Purification treatment method of high-concentration organic waste gas

A technology for organic waste gas and purification treatment, which is used in the purification treatment of low oxygen content organic waste gas, high organic concentration, and high concentration organic waste gas purification treatment. It can solve the problems of increasing the scale of heat exchange equipment and heating equipment, and reduce the scale , to avoid potential safety hazards, to prevent the effect of catalyst sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

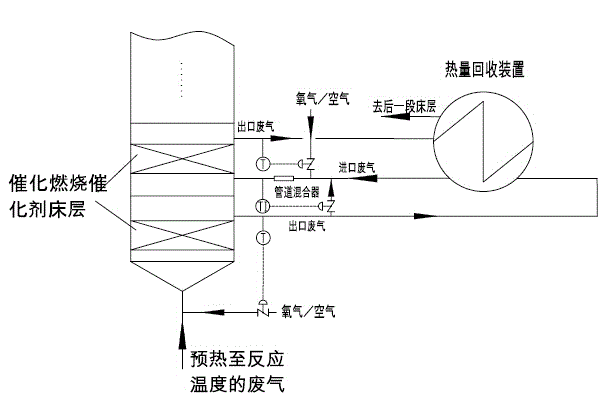

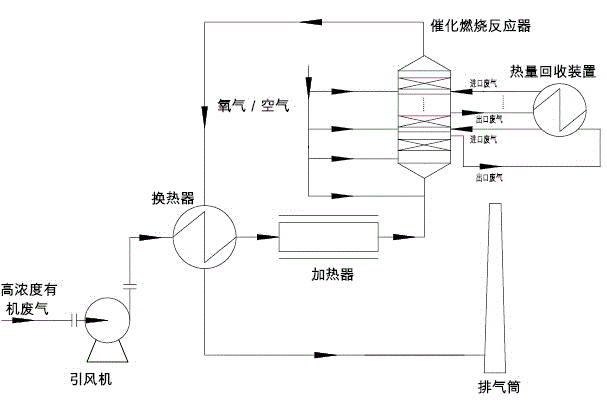

Image

Examples

Embodiment 1

[0023] A chemical company has multiple propylene oxide storage tanks, equipped with nitrogen protection, and the average exhaust gas emission of the storage tanks is 200Nm 3 / h, the concentration of propylene oxide is 138000mg / m 3 , the oxygen concentration is less than 1%, and the rest is N 2 .

[0024] If conventional catalytic combustion process is used to treat the exhaust gas, in order to make the bed temperature rise not exceed 220°C, the concentration of propylene oxide shall not exceed 9000mg / m 3 , you need to dilute the exhaust gas more than 15 times. Therefore, the scale of the exhaust gas treatment device is 3000Nm 3 / h, the scale of catalytic combustion reactor, induced draft fan, heat exchanger, heater and other equipment in the treatment process is 3000Nm 3 / h, equipment investment and operating costs are high, the volume space velocity of the catalyst bed is 20000h -1 , need catalytic combustion catalyst 150L. The catalytic combustion reactor is filled wit...

Embodiment 2

[0029] A chemical company has exhaust gas from a benzene chemical plant, with a gas volume of about 500Nm 3 / h, the total hydrocarbon concentration is about 53000mg / m 3 , the main pollutants are benzene, toluene, aniline, cyclohexylamine, cyclohexane, etc., the oxygen concentration is less than 2%, and the rest is N 2 .

[0030] If conventional catalytic combustion process is used to treat the exhaust gas, in order to make the temperature rise of the bed layer not exceed 250°C, the combustion amount of organic matter shall not exceed 7500mg / m 3 (in terms of total hydrocarbon concentration), it is necessary to dilute the exhaust gas by more than 7 times, and the scale of the exhaust gas treatment device is 3500Nm 3 / h, the scale of catalytic combustion reactor, induced draft fan, heat exchanger, heater and other equipment in the treatment process is 3500Nm 3 / h, equipment investment and operating costs are high. The volume space velocity of the catalyst bed is 18000h -1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com