Gob-side entry retaining concrete partition wall construction mold bag and construction method thereof

A concrete and separation wall technology, applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve problems such as poor connection reliability of mold bags, defects of mold bag erection, and insufficient simplicity of mold bag manufacturing process, etc. The bag is convenient, the construction speed is fast, and the effect of fast fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

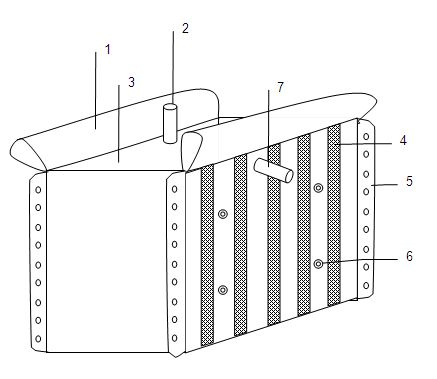

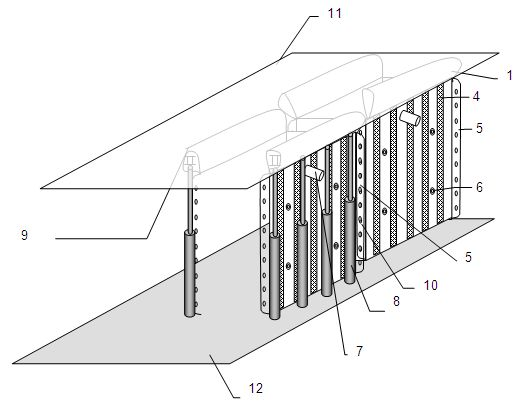

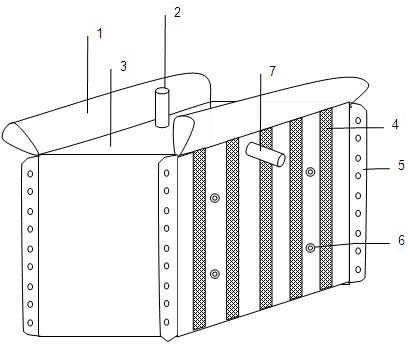

[0024] see figure 1 , according to the geometric dimensions of the gob-side entry retaining wall, the construction mold bag of the gob-side entry concrete separation wall is made. It is composed of connecting feather eaves 5, anchor reinforcement holes 6 and grouting tunnels 7.

[0025] In this embodiment, the diameter of the top-fixed ear tube 1 is 30mm;

[0026] The channel length of the grouting vent hole 2 is 120mm;

[0027] The flexible fiber 3 top is made of knitted cloth;

[0028] The connecting cornice 5 is a cylindrical structure without folding and sewing, and a connecting hole with a diameter of φ15 is punched every 50 mm on the connecting cornice 5 .

[0029] The anchor bar hole 6 and the grouting channel 7 are a cylindrical soft cloth structure that runs through the inside and outside of the mold bag, and the grouting channel 7 is made of a cylindrical cloth with a diameter of φ150;

[0030] The reinforcing ribs 4 are evenly distributed on both sides of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com