Waterborne heavy-duty coating containing silane coupling agent modified graphene, preparation method and application

A silane coupling agent, heavy-duty anti-corrosion technology, used in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of water-based industrial resins that are not mentioned, and achieve the effect of excellent anti-corrosion performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Under nitrogen protection, put 565g of methanol solvent into a 2L four-neck flask equipped with a stirrer, thermometer, distiller, and condenser, and slowly add 5g of graphene oxide under stirring, and slowly stir for 30 minutes, and heat up to 55 °C (referred to as the first temperature in Table 1). Then, slowly drop 250g silane coupling agent KH560 thereinto, be warmed up to 90 ℃ (referred to as second temperature in Table 1) after dropwise addition is completed, insulation 24 hours (referred to as first heat preservation time in Table 1), obtain mixture a. Then cool down to 65°C (referred to as the third temperature in Table 1), slowly add 180g ferrous sulfate reducing agent under stirring, and keep warm for 2.5 hours (referred to as the second holding time in Table 1), to obtain product b. Then, the vacuum pump was turned on, the temperature of the system was raised to 100° C. (referred to as the fourth temperature in Table 1), and the solvent in the product b was ...

Embodiment 2-5

[0118] The process of Example 1 was repeated, except that the raw material consumption and experimental conditions listed in Table 1 were used.

Embodiment 6-7

[0119] Embodiment 6-7 (as comparative example)

[0120] The process of Example 4 was repeated, except that the raw material consumption and experimental conditions listed in Table 1 were used.

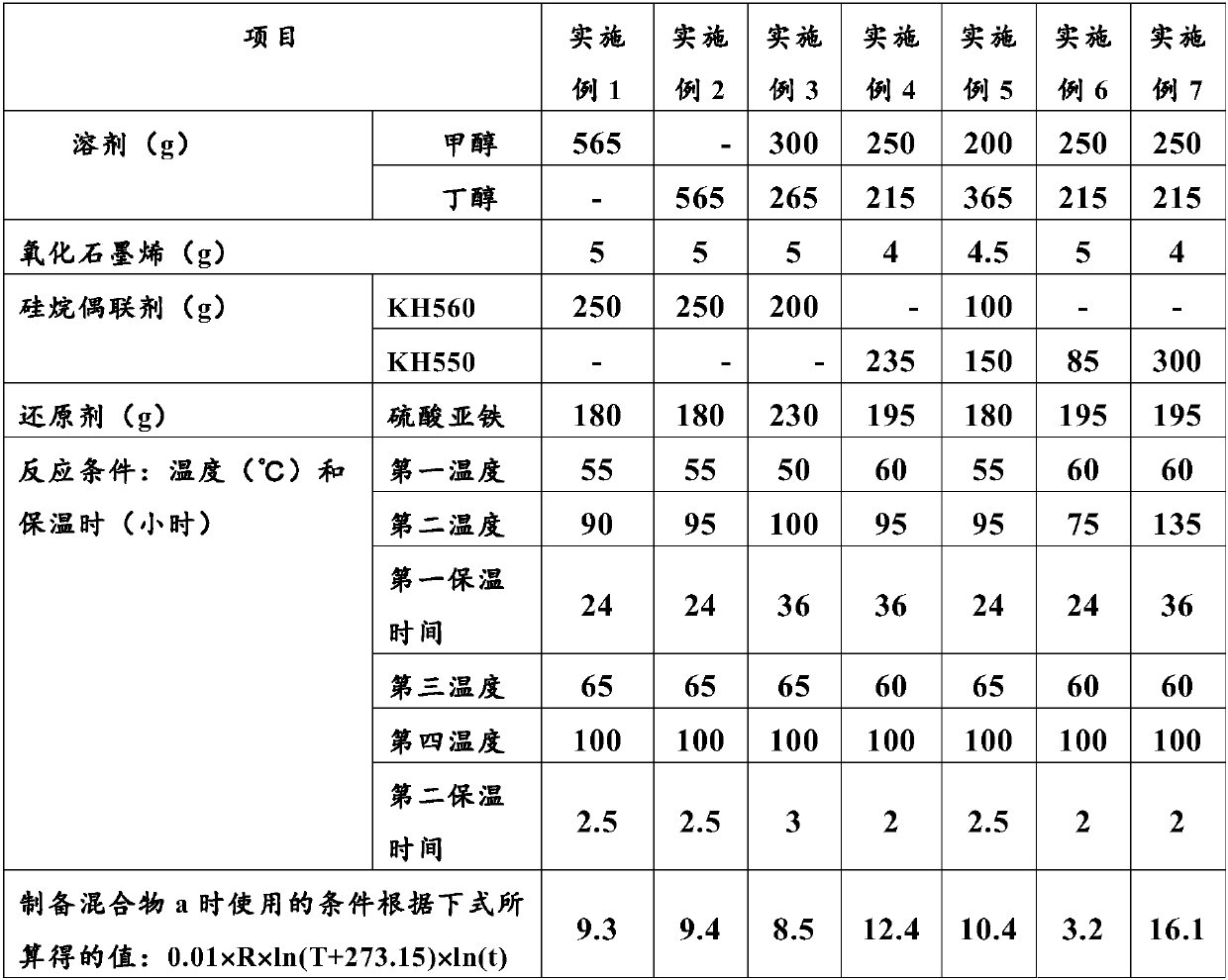

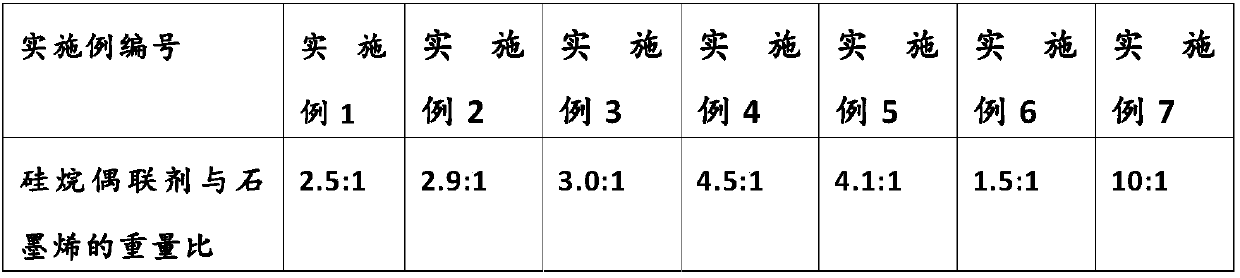

[0121] Table 1: Experimental data and results of Examples 1-7

[0122]

[0123]

[0124] Note: In the formula 0.01×R×ln(T+273.15)×ln(t), R represents the ratio of added silane coupling agent to graphene oxide; T represents the second temperature in °C; and, t Represents the first heat preservation time, the unit is hour.

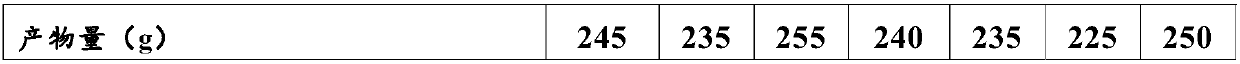

[0125] Tested the content of residual silane coupling agent in the prepared silane coupling agent modified graphene with capillary chromatography, thereby deduced the optimal ratio of silane coupling agent and graphene in the prepared modified graphene, experiment The proportions are shown in Table 2 below:

[0126] Table 2

[0127]

[0128] As can be seen from the test results, the weight ratio of silane coupling link and graphene in the modified graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com