Purification method for durene

A technology of durene and purification method, which is applied in the direction of crystallization purification/separation, organic chemistry, etc., can solve the problems of industrialized production scale and low output, achieve huge economic and social benefits, increase concentration, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

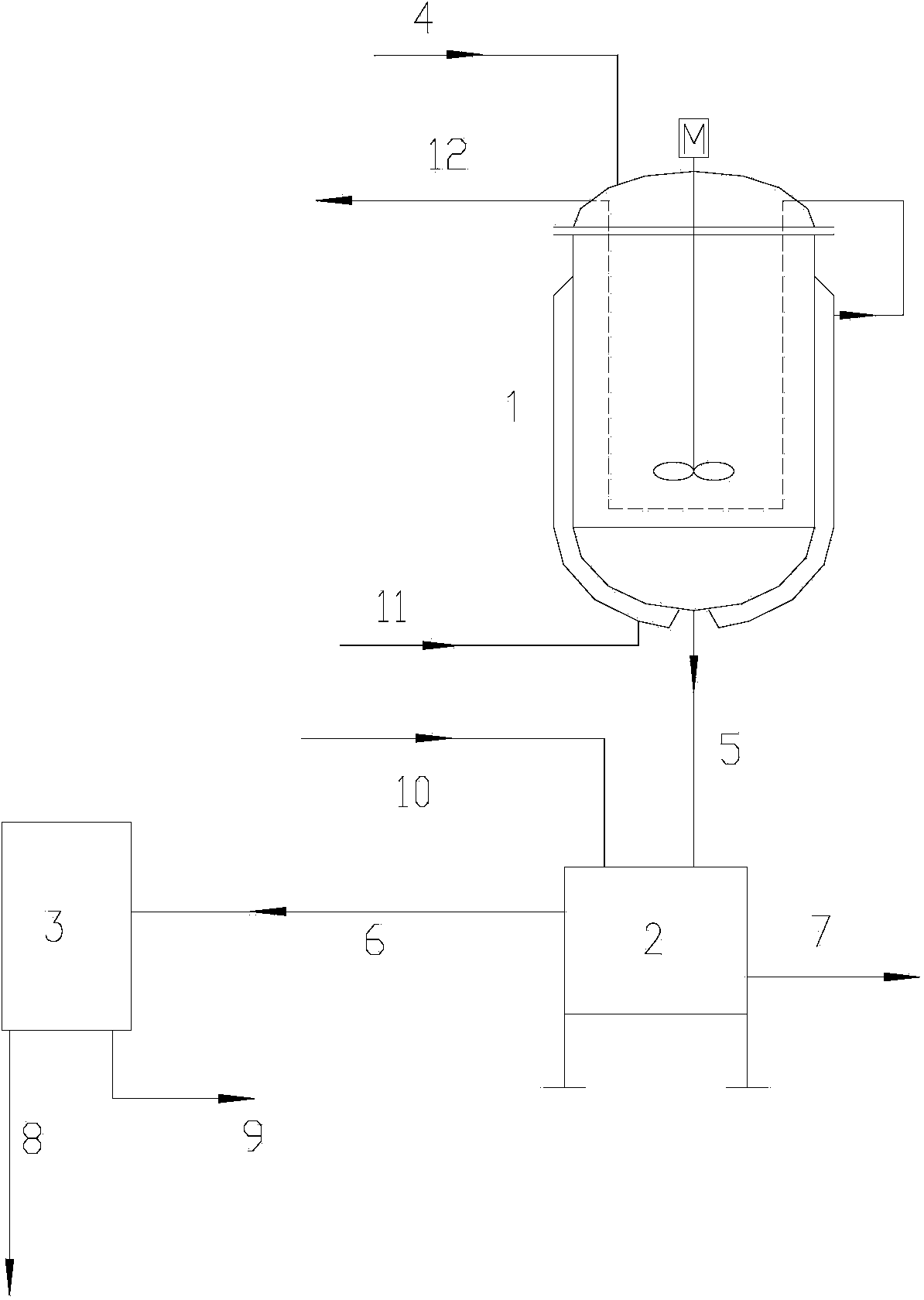

[0022] The operation process is: 50% durene solution 4 enters the freezing crystallizer 1 for freezing and crystallization, the operating temperature is -15°C, the cooling medium of the freezing crystallizer uses frozen water, and after freezing and crystallization, durene crystals containing crystallization mother liquor are obtained 5; use the centrifuge separation device 2 to adopt a rotating speed of 600r / min to separate the crystallization mother liquor, obtain the crystallization mother liquor 7 and the solid product 6 after centrifugation, and use the squeezer 3 to squeeze the solid product for 30min to obtain the durene product 8 with a concentration of 60 %, and the squeezed crystallization mother liquor 9.

Embodiment 2

[0024] The operation process is as follows: 60% durene solution 4 enters the freezing crystallizer 1 for freezing and crystallization, the operating temperature is 0°C, the cooling medium of the freezing crystallizer uses chilled water, and after freezing and crystallization, durene crystals 5 containing crystallization mother liquor are obtained It is 1200r / min that the crystallization mother liquor is separated with the centrifugal separation device 2, and this process adds washing liquid gasoline accounting for 5% of the quality of durene in the raw material to obtain the crystallization mother liquor 7 and the centrifuged solid product 6, and the solid product is squeezed The machine 3 performs the squeezing operation for 120 minutes to obtain the durene product 8 with a concentration of 70%, and the squeezed crystallization mother liquor 9.

Embodiment 3

[0026] The operation process is as follows: 70% durene solution 4 enters the freezing crystallizer 1 for freezing and crystallization, the operating temperature is 20°C, the freezing water is used as the cooling medium of the freezing crystallizer, and after freezing and crystallizing, durene crystals 5 containing crystallization mother liquor are obtained It is 1800r / min to separate crystallization mother liquor with centrifuge separation device 2 adopting rotating speed, this process adds the washing liquid light diesel oil that accounts for 10% of durene quality in the raw material, obtains crystallization mother liquor 7 and centrifuged solid product 6, and this solid product adopts The squeezing machine 3 performs the squeezing operation for 180 minutes to obtain the durene product 8 with a concentration of 80% and the squeezed crystallization mother liquor 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com