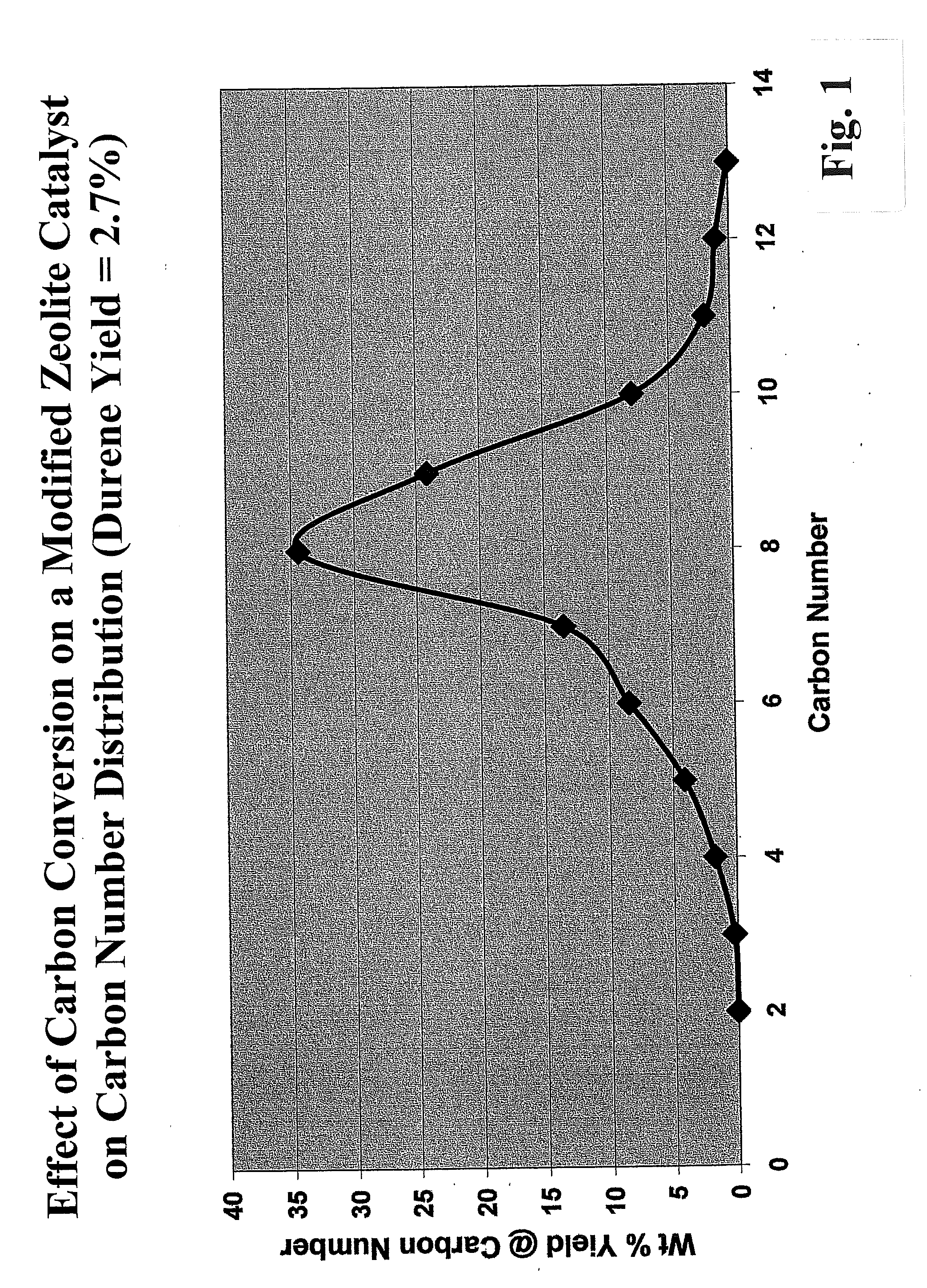

ActiveUS20100041932A1Molecular sieve catalystsHydrocarbon from oxygen organic compoundsCarbon numberGasoline

A process of modifying a zeolite catalyst to produce a modified zeolite catalyst wherein the modified zeolite catalyst has blocked pore sites. An oxygenated feed is flowed over the modified zeolite catalyst, wherein the oxygenated feed comprises hydrocarbons, methanol and dimethyl ether or a mixture thereof. The hydrocarbons, methanol and dimethyl ether in the oxygenated feed react with the modified zeolite catalyst to produce cyclic hydrocarbons, wherein the cyclic hydrocarbons produced has less than 10% durene and a median carbon number is C8.

Owner:PHILLIPS 66 CO

Method for capturing and purifying pyromellitic dianhydride

InactiveCN102336761AEfficient separationSufficient dwell timeOrganic chemistrySublimationGas phaseCatalytic oxidation

The invention discloses a method for capturing and purifying pyromellitic dianhydride. The method comprises the following steps of: directly performing heat exchange on a gas-phase product prepared from durene through gas-phase catalytic oxidation twice, introducing into a capture device, exchanging heat between air and the reaction product, making the gas-phase reaction product pass through the inside of the capture device and cooling air pass through a jacket layer of the capture device, separating out the pyromellitic dianhydride and byproducts from the gas-phase reaction product through heat exchange and cooling, and finally obtaining high-purity pyromellitic dianhydride. By the method, the pyromellitic dianhydride and the byproducts in the gas-phase reaction product prepared from the durene through a fixed bed gas-phase catalytic oxidation process are effectively separated, the high-purity pyromellitic dianhydride can be continuously and efficiently captured directly, and the method has the advantages that the technological process is simple, the cost is low, the energy consumption in the process can be reduced, the operating environment is improved and the floor area is reduced.

Owner:常熟联邦化工股份有限公司

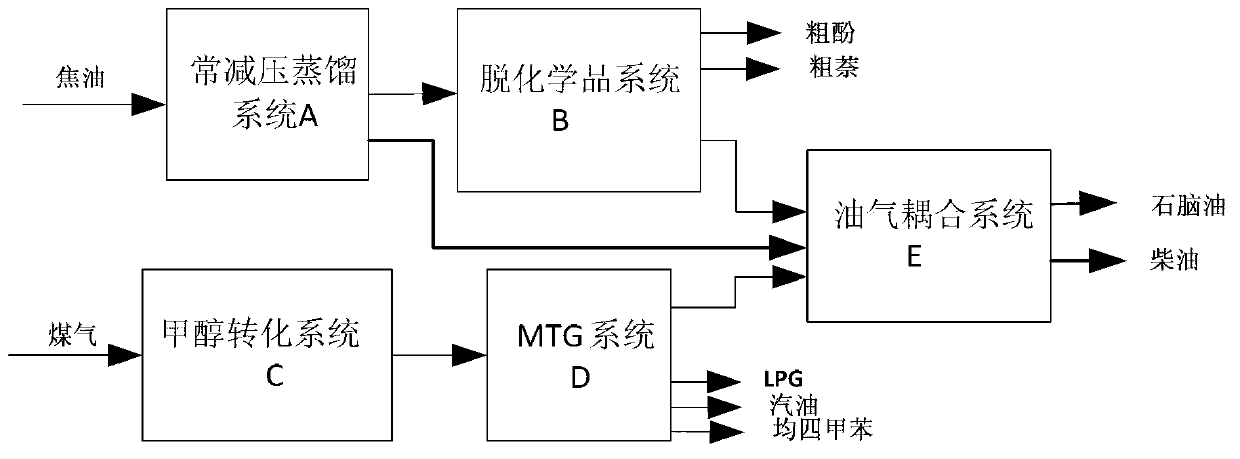

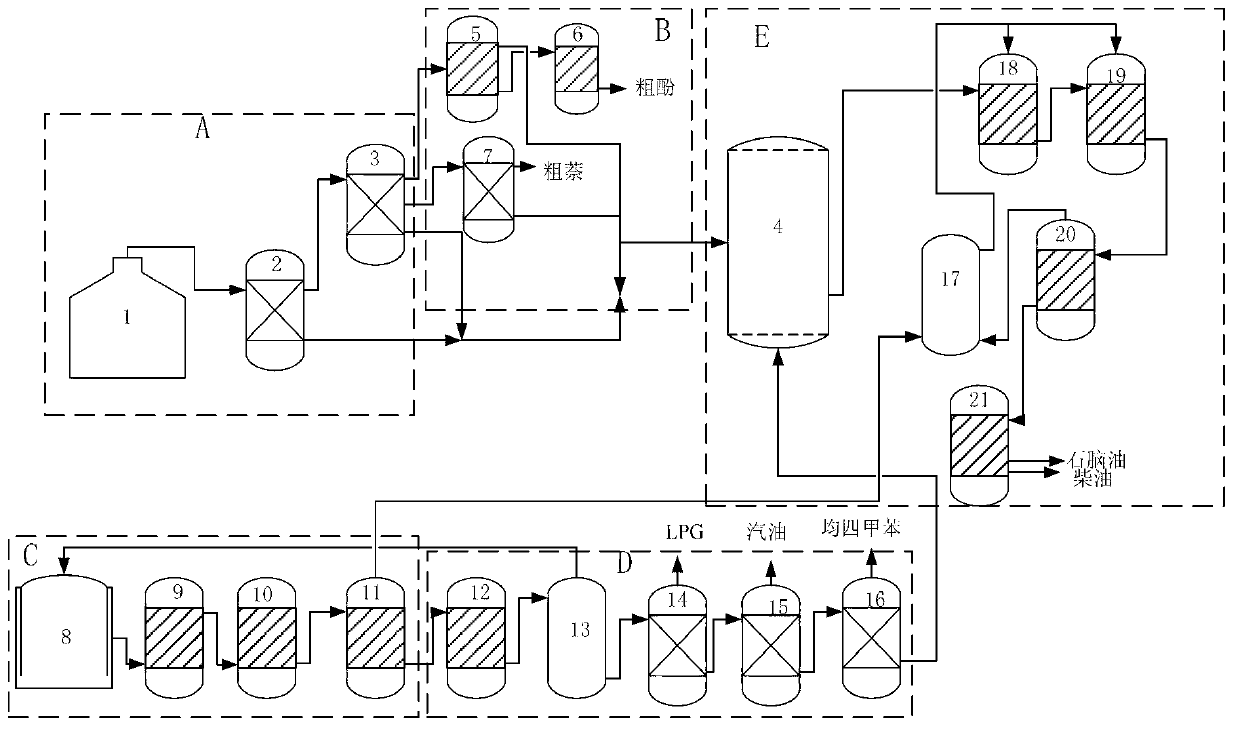

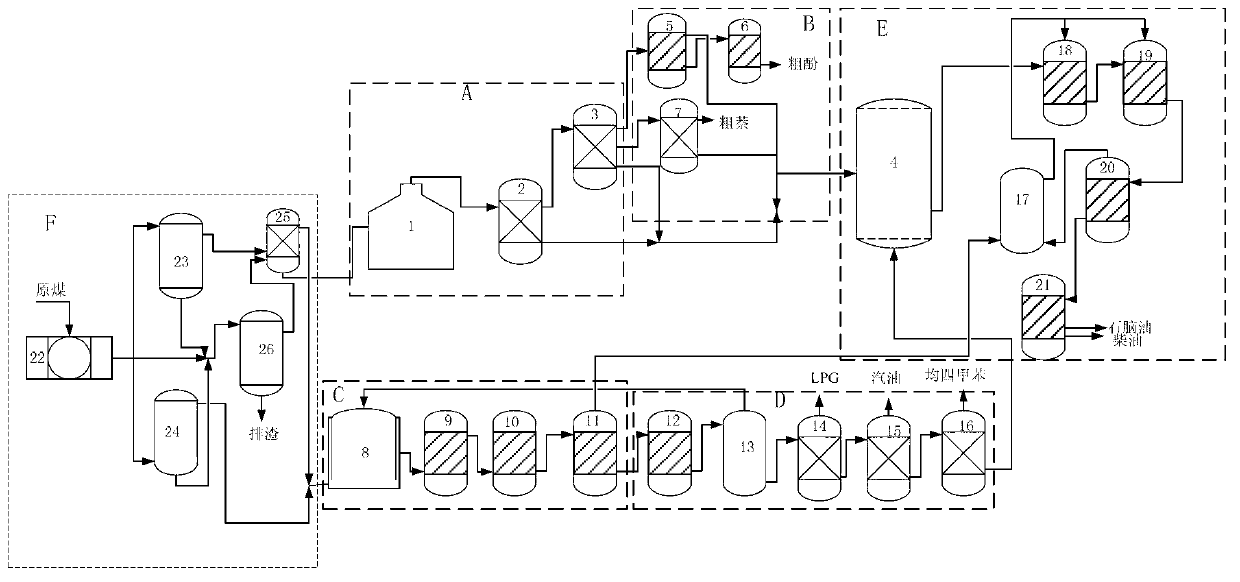

Oil-gas coupling poly-generation method in coal chemical engineering industry

ActiveCN103275757ASolve the problem of single processing method and low product priceAvoid wastingOrganic compound preparationDistillation purification/separationDistillationEngineering industry

The invention provides an oil-gas coupling poly-generation method in the coal chemical engineering industry. The oil-gas coupling poly-generation method comprises the following steps of: treating and dividing coal tar into heavy oil fraction, crude phenol, dephenolized oil, crude naphthalene, naphthalene-removed oil and washing oil by virtue of a normal-pressure distillation system and a chemical-removing system; discharging the crude phenol and the washing oil; feeding the heavy oil fraction, the washing oil, the dephenolized oil and the naphthalene-removed oil to an oil-gas coupling system; treating the coal gas to obtain LPG (Liquefied Petroleum Gas), petrol, durene and dealkylation heavy oil by virtue of a methanol conversion system and an MTG (Methanol To Gasoline) system; discharging the LPG, the petrol and the durene; feeding the dealkylation heavy oil to the oil-gas coupling system and carrying out coupling hydrogenation treatment in the oil-gas coupling system to obtain naphtha and diesel oil. According to the oil-gas coupling poly-generation method in the coal chemical engineering industry disclosed by the invention, the tar and the coal gas are effectively coupled, so that the resource waste is avoided; the high-additional value oil and chemicals including phenol, naphthalene, aromatic hydrocarbon and the like are generated, so that the direct emission of coal gas and the car is prevente, and therefore, the environment pollution is reduced and the method is more friendly to the environment.

Owner:SHAANXI COAL & CHEM TECH INST

Single loop multistage fuel production

ActiveUS8686206B2Speed up the conversion processImprove efficiencyRefining to change hydrocarbon structural skeletonHydroxy compound preparationBenzeneReactor system

Synthetic fuels are produced from synthesis gas in a four-stage reactor system with a single recycle loop providing the requisite thermal capacity to moderate the high heat release of the reactions and to provide the reactants and reaction environments for the efficient operation of the process. The first stage converts a portion of the synthesis gas to methanol, the second stage converts the methanol to dimethylether, the third stage converts the methanol and dimethylether to fuel and the fourth stage converts the high melting point component, durene, and other low volatility aromatic components such as tri- and tetra-methylbenzenes to high octane branched paraffins.

Owner:BLUESCAPE CLEAN FUELS LLC

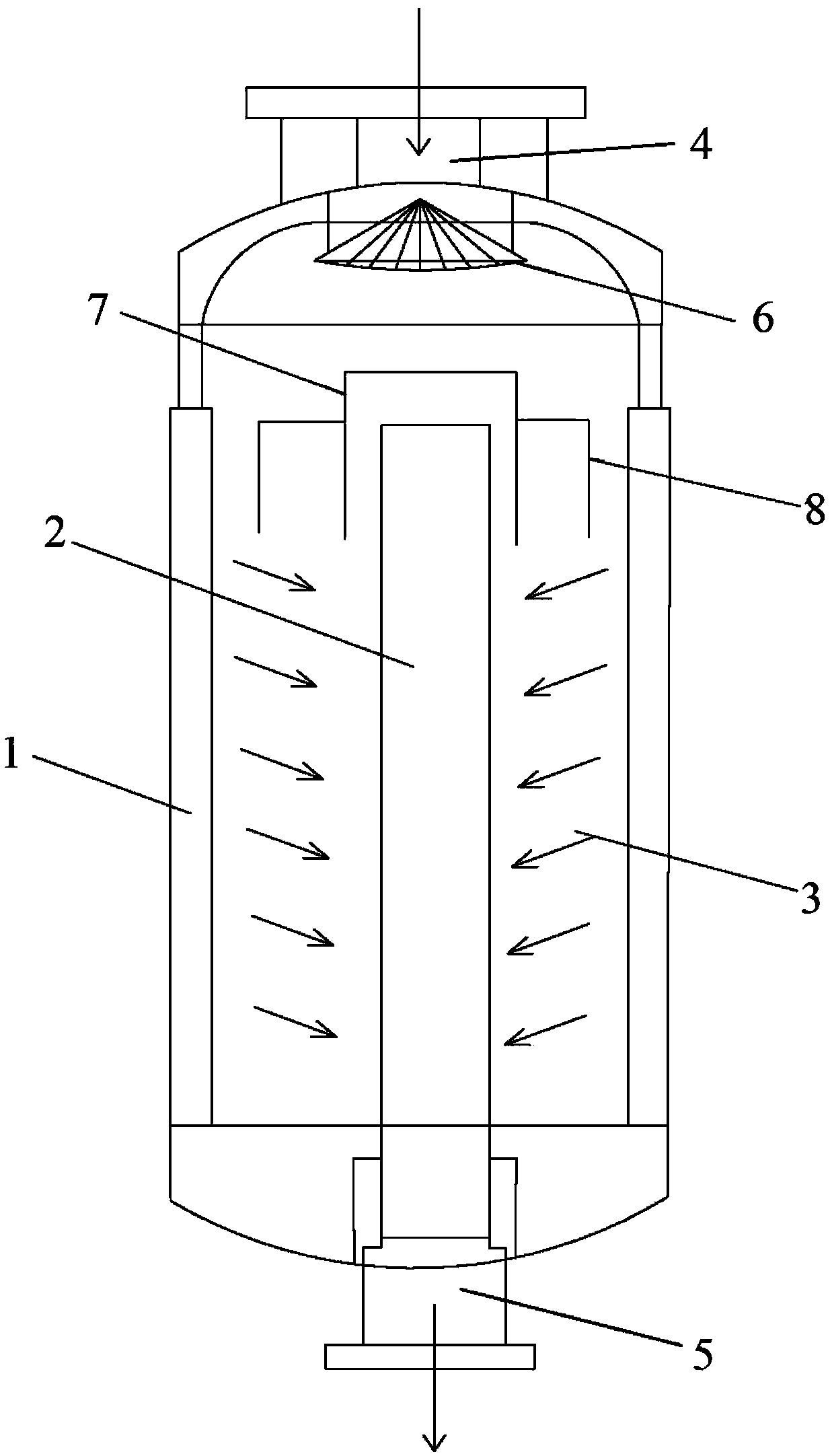

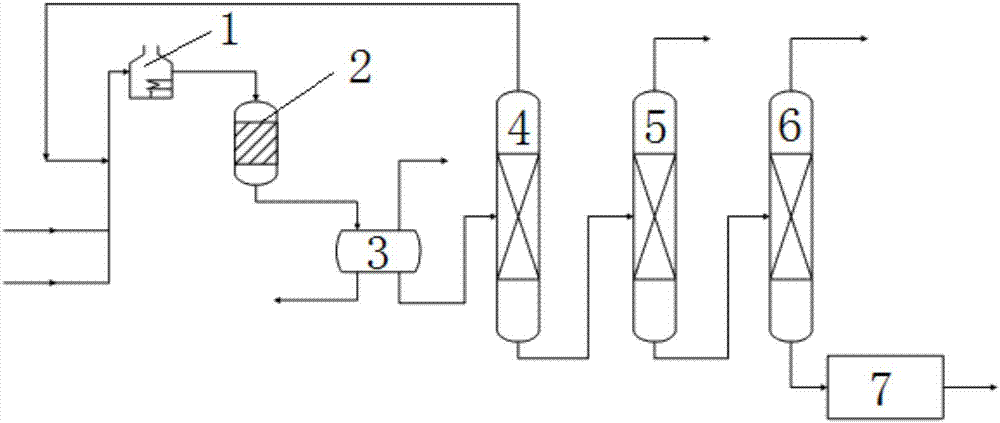

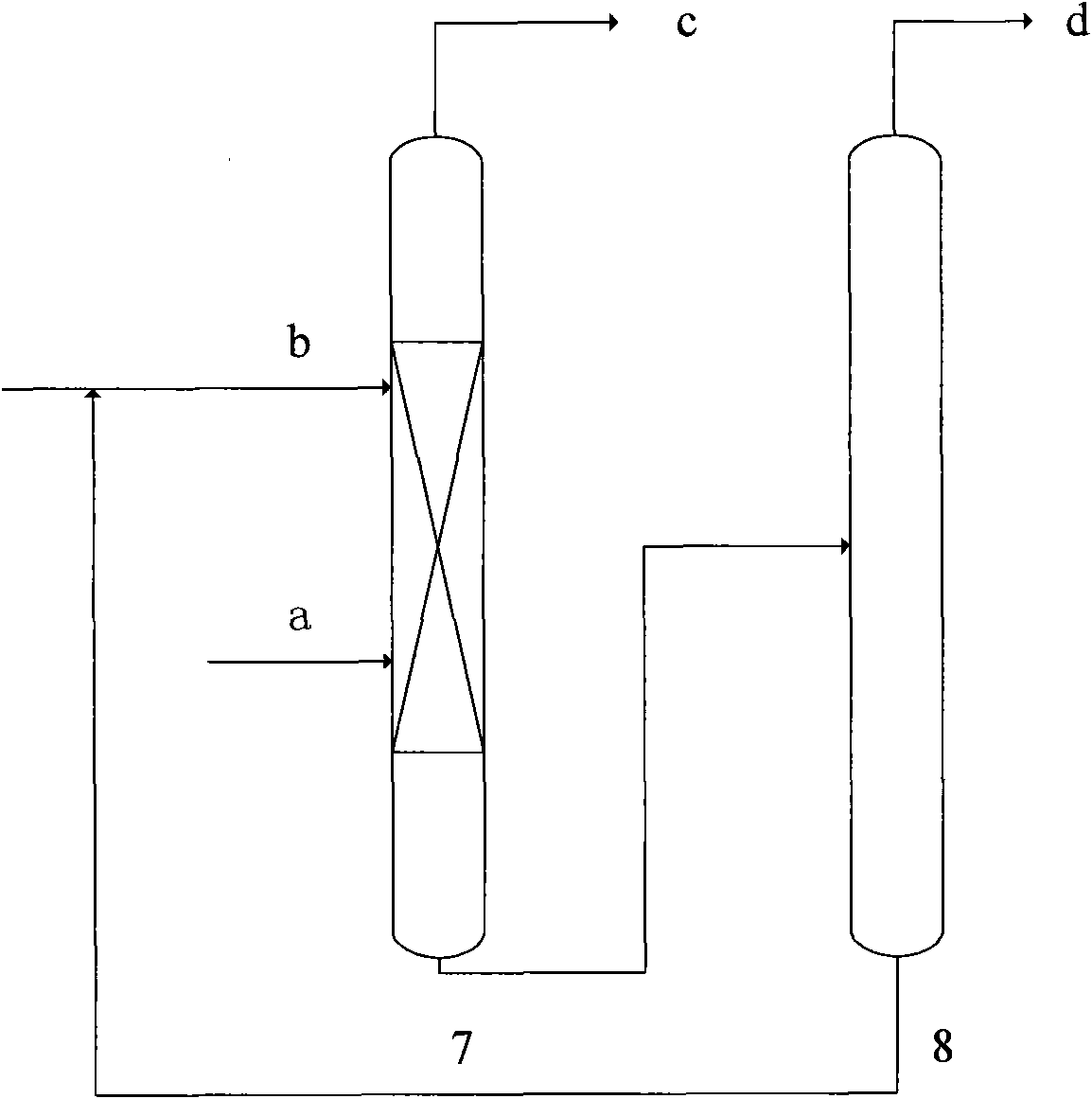

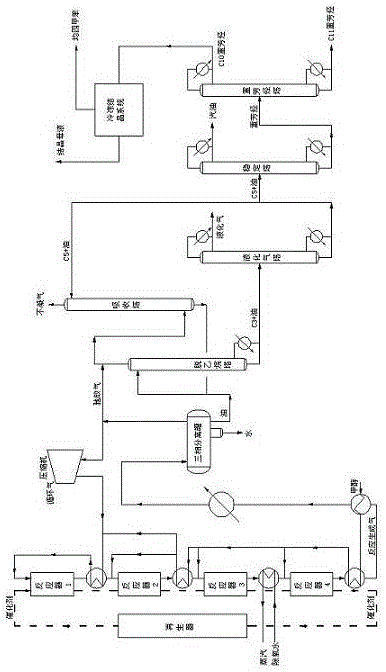

Method for production of durene by pseudocumene alkylation and reactor thereof

InactiveCN109966997ARelieve pressureIncrease contact areaMolecular sieve catalystCatalystsAlkyl transferFiltration

The invention discloses a method for production of durene by pseudocumene alkylation. The method includes: raw material gasification mixing, alkylation reaction, gas-oil-water separation, refining, freezing crystallization filtration and squeezing, wherein a radial fixed bed reactor is employed for alkylation reaction of pseudocumene. The invention also provides the radial fixed bed reactor used by the above method. The method for production of durene by pseudocumene alkylation has the advantages of: high catalyst activity and long service life, high product selectivity, high production safety, few alkylation by-product, stable finished product quality, low consumption of raw and auxiliary materials, long equipment service life, and is suitable for large-scale industrial production.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

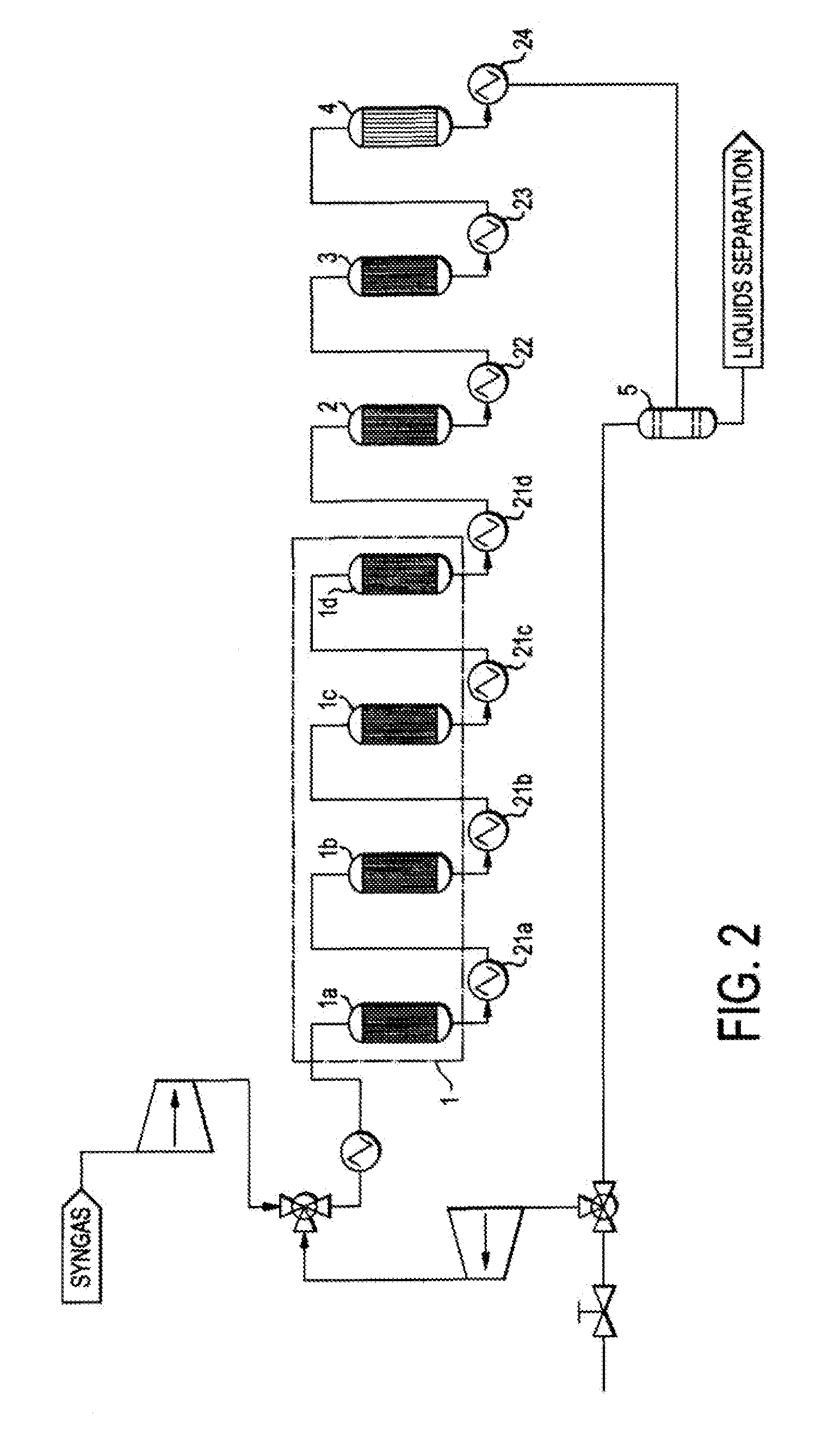

Process for the preparation of hydrocarbons

InactiveUS20120088944A1Attractive for productionRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesHydrodealkylation

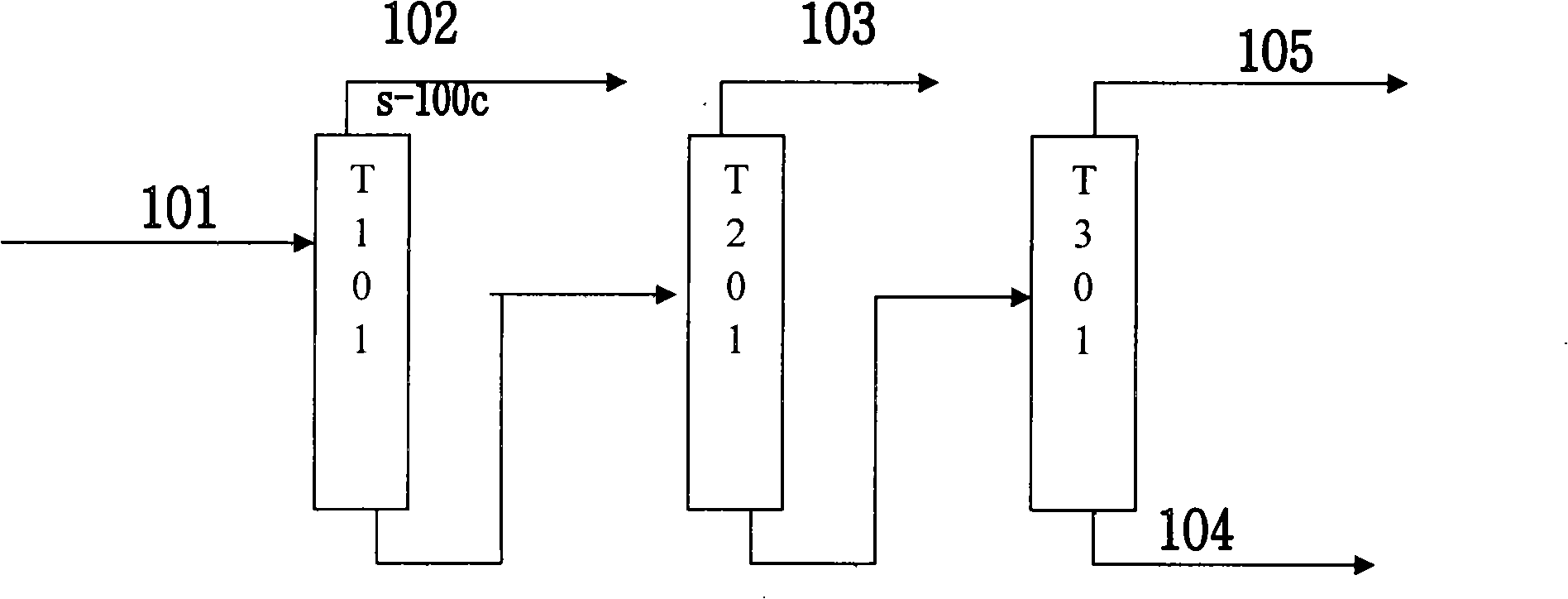

The invention provides a process for the preparation of hydrocarbons comprising the steps of:(a) contacting a mixture of carbon monoxide and hydrogen at an elevated temperature and pressure with a mixture of a methanol synthesis catalyst and a methanol conversion catalyst thereby forming C5+ hydrocarbons;(b) separating at least part of the C5+ hydrocarbons as obtained in step (a) into a light stream and a heavy durene-rich stream;(c) subjecting at least part of the heavy durene-rich stream to a hydrodealkylation treatment in the presence of hydrogen to obtain a stream of hydrocarbons having a reduced durene content; and(d) mixing at least part of the light stream as obtained in step (b) with at least part of the stream of hydrocarbons having a reduced durene content as obtained in step (c).

Owner:SHELL OIL CO

Method for preparing petroleum naphthalene by using C+10 heavy aromatic hydrocarbon as raw material

ActiveCN101250084AConvenient sourceReduce process stepsHydrocarbon by isomerisationDistillationToluene

A method for preparing petroleum naphthalene from C10 heavy Aromatic Hydrocarbon material belongs to the preparation technical field of petroleum naphthalene, which comprises exchanging the heat of C10 heavy Aromatic Hydrocarbon material with low naphthalene with the light fraction distillate at the top of a first distillation column, leading the material into the distillation column to be distilled, exchanging the heat and condensing the light fraction at column top, feeding condensate into a reflux tank at column top, leading the top distillate as a first solvent via a pipeline, leading out rich durene solution from the first side pipeline of the first distillation column, separating out the light fraction distillate and the rich durene solution, leading the heavy fraction distillate at the column bottom into a second distillation column to be distilled, leading out the top distillate of the second distillation column as a second solvent via a pipeline, separating out the light and heavy fraction distillates in the second distillation column, leading out rich naphthalene solution from a second side pipeline of the second distillation column, cooling, crystallizing the rich naphthalene solution via a crystallization device, and separating crystallization mother liquor via a centrifugal separator, to obtain final product of petroleum naphthalene. The invention has few process, simple operation and low cost, while the whole preparation has no generation of three wastes.

Owner:常熟华虞环境科技有限公司

Aromatic polycarboxylic acid manufacturing method

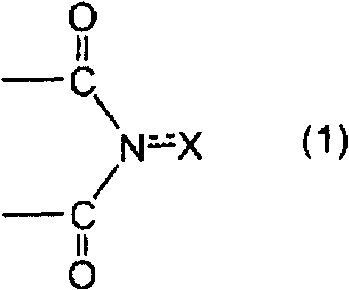

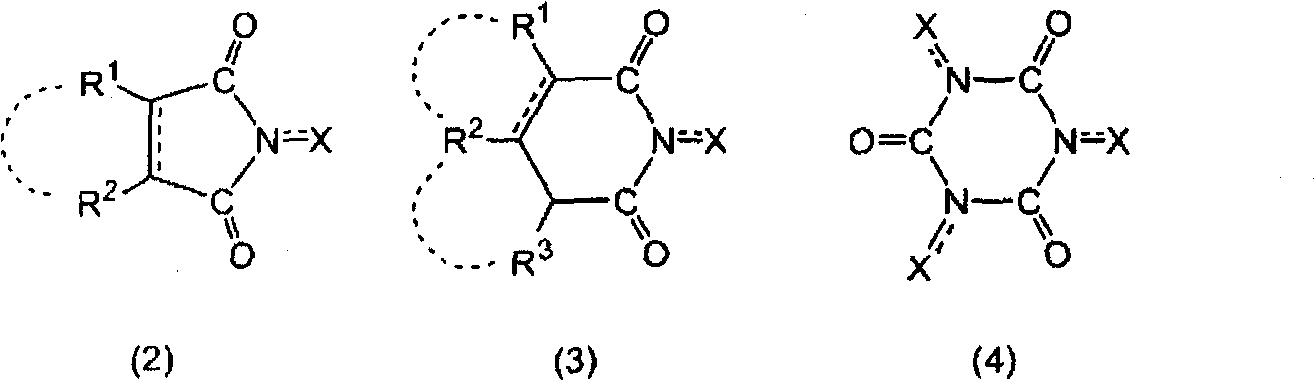

InactiveCN102066306ASuppress generationEasy and efficient to manufactureOrganic compound preparationOrganic chemistry methodsManganeseReaction temperature

Disclosed is a method by which the amount of residual intermediate product can be reduced and an aromatic polycarboxylic acid can be manufactured wherein all of the alkyl groups are converted into carboxy groups at a high yield. In the presence of a catalyst having ring-shaped imino units having an N-OR group (R is a hydrogen atom or a protective hydroxy group) and a transition metal co-catalyst (for example, a cobalt compound, manganese compound, or zirconium compound), an aromatic compound that has multiple alkyl groups (durene or the like) is heated in a low temperature range and then a high temperature range to undergo oxygen oxidization, to manufacture an aromatic polycarboxylic acid wherein the multiple alkyl groups are oxidized into carboxy groups. In the initial stage of the reaction, the reaction may be carried out in a first low temperature range with a reaction temperature of 60-120 DEG C and in a second low temperature range (intermediate temperature range) with a reaction temperature of 100-140 DEG C. Then, in the later stage of the reaction, the reaction may be carried out in a high temperature range with a reaction temperature of 110-150 DEG C.

Owner:DAICEL CHEM IND LTD

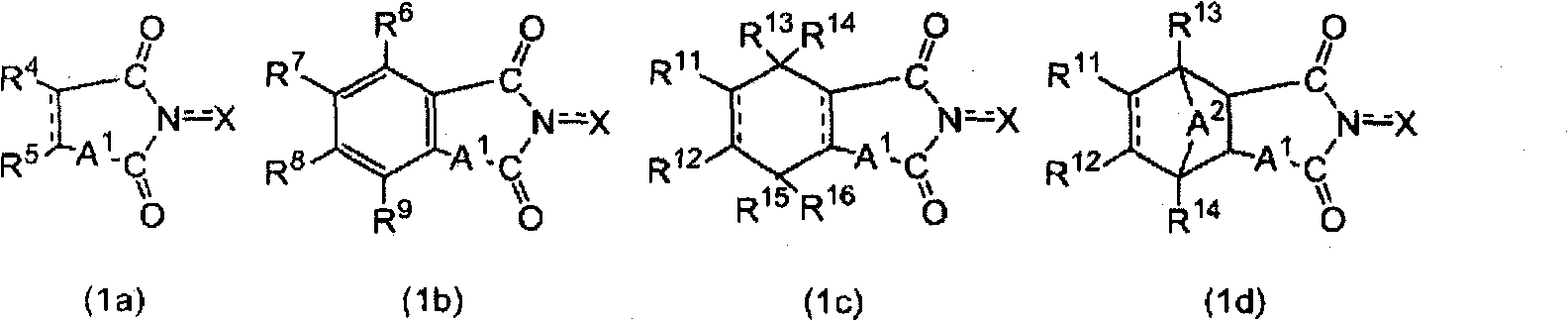

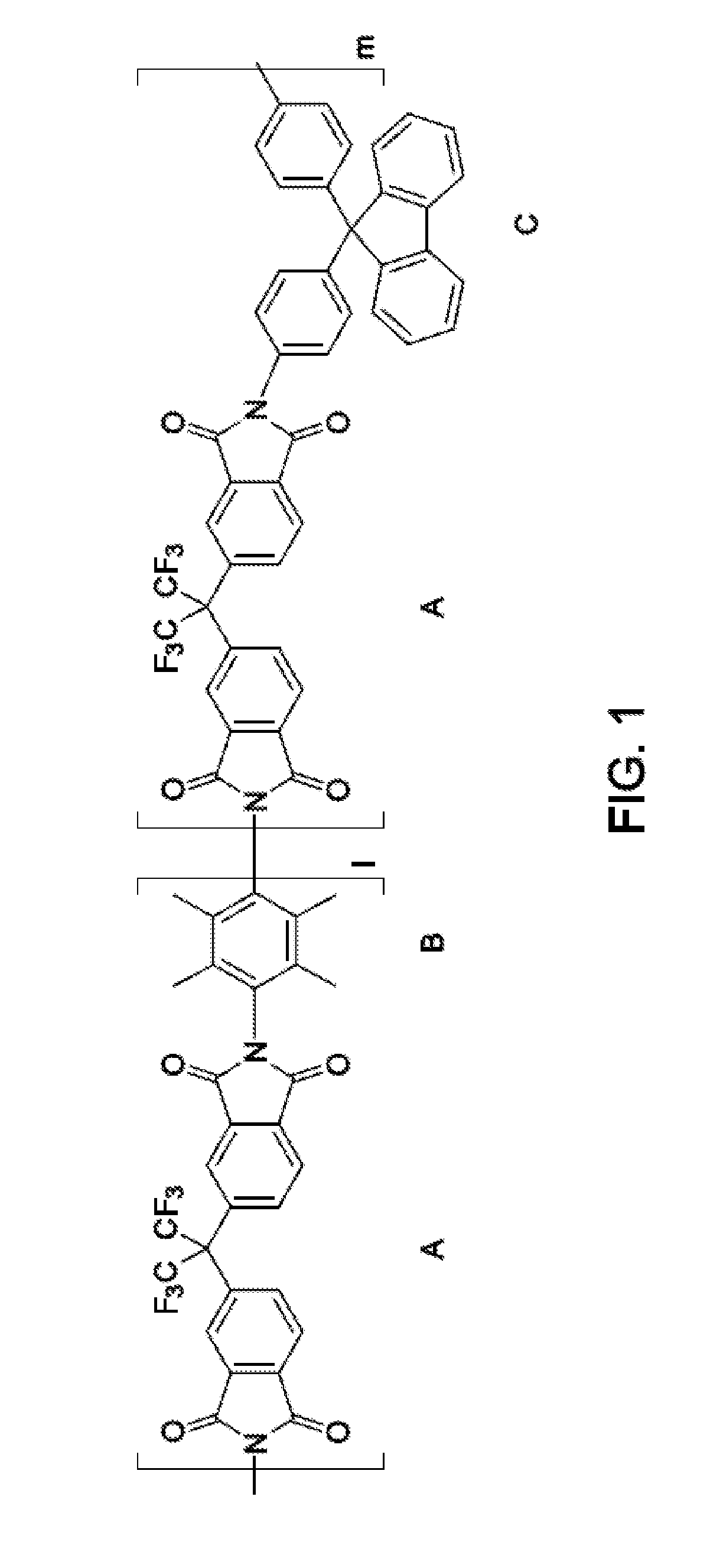

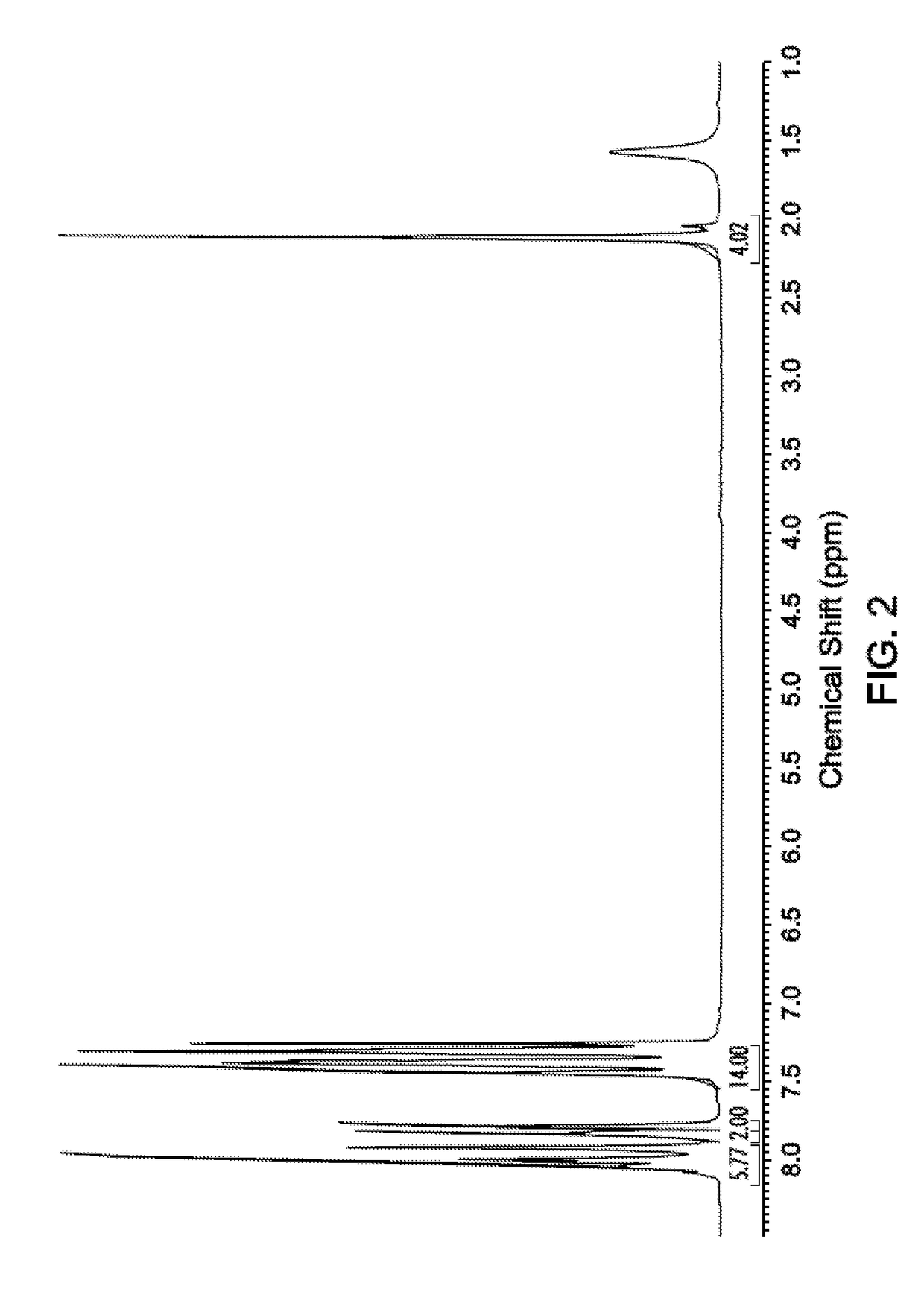

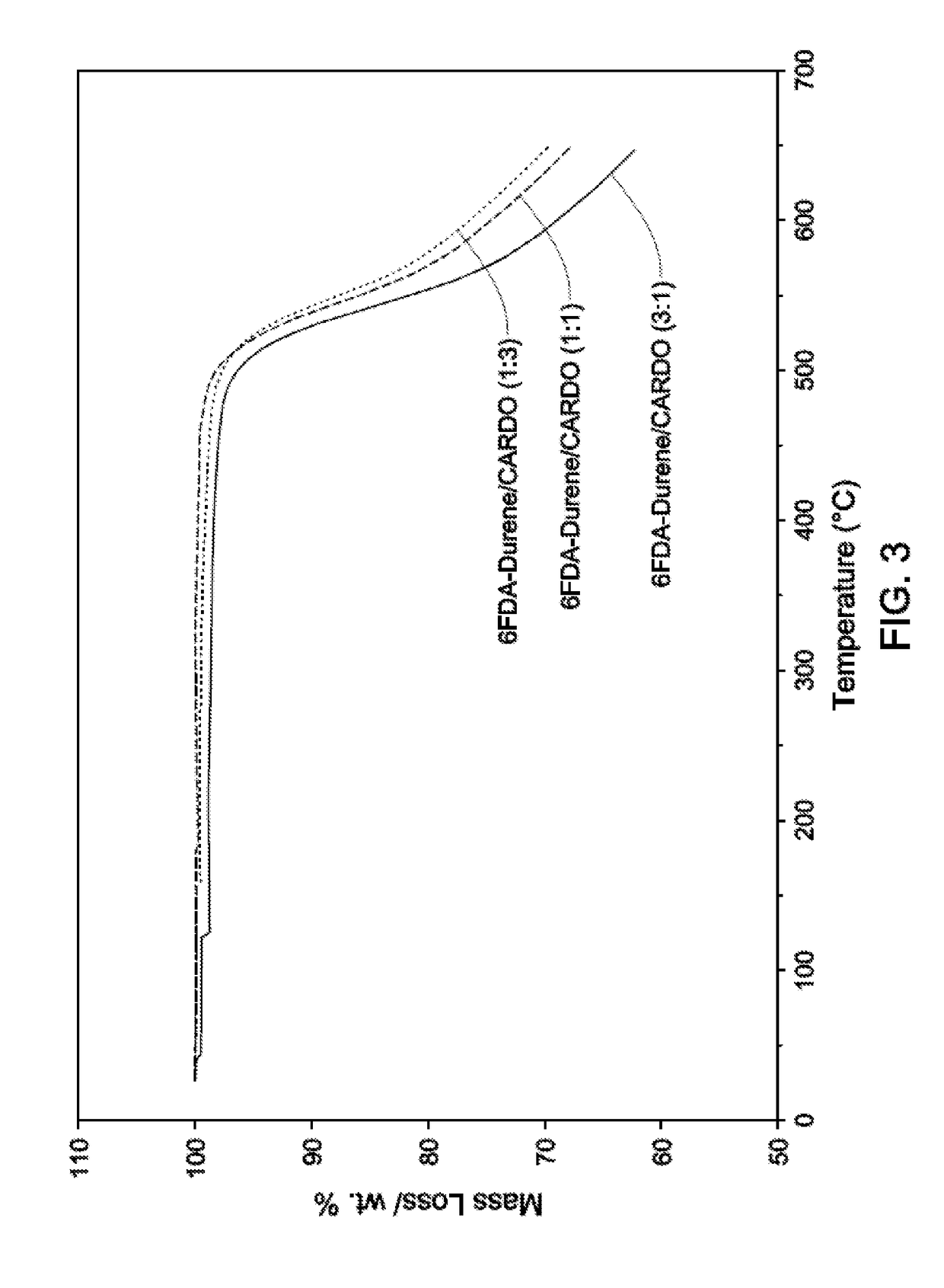

Cardo-Type Co-Polyimide Membranes For Sour Gas Feed Separations From Natural Gas

ActiveUS20180345229A1Less footprintFlexible operationSemi-permeable membranesGas treatmentPolyimide membraneMethyl group

Co-polyimide membranes for separating components of sour natural gas where embodiments can include at least three distinct moieties polymerized together, the moieties including a 2,2′-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (6FDA) based moiety; a 9,9-bis(4-aminophenyl) fluorene (CARDO) based moiety; and 2,3,5,6-tetramethyl-1,4-phenylenediamine (durene diamine) based moiety.

Owner:SAUDI ARABIAN OIL CO

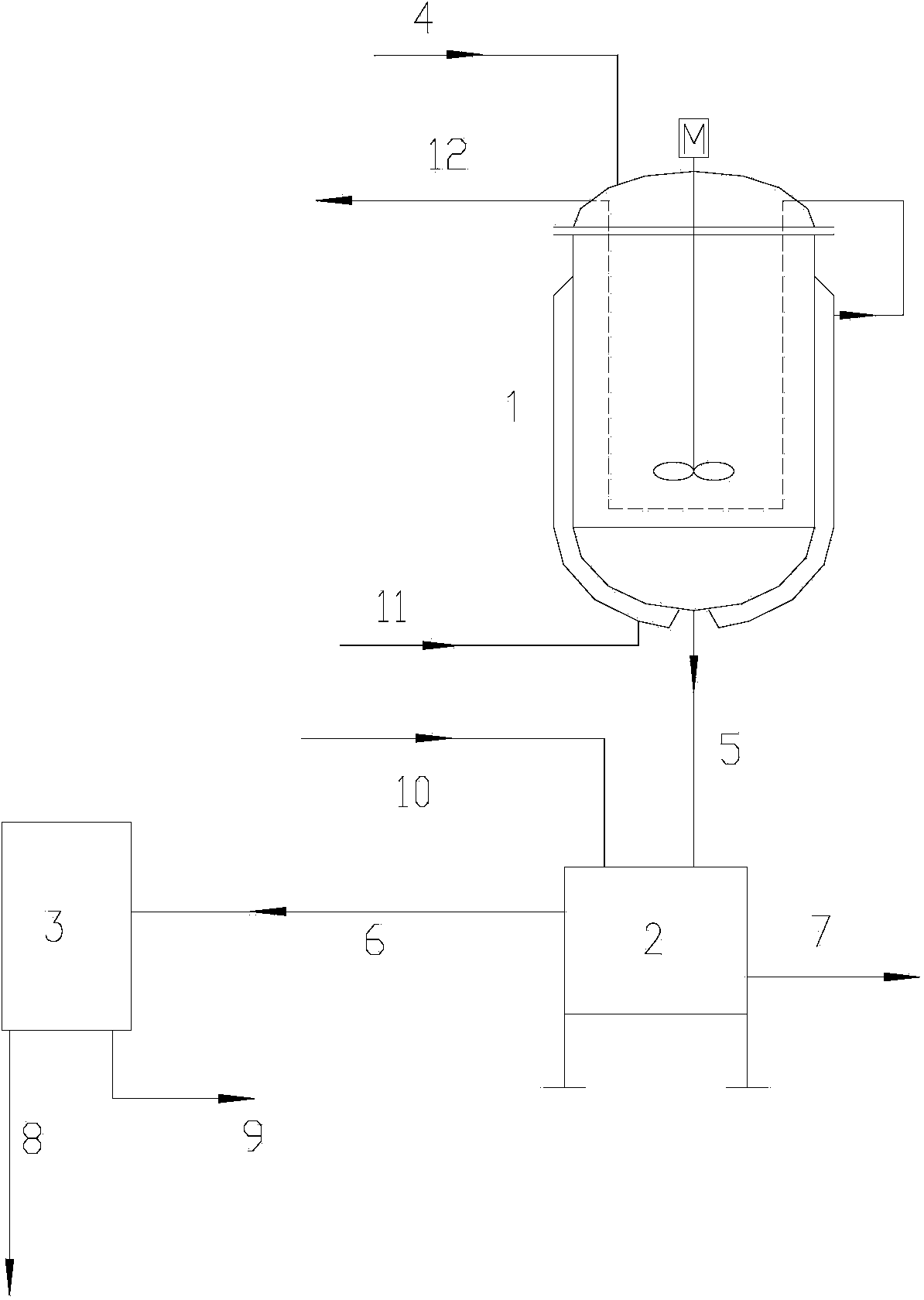

Purification method for durene

ActiveCN103524288AIncrease concentrationEasy to operateCrystallisation purification/separationHigh concentrationPurification methods

The invention relates to a purification method for durene. A durene solution (4) is added into a freezing crystallizer (1) for freezing crystallization, wherein a clod source is obtained through feed (11) of a cooling medium of the freezing crystallizer and discharge (12) of the cooling medium. After the freezing crystallization, durene crystals (5) containing crystallization mother liquor are obtained. The crystallization mother liquor is separated by a centrifugal separation device (2) to obtain crystallization mother liquor (7) and a solid product (6) after centrifugation. The solid product is squeezed by a squeezer (3) to obtain a durene product (8) and squeezed crystallization mother liquor (8) According to the purification method for the durene, the durene with a high concentration can be obtained, thus bringing great economic benefit and social benefit.

Owner:TIANJIN UNIV +1

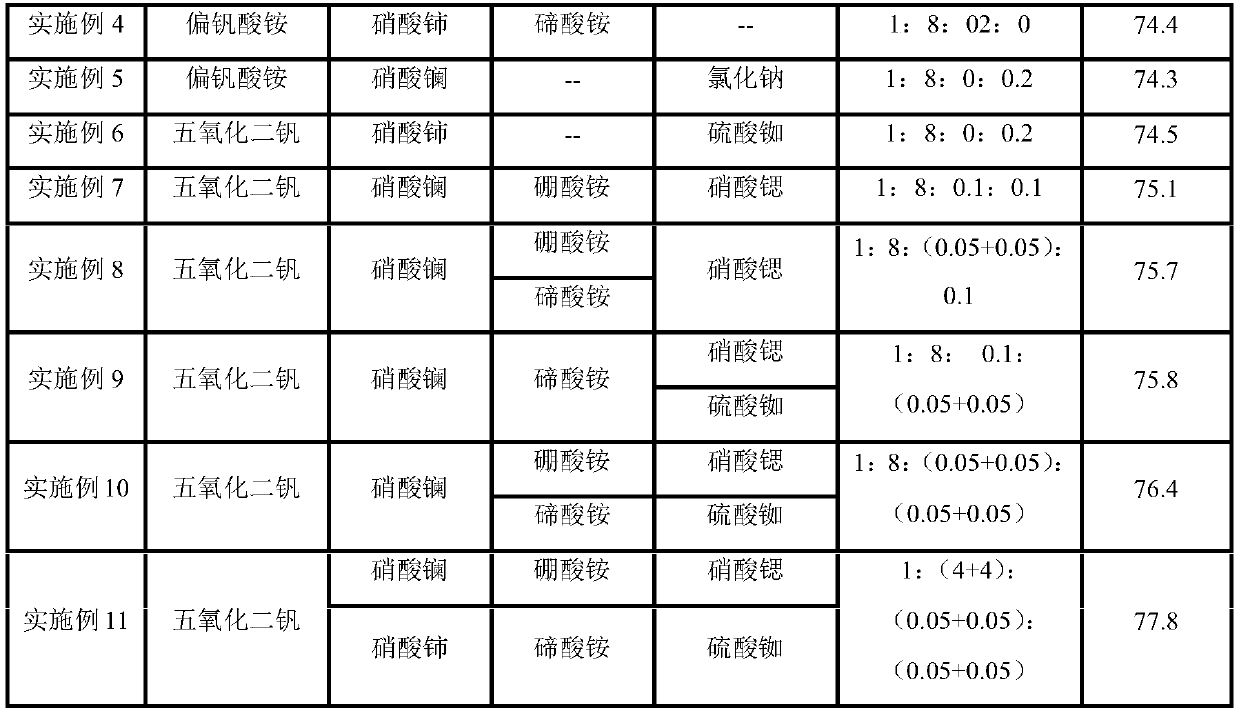

Catalyst for synthetizing benzenetetracarboxylic anhydride and preparation method of catalyst

InactiveCN103203244ARich sourcesReduce usagePhysical/chemical process catalystsOrganic chemistryCooking & bakingOxalate

The invention discloses a catalyst capable of being used for synthetizing benzenetetracarboxylic anhydride and a preparation method of the catalyst, and belongs to a catalyst technology. The catalyst comprises the main catalytic active components V and Ti; the weight ratio is (0.9 to 0.1) to (0.1 to 0.9); the total mass is 10-50% of that of an inert carrier; the total mass reference of the main catalyst is 1; the component P of a cocatalyst is 0.01-0.3; Nb is 0.01-1; and Sb is 0.01-0.3. The method comprises the following steps of: adding proper ammonium metavanadate to reflux and react in an oxalate solution; adding different cocatalysts and titanium dioxide to steep over the night; spraying prepared turbid liquid to a high-temperature spherical inert carrier; and heating and baking in a muffle furnace to obtain the catalyst. The catalyst disclosed by the invention has the advantages that the prepared material is abundant in source; use of toxic vanadium metal is reduced; the catalyst is used for synthesizing the benzenetetracarboxylic anhydride from durene air in a gas phase oxidation manner, and is good in performance; and the yield of the benzenetetracarboxylic anhydride can be effectively improved.

Owner:天津北洋国精科技有限责任公司

Method for separating durene by freezing crystallization

InactiveCN101973840AHigh yieldIncreased mass percent concentrationCrystallisation purification/separationTolueneRevolutions per minute

The invention discloses a method for separating durene by freezing crystallization and relates to the technical field of industrial production of centrifugal separation and crystallization of durene from solution of durene. In the method, durene-containing solution is frozen to the temperature of between 15 below zero and 5 DEG C and is introduced into a centrifugal machine; and the method is characterized by comprising the following steps of: adjusting the rotating speed of the centrifugal machine to be 800 revolutions per minute, and stopping introducing the durene-containing solution into the centrifugal machine when the thickness of a filter cake in the centrifugal machine is 2 to 15 mm; and adjusting the rotating speed of the centrifugal machine to be 1,200 revolutions per minute, recovering the thrown liquid phase and taking a solid phase. The mass percentage concentration of the durene in the thrown liquid phase is only 7.5 percent when the rotating speed of the centrifugal machine is 800 revolutions per minute, while the mass percentage concentration of the durene in the thrown liquid phase is 16 percent when the rotating speed of the centrifugal machine is improved to 800 revolutions per minute; and the liquid phase can be recovered for freezing crystallization. The method can improve the yield of the durene to 60 percent.

Owner:JIANGSU HUALUN CHEM

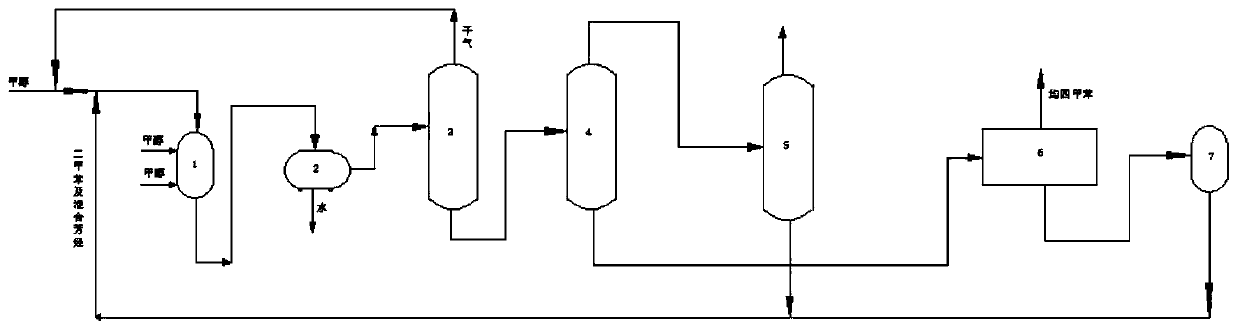

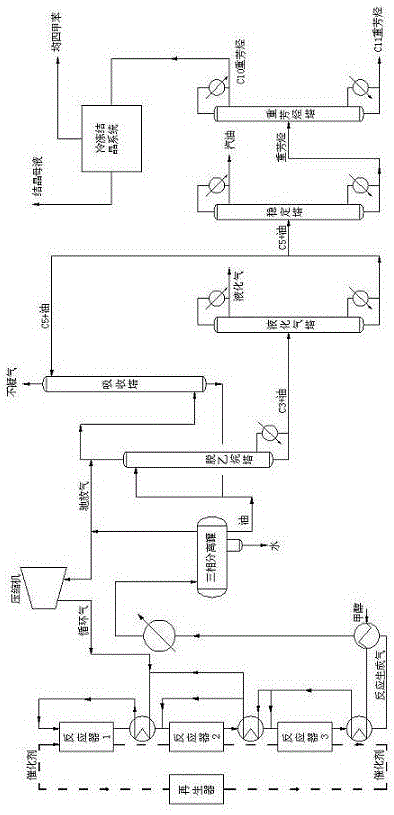

System and method for preparing durene by utilization of toluene and methanol

PendingCN106927990AHigh yieldHigh purityMolecular sieve catalystDistillation purification/separationXylylenePtru catalyst

The invention discloses a system and a method for preparing durene by the utilization of toluene and methanol. The problems such as limited sources of raw materials, high cost of raw materials, low yield of durene, low purity of durene and the like existing in the durene preparation technologies in the prior art are solved. The prepared durene has high yield and high purity. The technical scheme comprises the following steps: preheating toluene and methanol and introducing the preheated toluene and methanol into an alkylation reactor, and reacting at the reaction temperature of 350-400 DEG C at the reaction pressure of 2.0-5.0 MPa at the mass space velocity of 1-5 h<-1> for the reaction retention time of 1-5 s by using an HZSM-5 molecular sieve catalyst as a reaction catalyst; removing moisture and dry gas by oil-water separation of the reaction liquid, removing toluene, mixed xylenes and mixed trimethylbenzenes by rectifying the oil phase, and cooling for crystallization so as to obtain pure durene.

Owner:潍坊弘润新材料有限公司

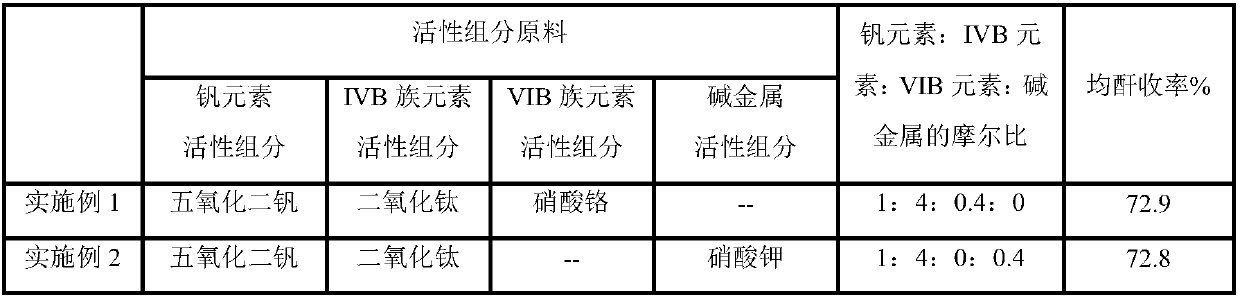

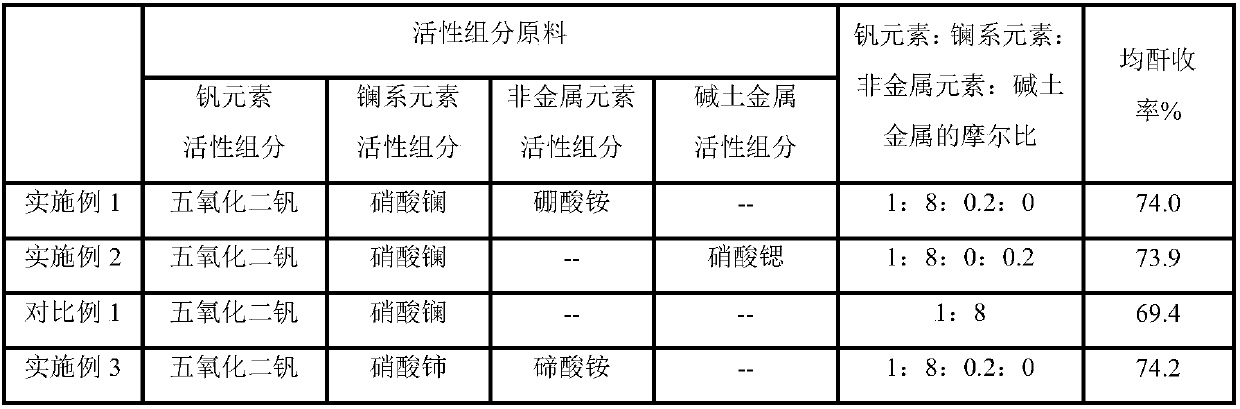

Catalyst for synthesizing pyromellitic dianhydride from durene

ActiveCN107866215AHigh activityImprove stabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActive componentPyromellitic dianhydride

The invention relates to a catalyst for synthesizing pyromellitic dianhydride from durene. The catalyst mainly overcomes the problem of low yield of the target product pyromellitic dianhydride due toa great number of side reactions in oxidation of durene in the prior art. According to the invention, an oxide catalyst is employed; the catalyst adopts alpha-Al2O3, silicon carbide, a ceramic ring ora mixture thereof as a carrier; and the active component of the catalyst is at least one selected from a group consisting of elemental vanadium, group-IVB elements, group-VIB elements and alkali metal elements. With such a technical scheme, the above technical problem is overcome, side reactions in oxidation of durene are reduced, and the yield of pyromellitic dianhydride is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

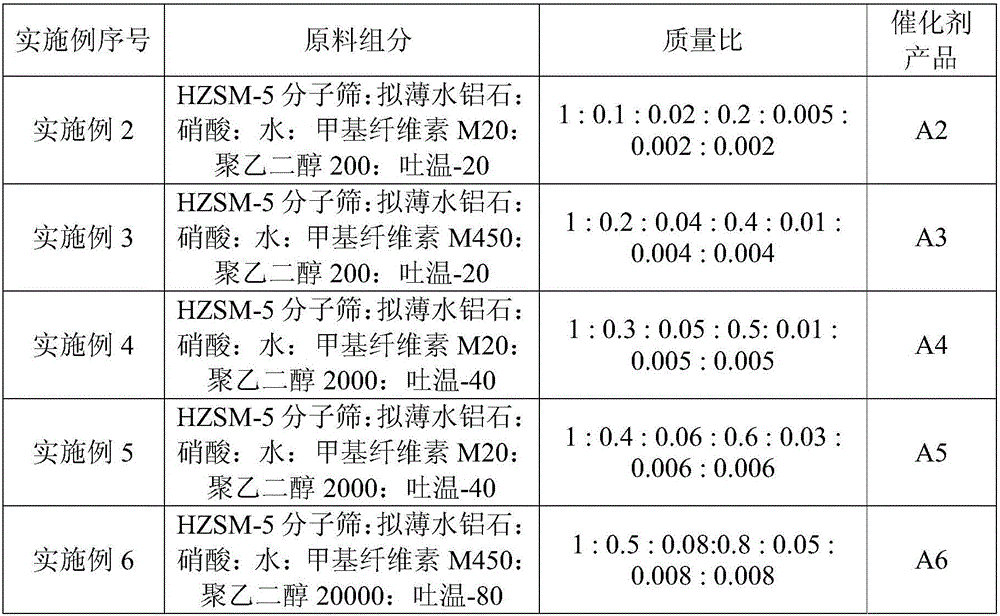

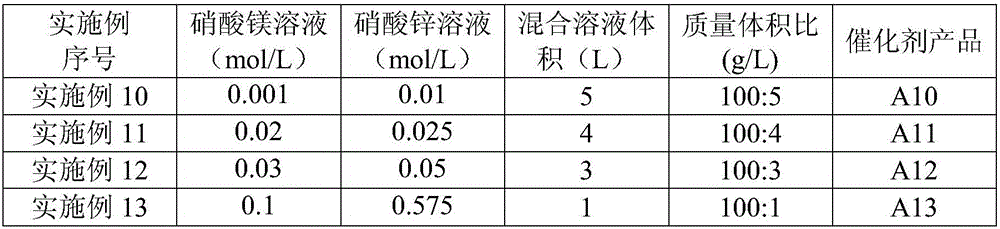

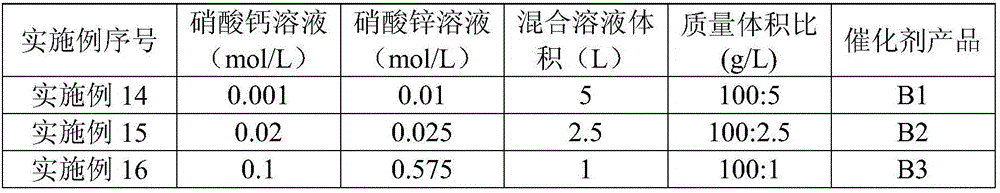

Preparation method and application of modified HZSM-5 molecular sieve catalyst

ActiveCN106582789ASimple preparation processReduce preparation energy consumptionMolecular sieve catalystsLiquid hydrocarbon mixture productionMass ratioPolyethylene glycol

The invention provides a preparation method of a modified HZSM-5 molecular sieve catalyst. The method includes the following steps that firstly, a nano aggregate HZSM-5 molecular sieve, pseudo-boehmite, nitric acid, water, methyl cellulose, polyethylene glycol and tween are evenly mixed in the mass ratio of 1:(0.1-0.5):(0.02-0.08):(0.2-0.8):(0.005-0.05):(0.002-0.008):(0.002-0.008), extruded and formed, drying, bar breaking and calcination are conducted, and a catalyst precursor is obtained; secondly, the catalyst precursor is soaked in a mixed solution containing a proper amount of magnesium nitrate and zinc nitrate or a mixed solution containing calcium nitrate and zinc nitrate, dried and calcinated to obtain the modified HZSM-5 molecular sieve catalyst, wherein the massic volume ratio of the catalyst precursor to the mixed solution is 100:(1-5) (g / L). When a catalyst in the method is applied in a reaction for preparing gasoline with methyl alcohol as the raw material or methyl alcohol and naphtha as mixed raw materials, the methyl alcohol conversion rate and the oil product yield can be increased, the content of durene is remarkably reduced, and the octane number of the gasoline is increased. Methyl alcohol and naphtha serve as the raw materials to synthesize the gasoline, the heat exchange process is optimized, and the octane number of naphtha and the gasoline yield are increased.

Owner:SHANGHAI NOVEL CHEM TECH

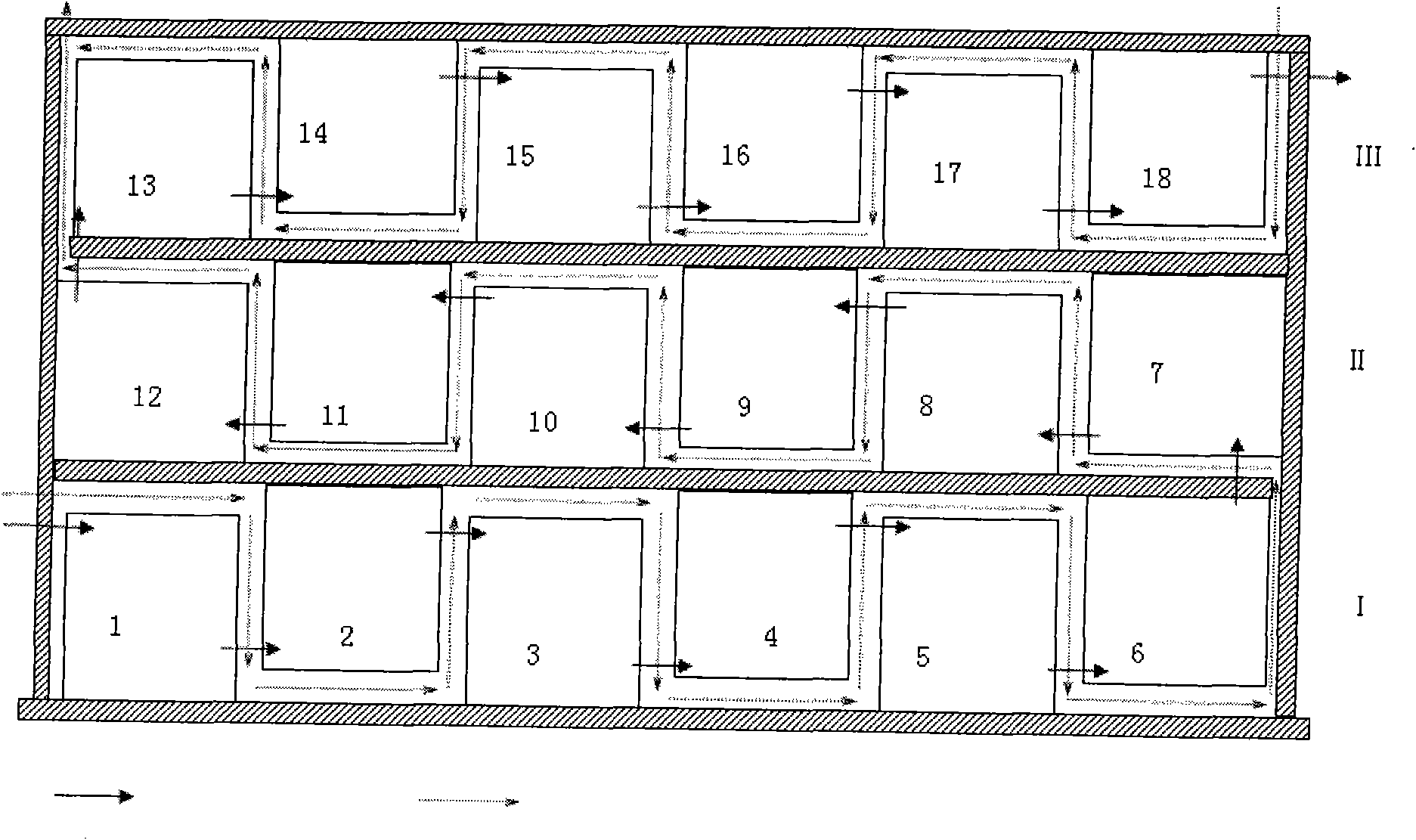

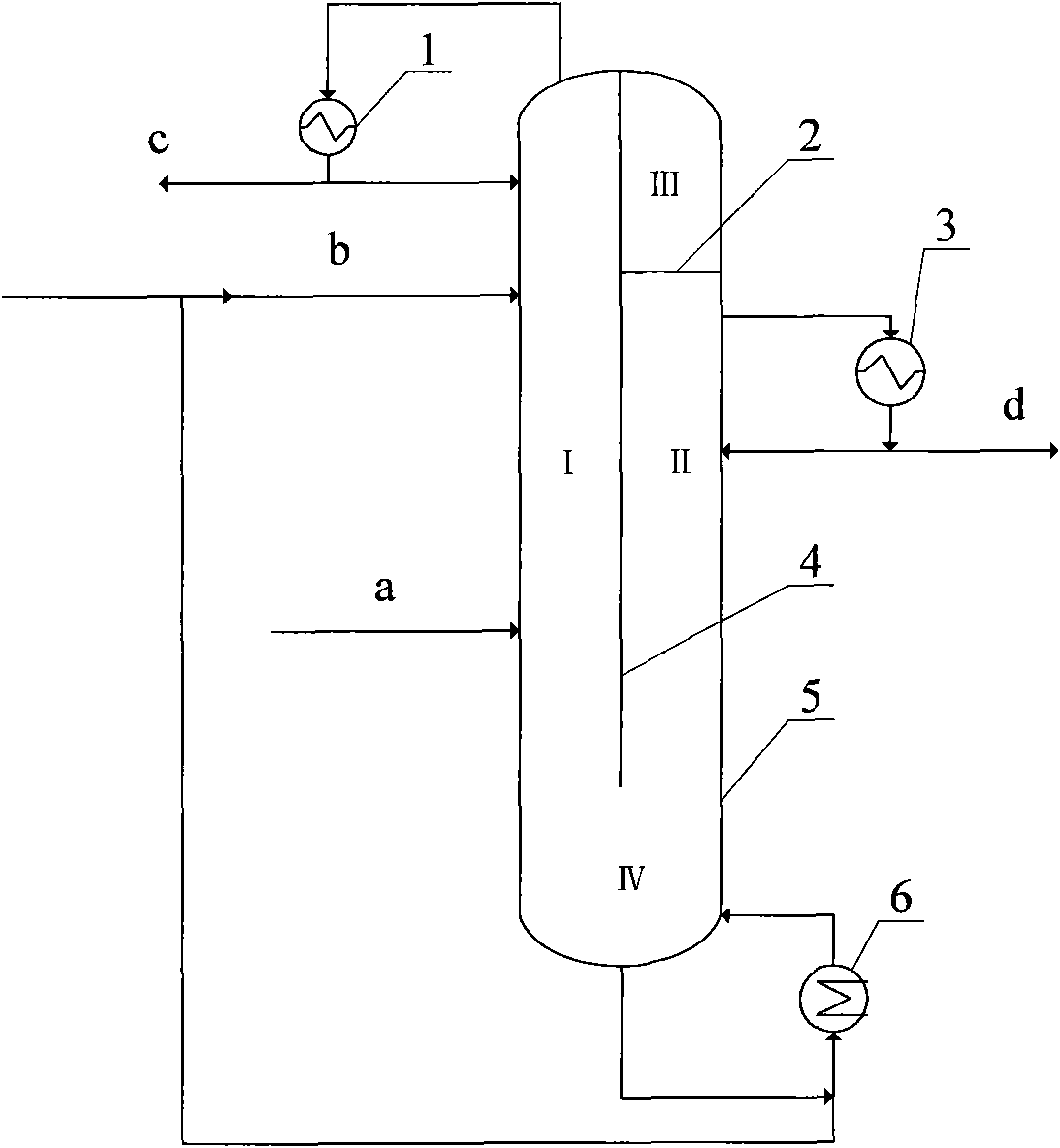

Method for extracting, distilling and separating acetonitrile-phenylmethane by utilizing dividing-wall rectifying tower

ActiveCN101830830AReduce consumptionLess investmentDistillation purification/separationExtractive distillationTheoretical plateAcetonitrile

The invention discloses a method for extracting, distilling and separating acetonitrile-phenylmethane by utilizing dividing-wall rectifying tower, which belongs to separation techniques for an acetonitrile-phenylmethane azeotropic mixture. In the method, durene (1,2,4,5-durene) is preferably used as an extracting agent, the adopted device is an extractive rectifying tower provided with a dividingwall, and a dividing wall is installed in the vertical direction of a common rectifying tower to divide the tower into four parts. Region I is an extractive rectifying region, and the main body of the region I is provided with a tower tray and a filler; a sealing plate is arranged between region II and region III; the region II is an extracting agent recovery region; and since the extracting agent can be more easily separated in general and the extracting agent recovery region requires a smaller number of theoretical plates as compared with the extractive rectifying region, the position of the sealing plate can be adjusted by controlling the quantity of the tower trays or the filler. Region III is not additionally provided with any tower tray or filler. Region IV is the common stripping section of the region I and the region II. The invention can separate out high-purity acetonitrile and phenylmethane by using accessible, cheap and efficient extracting agent through extractive rectification with a dividing wall. The method reduces the equipment investment and energy consumption by more than 20% as compared with the conventional continuous extractive rectification.

Owner:PETROCHINA CO LTD

Method for preparing durene from methanol and xylene

ActiveCN110627605AHigh yieldLow reaction temperatureMaterial nanotechnologyMolecular sieve catalystsReaction temperatureOil phase

The invention provides a method for preparing durene from methanol and xylene. Xylene is mixed with a part of methanol; the mixture enters from a top main line into a reactor, and the rest methanol enters the reactor in a side-line multi-section feeding manner; the materials are converted into a mixed hydrocarbon component rich in durene under the conditions that the temperature is 250-400 DEG C and the pressure intensity is 0.5-2.0 MPa, the mixed hydrocarbon component is separated to obtain heavy aromatic hydrocarbon rich in durene, and through multi-stage freezing crystallization and centrifugal separation squeezing system, high-purity durene is obtained. Bed layer temperature rise during alkylation is controlled by adopting side line methanol multi-section feeding, reaction heat of an upper-section bed layer of the reactor is fully utilized to preserve heat of a middle-section bed layer and a tail-section bed layer, and a modified nano ZSM-5 molecular sieve catalyst is used for reducing the reaction temperature; xylene and mixed aromatic hydrocarbon thereof and methanol are continuously subjected to alkylation reaction for many times, so that the selectivity of durene in an oilphase product is improved. And the yield of durene is improved by fully utilizing reaction by-products.

Owner:大连龙缘化学有限公司

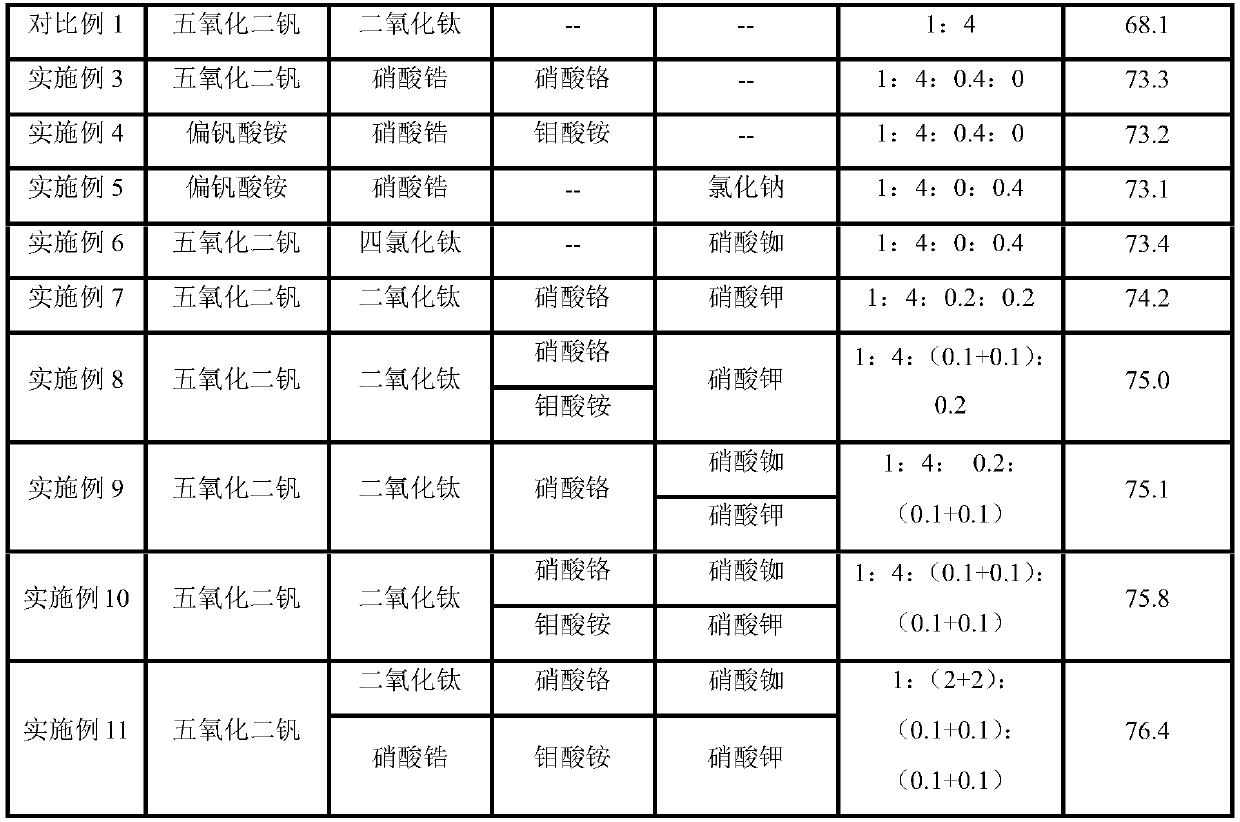

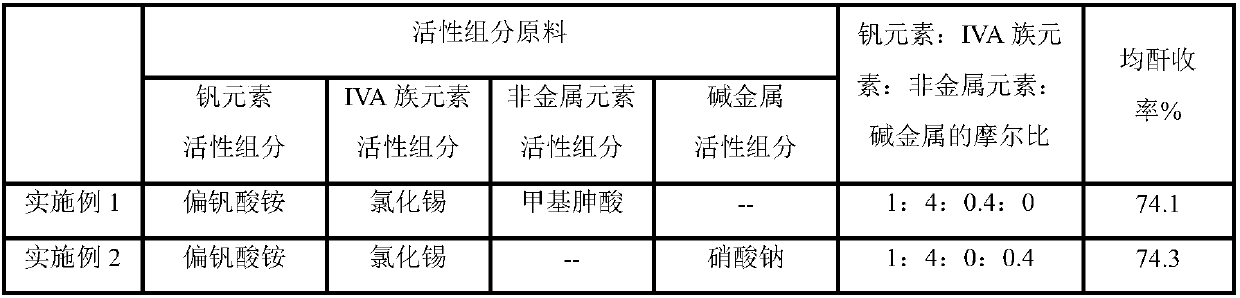

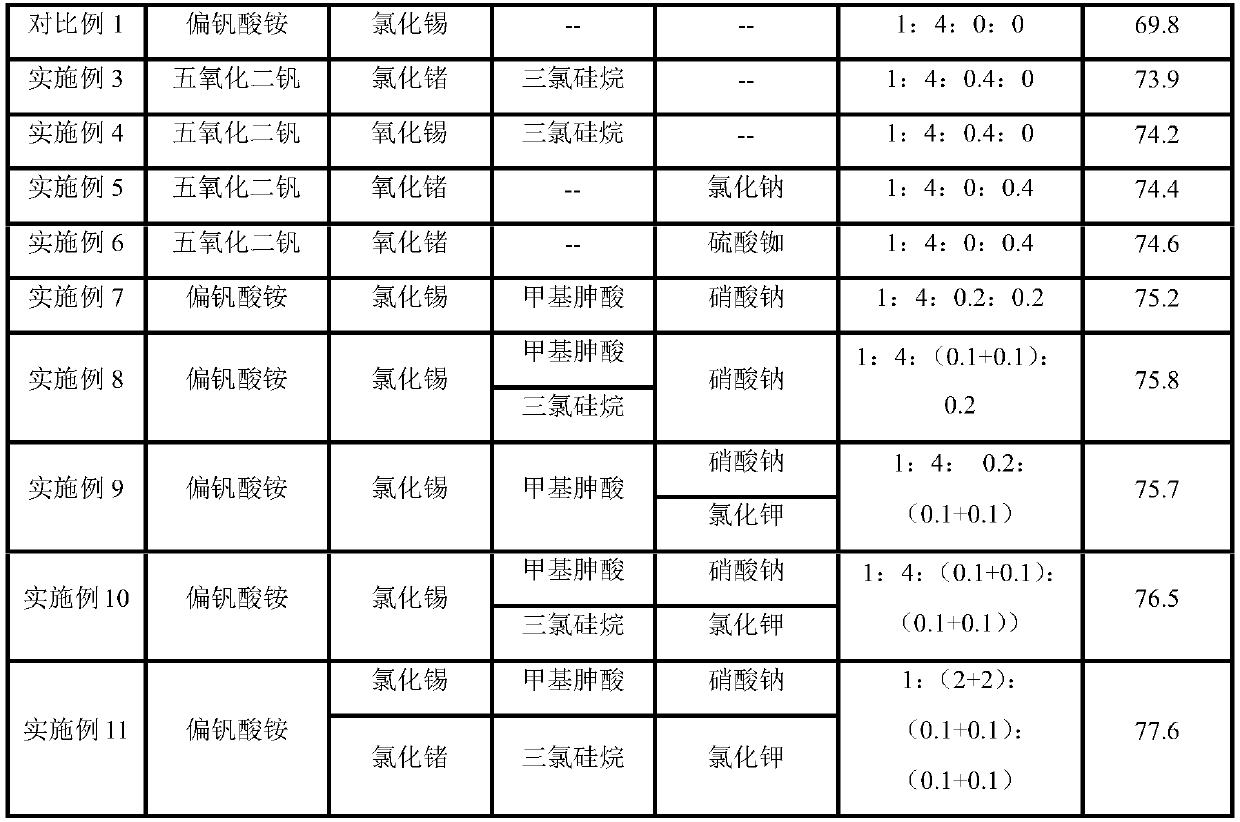

Catalyst for durene gas phase oxidation reaction

ActiveCN107866259AHigh activityImprove stabilityPhysical/chemical process catalystsOrganic chemistryCarbide siliconPtru catalyst

The invention relates to a catalyst for a durene gas phase oxidation reaction. The catalyst mainly solves the problem that the existing durene gas phase oxidation reaction produces more by-products and leads pyromellitic dianhydride yield reduction. An oxide catalyst utilizes alpha-Al2O3, silicon carbide, a porcelain ring or a mixture thereof as a carrier, and an active component comprises at least one of a vanadium element, a group IVA element, a nonmetal element and an alkaline-earth metal element. The catalyst solves the technical problem, reduces side reactions during the pyromellitic dianhydride synthesis and improves the yield of pyromellitic dianhydride.

Owner:CHINA PETROLEUM & CHEM CORP +1

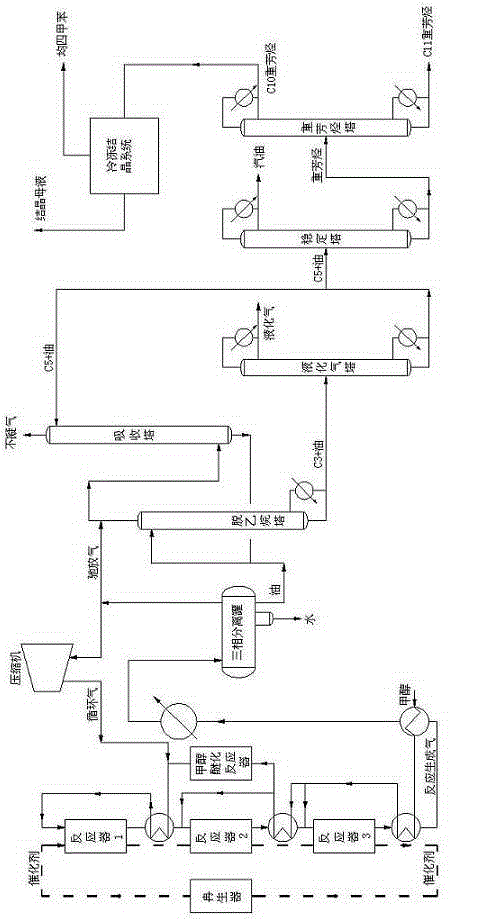

Durene-poly-generation technological method and production system for preparing light hydrocarbon through methyl alcohol

InactiveCN105130729AEfficiently control component distributionEffectively control the yieldGaseous fuelsHydrocarbon from oxygen organic compoundsHeat carrierMass ratio

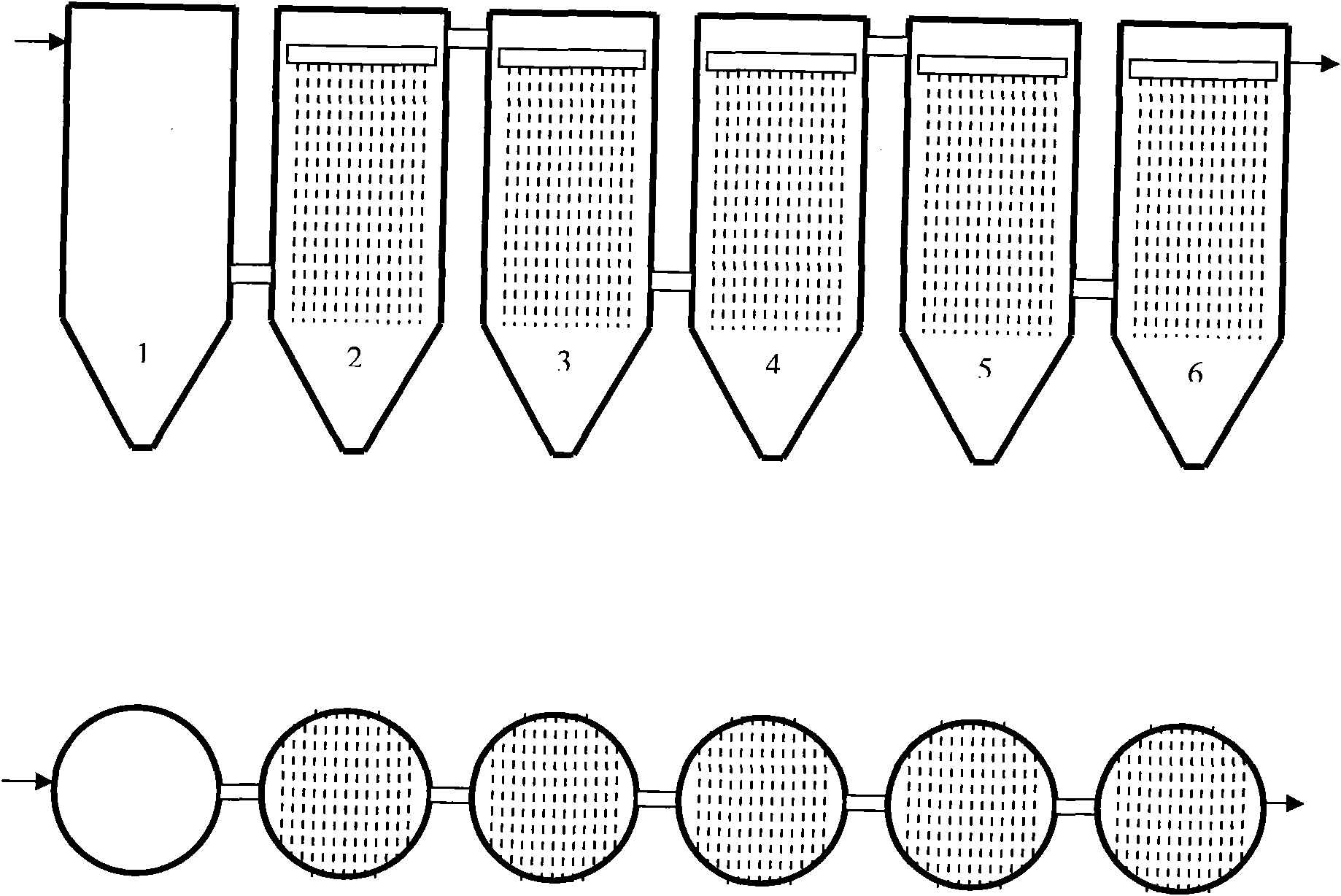

The invention relates to a durene-poly-generation technological method and production system for preparing light hydrocarbon through methyl alcohol. The technological method is adopted for the production system. The technological method includes the steps that multiple moving bed synthesis reactors connected in series form a synthesis reaction system; the methyl alcohol or the water-contained methyl alcohol serves as raw materials and is mixed with circulating gas, then the mixture is introduced into the synthesis reaction system to be subjected to a catalysis reaction, and a reaction product containing the C1-C11 light hydrocarbon is generated; an oil phase in the reaction product is further separated to prepare gasoline blending components and the high-purity durene; the circulating gas serves as heat carriers of heat generated by the reaction, and the synthesis reaction temperature is controlled to control the component distribution of the synthesis reaction product and the yield of the target product to enable the mass ratio of the durene to the hydrocarbon in the reaction product to be larger than or equal to 10%. The system comprises the corresponding synthesis reaction system and the light hydrocarbon separating system. By means of the technological method and production system, continuous production of light hydrocarbon produced through the methyl alcohol and poly-production of the durene and the like is achieved, technological conditions are stable and easy to control, and product quality is good.

Owner:CHINA KUNLUN CONTRACTING & ENG +1

Catalyst for preparing pyromellitic dianhydride through durene gas phase oxidation

ActiveCN107866254AHigh activityImprove stabilityOrganic chemistryPhysical/chemical process catalystsAlkaline earth metalGas phase

The invention relates to a catalyst for preparing pyromellitic dianhydride through durene gas phase oxidation. The catalyst mainly solves the problem that the existing durene gas phase oxidation reaction produces more by-products and leads pyromellitic dianhydride yield reduction. An oxide catalyst utilizes alpha-Al2O3, silicon carbide, a porcelain ring or a mixture thereof as a carrier, and an active component comprises at least one of a vanadium element, a lanthanum element, a nonmetal element and an alkaline-earth metal element. The catalyst solves the technical problem, reduces side reactions during the pyromellitic dianhydride synthesis and improves the yield of pyromellitic dianhydride.

Owner:CHINA PETROLEUM & CHEM CORP +1

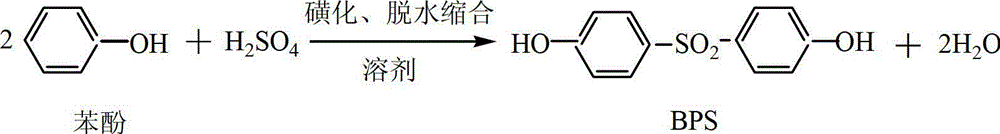

Method for preparing 4, 4'-dihydroxyl diphenyl sulfone

ActiveCN102942510AGood suspensionRaise the reaction temperatureOrganic chemistryOrganic compound preparationReaction temperatureSolvent

The invention provides a method for preparing 4, 4'-dihydroxyl diphenyl sulfone. The method comprises the following steps: adding 2,6-naphthalene disulfonic acid in a mixed solvent of mesitylene and durene, and then preparing the 4, 4'-dihydroxyl diphenyl sulfone by sulfonation and dehydration reaction between phenol and concentrated sulfuric acid, wherein the 2,6-naphthalene disulfonic acid is a by-product separated from the production of 2,7-naphthalene disulfonic acid, low in price and rich in source; the mass ratio of the 2,6-naphthalene disulfonic acid to the concentrated sulfuric acid (density of 98%) is (0.03-0.15):1; the mass ratio of the solvent to the concentrated sulfuric acid is (1.85-2.48):1; the mass ratio of the phenol to the concentrated sulfuric acid is (1.89-2.03):1; in the solvent, the mass ratio of the mesitylene to durene is (2.8-4):1; and the time of reflux dehydration reaction is 6-10h. The material of the method is excellent in suspension, high in reaction temperature and beneficial to dehydration reaction and the yield of 4, 4'-dihydroxyl diphenyl sulfone is high.

Owner:KEMAI CHEM

Method for preparing catalysts for preparing benzenetetracarboxylic anhydride

InactiveCN107649156AGuarantee full expressionGuaranteed activation effectOrganic chemistryCatalyst activation/preparationGas phasePhosphate

The invention discloses a method for preparing catalysts for preparing benzenetetracarboxylic anhydride from durene by means of gas-phase catalytic oxidation. The catalysts comprise spray liquid and carriers. The spray liquid mainly comprises, by weight, 3-5 parts of ammonium metavanadate, 11.2-11.4 parts of oxalic acid, 0.2-0.4 part of diammonium hydrogen phosphate, 0.1-0.3 part of trisodium phosphate anhydrous, 0.18-0.2 part of antimony oxide, 1.1-1.3 parts of ammonium molybdate, 0.98-1 part of potassium hydroxide, 0.6-0.8 part of sodium dihydrogen phosphate, 0.18-0.2 part of potassium carbonate, 0.68-0.7 part of potassium dihydrogen phosphate, 1.16-1.18 parts of potassium phosphate and 8.6-8.8 parts of titanium dioxide powder; the carriers are 78.5-78.7 parts of porcelain rings. The method includes four steps of weighing, liquid preparing, spraying and calcining. The method has the advantages that the catalysts prepared by the aid of the method are good in activity, high in selectivity, low in hotspot reaction temperature and long in service life when applied, and partial energy consumption can be reduced when the catalysts are applied.

Owner:RUGAO CITY LEHENG CHEM COMPANY

Synthesis method of C10 mixed ester plasticizer

InactiveCN105175258AIncrease profitEmission reductionPreparation rom asymmetrical anhydridesOrganic compound preparationIsooctyl alcoholAlcohol

The invention discloses a synthesis method of a C10 mixed ester plasticizer, which comprises the following steps: (1) mixing mixed anhydride and isooctyl alcohol in a certain proportion, and then carrying out catalytic reaction; (2) after the catalytic reaction, filtering the catalyst out of the reaction product; (3) carrying out dealcoholization and dehydration treatment on the reaction product in which the catalyst is removed; and (4) carrying out decoloration treatment on the reaction product to obtain a finished product of the C10 mixed ester plasticizer, wherein the mixed anhydride and isooctyl alcohol used in the step (1) are byproducts obtained after oxidation of durene. In the invention, the synthesis raw material used for the synthesis method of the C10 mixed ester plasticizer is a C10 mixed anhydride byproduct, and byproducts obtained in actual production, such as phthalic anhydride and trimellitic anhydride, can be comprehensively utilized, so that the utilization ratio of C10 aromatic hydrocarbon is greatly increased, the waste discharge is reduced and the environment is protected.

Owner:NANJING POLYTECHNIC INSITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com