Multi-shell-pass tube type heat exchanger

A tube-and-tube heat exchanger and multi-shell technology, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of uncompact equipment and pipelines, large system resistance, and high power consumption , to achieve the effect of eliminating the need for pipelines between equipment, reducing fluid resistance, and reducing equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

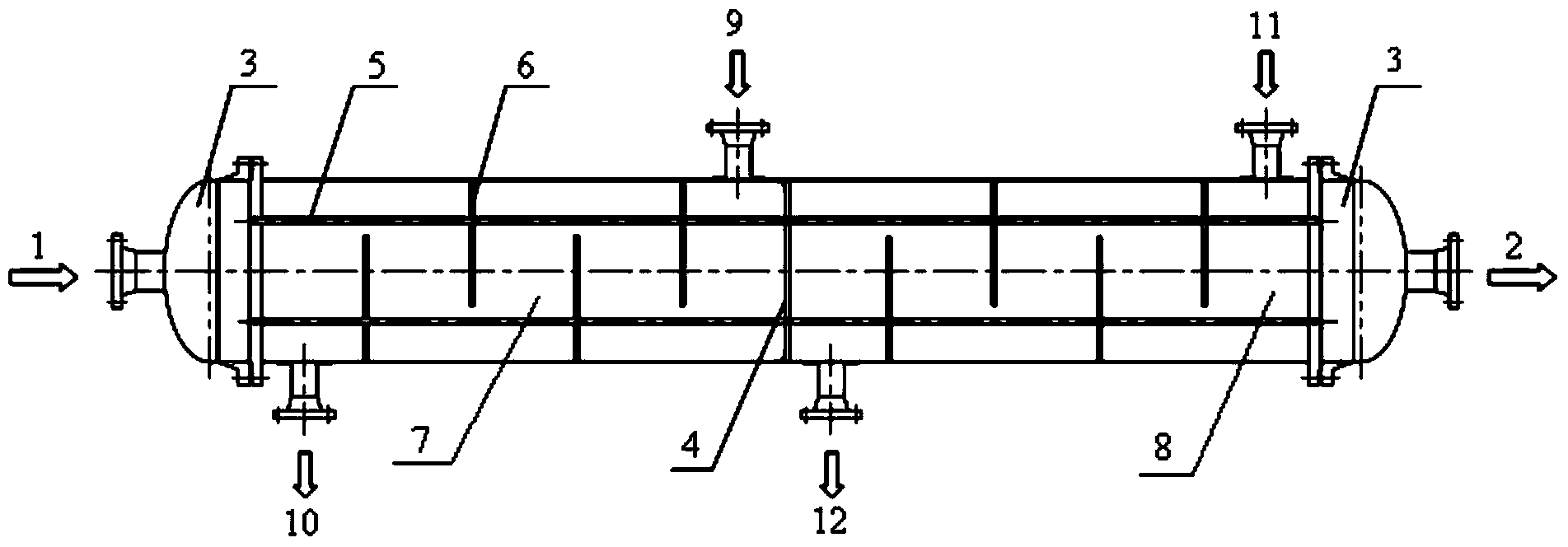

[0021] use figure 1 In the tube-and-tube heat exchanger shown, the heat exchange tubes are 12 meters long (according to the standard series of heat exchanger tube lengths), and the shell side is divided into 5.5 meters and 6.5 meters at a distance of 5.5 meters from one end of the tube plate with an internal sealing partition. There are two mutually isolated heat exchange sections, and there are four baffle plates in each heat exchange section. The reaction outlet gas goes through the tube side, and the two streams before and after the acetic acid evaporator exchange heat with the tube side fluid in two isolated heat exchange sections of 5.5 meters and 6.5 meters respectively.

[0022] Compared with two separate tube-and-tube heat exchangers, the combined heat exchanger equipment can save more than ten tons of high-grade acid-resistant alloy steel and more than 30 meters of high-grade acid-resistant alloy steel pipes with a diameter of 800mm, reducing the system resistance by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com