Elastomer-containing polycarbonate-based blending material and method for making same

A polycarbonate and elastomer technology, which is applied in the field of polycarbonate-based blend materials containing elastomers and their preparation, can solve the problems of low impact performance, easy stress cracking of products, low mechanical properties, etc., and achieves low temperature resistance. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

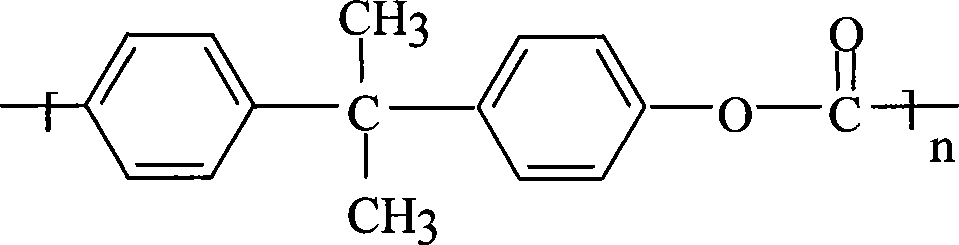

[0039] formula:

[0040] 85 parts of polycarbonate (PC), 10 parts of polyethylene (PE), 10 parts of acrylonitrile-butadiene-styrene copolymer (ABS), 1 part of vinyl acetate, and 10 parts of polyurethane.

[0041]Polycarbonate (Makrolon 2858, produced by BAYER, Germany), low-density polyethylene (LDPE) (Q200, produced by Shanghai Petrochemical), and acrylonitrile-butadiene-styrene copolymer (ABS) (ABS757, produced by Chimei, Taiwan) Mix evenly with polyurethane powder, then pour the mixture into a twin-screw extruder (SHL-35 type) for melting and kneading, cool and granulate to obtain blended pellets (the temperature settings of each section of the extruder are respectively, one section : 220°C, second stage: 225°C, third stage: 235°C, fourth stage: 260°C, die head: 235°C). The blended pellets were dried in a common oven at 100°C for 10 hours and then cooled to room temperature naturally. Then according to the ASTM test standard, the blended pellets were injected, and the tem...

Embodiment 2

[0044] formula:

[0045] 50 parts of polycarbonate (PC), 15 parts of polyethylene (PE), 15 parts of acrylonitrile-butadiene-styrene copolymer (ABS), 5 parts of vinyl acetate, 5 parts of EPDM rubber, Malay Anhydride modified polyethylene 10 parts.

[0046] Polycarbonate (Makrolon 2858, produced by BAYER, Germany), low-density polyethylene (LDPE) (Q200, produced by Shanghai Petrochemical), and acrylonitrile-butadiene-styrene copolymer (ABS) (ABS757, produced by Chimei, Taiwan) Mix evenly with EPDM powder, then pour the mixture into a twin-screw extruder (SHL-35 type) for melting and kneading, cool and granulate to obtain blended pellets (the temperature setting of each section of the extruder Respectively, first stage: 220°C, second stage: 225°C, third stage: 235°C, fourth stage: 260°C, die head: 235°C). The blended pellets were dried in a common oven at 100°C for 10 hours and then cooled to room temperature naturally. Then according to the ASTM test standard, the blended pel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com