Patents

Literature

242 results about "Engineering industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engineering industry primarily comprise of sectors like civil, industrial, mechanical and chemical. Engineering industry comprises of chemical, civil, industrial and mechanical engineering divisions, where civil engineering division basically concerned with the activities like planning, construction, designing or manufacturing of structures.

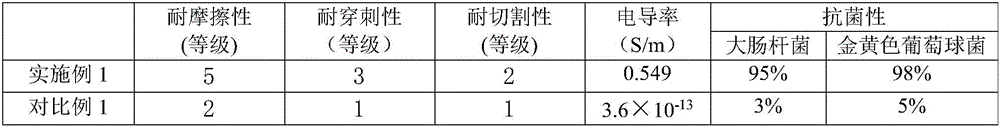

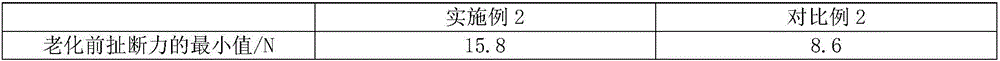

Graphene-latex functional high-strength protection glove and production method thereof

InactiveCN106065095AComfortable to wearImprove friction resistanceGlovesBulk chemical productionElectricityAviation

The invention discloses a graphene-latex functional high-strength protection glove and a production method thereof. The method comprises the following steps: (1) immersing a glove blank in a coagulating agent, immersing the glove blank in a graphene-latex composite liquid, and drying the immersed glove blank to obtain the glove; or (2) immersing the glove blank in the coagulating agent, drying the immersed glove blank, immersing the dried glove blank in the graphene-latex composite liquid, leaching the immersed glove blank, crimping the leached glove blank, drying the crimped glove blank, vulcanizing the dried glove blank, leaching the vulcanized glove blank, and drying the leached glove blank to obtain the glove. Compared with gloves in the prior art, the graphene-latex functional high-strength protection glove produced in the invention fully performs the advantages of high electricity conductivity, high strength, friction resistance and strong bacteriostasis of graphene, and has wide uses in the fields of the manufacturing industry, the medical industry, the chemical engineering industry and the space flight and aviation industry.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

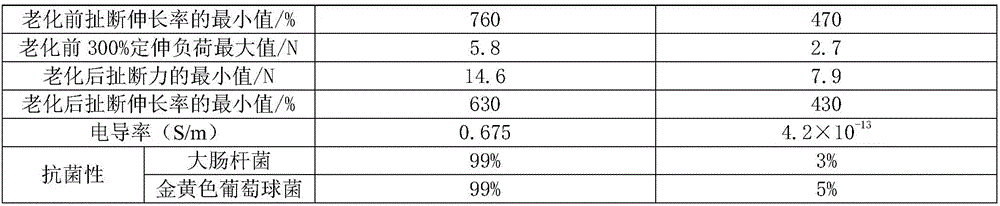

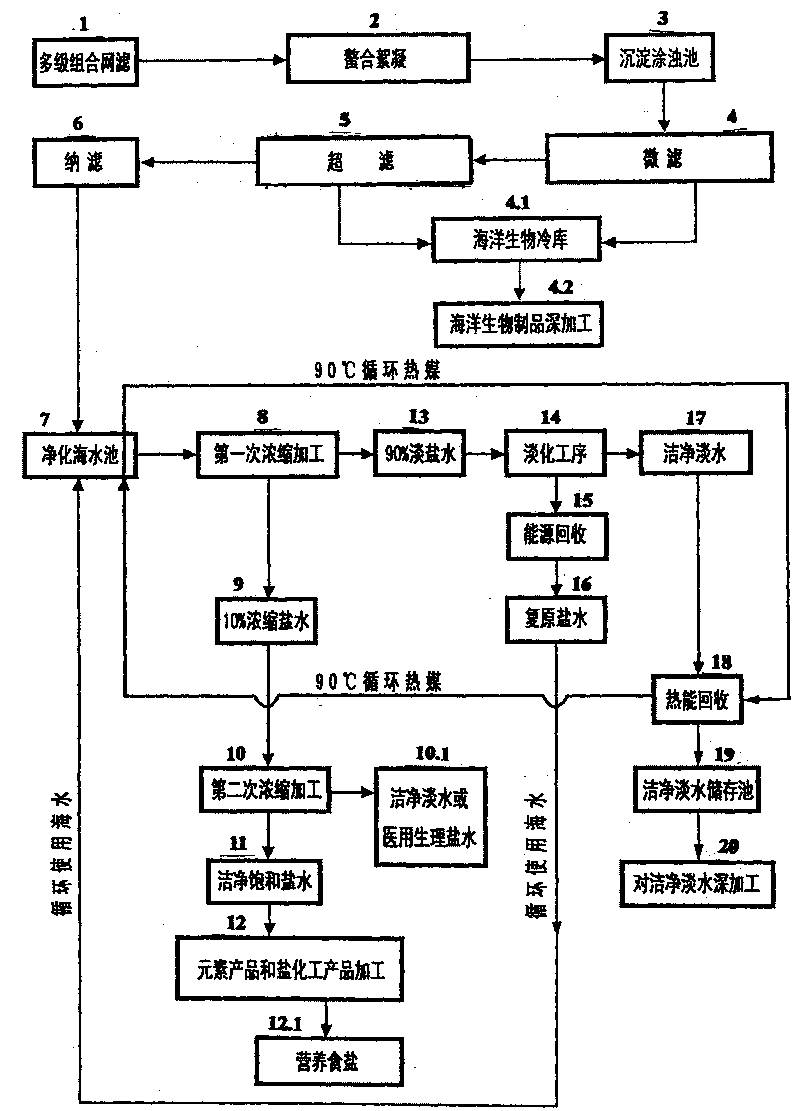

Production process for achieving hundred-percent comprehensive utilization and zero emission by recycling and extracting seawater

InactiveCN101717161AEliminate pollutionInexpensive and eternal fresh water resourcesGeneral water supply conservationSeawater treatmentMedical productChain type

The invention aims at providing a production process for achieving hundred-percent comprehensive utilization and zero emission by recycling and extracting seawater, which is characterized by recycling, extracting and processing used seawater, realizing the all-sided and hundred-percent comprehensive utilization to seawater, eliminating production wastes, thoroughly eliminating the pollution to oceans from 'disabled seawater', creating marine organism medicine sources for serve all mankind, providing low-cost and unexhausted clean fresh water resource for mankind, ensuring that salt chemical engineering industry becomes a plurality of compound three-sort products in an industry-chain type: marine organism medical products, seawater element products and salt chemical engineering products from the original single products, cleaning fresh water, achieving the hundred-percent comprehensive utilization to seawater and realizing clean production and zero emission.

Owner:葛文宇

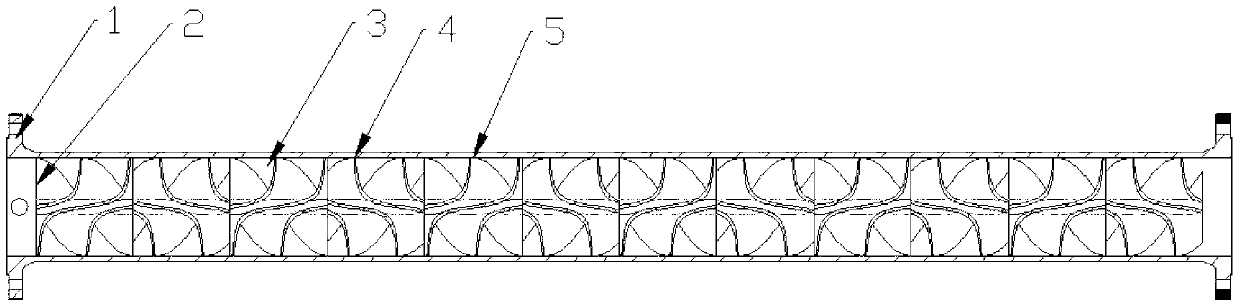

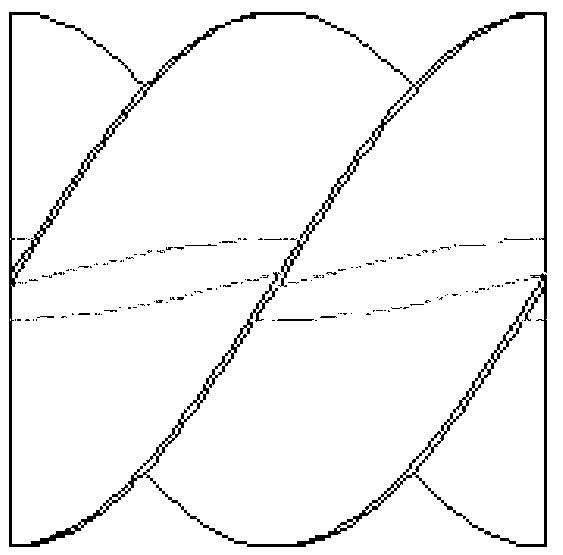

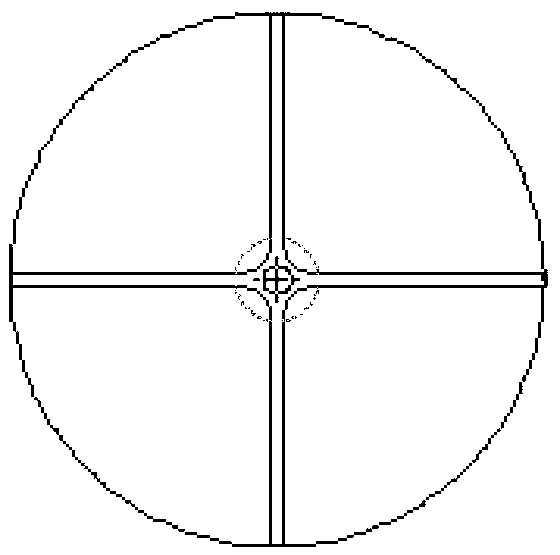

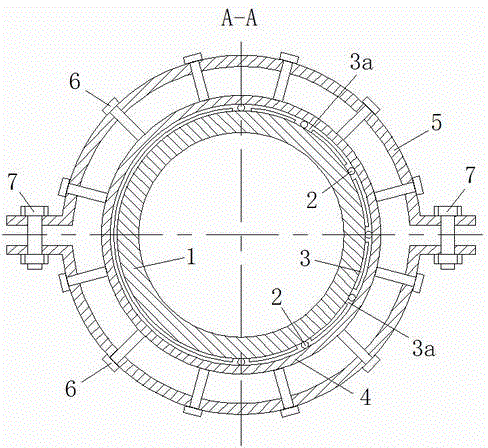

Spiral static mixer

The invention discloses a spiral static mixer which is applied to mixing of multiple materials and particularly mixing of high-viscosity materials. The spiral static mixer comprises a shell, mounting flanges, left rotating blades and right rotating blades and is characterized in that the mounting flanges are respectively arranged at the two ends of the shell, the left rotating blades and the right rotating blades are in multiple-spiral blade structures and sequentially and alternately arranged from an inlet of the shell to an outlet of the shell, the adjacent left rotating blades and right rotating blades are fixedly connected at the periphery in a staggering manner, and a washing lifting ring is connected at one end of a blade group formed by the left rotating blades and the right rotating blades. The spiral static mixer provided by the invention has the advantages of simple structure, high mixing efficiency, convenience and fastness in installation, low cost, convenience in washing and suitability for long-time working; a mixed blade unit can be replaced; and the spiral static mixer is more widely applied to mixing of the high-viscosity materials in the chemical engineering industry.

Owner:MECHANICS RES & DESIGN ACAD SICHUAN PROV

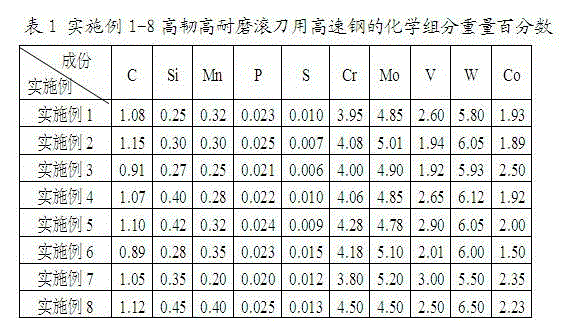

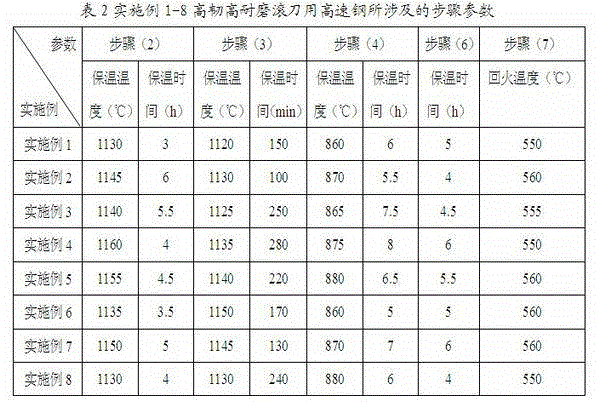

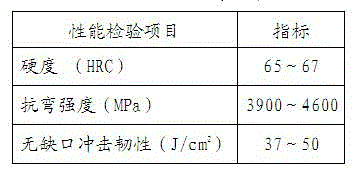

High-speed steel for high-toughness high-abrasion resistance hobbing cutter and preparation method thereof

The invention discloses high-speed steel for a high-toughness high-abrasion resistance hobbting cutter and a preparation method thereof. Compared with chemical components of traditional high-performance high-speed steel, the usage of noble metal cobalt is reduced, the content of carbon and vanadium with low prices are correspondingly added, so that the grain tissue of the high-speed steel can be refined, the hardenability can be increased, and the production cost can be reduced on the premise of guaranteeing corresponding functions of high toughness and high-abrasion resistance; and by utilizing the method for preparing the high-toughness high-abrasion resistance high-speed steel provided by the invention, the content of N is controlled to be lower than 150ppm, the formation of large-particle carbide is weakened, and the grindability is improved. The method for preparing the high-speed steel can be used for preparing hobbing cutter and gear and other rotary elements in automobile and mechanical engineering industries.

Owner:HEYE SPECIAL STEEL

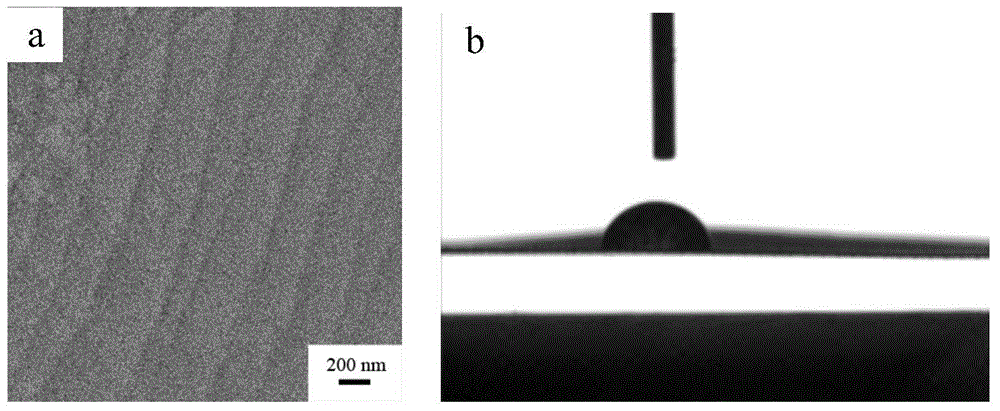

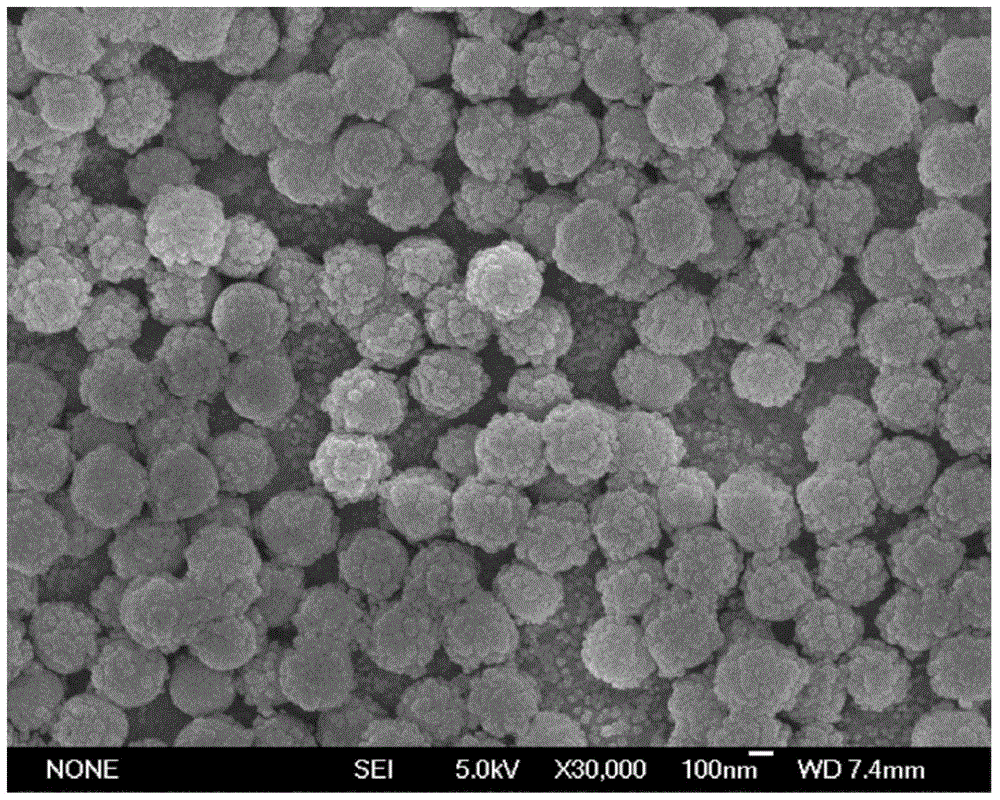

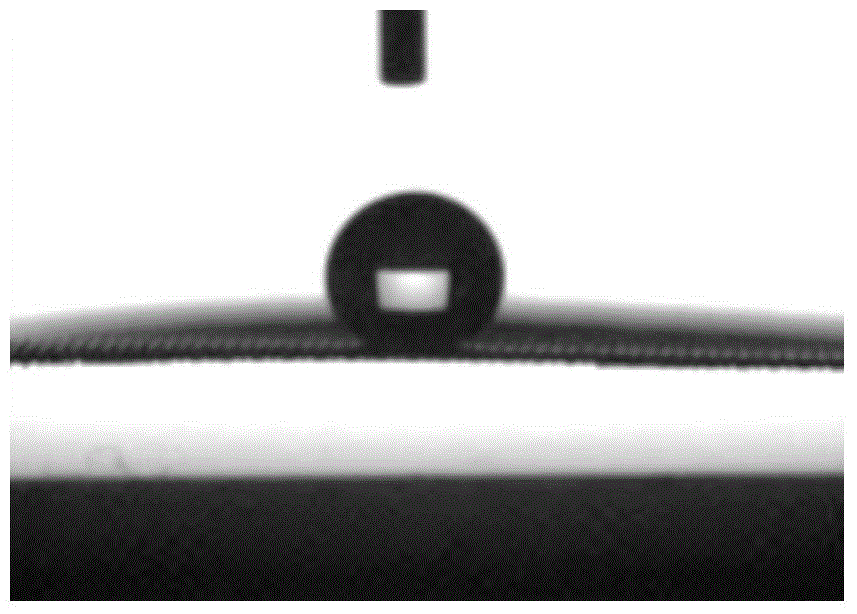

Super-hydrophobic coating layer used for oil-water separation and having hierarchical structure, super-hydrophobic material thereof, and preparation method of material

ActiveCN104802488AEasy to separateSimple processLayered productsCoatingsChemical industryOil water emulsion

The invention belongs to the technical field of preparation of nano-materials, and relates to a super-hydrophobic oil-water separation material containing a hierarchical structure coating layer. The hierarchical structure coating layer is formed by a layer of solid spherical SiO2 nano-particles with the particle size of 10-50nm and the particle size of 70-500nm, and the surface of the coating layer is provided with a layer of a low surface energy substance. The coating layer is obtained through layer-by-layer electrostatic in situ self-assembling, and can be used on stainless steel wire nets, stainless steel fiber sintered felts and other metal net products. The water contact angle of the stainless steel sintered nets coated with the hierarchical structure coating layer can exceed 150DEG. The material is simple to prepare, can be used to process filter core materials in coalescence separators, can be repeatedly used in oil-water separation, especially has a good separation effect on an oil-water emulsion, and can be widely used in oil-containing sewage treatment in the petroleum chemical industry, the metallurgy industry, the chemical engineering industry, the beverage industry, the food industry and the pharmacy industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation and use methods of nitrogen-vanadium co-doped modified titanium dioxide catalyst

InactiveCN101972662AHigh visible light activityImprove dust removal efficiencyPhysical/chemical process catalystsSulfur compoundsEngineering industryMixed crystal

The invention discloses preparation and use methods of a nitrogen -vanadium co-doped modified titanium dioxide catalyst, belonging to the technical field of preparation and use of catalysts. The preparation method comprises the following steps of: adding a nitrogen source and a vanadium source in a process of preparing titanium dioxide by using a sol-gel method; hydrolyzing the mixture to obtain gelatin and standing, aging and drying to form particles; then grinding and carbonizing and heating to 600 to 800 DEG C for roasting to obtain a mixed crystal type titanium dioxide catalyst with different doping amounts. The compounding of electron-hole pair is influenced by doping metal ions to improve utilization ratios of visible light.With simple operation and easy control, the prepared nitrogen -vanadium co-doped modified titanium dioxide catalyst can achieve greatly improved visible light activity and can be applied to sulphuric acid production in the chemical engineering industry, SO2 tail gas treatment in the smelting industry, sulfur dioxide control of coal-fired and fuel boilers, acid rain prevention and control, smoke gas adjustment of coal-fired power plants, improvement on the dust removal efficiency of an electric precipitator, and other fields.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

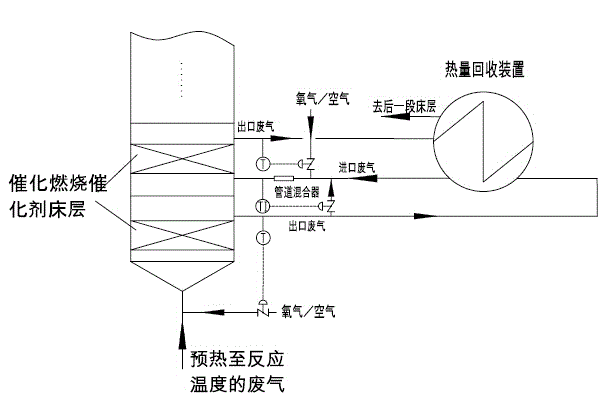

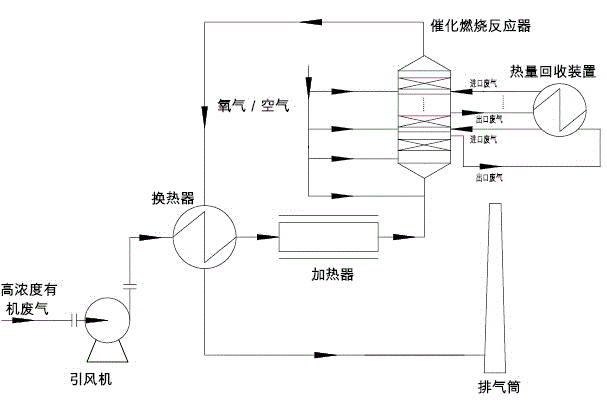

Purification treatment method of high-concentration organic waste gas

ActiveCN105650651AAvoid safety hazardsPrevent sinteringChemical industryIncinerator apparatusHigh concentrationDetonation

The invention discloses a purification treatment method of high-concentration organic waste gas. Organic waste gas is introduced into a catalytic combustion reactor after being subjected to heat exchange and preheating, isolated catalyst bed layers are arranged inside the reactor, each bed layer is provided with a waste gas inlet and a waste gas outlet, each waste gas inlet pipeline is provided with an oxygen supplying port and a pipeline mixer, and organic matter in waste gas is subjected to partial catalytic combustion reaction in each bed layer in a segmented oxygen supplying mode. In the waste gas flowing direction, the waste gas outlet of the former catalyst bed layer is connected with the waste gas inlet of the next catalyst bed layer through a heat energy recycling device, so that reaction heat released by catalytic combustion is fetched, and heat energy recovery is achieved. Potential safety hazards caused by detonation of combustible gas can be avoided, catalyst sintering caused by too high temperature of the catalyst bed layers is prevented, the scale and operation energy consumption of related devices for waste gas treatment are reduced, and the purification treatment method is especially suitable for purification treatment of organic waste gas with high organic matter concentration and low oxygen content in the petrochemical engineering industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

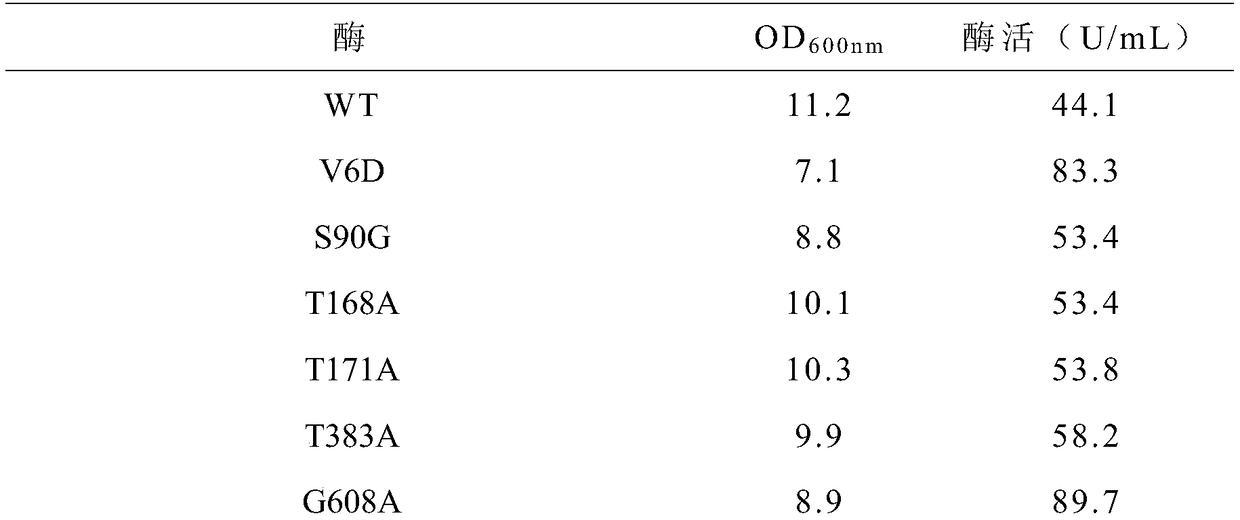

Cyclodextrin glucosyl transferase enzyme mutant

The invention discloses a cyclodextrin glucosyl transferase enzyme mutant, and belongs to the field of genetic engineering and enzyme engineering. The cyclodextrin glucosyl transferase enzyme is mutated to obtain a mutant having higher dismutation activity than that of the cyclodextrin glucosyl transferase enzyme. The shake-flask fermentation enzyme dismutation activities of mutants V6D, S90G, T168A, T171A, T383A, G608A and V6D / S90G / T168A / T171A / T383A / G608A are respectively 1.89, 1.21, 1.21, 1.22, 1.32, 2.03 and 3.16 times that of wild enzyme. The mutant has certain magnificence for industrialproduction of cyclodextrin glucosyl transferase enzyme, and the application potential of the enzyme in foods, medicine and chemical engineering industries can be improved.

Owner:JIANGNAN UNIV

Low-dosage steel fiber modified powder concrete

The invention discloses low-dosage steel fiber modified powder concrete which comprises the following raw materials in parts by weight: 600-1000 parts of cement, 150-300 parts of active mineral admixture, 60-100 parts of inert admixture, 900-1300 parts of sand, 26-35 parts of a water reducing agent, 135-160 parts of water, 30-100 parts of extra-fine steel fibers and 7-12 parts of a corrosion inhibitor. According to the low-dosage steel fiber modified powder concrete, provided by the technical scheme of the invention, the extra-fine steel fibers with the diameters being smaller than 0.13 mm and the lengths being 6-12 mm are adopted for replacing common steel fibers, therefore on the one hand, the mechanical property of the concrete is improved, on the other hand, the additive amount of steel fibers in the concrete is further reduced, and the production cost of the low-dosage steel fiber modified powder concrete is reduced; besides, the low-dosage steel fiber modified powder concrete is relatively low in the wholesale cost, good in the fiber distribution uniformity, high in fracture resistance and shock resistance and is suitable for popularization and application in the constructional engineering industry.

Owner:黄贺明

Wood powder-polyvinyl chloride compound material and preparation method thereof

InactiveCN101942207ASave resourcesImprove mechanical propertiesPolyvinyl chlorideEngineering industry

The invention provides a wood powder-polyvinyl chloride compound material and a preparation method thereof. The wood powder-polyvinyl chloride compound material comprises the following raw materials in percentage by weight: 50 to 70 percent of wood powder serving as a base material, 20 to 50 percent of polyvinyl chloride resin, 5 to 10 percent of calcium carbonate and 2 to 5 percent of stearic acid, and the silane coupling agent is 1 to 10 percent based on the content of the wood powder. The invention also provides a method for preparing the wood powder-polyvinyl chloride compound material. The wood powder content of the wood powder-polyvinyl chloride compound material is high, and the production cost is greatly lowered; not only the advantages of wood on processing property are kept, but also the defect that the wood is easily damaged by worms is overcome, so that the wood powder-polyvinyl chloride compound material can replace the wood packaging material and matting material, and also be applicable for decorative boards, floors and anti-corrosive work sheds, passages, racks, casting models, and the like in chemical engineering industry.

Owner:HUNAN UNIV OF TECH

Iron-based self-lubricating wear-resistant alloy

The invention was about a method of preparation of Fe-base self lubrication wear-resisting alloy. It was prepared by using medium-frequency induction furnace. It has a high mechanical robustness, heat-durability and high temperature inoxidizability. It exhibited the property of low friction, stand wear and tear, self lubrication under the operating temperature of 20-600 deg.C, it fit for making mechanical bearing, axile bus, operating slide, bearing bush, airtight packing and actuated valve that using in the metallurgy, energy, material, petrochemical engineering industry, which has a broad application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

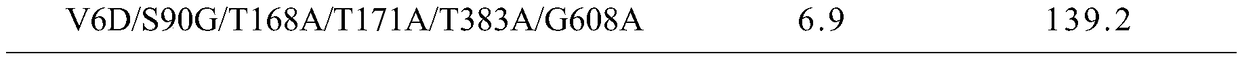

Production process for dry method extraction of nickel

InactiveCN1603439ASolve the technical problems of separationBroaden the mineral source channelsSlagFerrosilicon

The invention provides a kind of dry method withdraws the nickel the production method, it is take the petroleum majoring in engineering industry expelling spent catalyst, the waste sweetening agent or withdraws Gao Linhan after the aqueous method which the vanadium molybdenum expels the vanadium low nickel residual second pollutant as nickel raw material smelting to produce the ferronickel the technology, it according to the fertilizer conformity, the weighing mixture, the reducing smelting and oxidizes fining the step to carry on, in the dual alkali degree CaO% / SiO2% approximately 0.8~~1.8 scope, with the coke, the ferrosilicon makes the reducing agent to carry on the reducing smelting to remove 60~~70% phosphorus, again in in the slag dual Alkali degree CaO% / SiO2% approximately 1.2~~3.5 scope, selects the oxygen - iron ore union oxidation method, May cause 99% above the phosphorus and 98% above vanadium union produces CaO.P2O5 and CaO.V2O5 enters the slag, after refines the qualified ferronickel product, realizes from Gao Linhan in the vanadium nickel waste material the short flow, the low cost, the industry withdraws the nickel the goal, has the remarkable economic efficiency and the social environmental protection effect.

Owner:四川川投峨眉铁合金(集团)有限责任公司

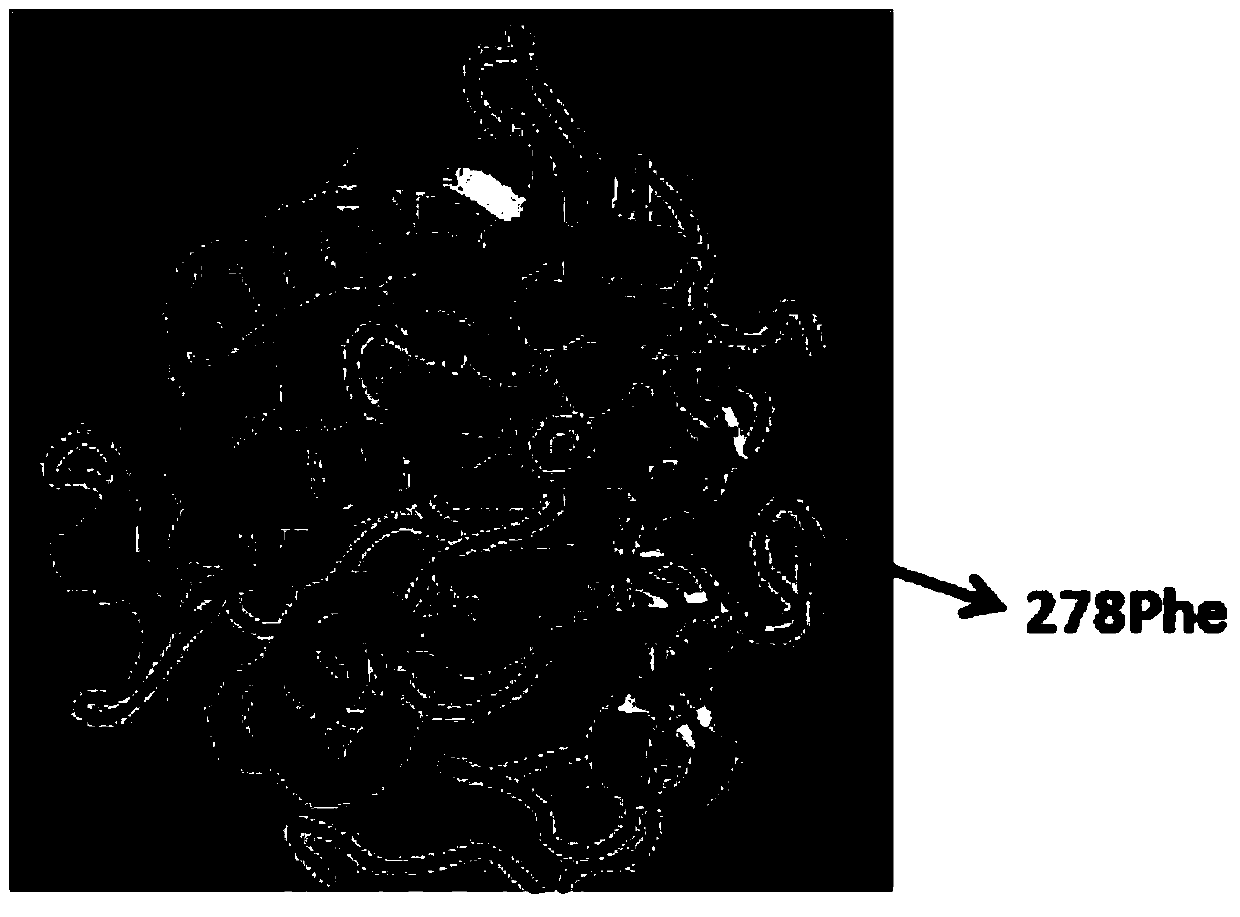

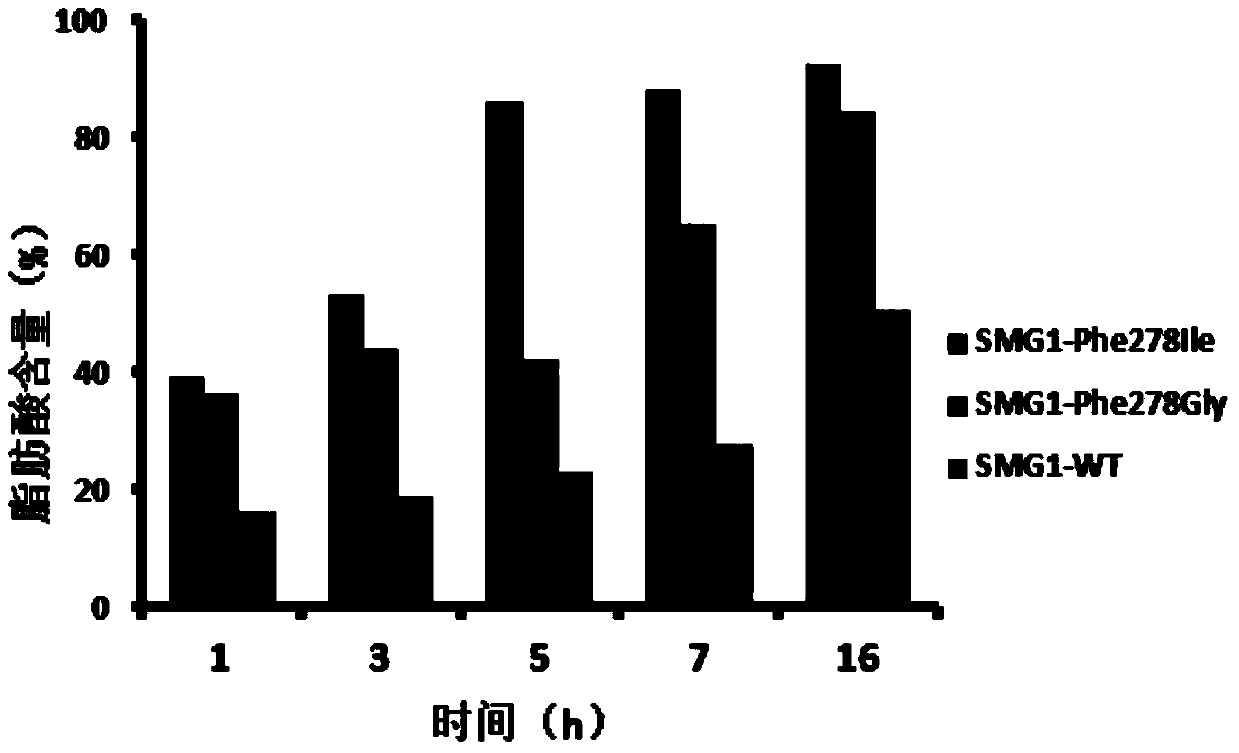

Higher-activity partial glyceride lipase mutant and application thereof

ActiveCN103627685AHigh hydrolytic activityHigh activityHydrolasesVector-based foreign material introductionWild typeSite-directed mutagenesis

The invention discloses a higher-activity partial glyceride lipase mutant and application thereof. The mutant is an enzyme mutant prepared by carrying out site-directed mutagenesis on Malassezia globosa partial glyceride lipase, wherein the mutant site is Phe at the 278th site, and the Phe at the 278th site is mutated into Ile or Gly. The obtained mutant Phe278Ile or Phe278Gly has higher partial glyceride hydrolysis activity, and is more suitable for application in biochemical engineering industry. The partial glyceride hydrolysis activities of the modified SMG1Phe278Ile and SMG1Phe278Gly mutants are enhanced to different degrees, which are respectively 1.84 times and 1.68 times of the wild type SMG1 lipase hydrolysis activity; and the modified SMG1Phe278Ile and SMG1Phe278Gly mutants have higher partial glyceride activity, and can be used for removing partial glyceride in grease.

Owner:SOUTH CHINA UNIV OF TECH

Solvent-resistant nanofiltration membrane and making method thereof

InactiveCN107029555AImprove performanceA wide range of environmentsMembranesUltrafiltrationHigh resistanceOrganic solvent

The invention relates to the technical field of membrane separation, and provides a solvent-resistant nanofiltration membrane and a making method thereof. The solvent-resistant nanofiltration membrane has chargeability, and is an integrated flat or hollow fiber solvent-resistant nanofiltration membrane; or the solvent-resistant nanofiltration membrane has chargeability, and comprises a separation functional layer and a supporting layer which is positioned below the separation functional layer. The solvent-resistant nanofiltration membrane produced in the invention can be a flat membrane, and also can be a hollow fiber membrane. Cross-linking treatment realizes good solvent resistance and wide use environment range, and the solvent-resistant nanofiltration membrane can be applied to the treatment of industrial wastewater containing organic solvents, and especially has high resistance to strong-polarity organic solvents. The limitation that existing commercial nanofiltration membranes can not be used in water containing the strong-polarity organic solvents is solved in the invention, and the application of the nanofiltration membrane can be developed to the petrochemical engineering industry and the field of treatment and reuse of industrial wastewater containing organic solvents.

Owner:DALIAN UNIV OF TECH

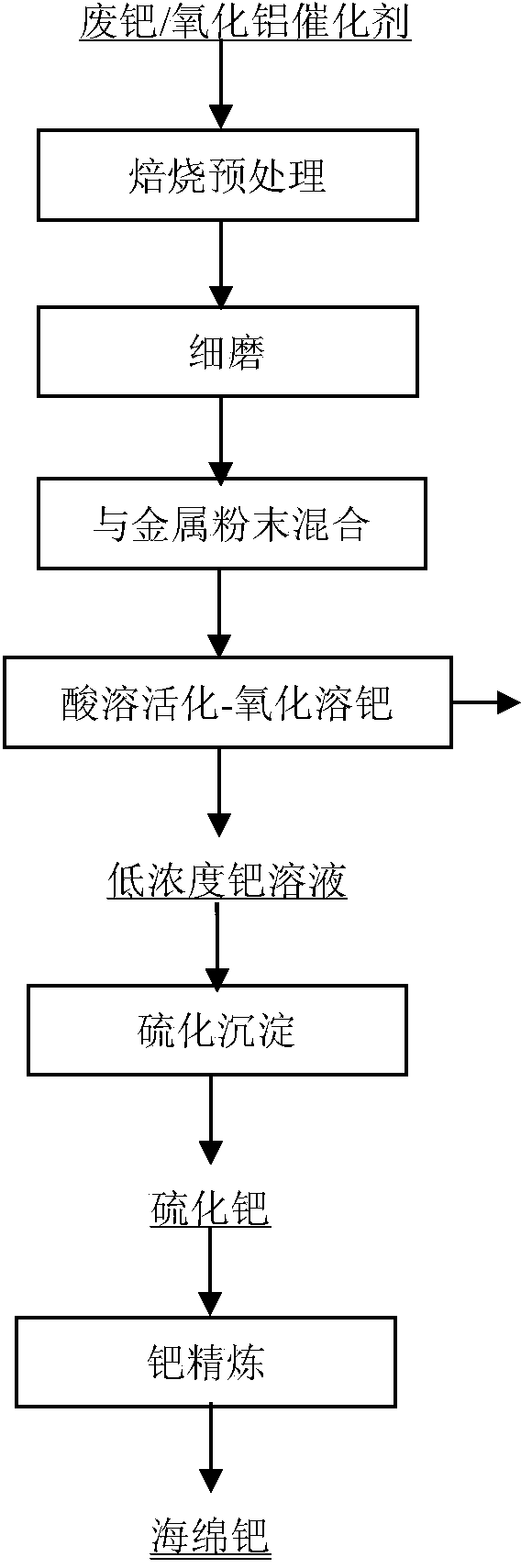

Method for recovering palladium from waste palladium/alumina catalyst

InactiveCN104232900AAchieve restorationAchieve dissolutionProcess efficiency improvementVulcanizationAcid dissolution

The invention discloses a method for recovering palladium from a waste palladium / alumina catalyst, which comprises the following steps: (1) roasting pretreatment; (2) material fine grinding; (3) acid dissolution activation by metal powder addition; (4) oxidization and dissolution of palladium; (5) vulcanization and precipitation; and (6) palladium refinement. In the step (3), the metal powder and acid react to generate H2, and the H2 reduces part of insoluble PdO in the waste catalyst into the metal Pd in the reaction process; no solid-liquid separation is needed between the step (3) and step (4), thereby implementing the palladium dissolution in one step; and the low-concentration palladium solution obtained in the step (5) is vulcanized and precipitated to obtain the high-grade palladium concentrate (palladium sulfide). The method can be used for recovering palladium from the waste palladium / alumina catalyst in petrochemical industry and fine chemical engineering industry. The recovery rate of the palladium is greater than 98%, and the purity of the palladium is 99.95%.

Owner:KUNMING INST OF PRECIOUS METALS

Method for mineralization-immobilization of carbon dioxide (CO2) through strengthening calcium-based solid wastes by using ammonia medium system

InactiveCN103145148AIncrease profitImprove conversion rateCalcium/strontium/barium carbonatesDispersed particle separationAdditive ingredientSlag

The invention relates to a method for mineralization-immobilization of carbon dioxide (CO2) through strengthening calcium-based solid wastes by using an ammonia medium system. According to the method, the calcium-based solid wastes, such as phosphogypsum and fluorgypsum produced by the chemical engineering industry, desulfurized gypsum produced by the power industry and waste slag produced during the desulfurization of molten iron in the iron and steel industry, are taken as raw materials, in the ammonia medium system, strengthened carbonation reaction conditions, such as high temperature of 60-200 DEG C and high pressure of 1-20bar, and operating steps such as pre-carbonation, strengthened carbonation and flash vaporization are adopted, so that the reaction between a calcium oxide ingredient in the calcium-based solid wastes and CO2 is strengthened, the carbonation conversion ratio of calcium-containing ingredients in the calcium-based solid wastes and the utilization ratio of CO2 are increased, the reaction time for mineralization-immobilization of CO2 by the calcium-based solid wastes is shortened, and the consumption of an ammonia medium and sulfuric acid and the energy consumption during the vaporization of ammonium-sulfate mother liquid are effectively reduced. According to the method, the calcium-based solid wastes can be efficiently converted into calcium carbonate and ammonium sulfate products, the carbonation conversion ratio and the CO2 utilization ratio are high, the consumption of materials, such as the ammonia medium and the sulfuric acid during production is low, and the energy consumption during production is low, so that the method has a good economic benefit and a broad industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

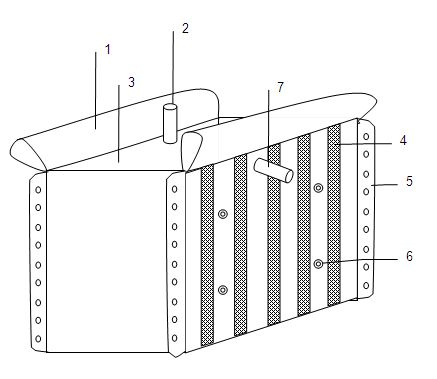

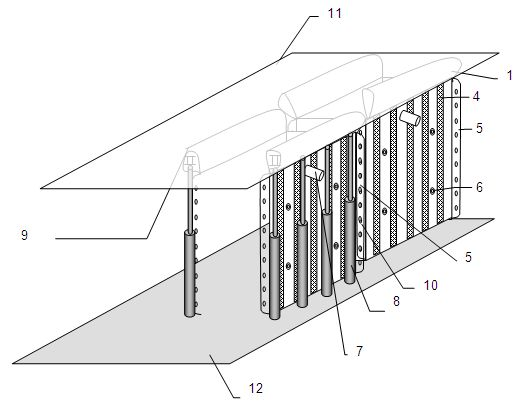

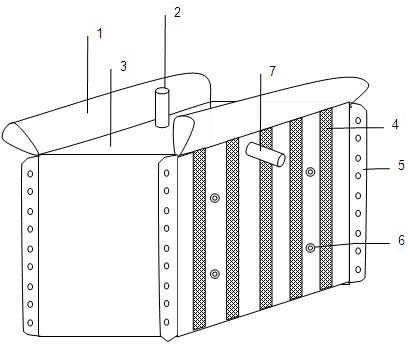

Gob-side entry retaining concrete partition wall construction mold bag and construction method thereof

InactiveCN101929342AGuaranteed sealing performanceEasy to bagUnderground chambersTunnel liningEavesEngineering

The invention discloses a gob-side entry retaining concrete partition wall construction mold bag and a construction method thereof. The mold bag is a bag with a closed structure; and the mold bag structurally comprises a fixed lug cylinder, a pouring exhaust hole, a mold bag top, a reinforcing rib, connecting feather eaves, an anchor bar hole and a concrete grouting duct. The construction method comprises the following steps of: penetrating a rigid beam into the fixed lug cylinder, jacking the rigid beam to a top plate by using a strut and fixing the rigid beam; penetrating a rope into a connecting hole of the connecting feather eaves to connect and position the adjacent mold bag; then penetrating an anchor bar and controlling a concrete pumping device; and finally, pumping concrete to fill the whole mold bag till the mold bag is full to the top. The mold bag is adaptive to the pouring of a gob-side entry retaining masonry partition wall of a coal mine, has a simple structure and high construction speed, and can be widely applied in quick masonry of the gob-side entry retaining partition wall of the mine and water conservancy, war industry and other civil engineering industries.

Owner:XIAN UNIV OF SCI & TECH

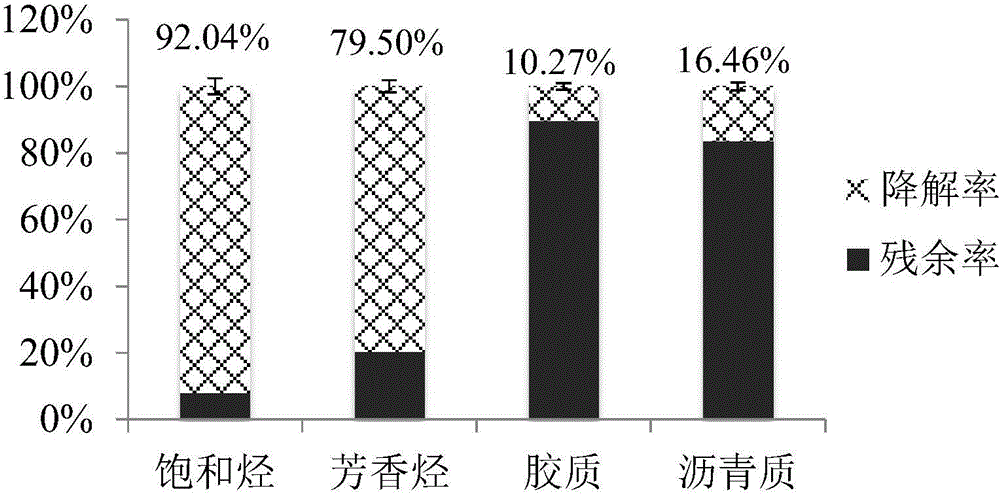

Saline-alkaline tolerant microbial flora and applications thereof

ActiveCN104403967AWide adaptabilityStable adaptabilityWaste water treatment from quariesBacteriaEndurance capacityHazardous substance

The invention provides a saline-alkaline tolerant compound active microbial flora, which is used to process waste drilling well slurry and oil-containing slurry with a high saline-alkaline content. The provided saline-alkaline tolerant active microbial flora contains shewanella mac donell, pseudomonas, and halomonas, wherein the preferable number ratio of shewanella mac donell to pseudomonas to halomonas is 4:3:1. The provided flora has a strong endurance capacity on pH and salt content, and can well adapt to the various environments of waste slurry in drilling well and soil polluted by petroleum. The additives and harmful substances in the waste slurry do not have a prominent inhibition effect on the active microbial flora. The growth speed of the flora is quick, the activity of the flora is stable, and the adaptability of the flora is strong. The production cost is low. The flora can be applied to the biodegradation of waste slurry in drilling wells, repairmen of environment destroyed by petroleum, and chemical engineering industry. The provided flora can increase the biodegradation efficiency on slurry in drilling wells and further improve the related processing technology.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

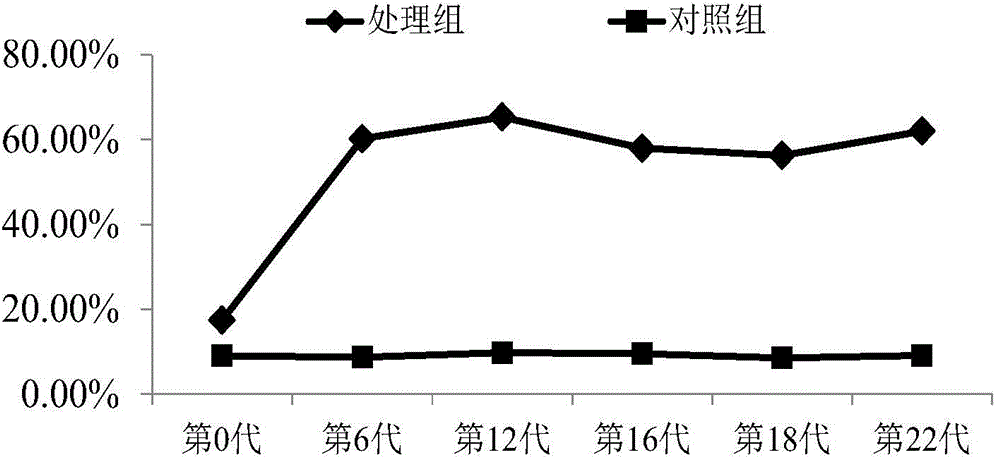

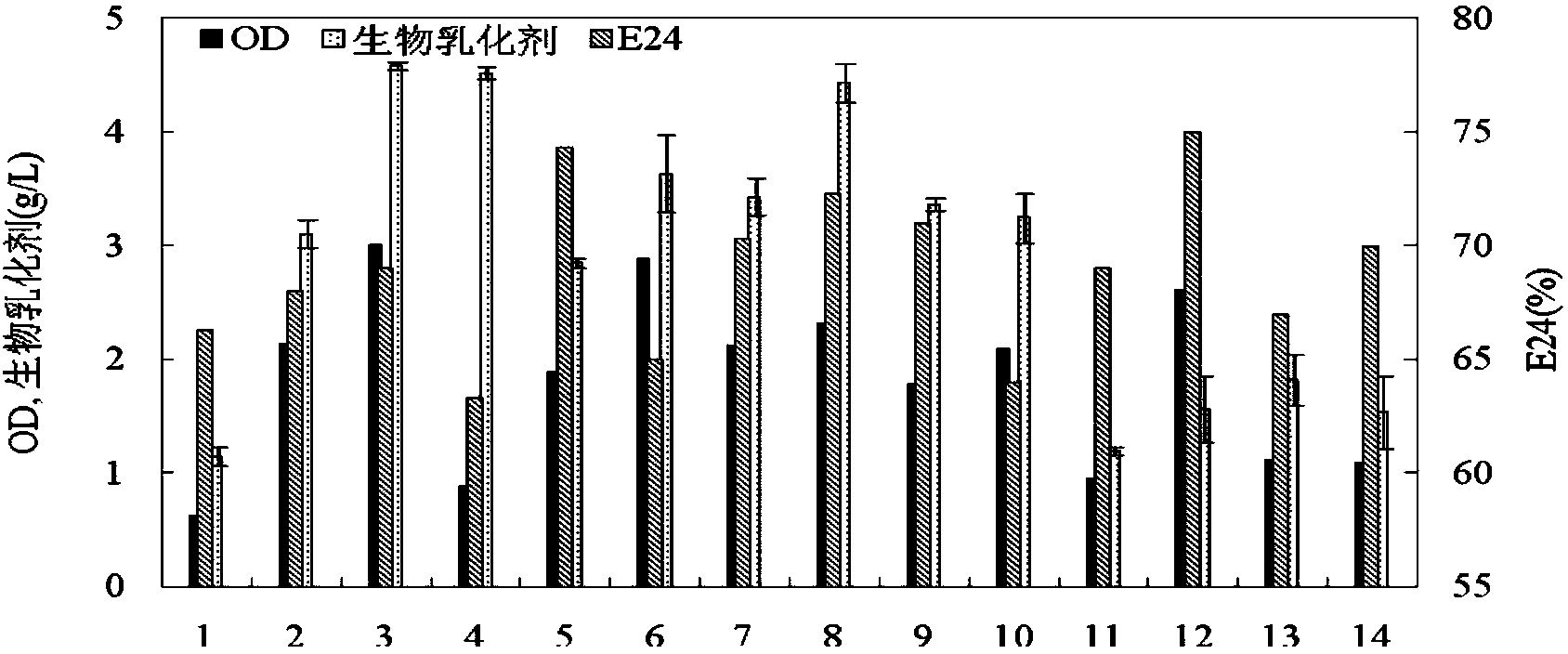

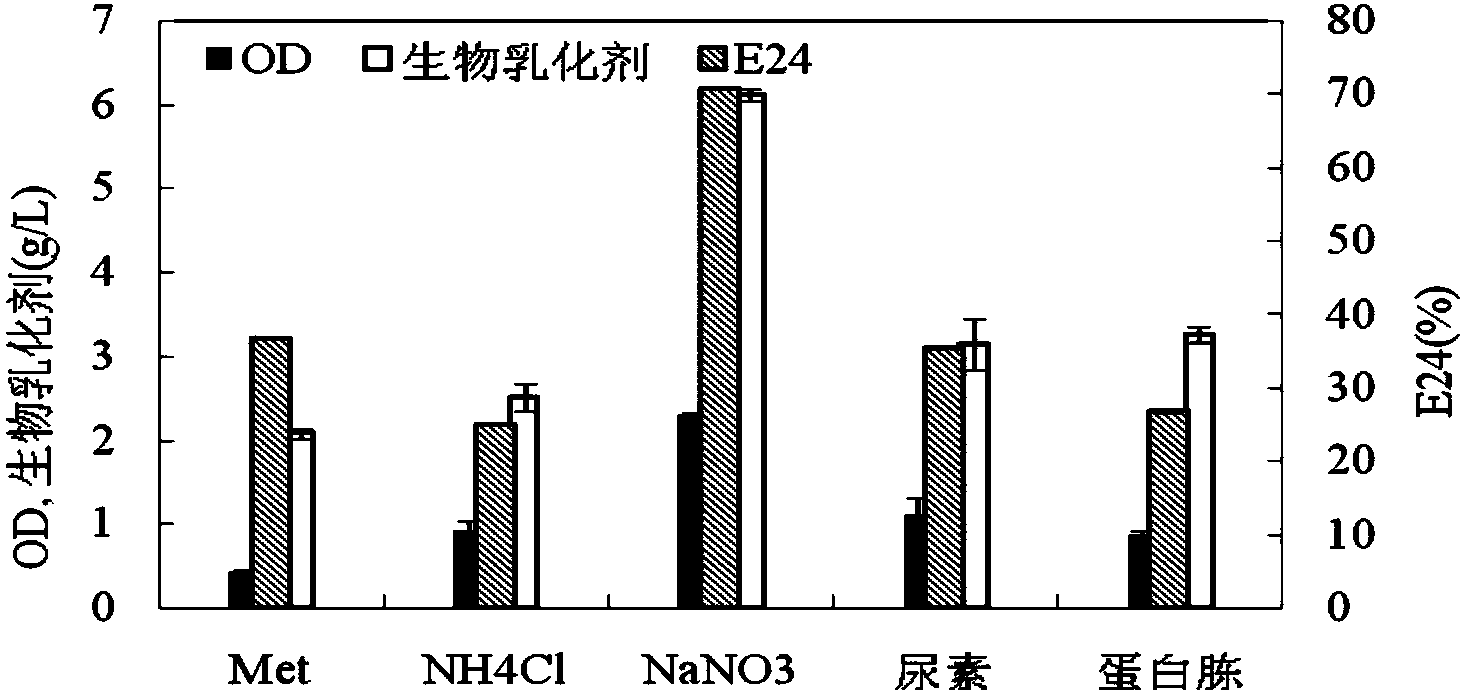

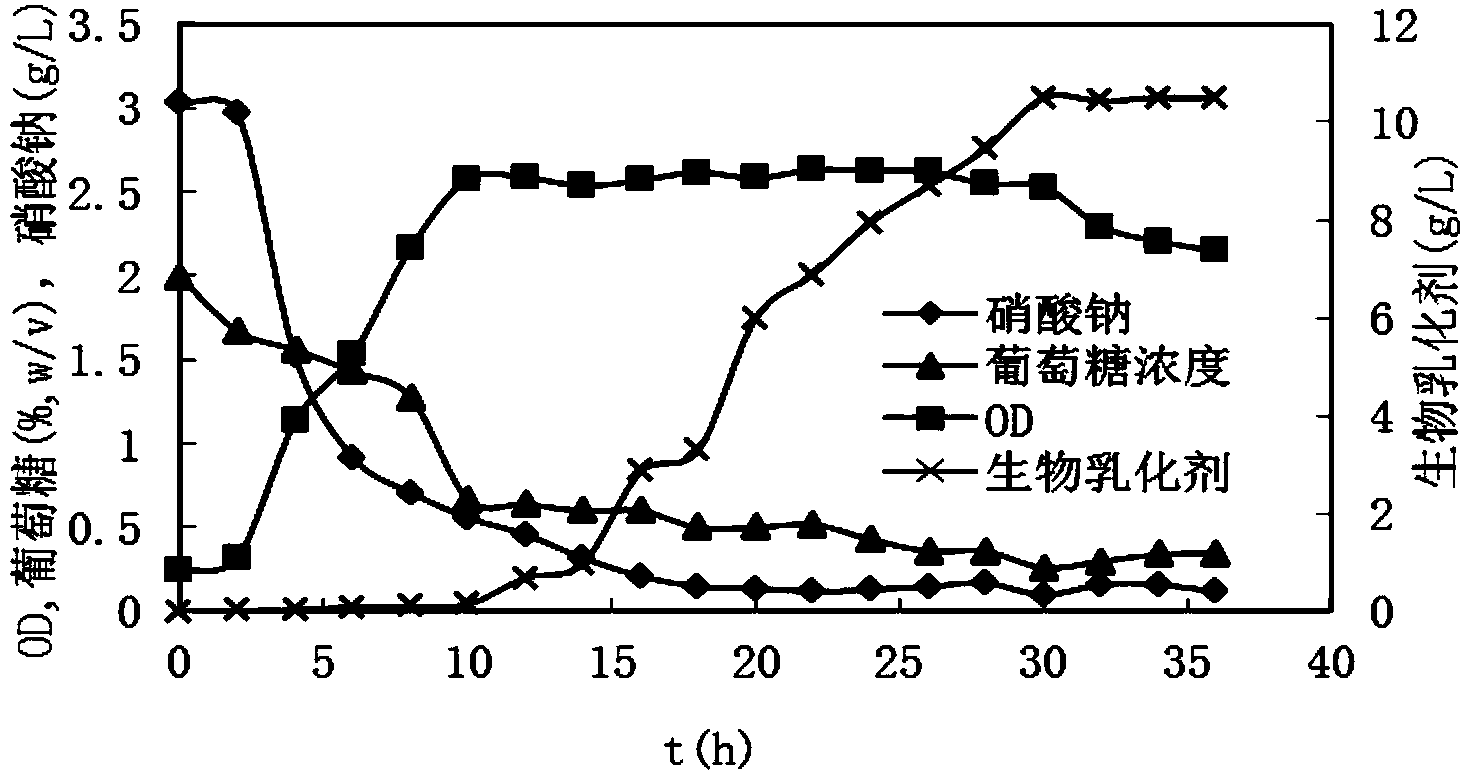

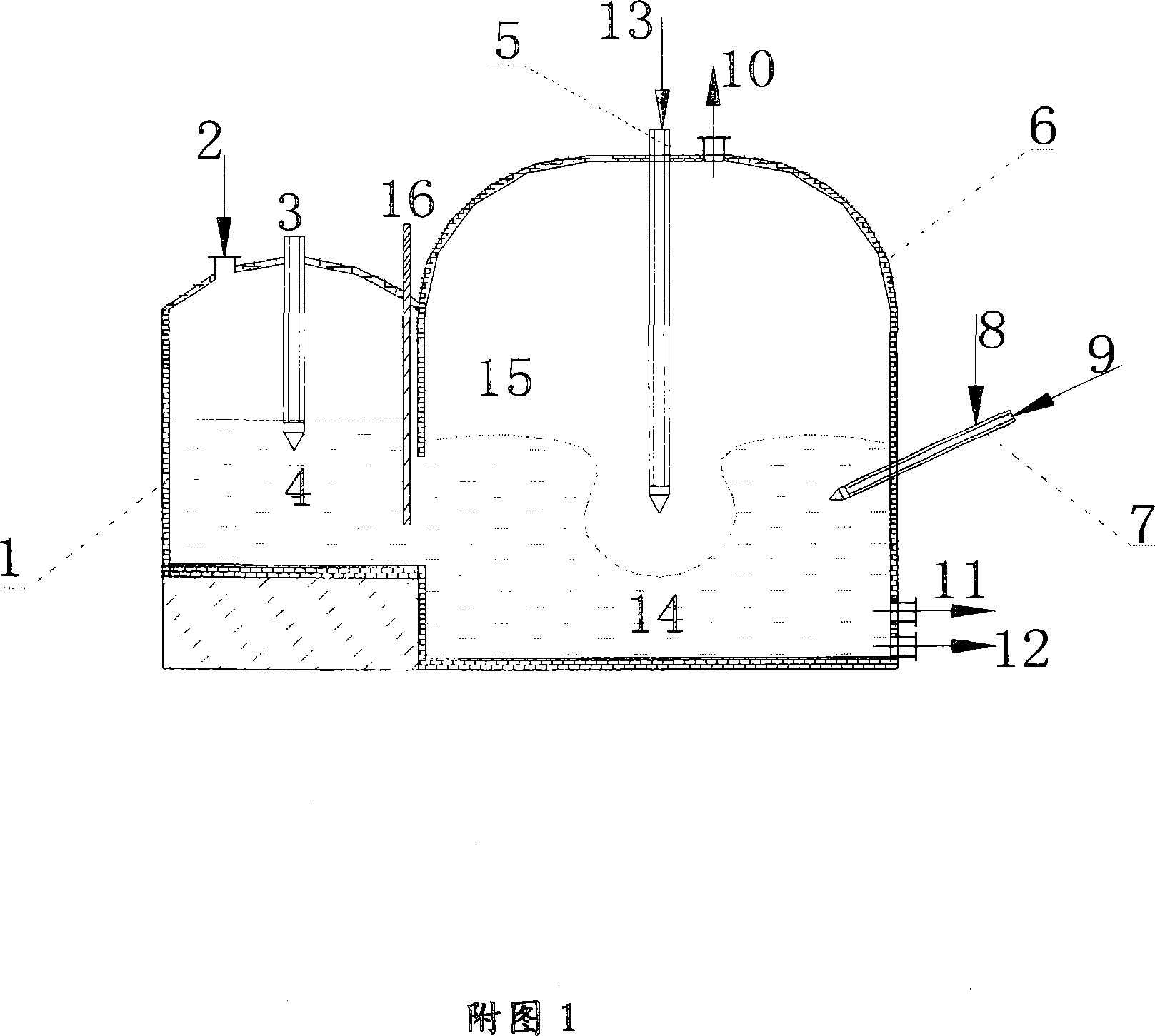

Active thermophilic bacterial strain and applications thereof

ActiveCN103834590AImprove emulsion stabilityReduce manufacturing costBacteriaContaminated soil reclamationBacillus licheniformisHigh resistance

The invention provides a thermophilic microorganism that is bacillus licheniformis XS2 bacterial strain (Geobacillus pallidus). The accession number of the bacterial strain is CMCCC No.8338. The XS2 bacterial strain is used for production of an extracellular bioemulsifier by fermentation. The thermophilic bacterium XS2 has high resistance to pH, temperature, and salt components, and has wide adaptability for the petroleum polluted environment and the oil reservoir environment. The active bioemulsifier produced by the bacterial strain XS2 has advantages of high output, activity stability, high adaptability, relatively low production cost, and the like, can be used for enhancing oil recovery by microorganisms and repairing environment pollution and used for the chemical engineering industry, and has high development potential for broadening the application scope and increasing the efficiency of industrial bioemulsifiers in China.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Method for direct production of phosphorus pentoxide with phosphorus ore

ActiveCN101172589ARealize continuous operationIncrease productivityPhosphorus oxidesChemical industryOxidation zoneEngineering industry

The invention discloses a production method of phosphorus pentoxide by directly using phosphorus ore. Phosphorus ore and silica are mixed pro rata, delivered to a heating furnace to be heated and molten, after the molten mass flows into a reaction furnace, carbon is directly added into the high temperature molten mass, the carbon is kept to be excess, the temperature of the molten mass is controlled above 1200 DEG C, thereby leading the molten mass to generate reducing reaction, high temperature and high speed oxygen is sprayed downward into the molten mass through an upper spray gun, thereby providing oxygen for the oxidation of phosphorus vapor and carbon monoxide generated in the reducing zone, and a dished high temperature zone can be formed on the surface of the center of the molten mass, therefore, the heat transfer rate of the mass transfer in the reduction oxidation zone is greatly intensified, the finished quality is ensured, the percent reduction of the phosphorus ore is improved, and the continuous phosphorus pentoxide and phosphonic acid production can be realized. The invention has the advantages that the flow is simplified, the cost is reduced, the finished quality is improved, the percent reduction of the phosphor reaches 98 percent, the energy and resource are saved, the three wastes are basically eliminated, therefore, the invention provides the epoch-making revolution for the phosphor chemical engineering industry.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Separating membrane for filtering heavy metal ions as well as preparation method thereof

InactiveCN103977716AStrong complexing abilityTo achieve retentionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFoaming agentCellulose acetate

The invention discloses a separating membrane for filtering heavy metal ions, wherein the separating membrane is composed of a non-woven cloth layer, a porous support layer and an algin layer on the surface of the porous support layer; the non-woven cloth layer is coated with the porous support layer, the porous support layer is a membrane layer formed by mixing cellulose acetate, a pore-foaming agent and a solvent. The separating membrane prepared by the method has a favorable interception performance to heavy metal ions (such as Cd(II), Cu (II) and Fe (III)) in a water solution, and can be applied to waste water treatment in the chemical engineering industry.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Inorganic high performance fiber composite material and preparation method thereof

The invention discloses an inorganic high performance fiber composite material, prepared from the following raw materials in parts by weight: 450-900 parts of cement with the mean grain size of 30-60 mu. m and strength grade not less than 42.5, 180-360 parts of active mineral admixture with the mean grain size of 0.1-60 mu. m, loss on ignition being less than or equal to 3.0 percent, and a 28-day activity index not lower than 90 percent, 70-120 parts of inert admixture with the mean grain size of 0.1-60 mu. m, 850-1250 parts of sand with the continuous grading grain size of 0.16-4.75mm, 25-32 parts of water reducer with a water reducing rate greater than 30 percent, 130-150 parts of water, and 50-120 parts of copper plating end hook-shape steel fiber with the diameter less than 0.20mm and length of 12-14mm. The composite material is relatively low in overall price, uniform in fiber distribution, high in compressive strength and flexural strength, good in tenacity and suitable for being popularized and used in the constructional engineering industry.

Owner:黄贺明

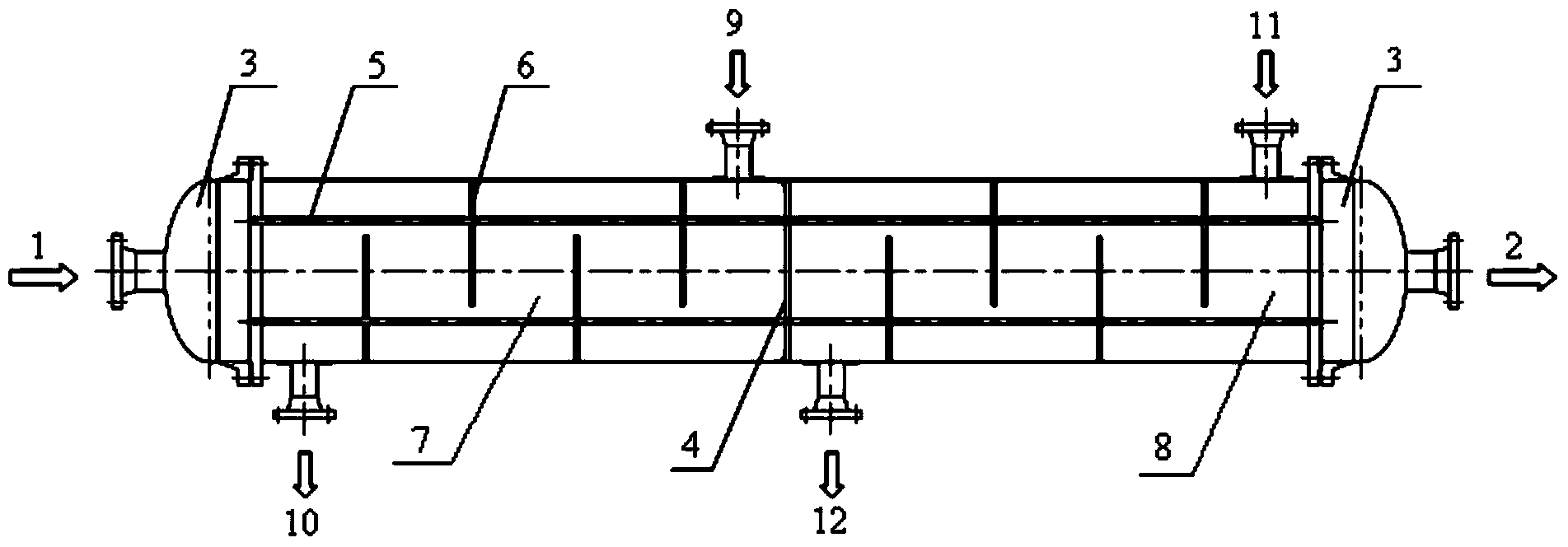

Multi-shell-pass tube type heat exchanger

ActiveCN103822510AReduce power consumptionReduce resistanceHeat exchanger casingsStationary tubular conduit assembliesCompound (substance)Engineering

The invention relates to a multi-shell-pass tube type heat exchanger, which mainly solves the problems that in the prior art multiple heat exchangers are adopted when a fluid is in heat exchange with various other fluids sequentially, the equipment and pipelines are not compact, the investment is large, the system resistance is large and the power consumption is large. The multi-shell-pass tube type heat exchanger comprises a tube pass fluid inlet, a tube box, a heat exchange area and a tube pass fluid outlet; the heat exchange area comprises a heat exchange tube nest for allowing tube pass fluid to pass through, baffle plates, shell pass fluid inlets and shell pass fluid outlets; a sealing clapboard is utilized for dividing the shell pass of the heat exchange area into at least two mutually independent shell pass heat exchange sub-areas, the independent shell pass heat exchange sub-areas are provided with independent shell pass fluid inlets and shell pass fluid outlets. By adopting the technical scheme, the problems are well solved, and the multi-shell-pass tube type heat exchanger can be applied to tube type heat exchanger combination in the petrochemical industry, the chemical engineering industry and the like.

Owner:SINOPEC SHANGHAI ENG +1

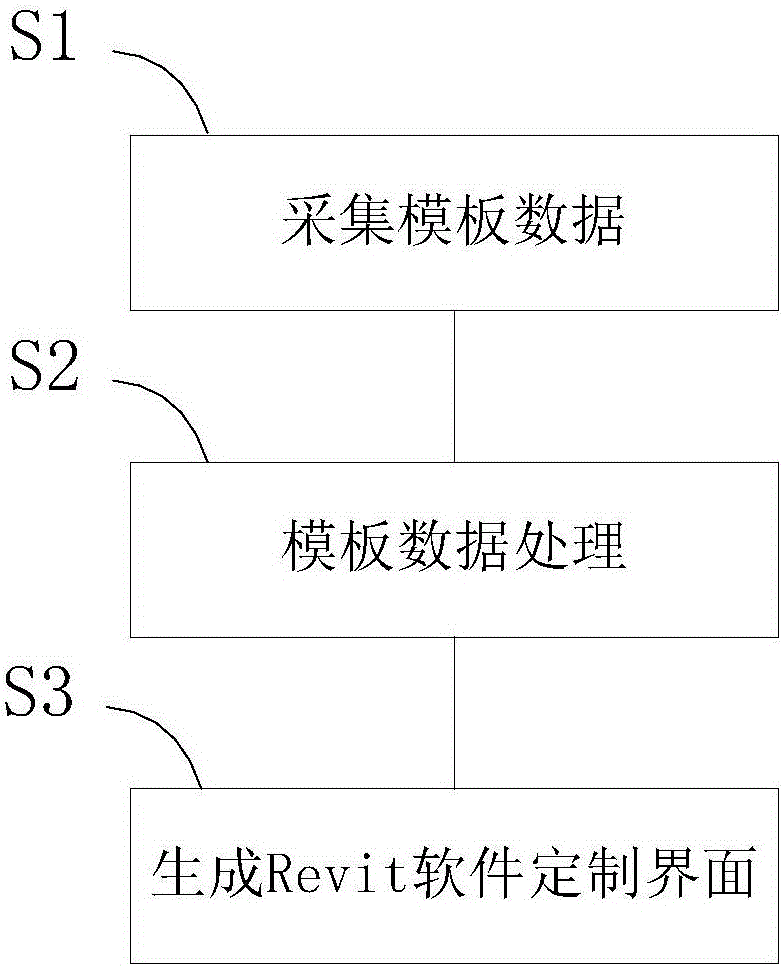

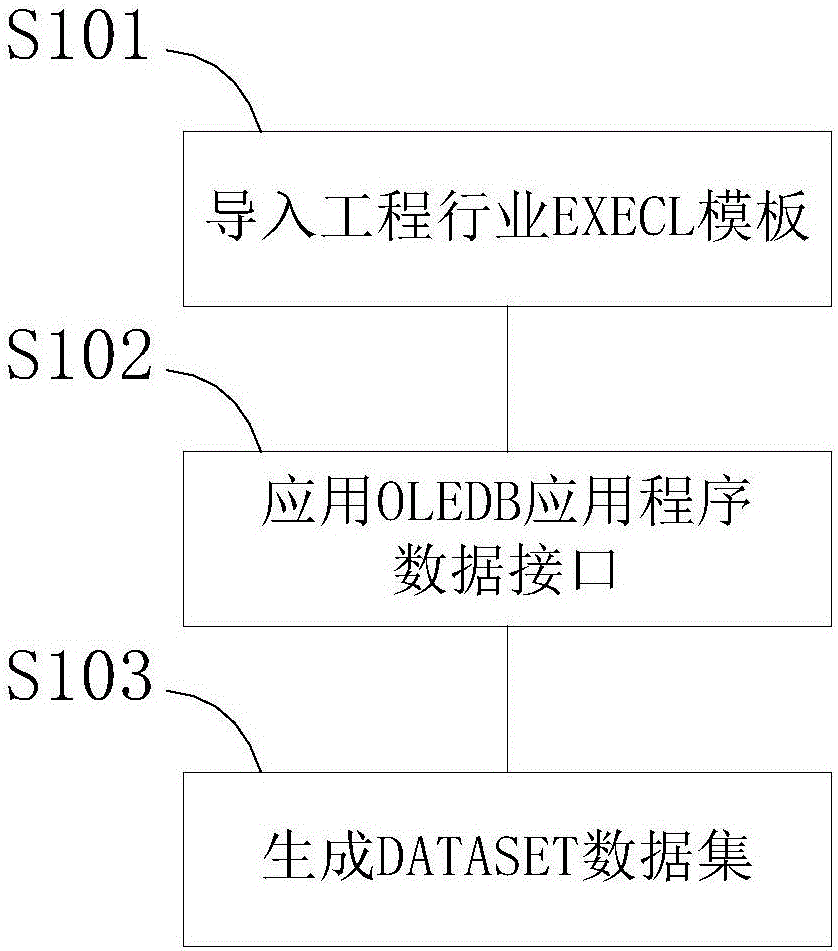

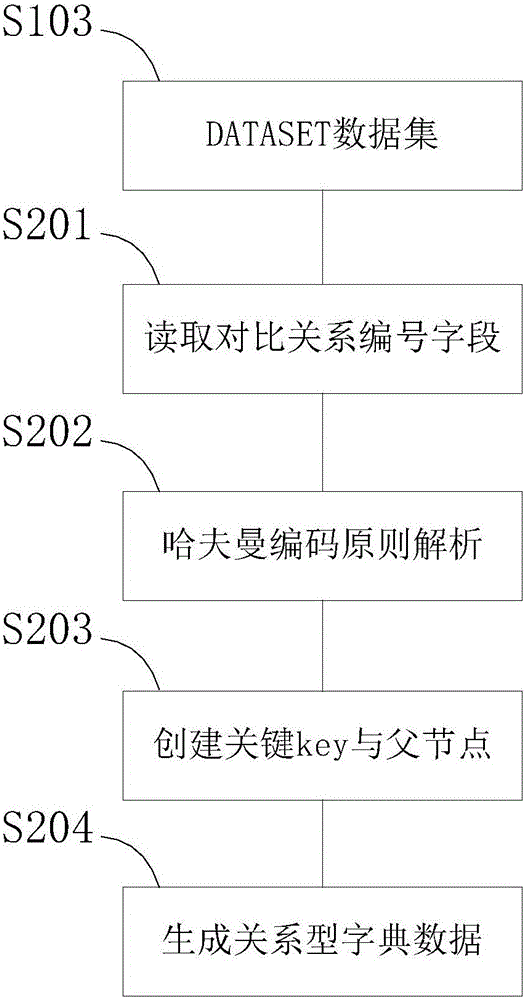

Analysis method applicable to diversified BIM modeling software interface

ActiveCN105786584AImprove modeling efficiencyFind quicklySoftware engineeringSpecific program execution arrangementsAnalytic relationData set

The invention discloses an analysis method applicable to a diversified BIM modeling software interface. The method includes the following steps that template data is acquired, an EXCEL file is opened, engineering major classification names, group names, display name information and relation numbers are obtained, and a DATASET is returned; the template data is processed, according to the DATASET, relation number fields are analyzed to obtain engineering group conditions and the hierarchical relation of groups according to the Huffman coding, and a dictionary dataset is generated; a Revit software customized interface is generated, that is, the dictionary dataset is traversed when a system runs, components are selected, and a final operation interface is generated. By means of the analysis method applicable to the diversified BIM modeling software interface, industrial design personnel are guided to quickly and correctly construct a BIM model, the defects that BIM model building is inconvenient and mistaken operations are likely to happen in the engineering industries like tunnel engineering and rail traffic engineering is overcome.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Rock abrasiveness determination method

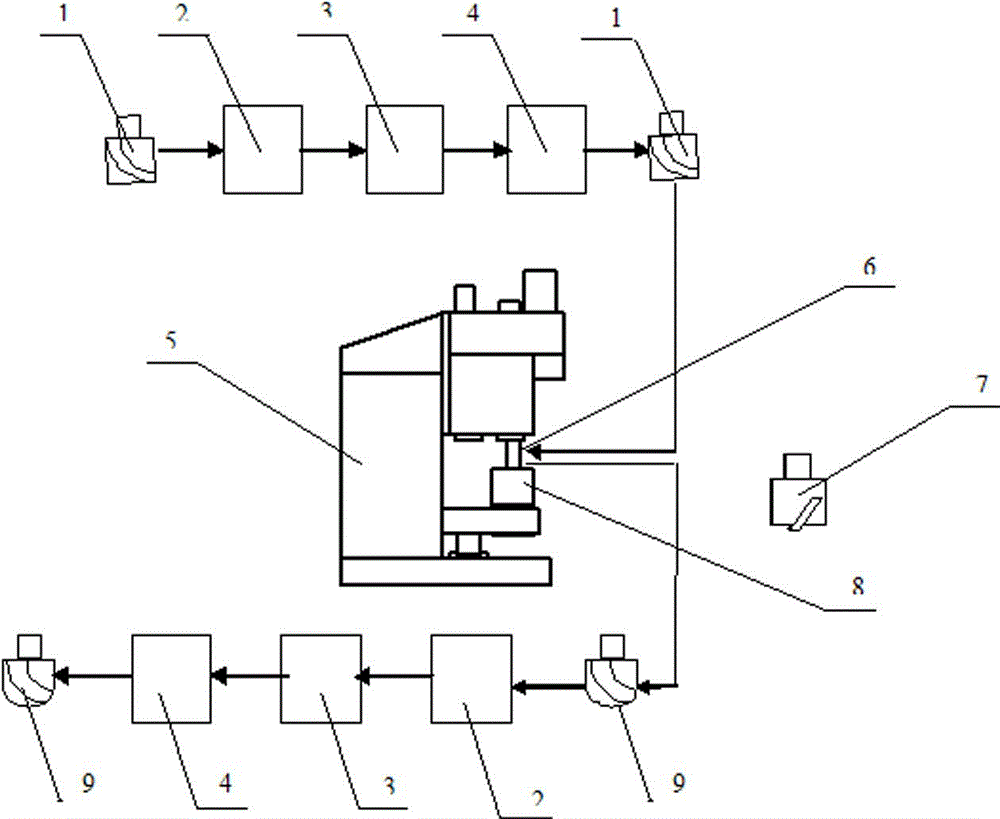

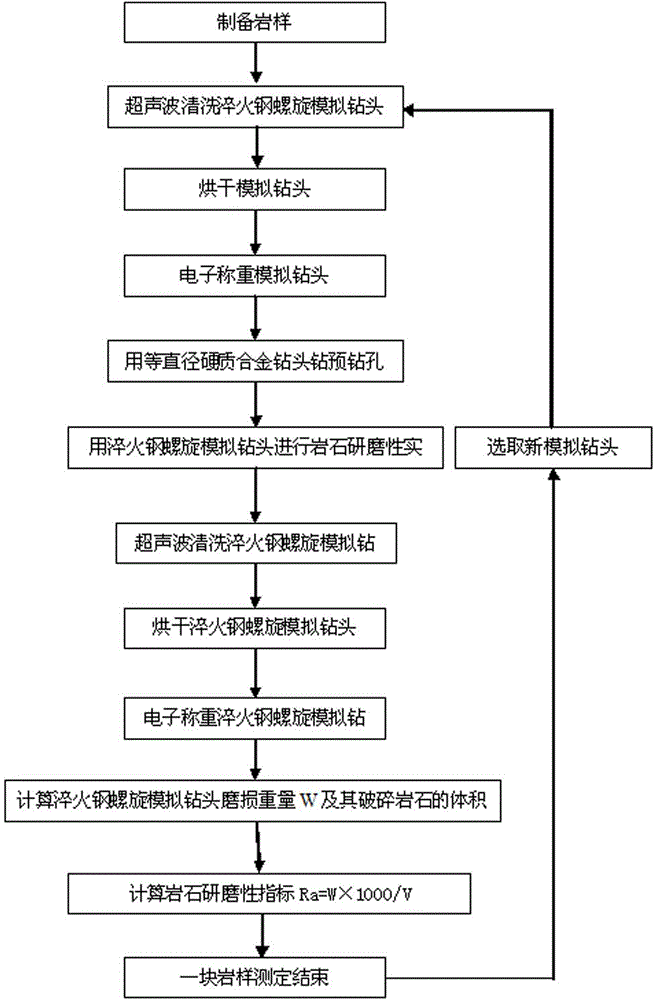

The invention relates to a rock abrasiveness determination method in the field of a rock abrasiveness experiment determination method in petroleum engineering industry. The rock abrasiveness determination method comprises the following steps: preparing a standard rock sample; washing, drying and weighing a quenched steel helix simulation drill bit before experiment; drilling a prebored hole; determining the rock abrasiveness; washing, drying and weighing after the quenched steel helix simulation drill bit after experiment; and calculating the rock abrasiveness index. The rock abrasiveness determination method truly shows the abrasiveness characteristics of rocks to rock breaking tools during drilling process: I. the frictional wear of the rock to the drilling bit in rock breaking; II. The frictional wear of generated rock chips to the drilling bit. The invention provides a new method for reasonably evaluating the rock abrasiveness for the technical field of petroleum engineering.

Owner:CHINA PETROCHEMICAL CORP +1

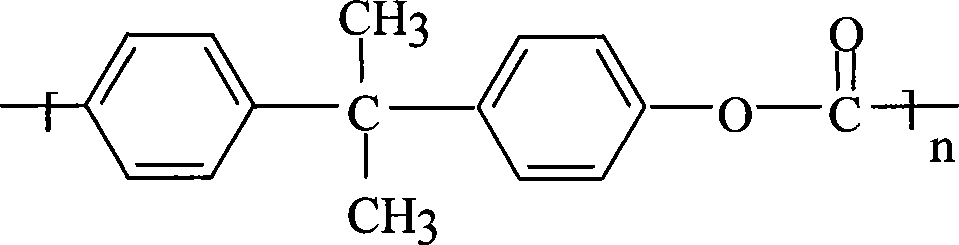

Elastomer-containing polycarbonate-based blending material and method for making same

InactiveCN101117433AImprove mechanical propertiesGood dimensional stabilityElastomerEngineering plastic

The present invention provides a blending material which contains an elastomer and is based on polycarbonate and the manufacturing method thereof, the contents of the components and parts by weight are as follows: 30-85 shares of polycarbonate, 5-50 shares of polyethylene, 5-65 shares of acrylonitrile-butadiene-cinnamene copolymer, 1 to 5 shares of vinyl acetate, 5 to 10 shares of elastomer, and the elastomer is selected from ethylene propylene terpolymer or polyurethane. The present invention uses three polymers of PC / PE / ABS as a base material with the elastomer and the vinyl acetate being added, the obtained material keeps the PC, PC / ABS alloy material improves resistance to low temperature greatly and is not easy to be cracked in low temperature condition in addition to good performances such as mechanical performance, dimension stability and heat resistance. The present invention can be used in fields such as electron electric industry, automobile manufactory and engineering industry, and is especially adapted for engineering plastic under moist and low temperature environment and hot water environment.

Owner:SHANGHAI CHLOR ALKALI CHEM

Fixture device for measuring temperature of outer wall of high-temperature pipeline

InactiveCN104535213AReduce vibrationReduce collisionThermometers using electric/magnetic elementsUsing electrical meansMeasurement pointContact type

The invention discloses a fixture device for measuring the temperature of the outer wall of a high-temperature pipeline and is applied to temperature measurement of walls of high-temperature pipelines in the nuclear power industry, the petroleum engineering industry, the chemical engineering industry, the metallurgy industry and the like. The fixture device comprises a detachable type inner layer installation belt, a detachable type outer layer installation belt and two semicircular protective shields, wherein the detachable type inner layer installation belt is provided with 2-8 measurement point grooved holes. The detachable type inner layer installation belt is installed in the manner of being closely attached to the outer wall of the high-temperature pipeline, and induction elements of a contact type temperature sensor are arranged in the measurement point grooved holes and are closely attached to the outer wall of the high-temperature pipeline. The detachable type inner layer installation belt and the induction elements of the contact type temperature sensor are covered with the detachable type outer layer installation belt, and the detachable type outer layer installation belt is fixed by combining fastening bolts and distance bolts on the two semicircular protective shields. The fixture device has the advantages of being capable of fixing the contact type temperature sensor to a measurement area, meanwhile reasonably protecting the contact type temperature sensor, reducing influences of vibration, collision and abrasion, achieving quick, simple and convenient installation and reducing safety risks caused by improper operation.

Owner:DALIAN UNIV OF TECH

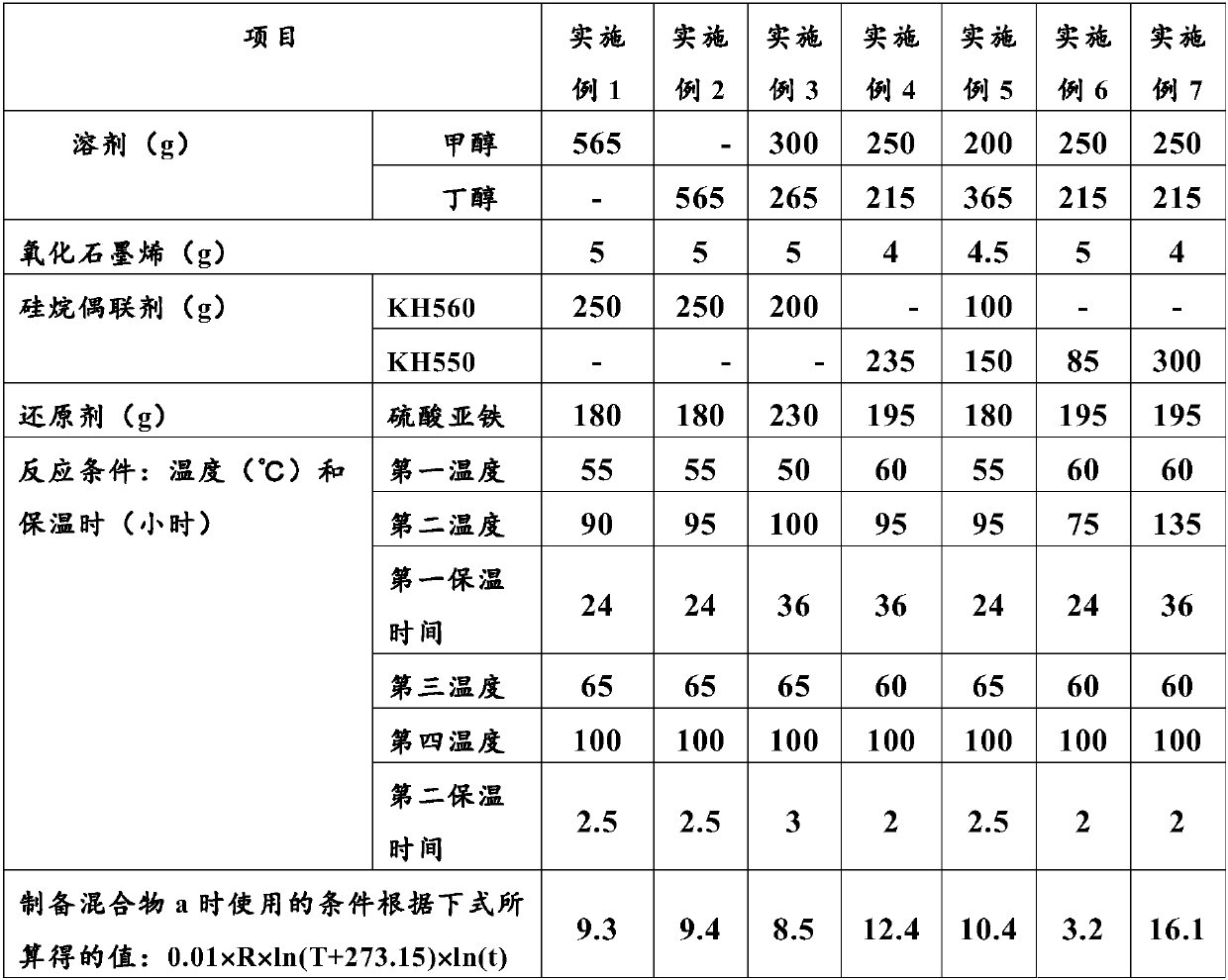

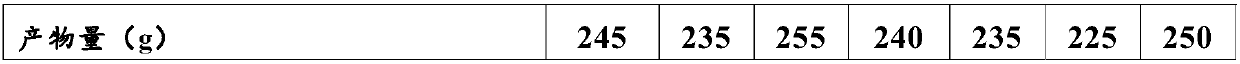

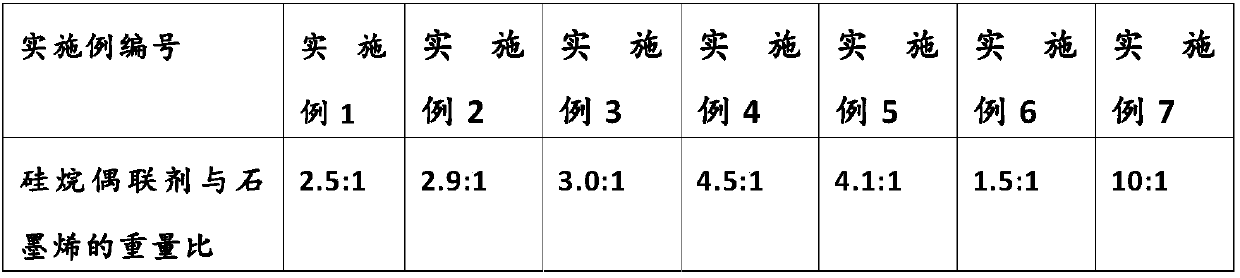

Waterborne heavy-duty coating containing silane coupling agent modified graphene, preparation method and application

ActiveCN110343455AImprove adhesionGood acid and alkali resistanceAnti-corrosive paintsPolyester coatingsEngineering industryGraphene

The invention relates to a waterborne heavy-duty coating. The waterborne heavy-duty coating is prepared from the components: (A) waterborne industrial resin and (B) silane coupling agent modified graphene, wherein the amount of the component (B) is 0.1-1.0% by weight based on the amount of the component (A), the total amount of the component (A) and the component (B) is 100% by weight, and the weight ratio of a silane coupling agent to graphene is (2.0 to 7.0) to 1. The invention further relates to a method for preparing the waterborne heavy-duty coating and application of the waterborne heavy-duty coating to the infrastructure, oil and gas and electric power industries, as well as in the industrial tank, shipping and chemical engineering industries.

Owner:DALIAN LICHUANG NEW MATERIAL SCI & TECHDEV

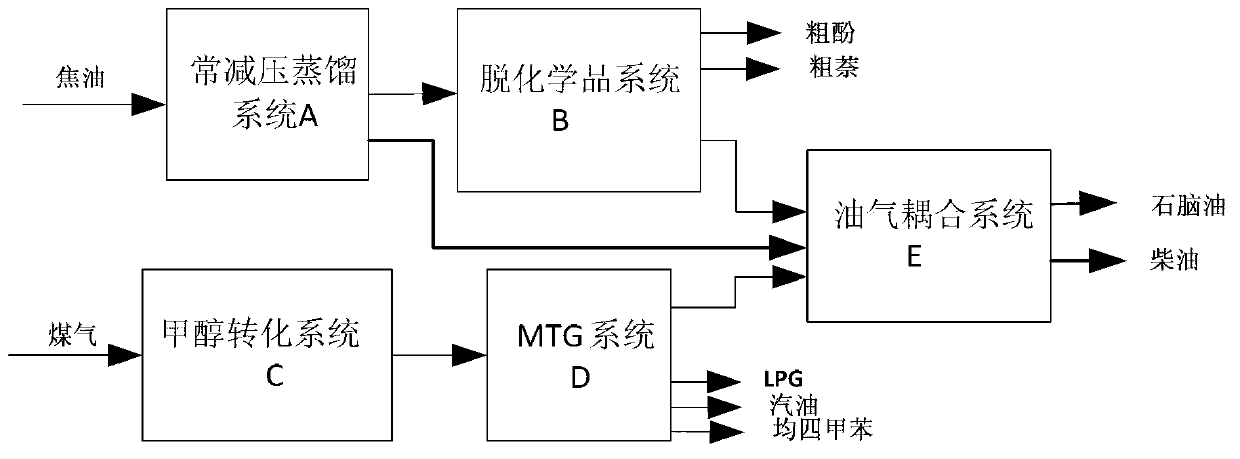

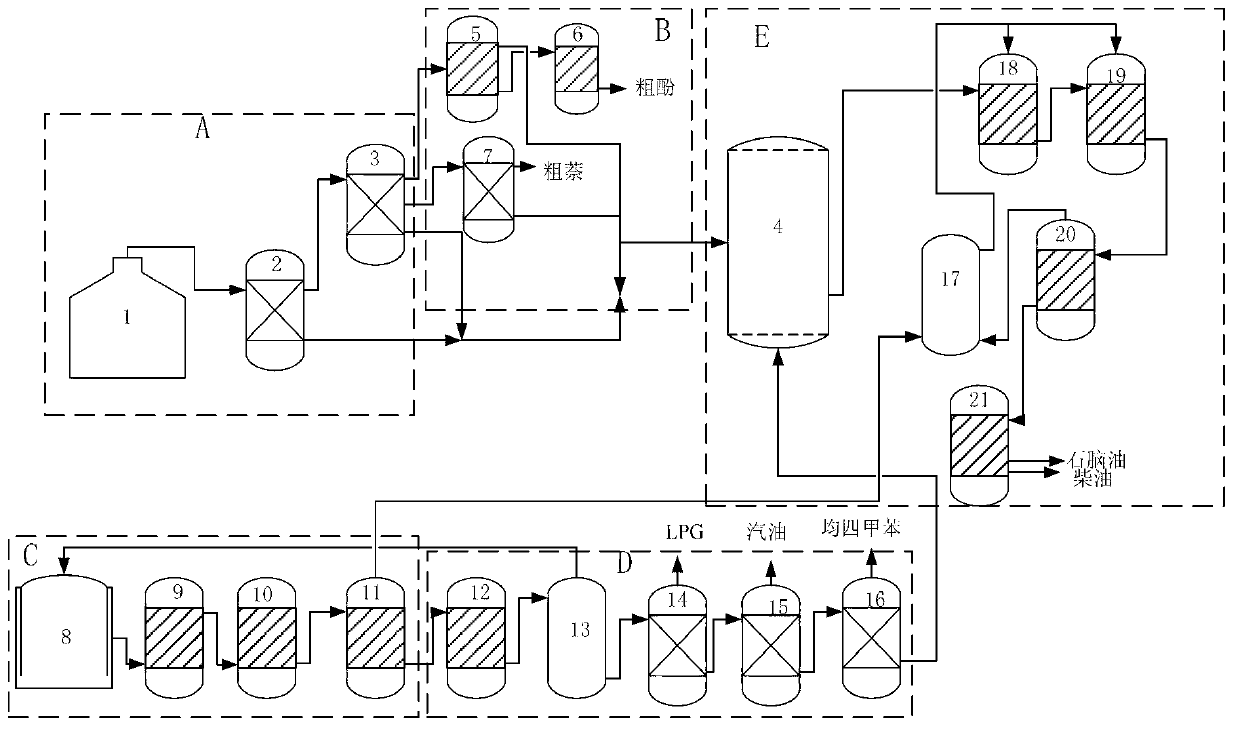

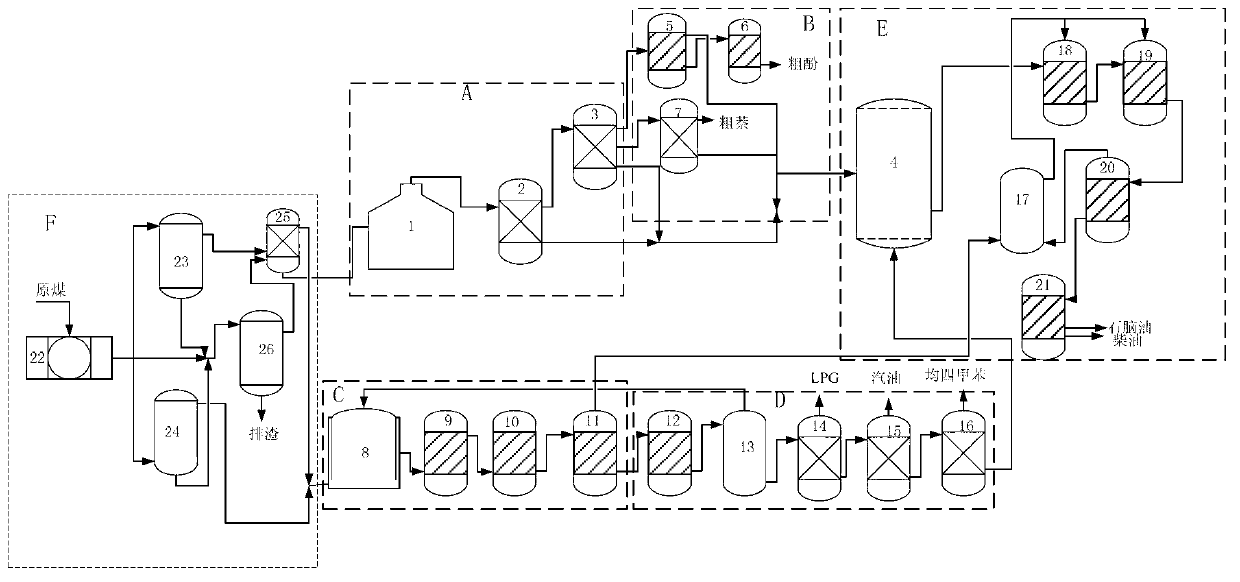

Oil-gas coupling poly-generation method in coal chemical engineering industry

ActiveCN103275757ASolve the problem of single processing method and low product priceAvoid wastingOrganic compound preparationDistillation purification/separationDistillationEngineering industry

The invention provides an oil-gas coupling poly-generation method in the coal chemical engineering industry. The oil-gas coupling poly-generation method comprises the following steps of: treating and dividing coal tar into heavy oil fraction, crude phenol, dephenolized oil, crude naphthalene, naphthalene-removed oil and washing oil by virtue of a normal-pressure distillation system and a chemical-removing system; discharging the crude phenol and the washing oil; feeding the heavy oil fraction, the washing oil, the dephenolized oil and the naphthalene-removed oil to an oil-gas coupling system; treating the coal gas to obtain LPG (Liquefied Petroleum Gas), petrol, durene and dealkylation heavy oil by virtue of a methanol conversion system and an MTG (Methanol To Gasoline) system; discharging the LPG, the petrol and the durene; feeding the dealkylation heavy oil to the oil-gas coupling system and carrying out coupling hydrogenation treatment in the oil-gas coupling system to obtain naphtha and diesel oil. According to the oil-gas coupling poly-generation method in the coal chemical engineering industry disclosed by the invention, the tar and the coal gas are effectively coupled, so that the resource waste is avoided; the high-additional value oil and chemicals including phenol, naphthalene, aromatic hydrocarbon and the like are generated, so that the direct emission of coal gas and the car is prevente, and therefore, the environment pollution is reduced and the method is more friendly to the environment.

Owner:SHAANXI COAL & CHEM TECH INST

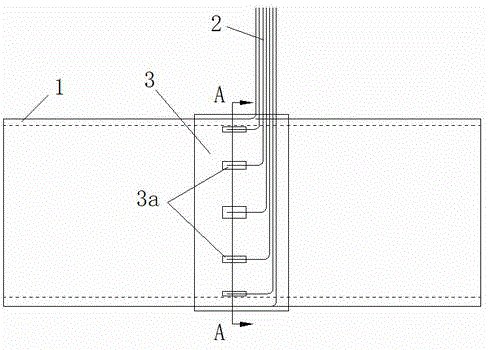

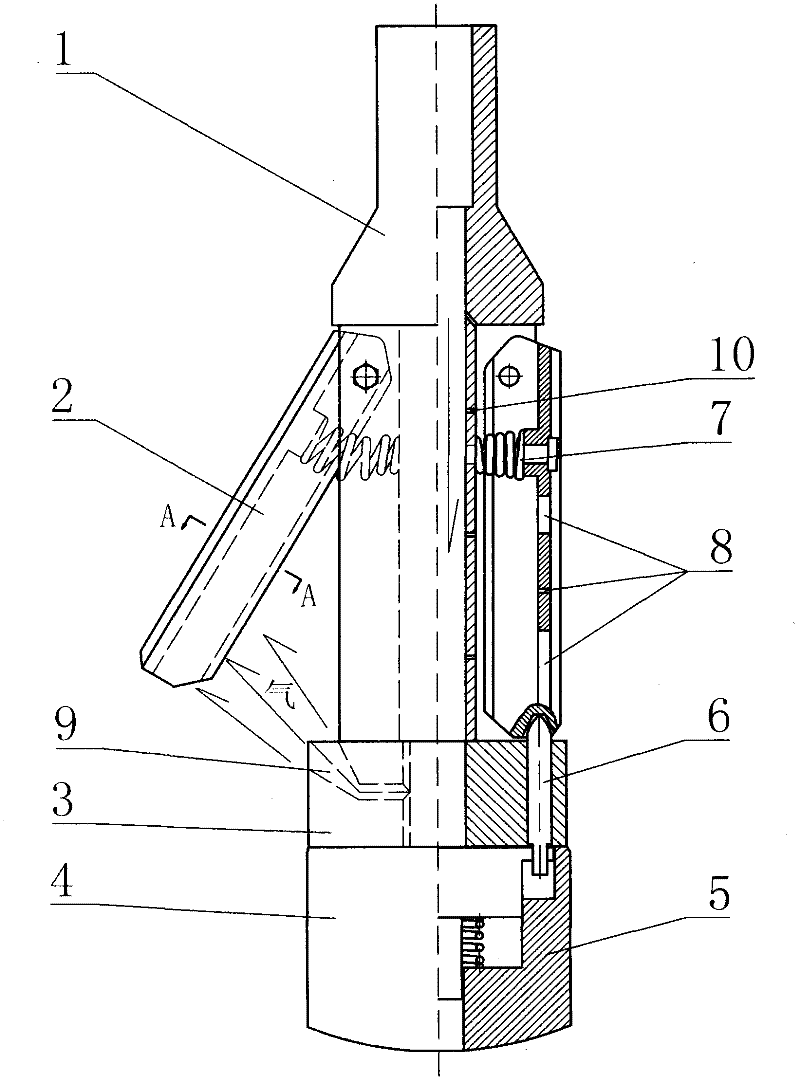

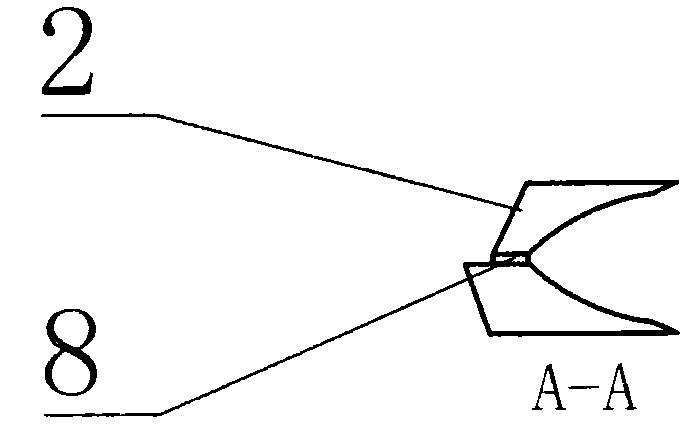

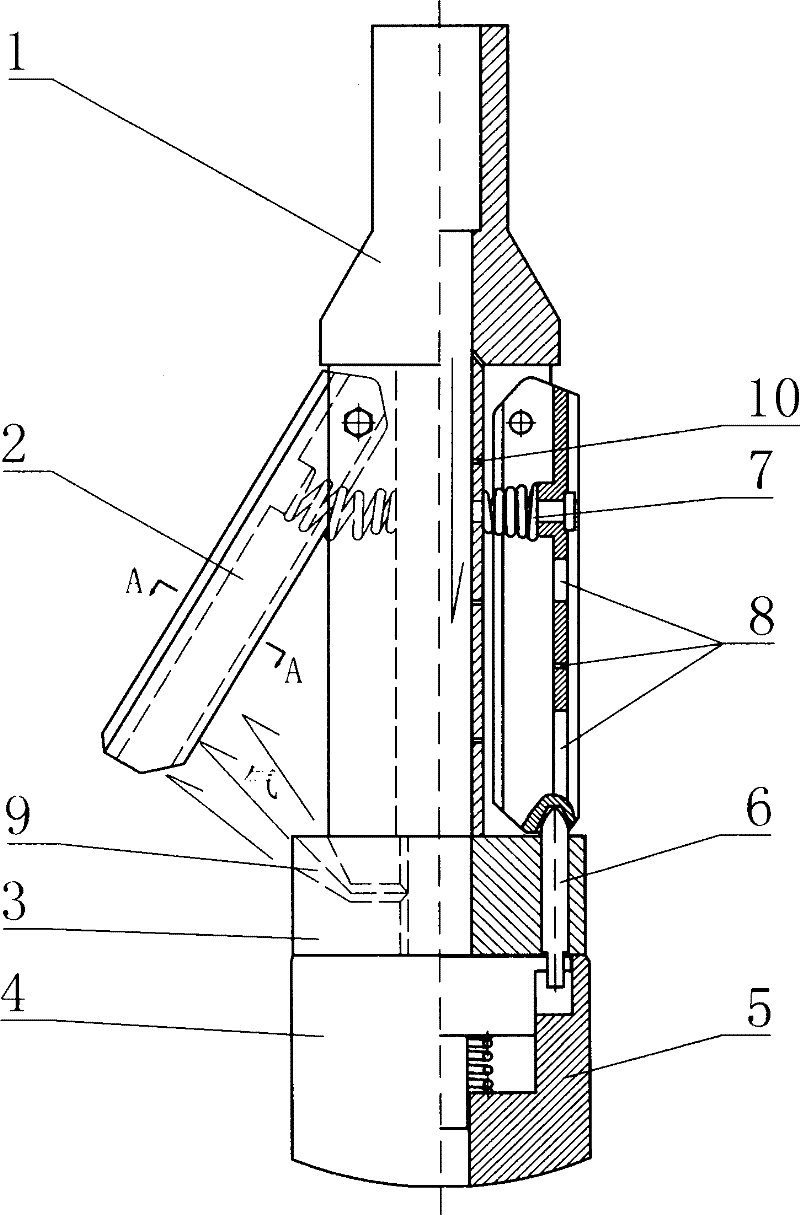

Soil-layer broaching bit

InactiveCN102477846AGuarantee unimpededReasonable designDrill bitsConstructionsEngineering industryDistributor

The utility model relates to the field of drilling tools in geotechnical engineering industries, and particularly relates to a soil-layer broaching bit. The utility model aims to provide a soil-layer broaching bit for solving the problems that cut soil bodies are easily accumulated, the broaching diameter is small, and the broaching bit is easily blocked and the like in the process of broaching. The soil-layer broaching bit provided by the invention comprises a pedestal (1), vanes (2), an airflow distributor (3), a bit head (4), a piston (5), a clamping pin (6), an expanding spring (7), airflow through holes (8), airflow holes (9) and an air hole (10). The main principle of the soil-layer broaching bit is as follows: an airflow is blown out of a plurality of airflow holes (9) which are opposite to the airflow direction in an aeration pipe and different in direction through the airflow distributor (3) and blown to the vanes (2), and the airflow is blown to the cut soil bodies from the airflow through holes (8) on the vanes (2), so that the cut soil bodies are blown out of the holes, thereby not only ensuring the smoothness of the interior of a drilled hole, but also enabling the bit not to be blocked. The soil-layer broaching bit provided by the invention has the advantages that the fault rate is low, the broaching diameter is large, and the bit head has less possibility of being blocked.

Owner:NORTHWEST RES INST CO LTD OF C R E C +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com