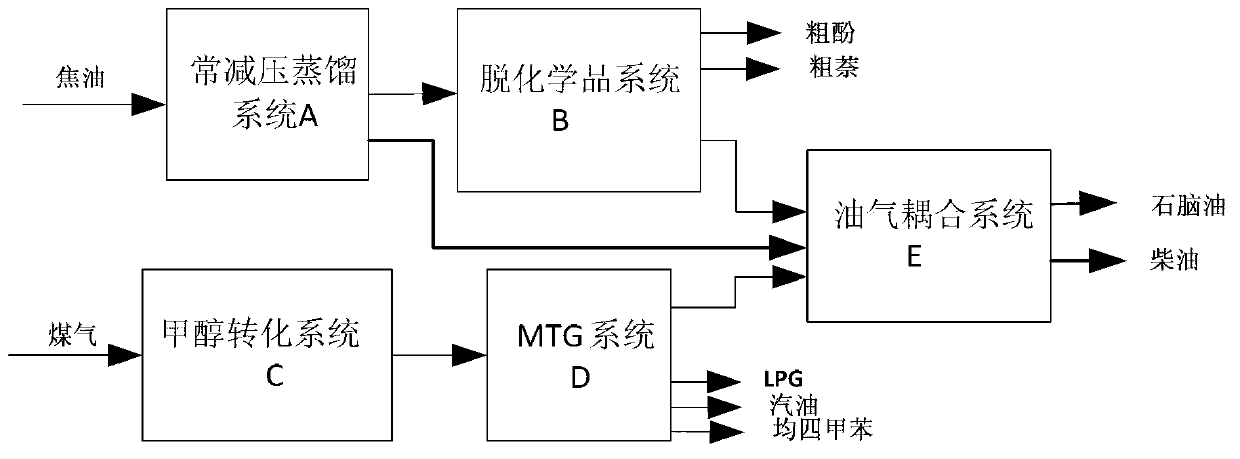

Oil-gas coupling poly-generation method in coal chemical engineering industry

A technology of oil and gas coupling and coal chemical industry, applied in the field of coal chemical industry, can solve the problems of low added value of products, low utilization rate of gas and tar, and achieve the effect of avoiding resource waste, reducing environmental pollution, and strong process flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

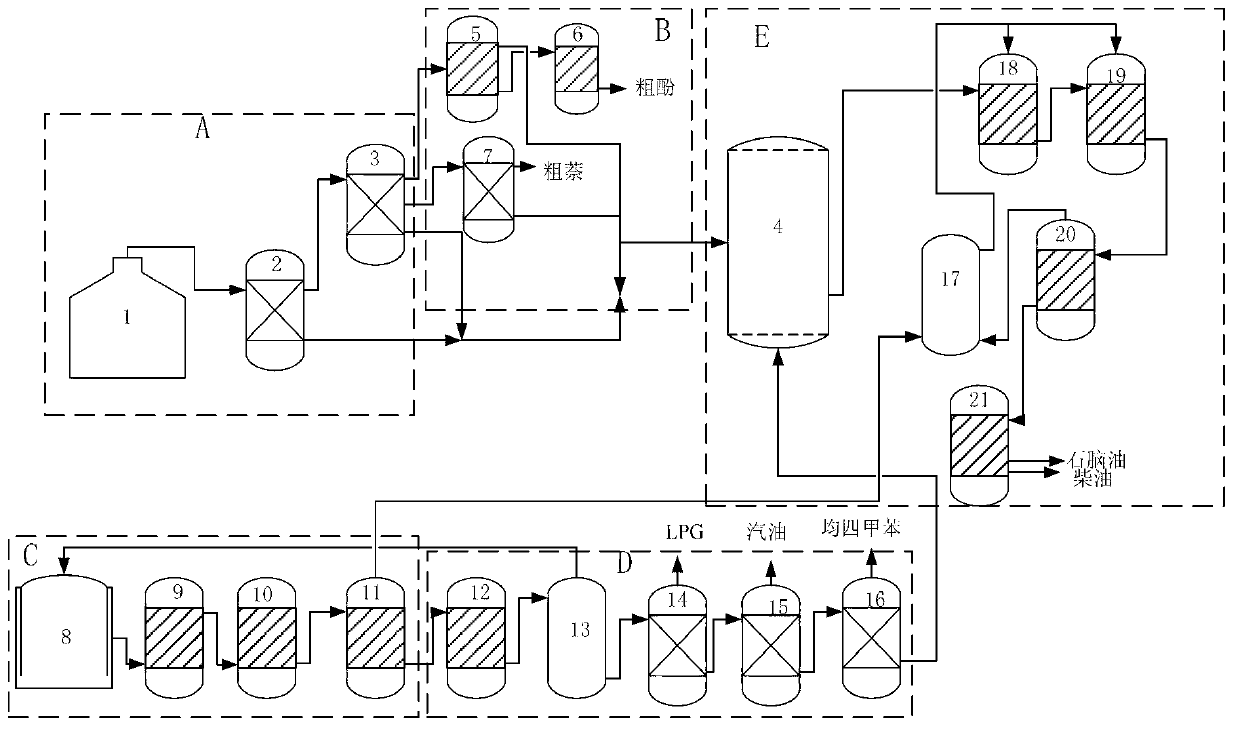

Embodiment 1

[0034] The atmospheric and vacuum distillation system A includes a tar storage tank 1 , an atmospheric distillation column 2 and a vacuum distillation column 3 . The tar storage tank 1 is connected to the inlet of the atmospheric distillation tower 2, the light oil outlet in the upper part of the atmospheric distillation tower 2 is connected to the inlet of the vacuum distillation tower 3, and the heavy oil outlet in the lower part of the atmospheric distillation tower 2 is connected to the oil-gas coupling system E The heavy oil mixing tank 4 in the middle is connected to the inlet, the outlet of the phenol oil in the upper part of the vacuum distillation tower 3 is connected to the inlet of the alkali washing tower 5 in the chemical removal system B, and the naphthalene oil outlet in the middle of the vacuum distillation tower 3 is connected to the chemical removal system B The inlet of the naphthalene rectifying tower 7 is connected, and the outlet of the washing oil at the ...

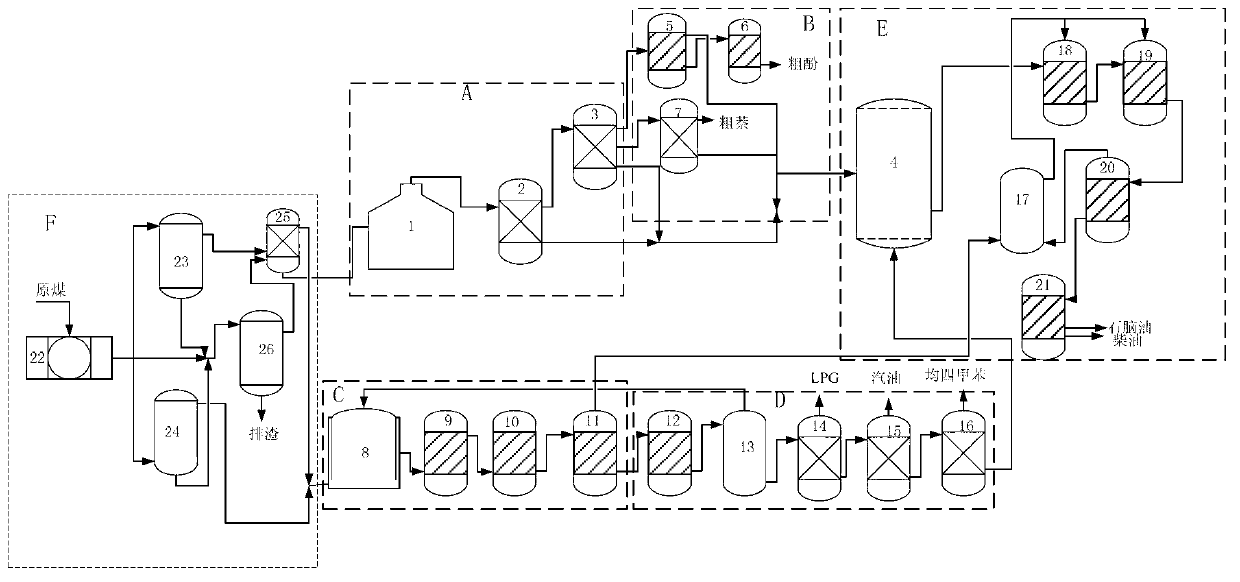

Embodiment 2

[0047] In order to further improve the whole system, raw coal pretreatment system F can be added. See the specific process image 3

[0048] The raw material pretreatment system F includes a raw coal screening device 22 , a dry distillation furnace 23 , a coke oven 24 , a high-efficiency separator 25 , and a gasifier 26 . The coking coal outlet of the raw coal screening device 22 is connected with the coking oven 24 , the non-coking coal outlet is connected with the dry distillation furnace 23 , and the pulverized coal outlet is connected with the gasifier 26 . The gas outlet of the carbonization furnace 23 and the gas outlet of the gasification furnace 26 are connected with the inlet of the high-efficiency separator 25, the gas outlet of the coke oven 24 is connected with the inlet of the gas storage tank 8 in the methanol conversion system C, the solid outlet of the carbonization furnace 23, the coking The solid outlet of the furnace 24 is connected to the inlet of the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com