Patents

Literature

177results about How to "Self-sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wiping base for electric coagulation forceps

InactiveCN105080876ASelf-sealingSimple structureCleaning using toolsCleaning using liquidsHydraulic cylinderForceps

The invention discloses a wiping base for electric coagulation forceps. Two partitioned cavities are arranged inside the base through a partition plate. Two through holes into which forceps rods are allowed to stretch are arranged in the upper surface of the base. An inductor is further arranged on the side wall of each through hole. A clamping groove is arranged in the side wall of the cavity on each side. A groove is formed in the side wall, close to one end of the partition plate of the base, of each clamping groove. Each cavity further comprises a containing bag. A first hydraulic cylinder is further arranged on the side wall of each cavity. Each first hydraulic cylinder is provided with two hydraulic rods. A second hydraulic cylinder is further arranged on the lower surface of the base. A heating strip is connected to the head of a hydraulic rod of the second hydraulic cylinder. An abutting plate is arranged at the position, corresponding to the heating strip, of the partition plate in the middle of the base. The wiping base is simple in structure and convenient to use, the wiping and disinfection functions can be achieved only by placing the forceps in the base, and waste can be automatically sealed; and the wiping base is low in manufacturing cost and has the higher practical value.

Owner:CHONGQING RUNZE PHARM CO LTD

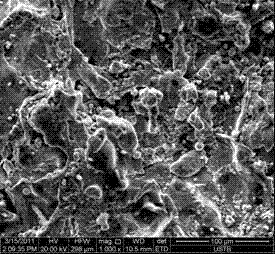

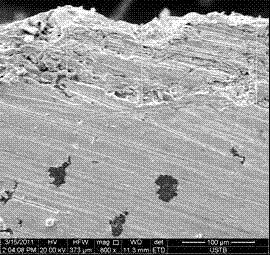

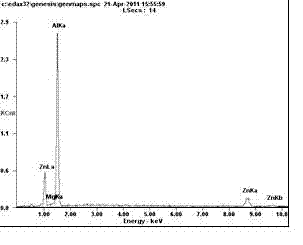

Multicomponent alloy composite anticorrosive coating for metal pipe/pipe fitting

InactiveCN102418831AReduce porosityImprove anti-corrosion performanceCorrosion preventionPipe protection against corrosion/incrustationPorosityPipe fitting

The invention discloses a multicomponent alloy composite anticorrosive coating for a metal pipe / pipe fitting, which comprises a Zn-Al-Mg-RE multicomponent alloy layer and a hole-sealing finishing layer, wherein the hole-sealing finishing layer is coated on the surface of the Zn-Al-Mg-RE multicomponent alloy layer, the Zn-Al-Mg-RE multicomponent alloy layer comprises the following components by weight percentage: 56-83% of Zn, 16-41% of Al, 0.05-2.0% of Mg and 0.05-1.0% of Re, and the hole sealing finishing layer is an organic or inorganic coating layer. The multicomponent alloy composite anticorrosive coating disclosed by the invention has the advantages of low porosity, good anticorrosive property and the like.

Owner:XINXING DUCTILE IRON PIPES CO LTD

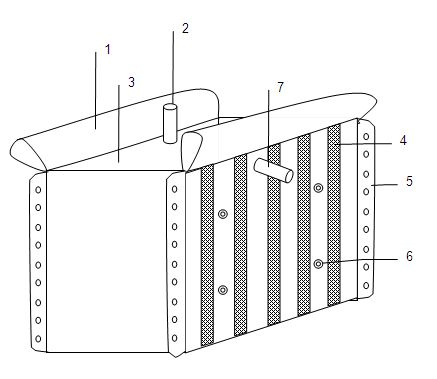

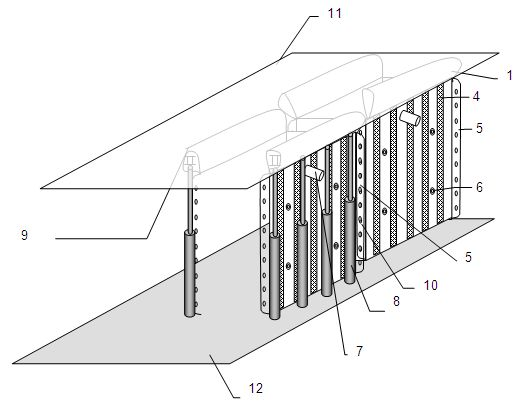

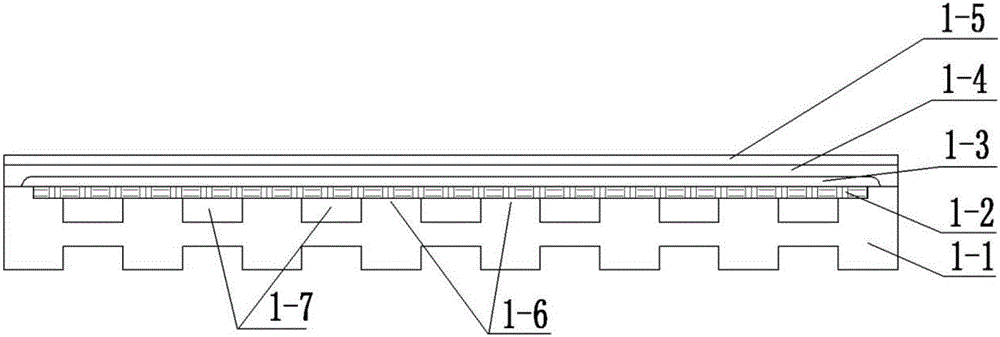

Gob-side entry retaining concrete partition wall construction mold bag and construction method thereof

InactiveCN101929342AGuaranteed sealing performanceEasy to bagUnderground chambersTunnel liningEavesEngineering

The invention discloses a gob-side entry retaining concrete partition wall construction mold bag and a construction method thereof. The mold bag is a bag with a closed structure; and the mold bag structurally comprises a fixed lug cylinder, a pouring exhaust hole, a mold bag top, a reinforcing rib, connecting feather eaves, an anchor bar hole and a concrete grouting duct. The construction method comprises the following steps of: penetrating a rigid beam into the fixed lug cylinder, jacking the rigid beam to a top plate by using a strut and fixing the rigid beam; penetrating a rope into a connecting hole of the connecting feather eaves to connect and position the adjacent mold bag; then penetrating an anchor bar and controlling a concrete pumping device; and finally, pumping concrete to fill the whole mold bag till the mold bag is full to the top. The mold bag is adaptive to the pouring of a gob-side entry retaining masonry partition wall of a coal mine, has a simple structure and high construction speed, and can be widely applied in quick masonry of the gob-side entry retaining partition wall of the mine and water conservancy, war industry and other civil engineering industries.

Owner:XIAN UNIV OF SCI & TECH

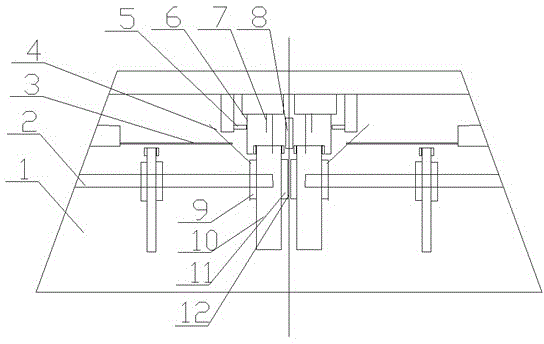

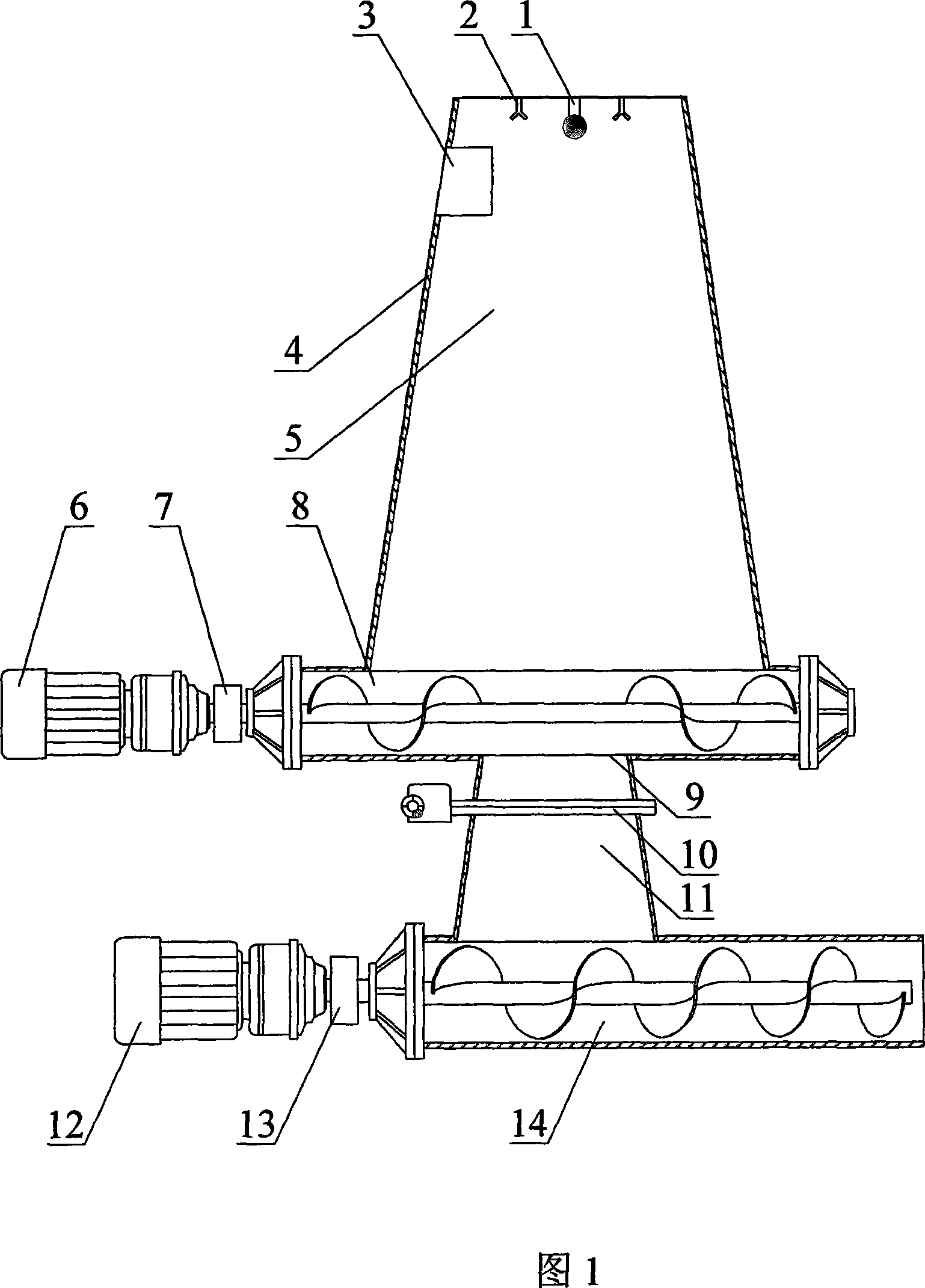

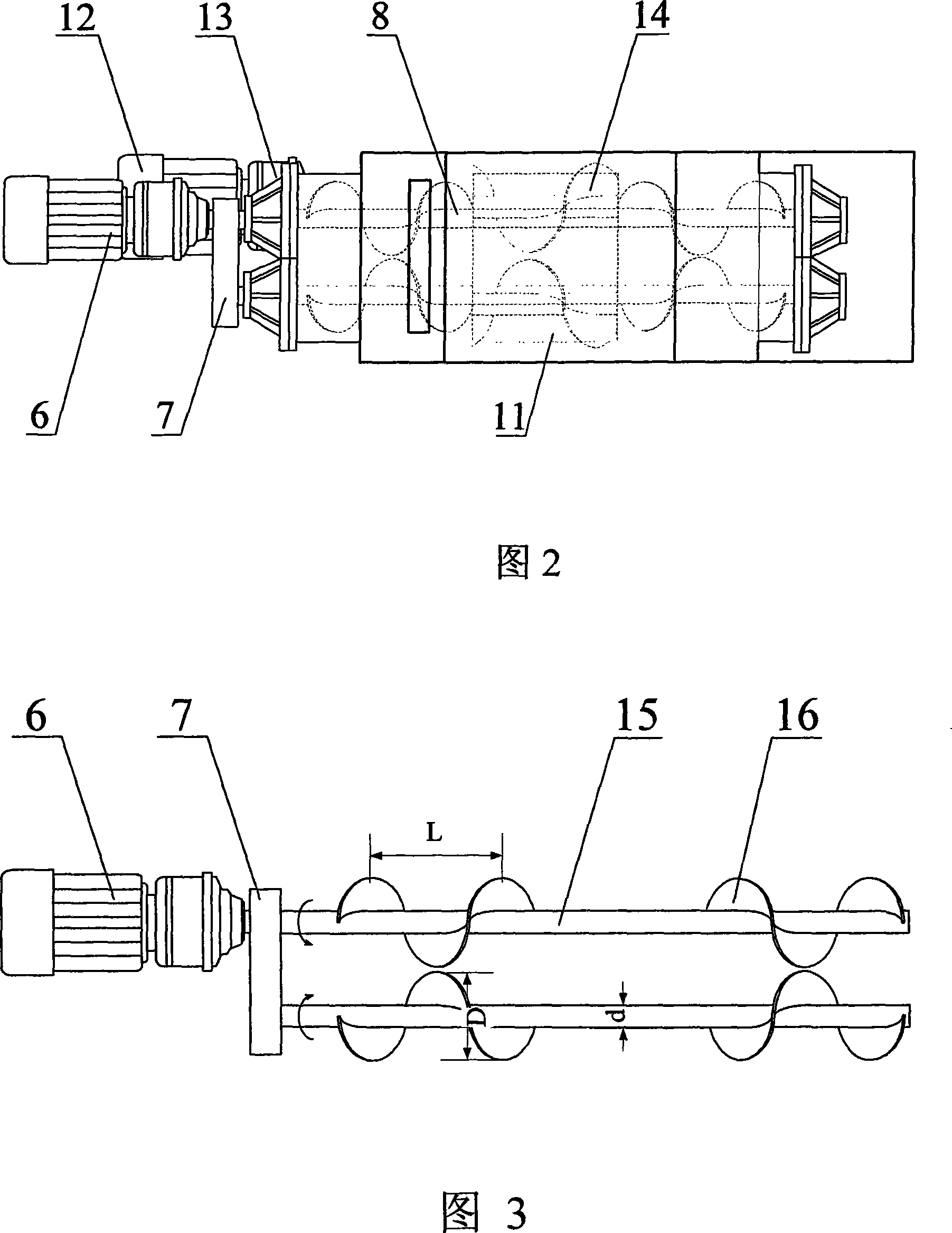

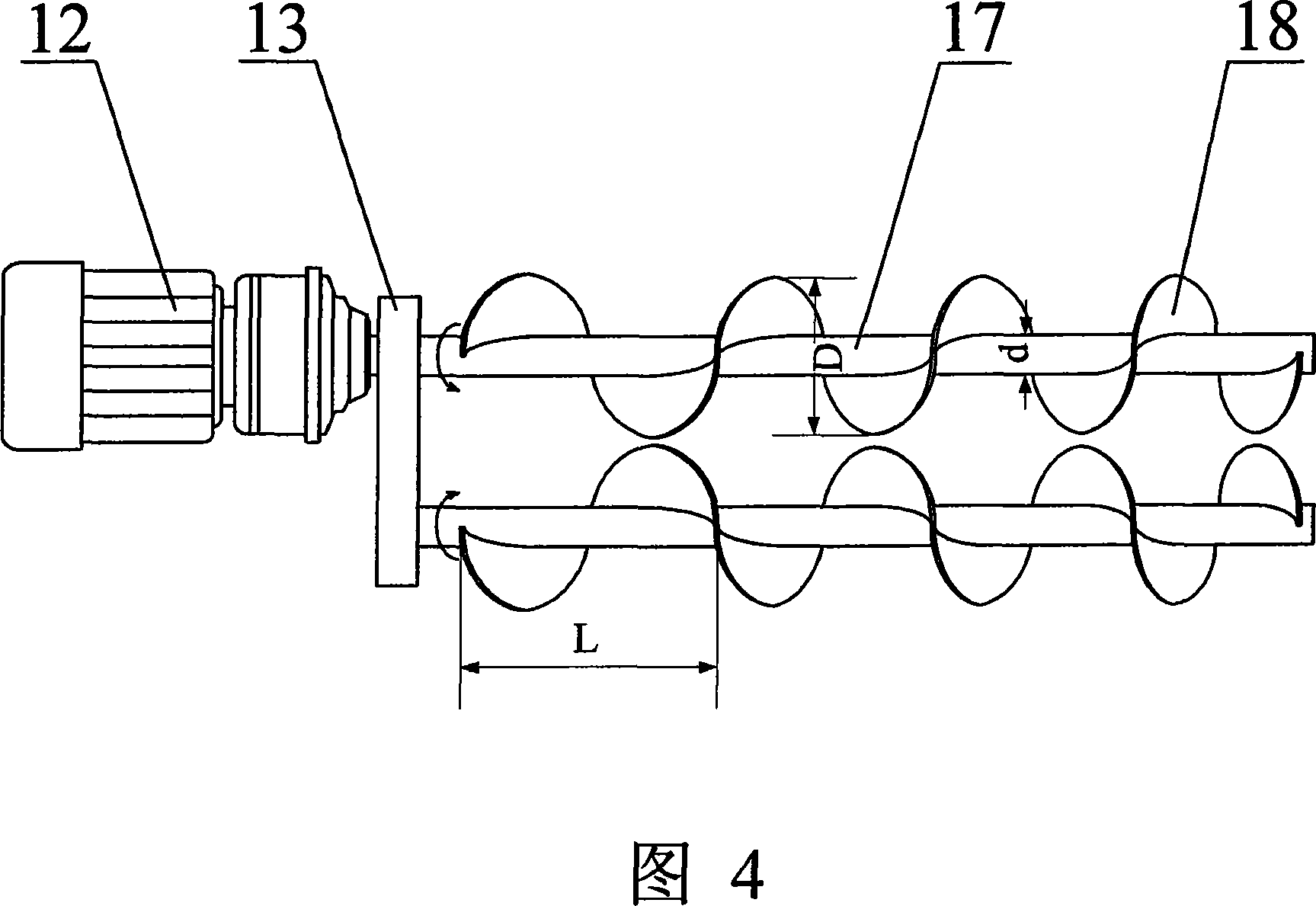

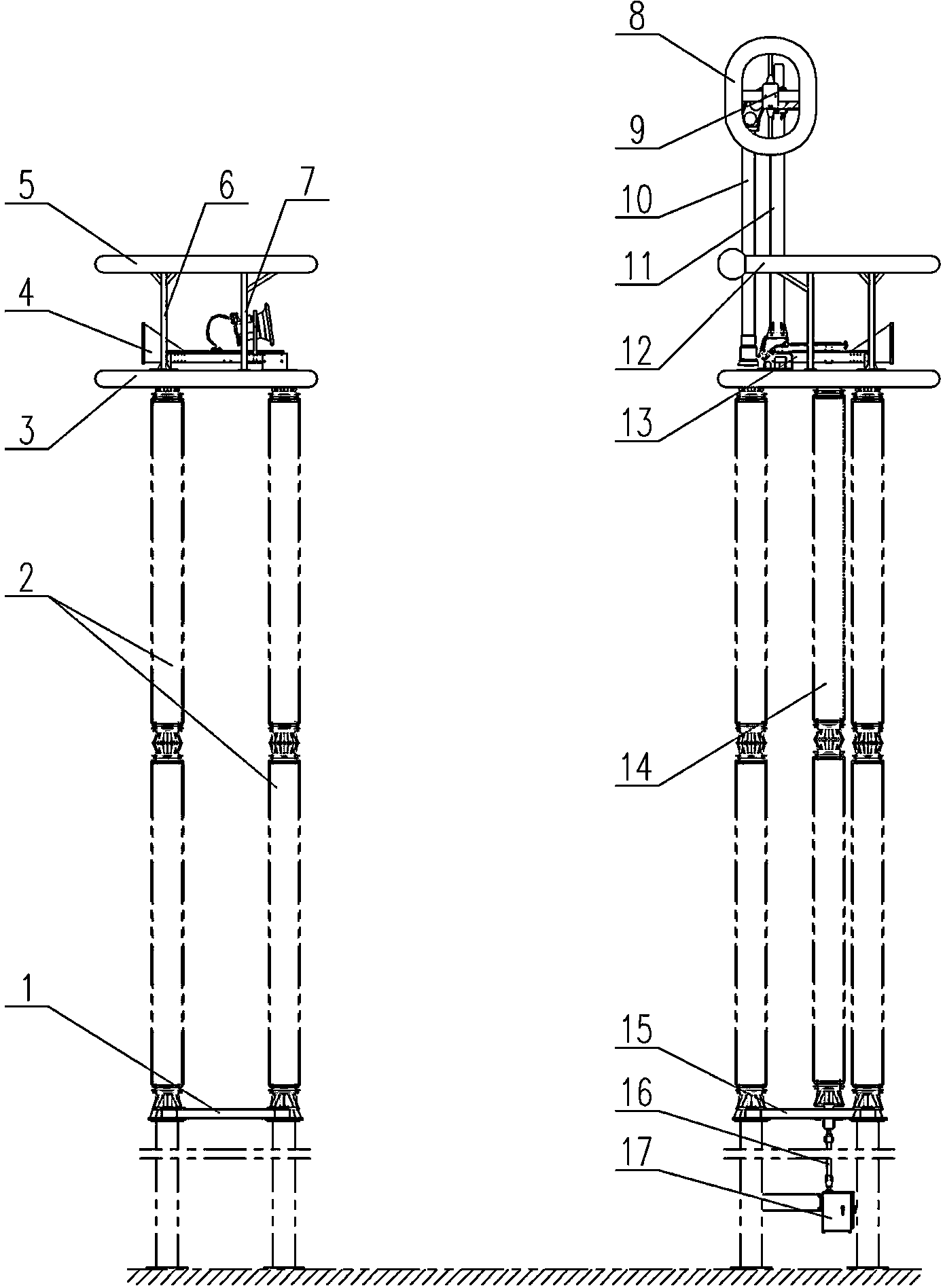

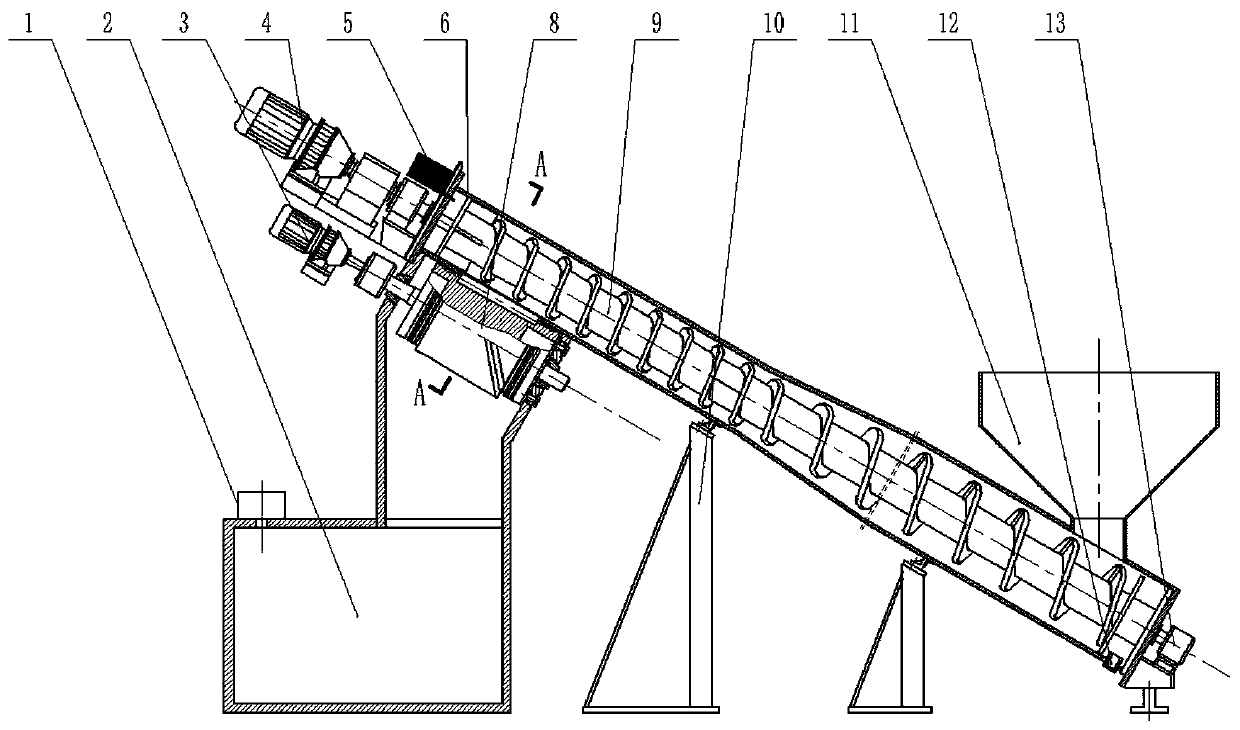

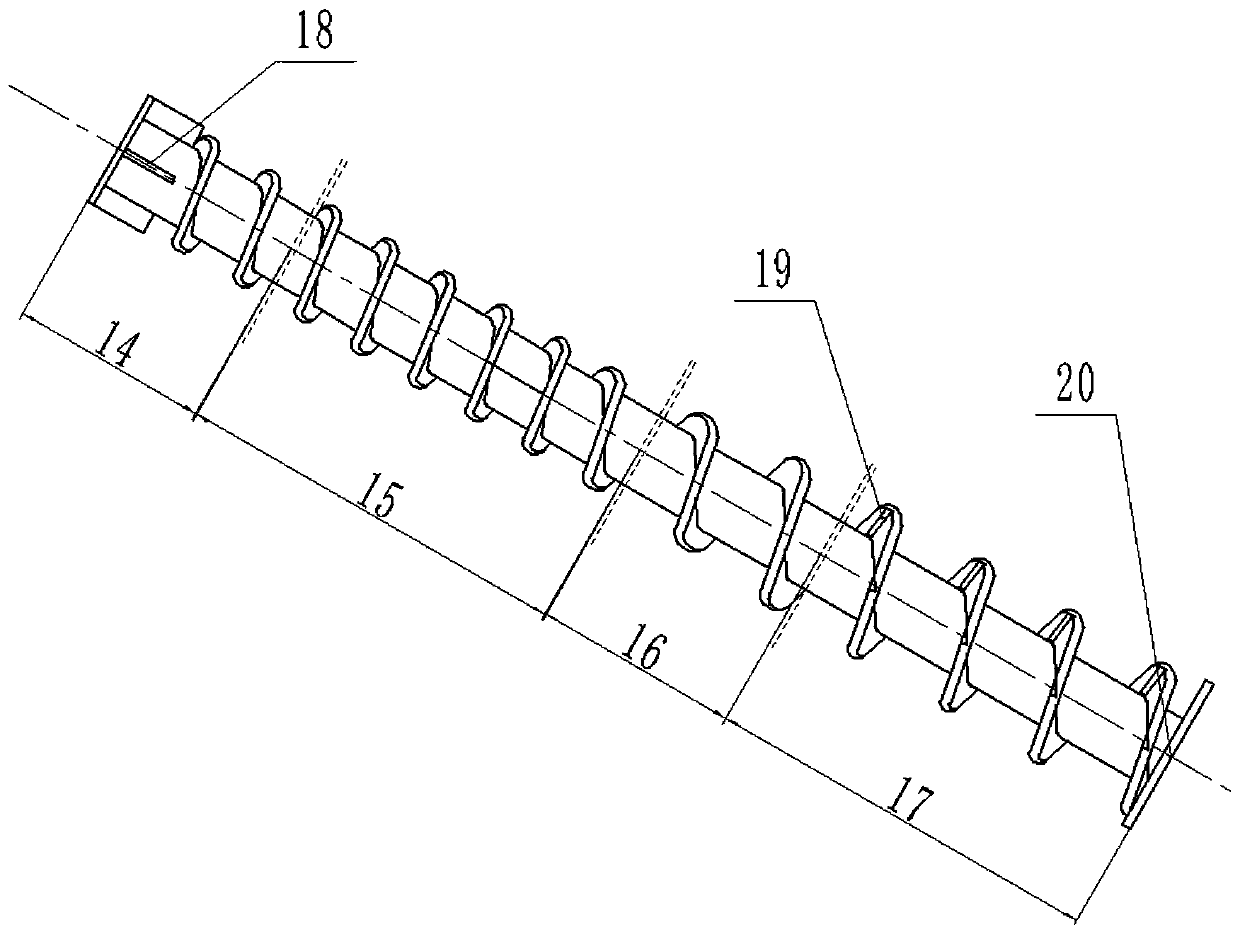

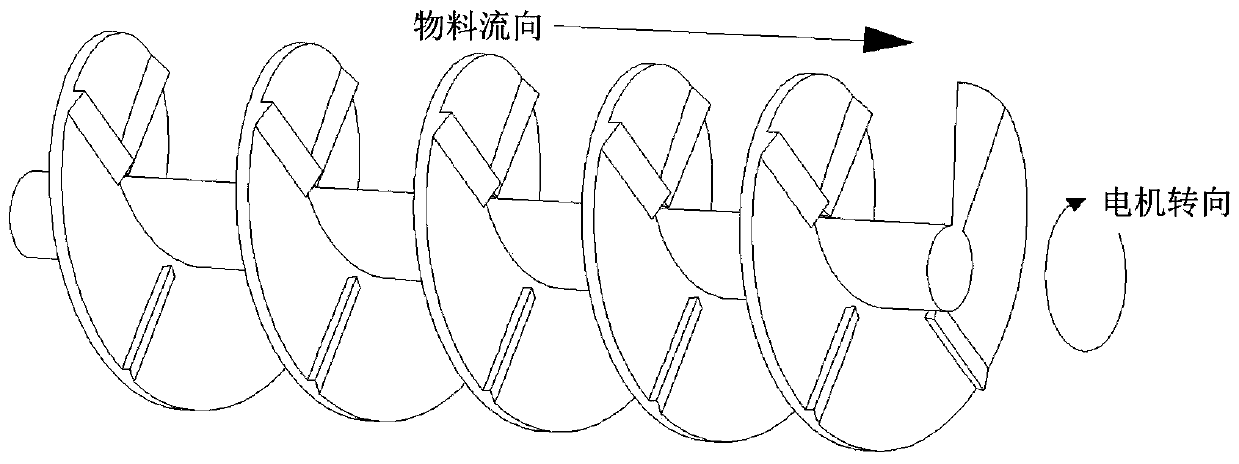

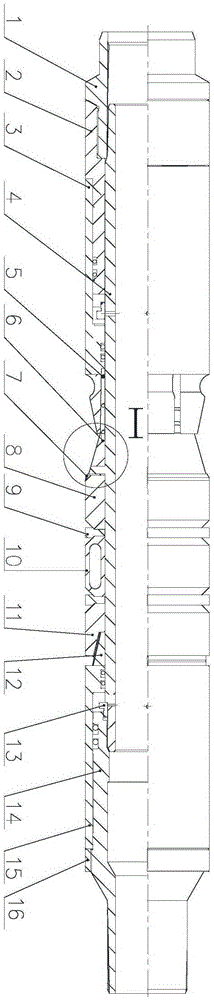

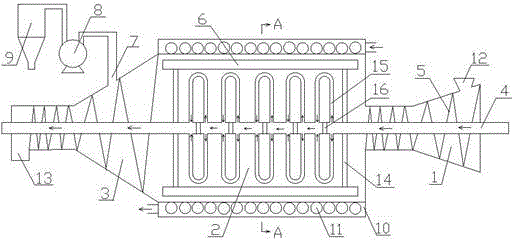

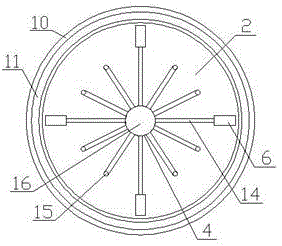

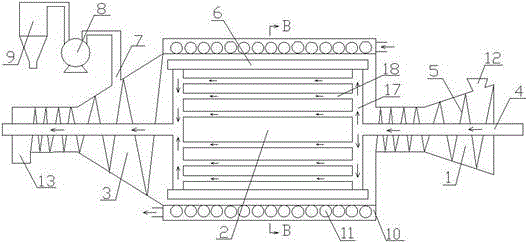

Biological matter straw burning-gasifying feeding apparatus

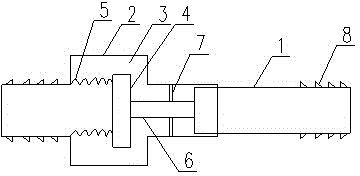

ActiveCN101025269AContinuous and stable feedingEliminate potential safety hazardsPackagingLump/pulverulent fuel feeder/distributionTransformerAgricultural engineering

The charging device of the straw burning and gasification uses the differential variable-pitch double helix to reach the charging continuously especially for the strip biological fuel. The device includes: material barn, the feeding helix, the middle hopper, the dehvery helix; the material barn is on the top which the upper mouth is connected with the upper side of the feeding helix middle which the material drop mouth is connected to the upper mouth of the middle hopper which the low mouth is connected to the upper side of the dehvery helix. The device transfers the straw of 10-200mm into the material barn by the double helix feeder, then it drops into the middle hopper, next the double helix transformer at the bottom of the hopper transfers the straw into the burning and gasification device.

Owner:SOUTHEAST UNIV

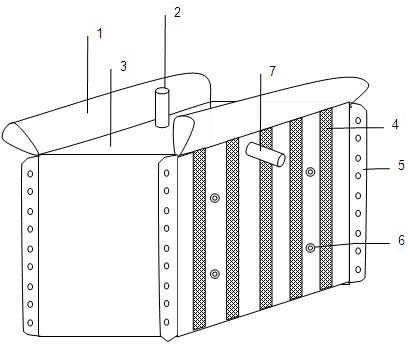

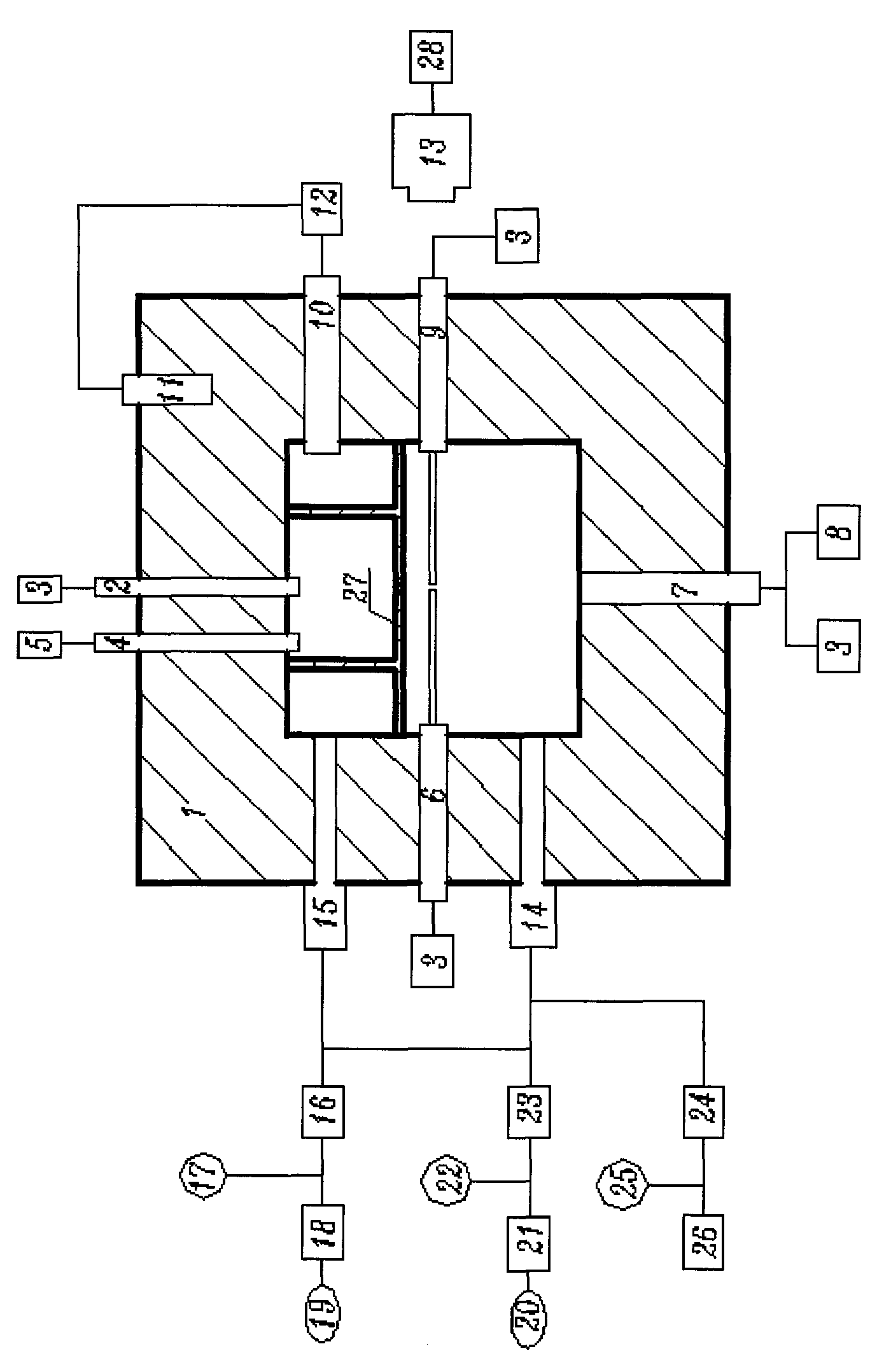

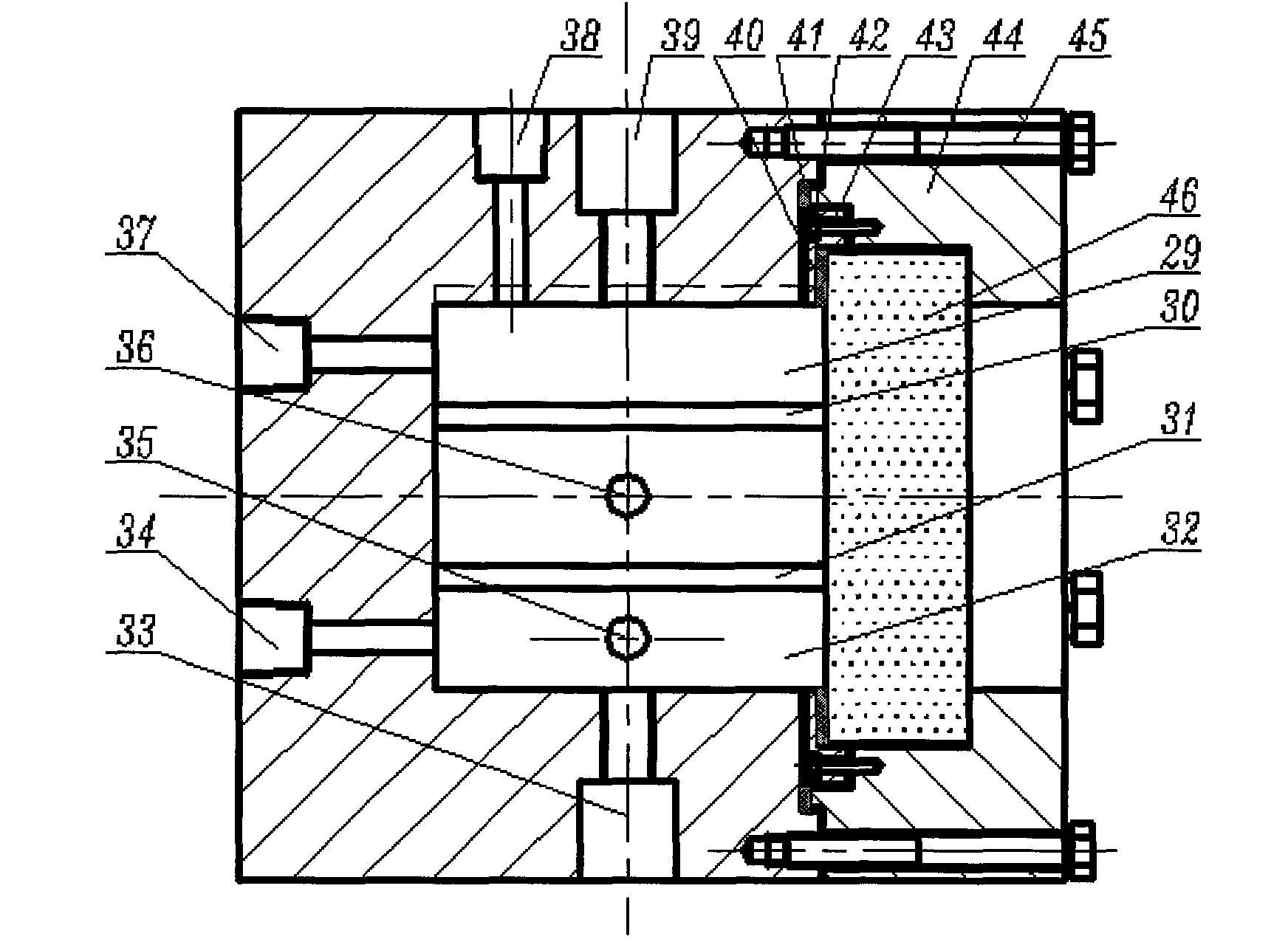

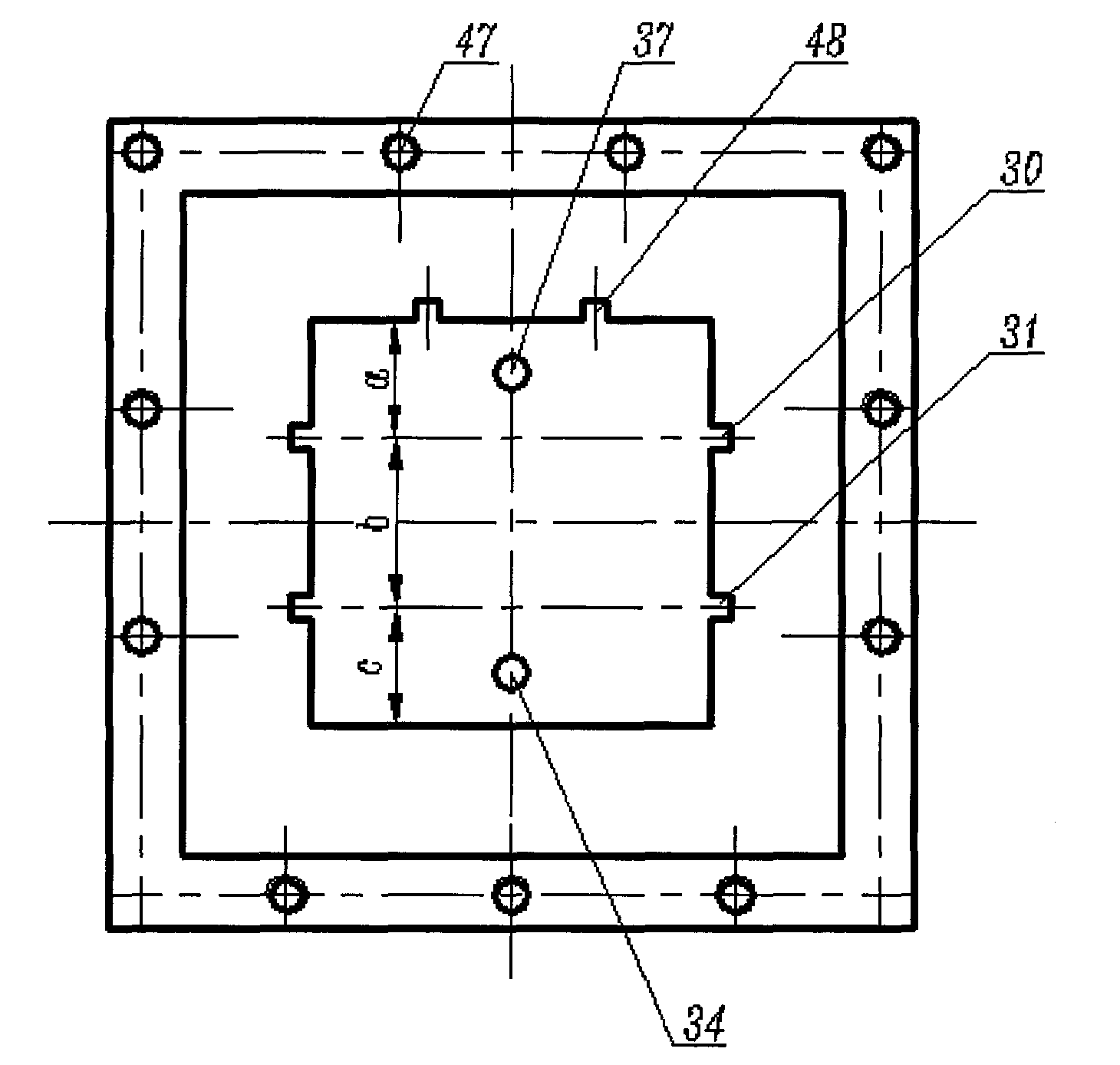

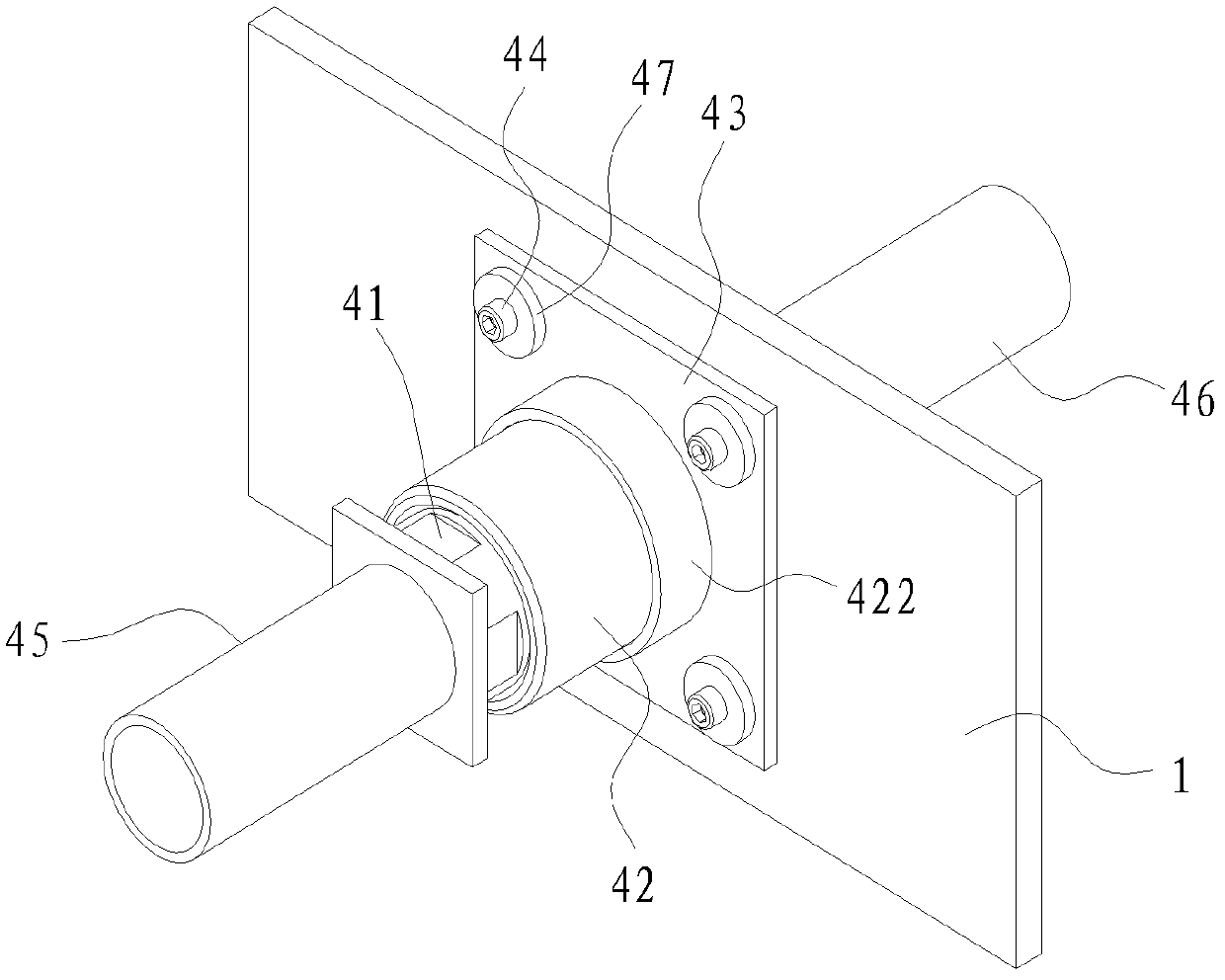

Gas fuel constant volume combustion chamber capable of being internally installed with diaphragm plate

InactiveCN101832174AEasy to spreadSelf-sealingInternal combustion piston enginesInterior spaceExternal combustion engine

The invention discloses a gas fuel constant volume combustion chamber capable of being internally installed with a diaphragm plate, belonging to the combustion field of internal combustion engines. The combustion chamber comprises a body (1), the diaphragm plate (27), a front end cover (44) and a window (46) and the like, and the inner part of the gas fuel constant volume combustion chamber is in a cube shape. The inner wall of the body (1) is provided with N pairs of diaphragm plate slots (63); the diaphragm plate is arranged in one pair of diaphragm plate slots; and the diaphragm plate is provided with holes or slots. When the diaphragm plate is not added, the combustion chamber is an ignition needle center ignition combustion chamber; when the diaphragm plate is added, the body (1) is divided into an upper combustion chamber and a lower combustion chamber thereby; the center at the upper part of the body (1) is provided with an ignition plug (2); and the center at the bottom of the body (1) is provided with an ignition plug type pressure sensor (7). When the built-in diaphragm plate is not adopted, the invention can be used for studying streamline flow combustion characteristics of gas fuel; when the built-in diaphragm plate is adopted, the upper combustion chamber (29) is used for the combustion study of spark ignition; and the lower combustion chamber (32) is used for the study of compression ignition or ignition or flame slit quenching effect.

Owner:BEIJING UNIV OF TECH

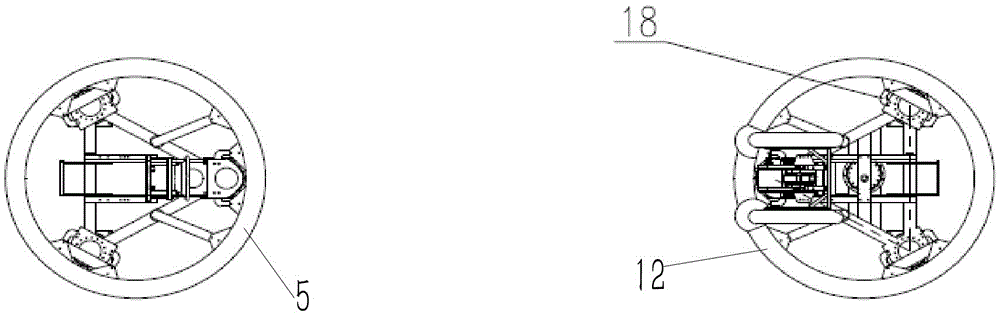

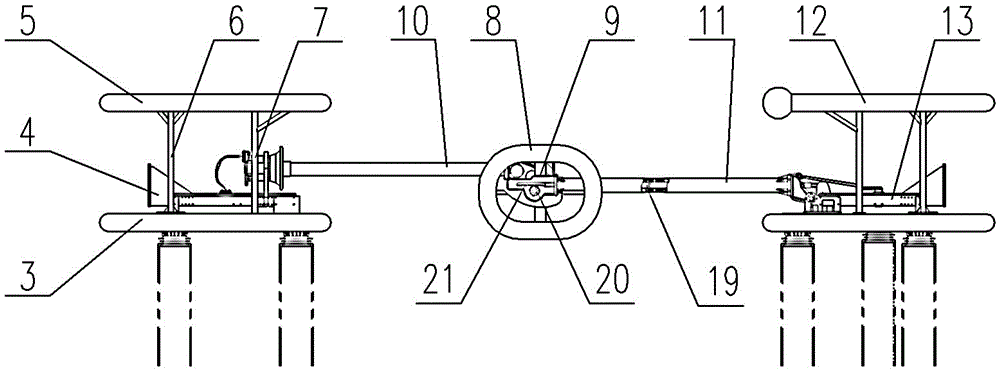

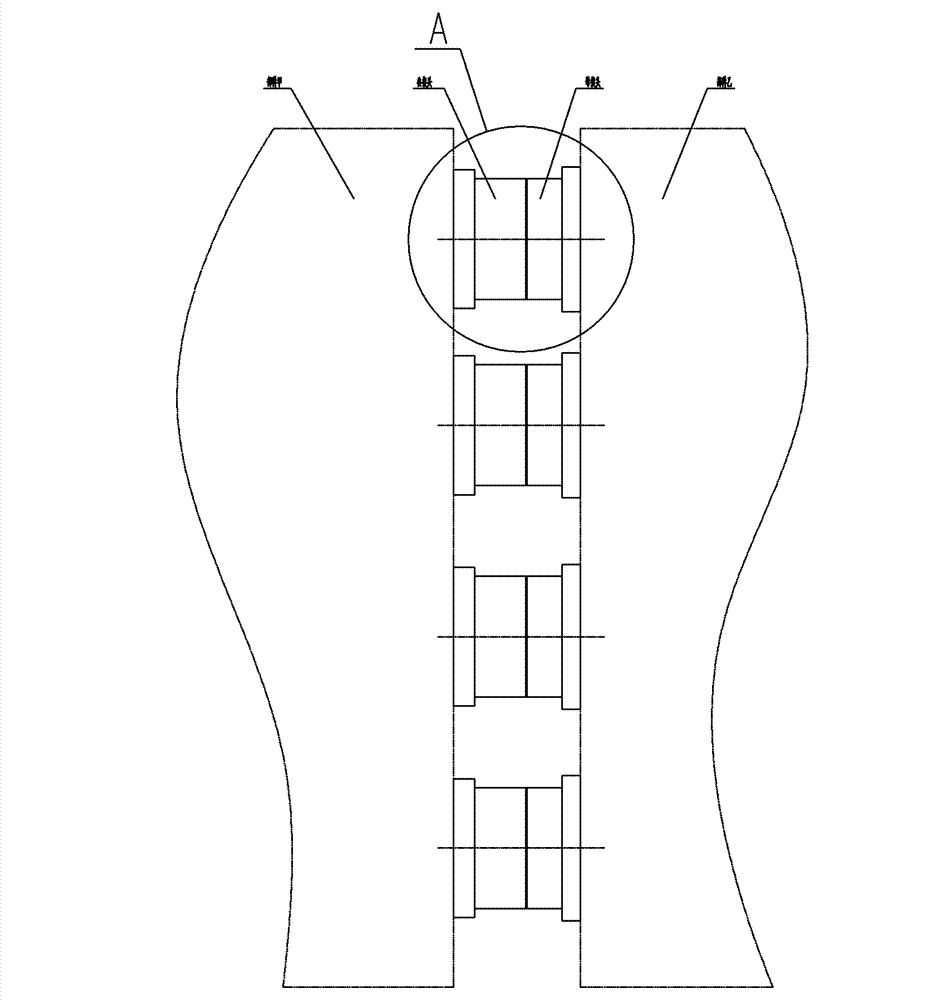

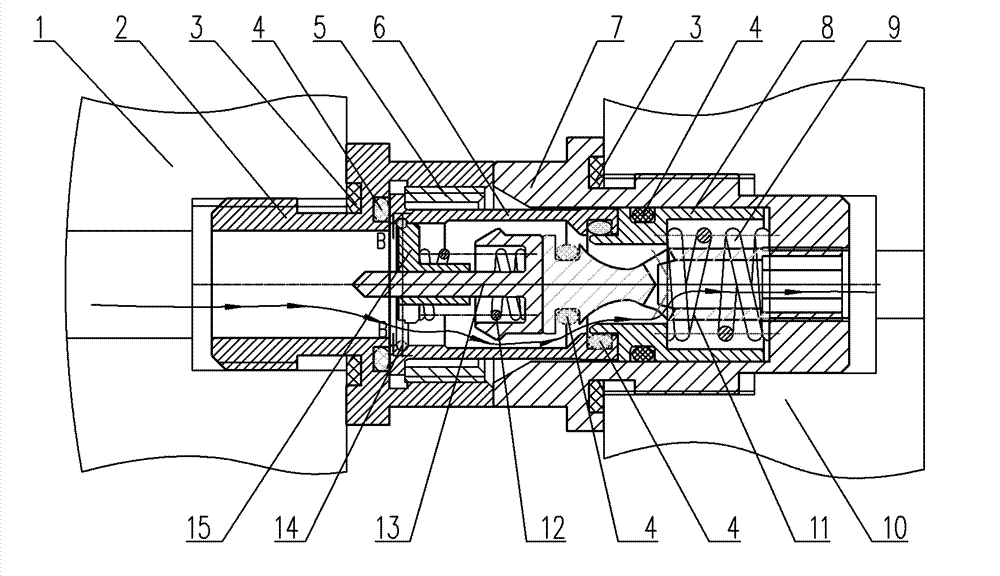

Isolating switch

ActiveCN104319157ASelf-sealingReduce erosionHigh-tension/heavy-dress switchesAir-break switchesMechanical engineering

The invention discloses an isolating switch. In the isolating switch, a moving main contact is formed by annular contact fingers which are fixed in a conducting tube or contact fingers which are annularly distributed in the circumferential direction of the conducting tube; a moving arc contact is a contact rod which penetrates into the inner ring of the moving main contact movably and extends front and back, the front end of the contact rod is provided with an arc striking disc, and the rear end of the contact rod is provided with a guide rod segment which is located behind the moving main contact and movably assembled on a guide frame fixed to the inner wall of a guide rod in a front-and-back guide mode; the guide frame is provided with a front supporting wall and a rear supporting wall, the guide rod segment penetrates through the front supporting wall and the rear supporting wall, and the front supporting wall and the rear supporting wall are arranged front and back in a spaced mode; a convex stop shoulder stopped by the front supporting wall is arranged on the periphery of the guide rod segment in a convex mode, and a return spring arranged on the periphery of the guide rod segment in a sleeving mode is arranged between the convex stop shoulder and the rear supporting wall in an abutting mode. In the opening state, part or whole of a forward opening will be sealed by the arc striking disc, so that debris in an outer space is less likely to fall onto the moving main contact through the forward opening of the moving main contact, and the moving main contact is less likely to be corroded by the surroundings in the opening state.

Owner:HENAN PINGGAO ELECTRIC +1

Pretightening sealing ball valve device

InactiveCN101603601AAchieve self-sealingSelf-sealingPlug valvesOperating means/releasing devices for valvesGear driveGear wheel

The invention relates to a pretightening sealing ball valve device which comprises a ball valve lower body, a spring, a sealing metal body, a sealing ring, a ball valve, a rack, a gear, hydraulic transfer tubes, a ball valve upper body and tightening screw nails. The ball valve lower body is connected with the ball valve upper body through the tightening screw nails; the ball valve upper body and the ball valve lower body are provided with circular holes for assembling the rack and the gear; the spring is arranged below the ball valve lower body; the sealing metal body and the ball valve are arranged inside the ball valve lower body and positioned above the spring; carbon materials are laid on the surfaces of the sealing metal body and the ball valve; the gear is connected with the ball valve through interlocking teeth; the rack is meshed with the gear through teeth, and fixed on the ball valve upper body and the ball valve lower body through the hydraulic transfer tubes at two ends; and when the ball valve is required to work, the hydraulic transfer tubes transfer liquid so as to exert a force on the rack, so that the rack rotates the gear, and the gear drives the ball valve to rotate to lead the ball valve to be in a closing mode. As the spring is arranged below the ball valve, the ball valve has self-tightness, thereby ensuring the tightness of the ball valve to be more reliable, and improving the feasibility of the operation.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

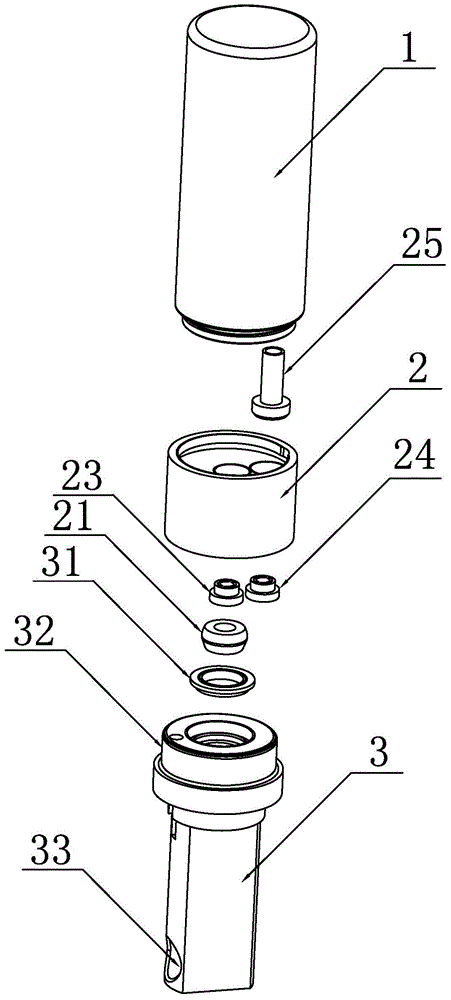

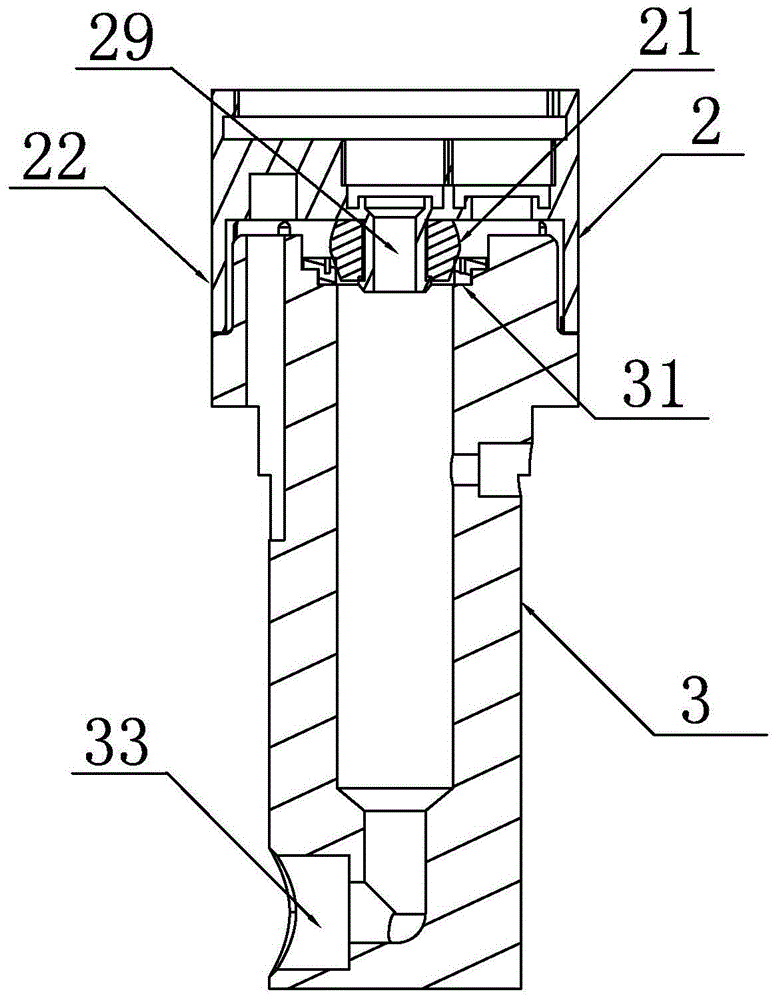

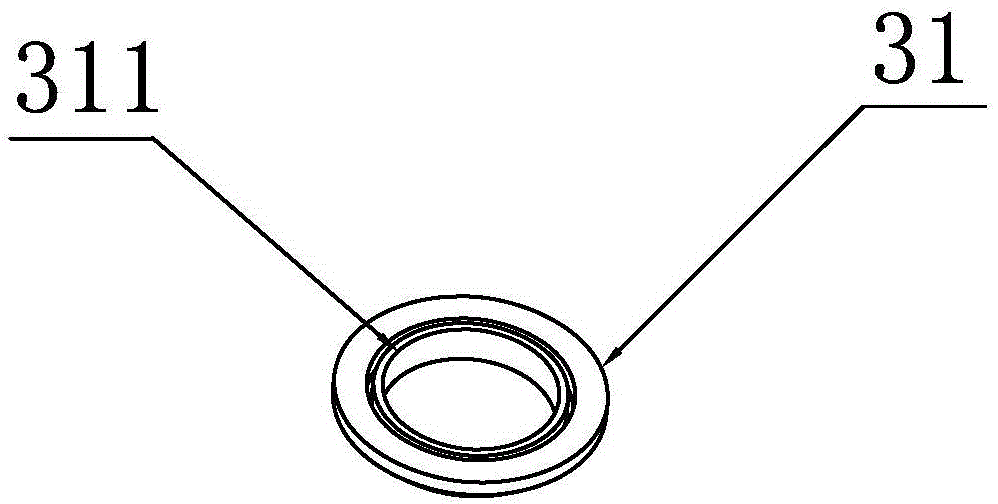

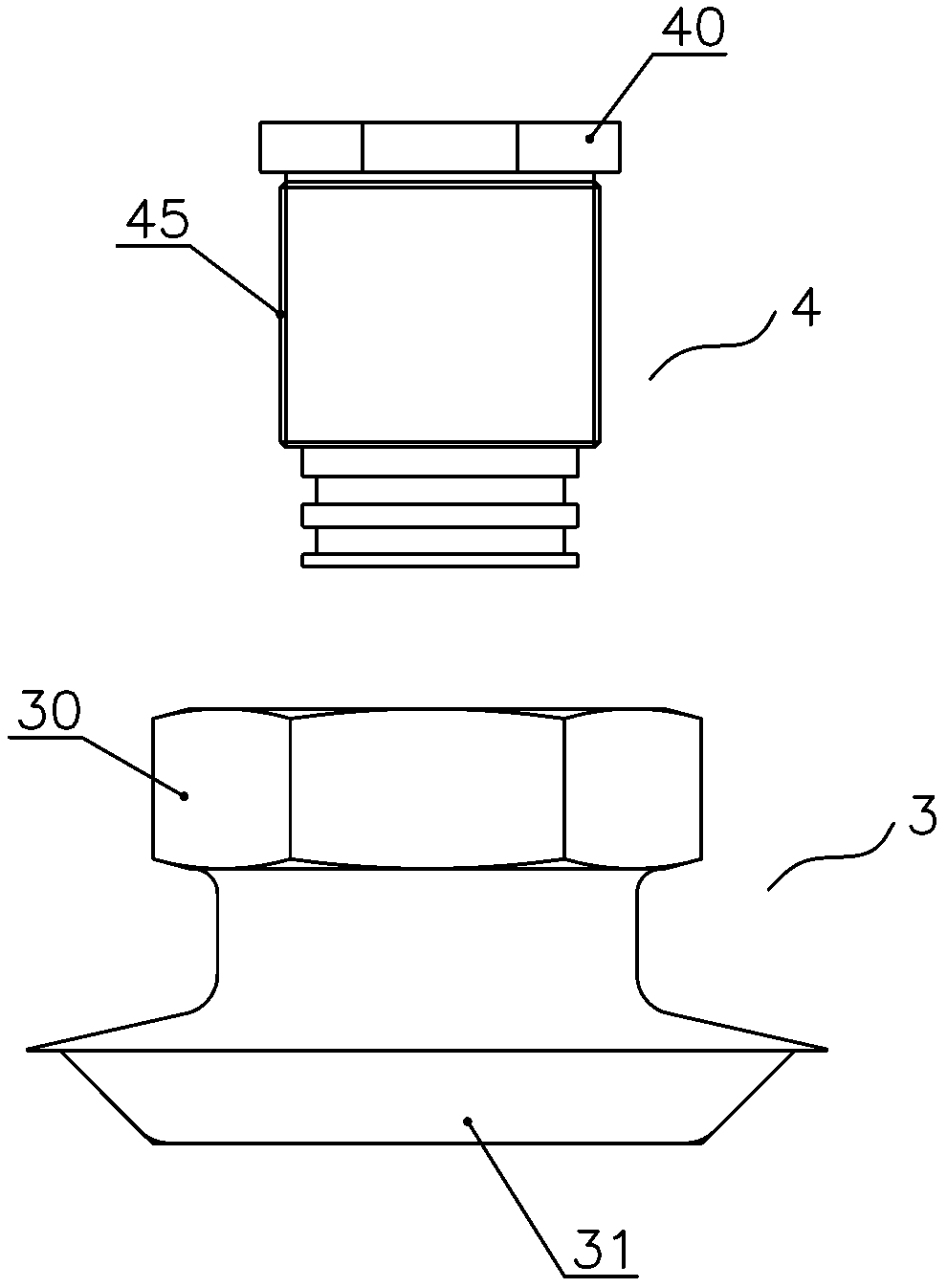

Liquid storage device and storage cover of dosing machine

ActiveCN104523172ASelf-sealingSimple and convenient disassemblyKitchen equipmentEngineeringLiquid storage

The invention provides a liquid storage device for a dosing machine. The liquid storage device comprises a liquid storage cavity, a storage cover and a hollow storage base. The bottom end of the storage cavity is connected with the top end of the storage cover. The hollow storage base is fixed to the dosing machine. A first sealing structure is arranged at the bottom end of the storage cover. A second sealing structure is arranged at the top end of the storage base. The storage cover is placed on the storage base after being provided with the storage cavity, and the liquid storage device is sealed by depending on self-sealing of the first sealing structure and the second sealing structure. The storage cavity with the storage cover can be placed into the storage base in any direction to achieve self-sealing, the assembling and disassembling mode is simple and convenient, the principle is ingenious, cost is low, and the sealing effect is stable and reliable. The invention further provides the storage cover which can be connected with the storage cavity of the dosing machine in a matched mode, and the self-sealing function of the storage cavity and the storage base is achieved.

Owner:珠海优特智厨科技有限公司

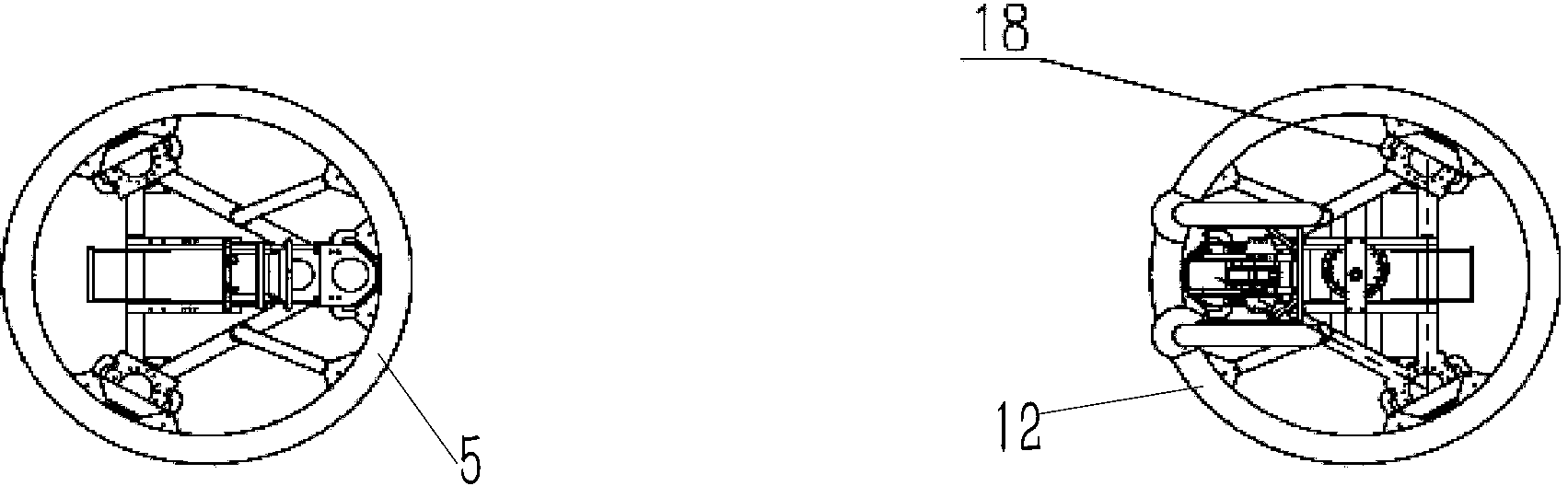

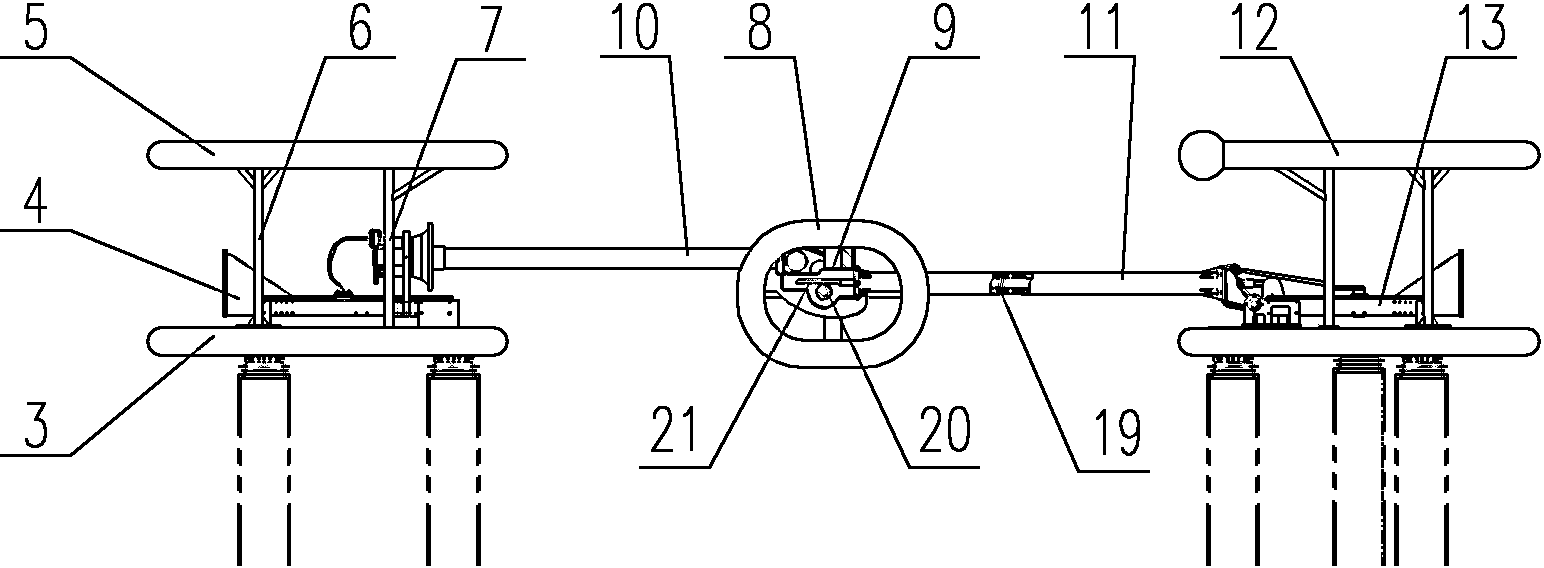

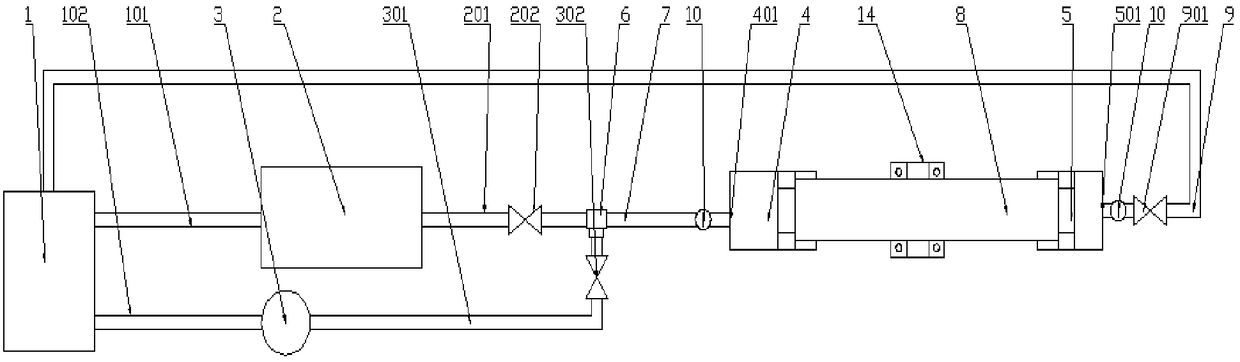

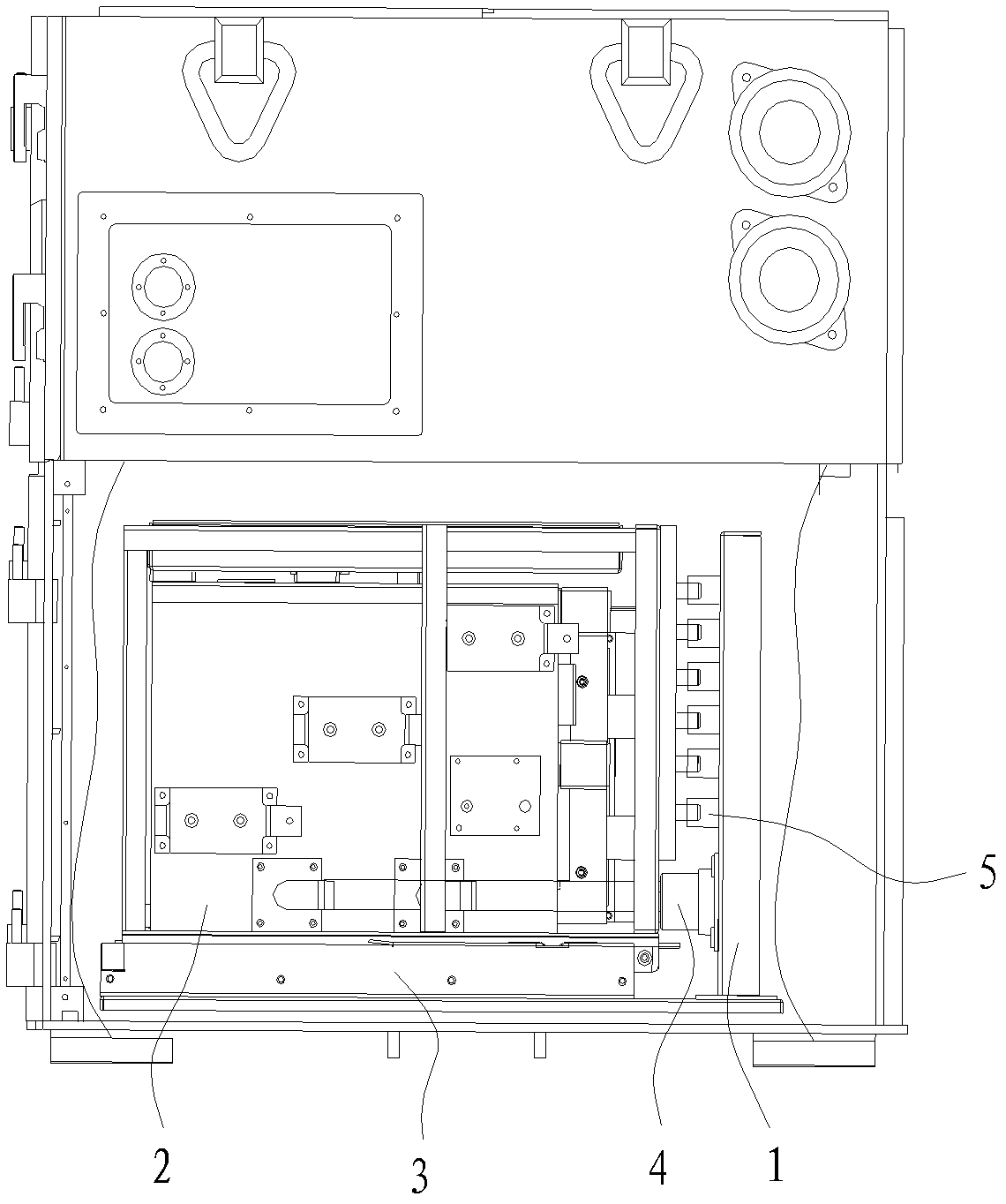

Pipe airtightness detecting worktable,

ActiveCN108562413AShorten the timeImprove work efficiencyMeasurement of fluid loss/gain ratePipe fittingEngineering

The invention discloses a pipe airtightness detecting worktable. The worktable comprises an inflation device, a high-pressure auxiliary tank, a detecting device, a first pipe member airtight pressurepositioning device, and a second pipe member airtight pressure positioning device; the detecting device is provided with a first air outlet pipe; the high pressure auxiliary tank is connected to the airing device through a second air inlet pipe; the high-pressure auxiliary tank is further provided with a second air outlet pipe, and the first air outlet pipe and the second air outlet pipe are connected to the main air intake pipe through a three-way pipe; the main intake pipe is connected to the first pipe member airtight pressure positioning device, and the other end of the first pipe member airtight pressure positioning device is connected with a pipe member. The other end of the pipe member is connected with the second pipe member airtight pressure positioning device, and the other end of the second pipe member airtight pressure positioning device is connected with a main air outlet pipe; the worktable controls the high-pressure auxiliary tank and the detecting device to pressurize the pipe member through the electromagnetic valve, thereby reducing the time for detecting the pipe fitting and improving the working efficiency.

Owner:武汉金福汽配有限公司

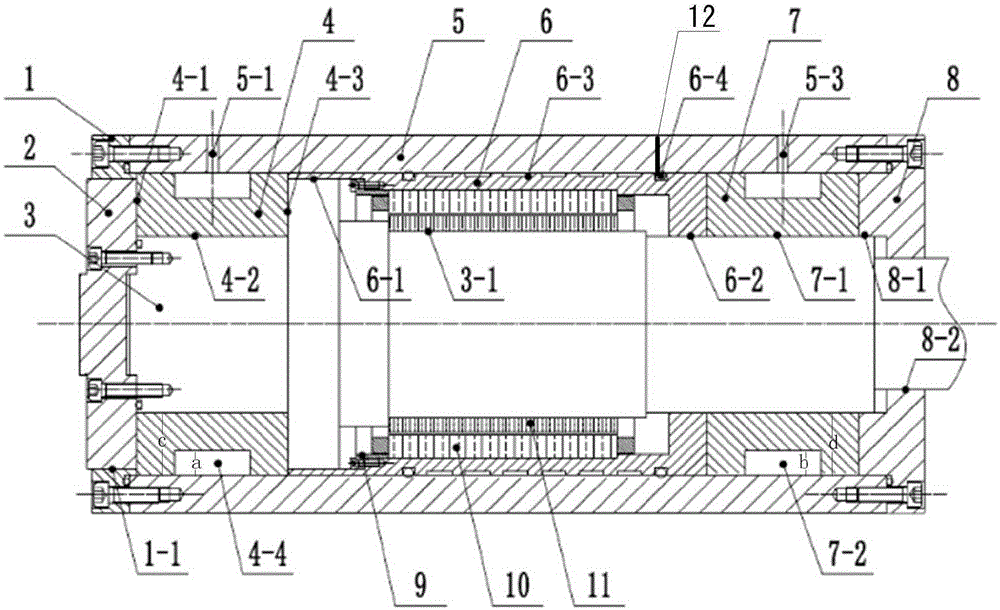

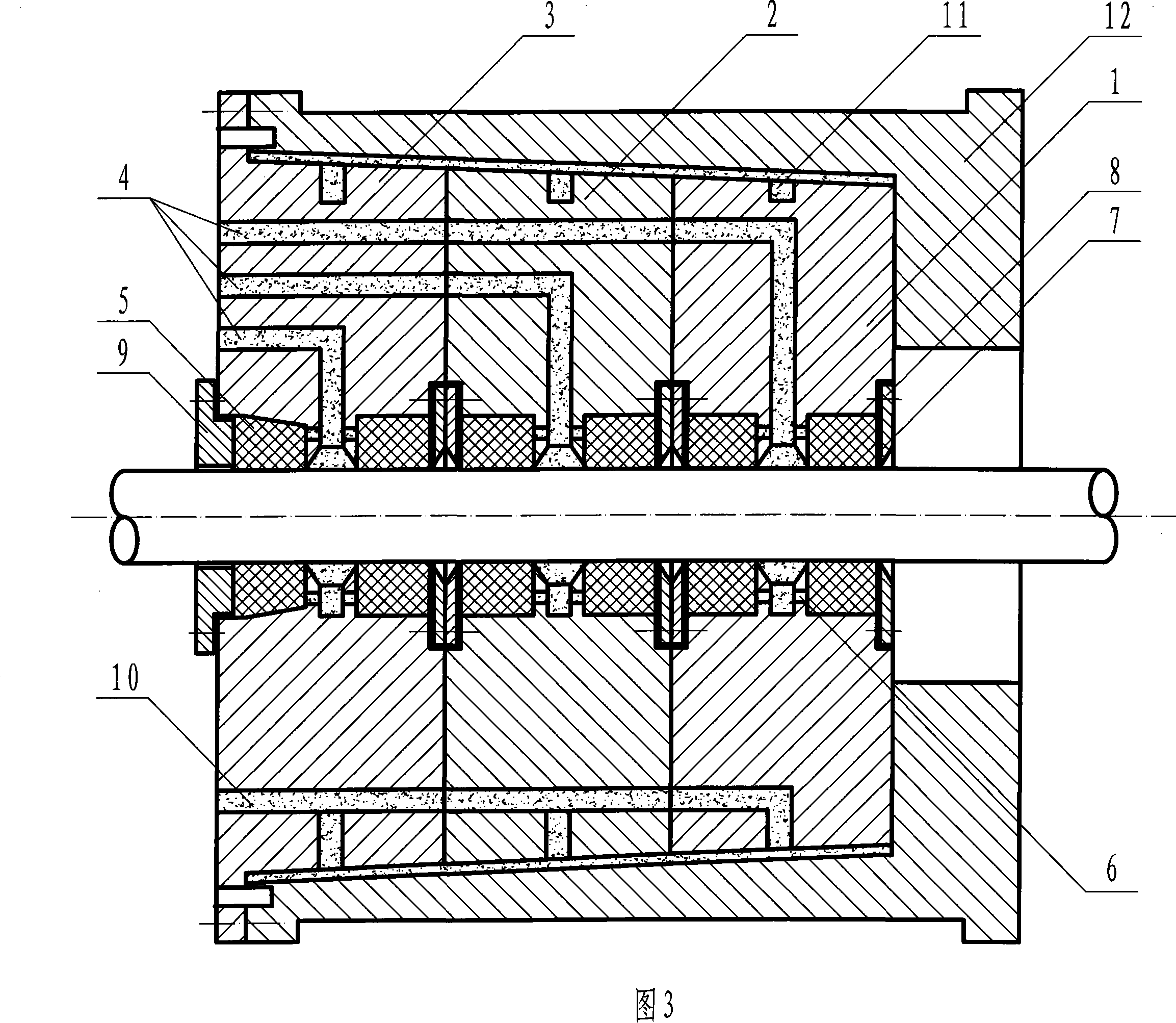

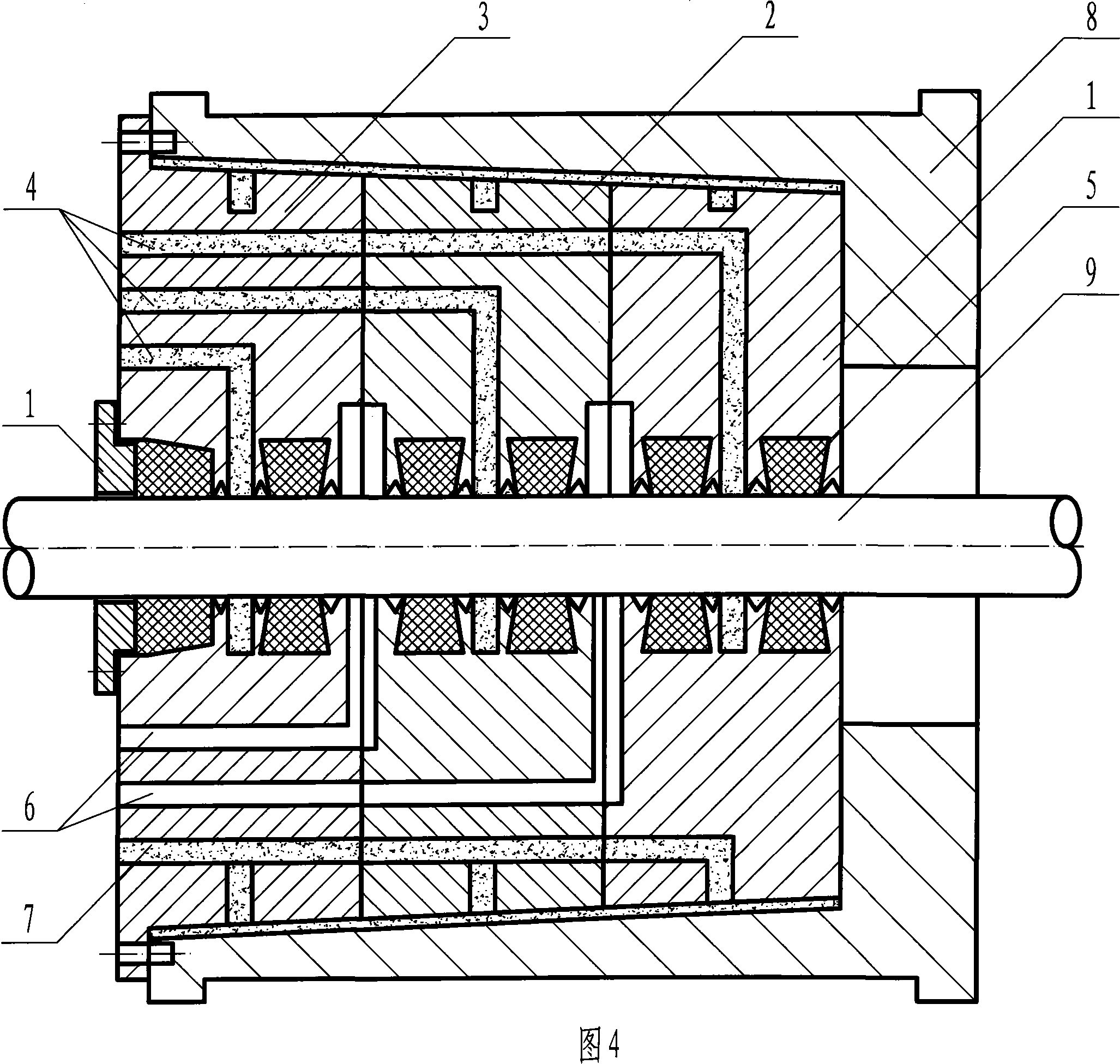

Self-lubricating self-sealing graphite gas-floatation electrostatic pressure spindle structure

ActiveCN105195764ALow costImprove rigidityLarge fixed membersMaintainance and safety accessoriesGraphiteLubricant

The invention relates to a self-lubricating self-sealing graphite gas-floatation electrostatic pressure spindle structure. The spindle structure comprises a spindle, a thrust collar arranged on the end part of the spindle, a sleeve arranged outside the spindle in a sleeving manner, a motor stator and a motor rotor, wherein a front bearing bush and a rear bearing bush which are made of a porous material are arranged between the sleeve and the spindle; the front bearing bush is arranged on the front end of an inner hole of the sleeve; the rear bearing bush is arranged on the rear end of the inner hole of the sleeve; a front end cover and a rear end cover are respectively arranged on both ends of the spindle. Because a porous bearing which has good radial rigidity and thrust rigidity is adopted and a throttler and the bearing are integrated into a whole, the cost of the throttler is saved; the front bearing bush and the rear bearing bush are made of the porous graphite material, and because graphite is a solid lubricant per se and a gas membrane is a gas lubricant per se while floating, the spindle does not easily undergo bearing shoe grinding and has good self-lubricating property when the rotating stability is relatively poor; the spindle structure disclosed by the invention also has the advantages of simple structure, relatively stable sealing property, difficulty in inclination of the spindle, stable swinging operation and the like.

Owner:SUZHOU CHENNA AUTOMATION TECH CO LTD

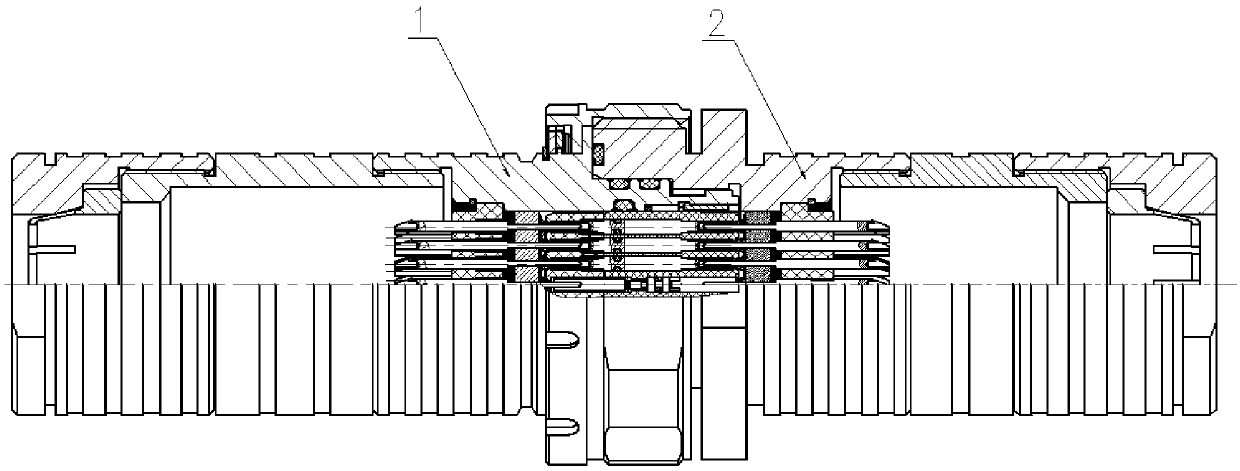

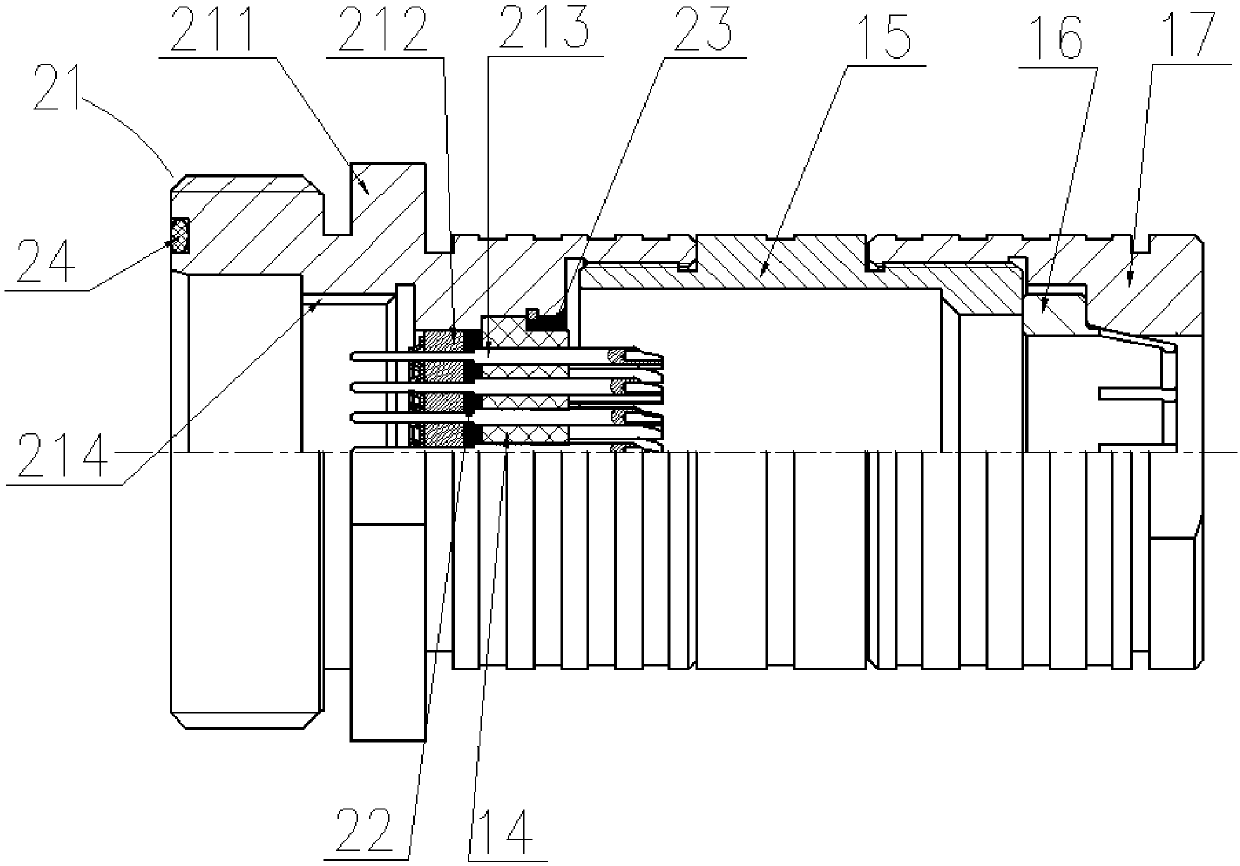

Circular underwater sealing electric connector capable of being plugged in blind manner

PendingCN109560420ASelf-sealingImprove maintainabilityEngagement/disengagement of coupling partsRelieving strain on wire connectionElectricityUnderwater

The invention relates to a circular underwater sealing electric connector capable of being plugged in a blind manner. The electric connector comprises a plug and a socket, wherein the plug comprises aconnecting nut, an anti-loose mechanism and a plug sealing-connecting assembly; and the socket comprises a socket sealing-connecting assembly. The circular underwater sealing electric connector capable of being plugged in the blind manner provided by the invention has the advantages that due to the fact that the plug and the socket are both sealed by sintering and forming a glass sintering layerand a contact part, and a sealing jack insulation assembly is arranged at the plugging end of the plug, so that the internal structure of the jack insulation assembly can realize self-sealing, and theoutside of the jack insulation assembly is sealed with the plug shell; when water enters the plugging end plane of the plug, the sealing structure of the jack insulation assembly plays an isolating role, so that short circuit in the plug caused by water entrance to the internal structure of the plug can be avoided; and after water entrance, the electric connector can be used as normal by only performing a simple operation on the plug, so that high product maintainability and high reliability are achieved, and the electric connector is suitable for application occasions with high-reliability sealing requirements.

Owner:杭州航天电子技术有限公司

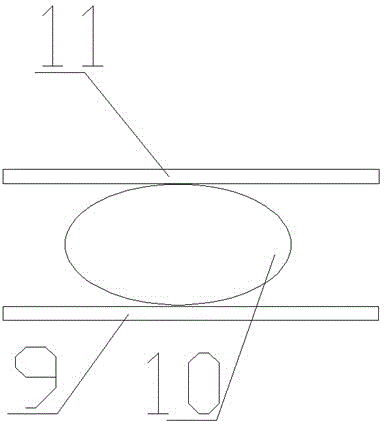

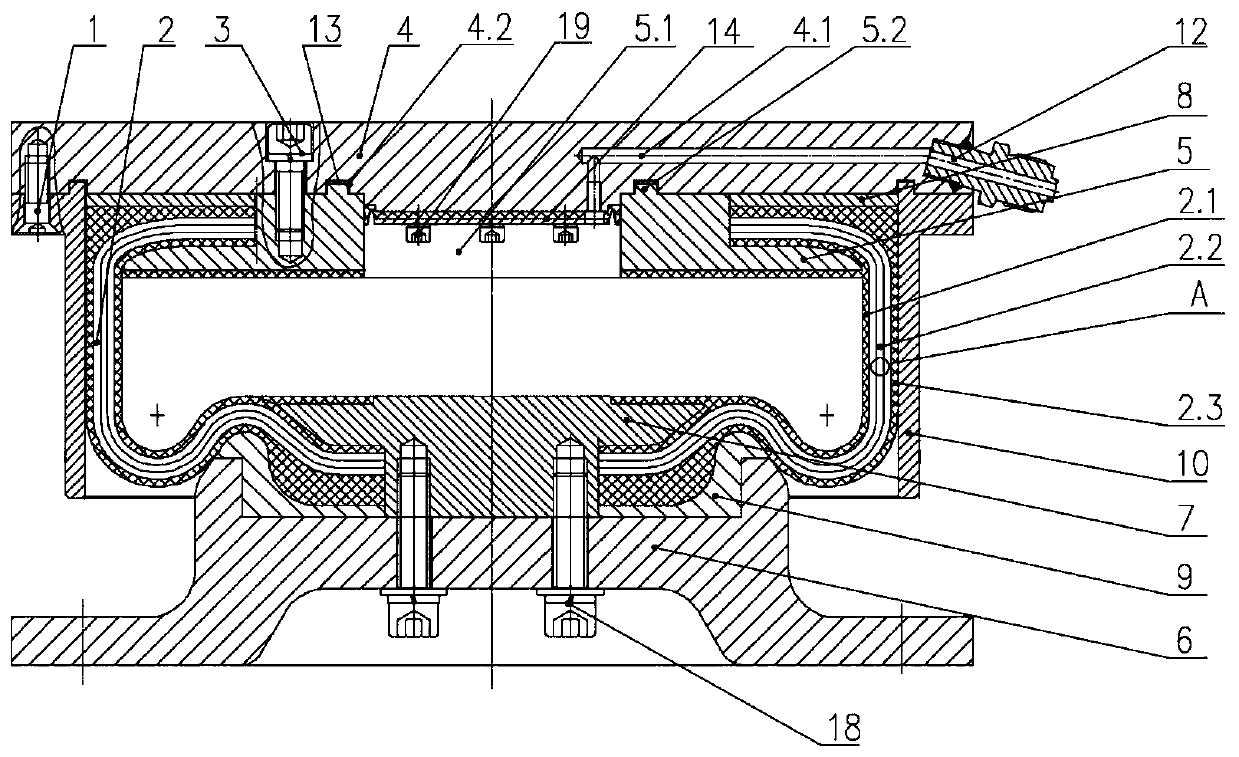

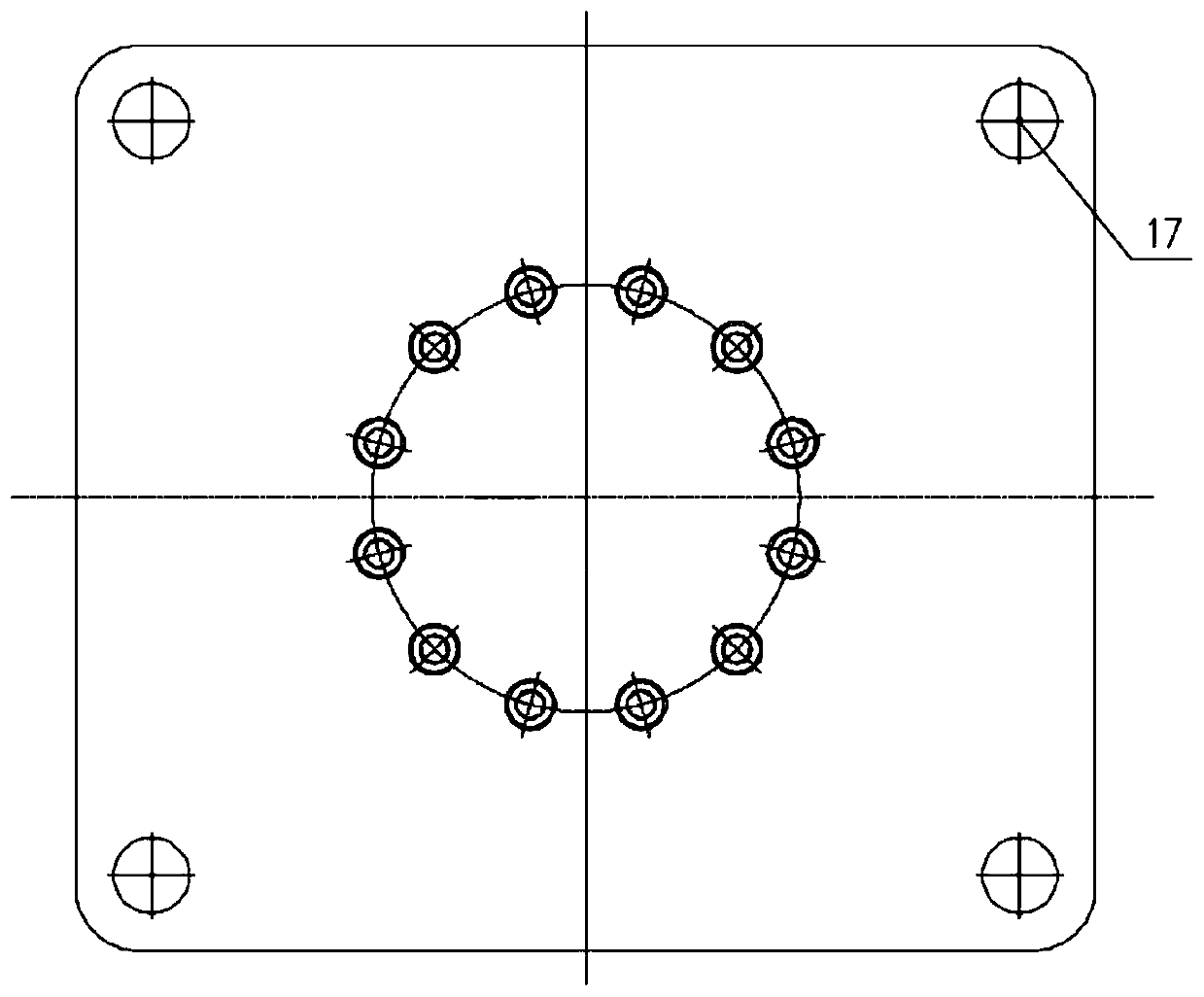

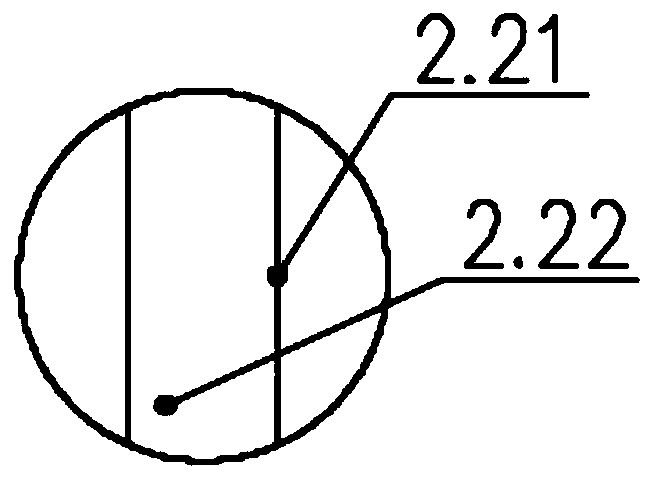

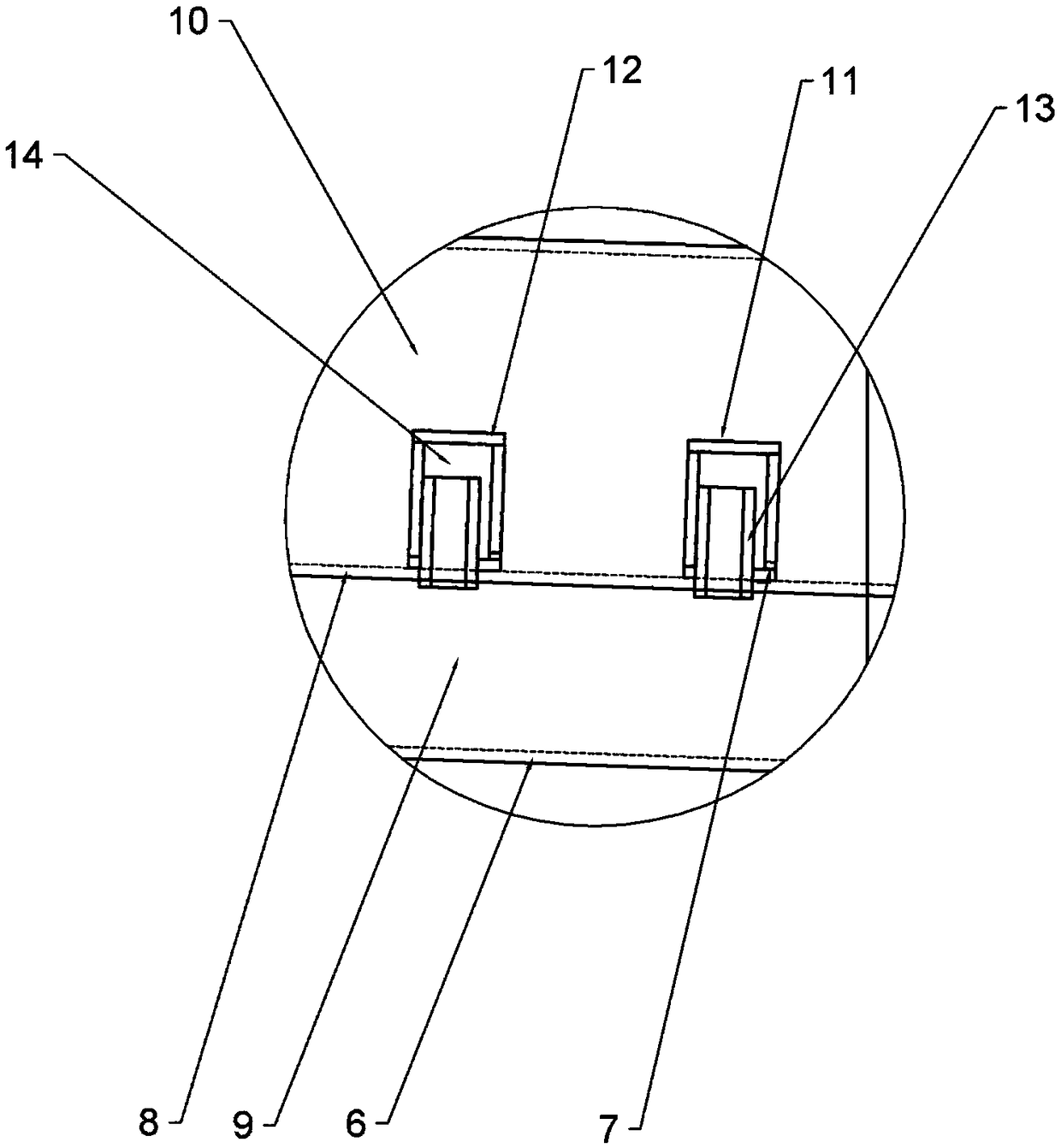

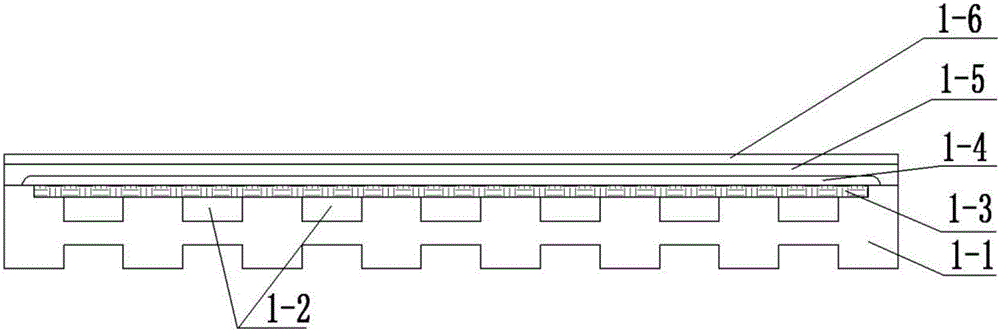

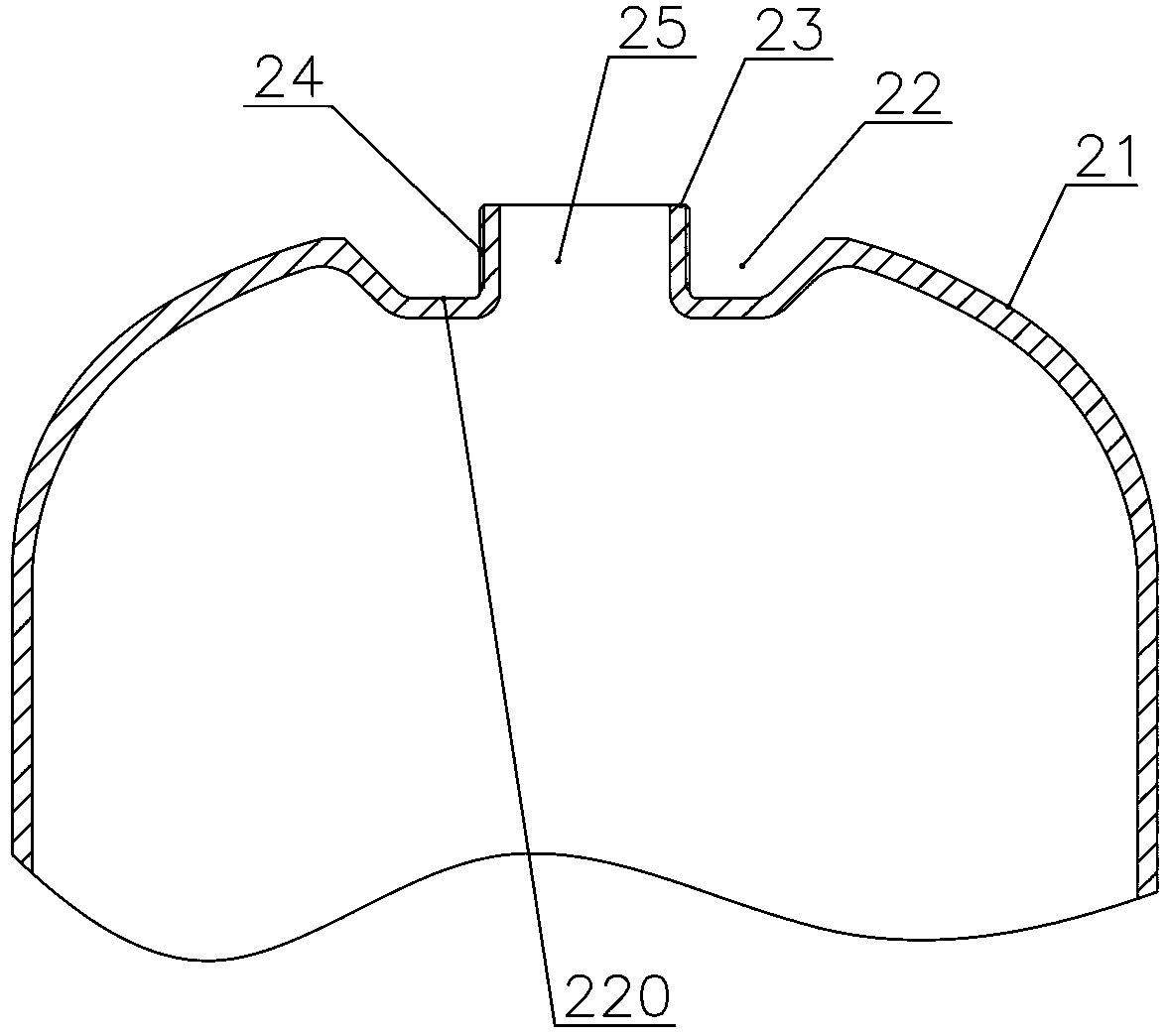

Cord thread integral winding reinforced rubber air spring

ActiveCN110159695AImprove overall connectivityImproves pull-out resistanceSpringsGas based dampersAir springReinforced rubber

The invention discloses a cord thread integral winding reinforced rubber air spring. The cord thread integral winding reinforced rubber air spring comprises upper and lower flanges, and a bag body integrally vulcanized with upper and lower pressing rings; the upper flange is connected with an upper cover plate by an upper fastening piece; the lower flange is connected with a lower cover plate by alower fastening piece; the upper and lower pressing rings are arranged between the bag body and the upper and lower cover plates; a constraint flange connected with the upper cover plate sleeves thebag body; the bag body consists of an inner rubber layer, a skeleton layer and an outer rubber layer; the inner rubber layer is integrally vulcanized with the upper and lower flanges; the outer rubberlayer is integrally vulcanized with the upper and lower pressing rings; and cord threads in the skeleton layer perform the cross netty winding on the inner rubber layer and the upper and lower flanges to form a net-structured cord thread layer capable of integrally bonding the upper and lower flanges.

Owner:NAVAL UNIV OF ENG PLA

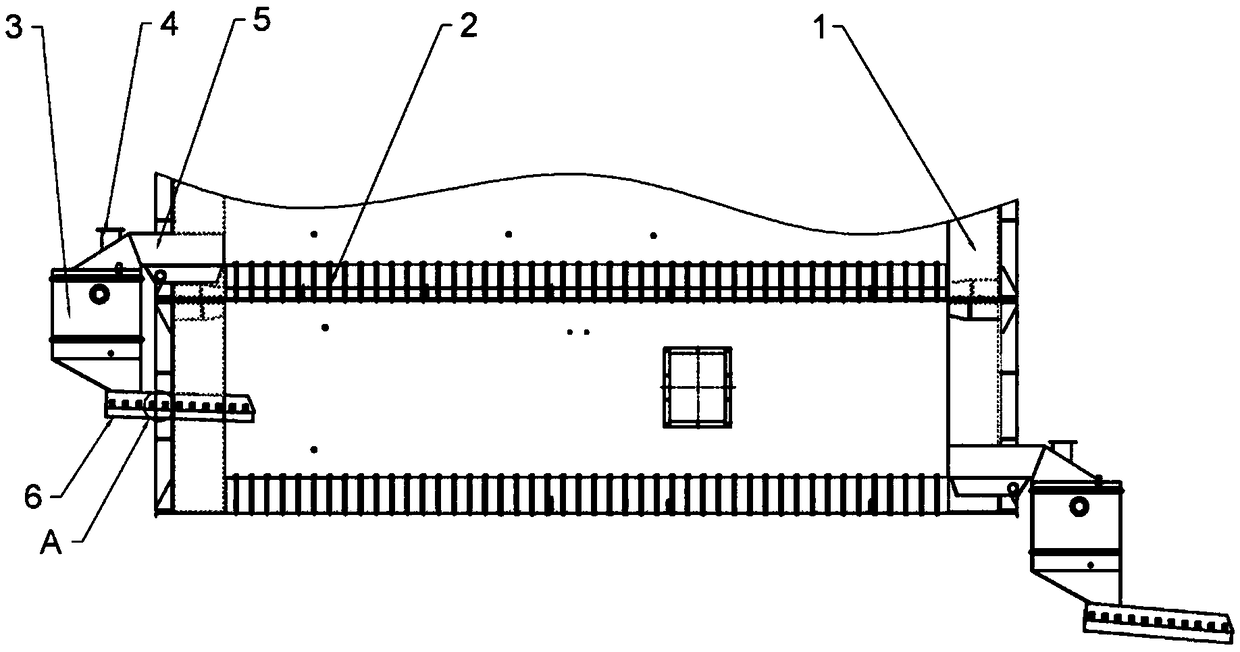

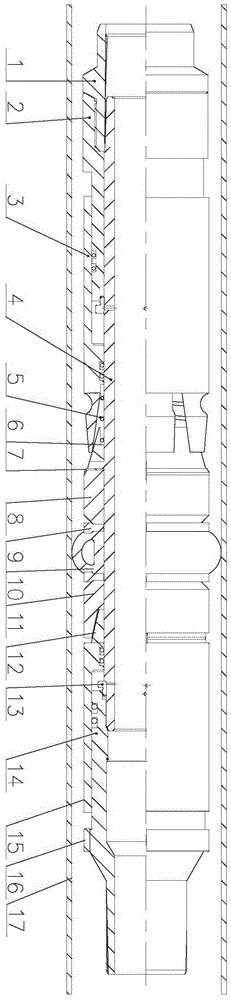

Multi-section spiral continuous feeding device for particle materials

The invention discloses a multi-section spiral continuous feeding device for particle materials. The multi-section spiral continuous feeding device for the particle materials comprises a spiral conveying device and a gear feeding device; the spiral conveying device comprises a machine cylinder, a feeding port, a discharging port, a spiral conveyor, an upper motor, a material scraper plate, a material baffle, a spraying port, a dust outlet and a support; and the gear feeding device comprises a material bin, a feeding gear, a material leakage blocking groove, a flange disc, a mechanical seal anda bearing. The materials can be compacted into a material plug in a reducing variable-pitch spiral mode, and self-sealing of the materials is formed; and the material plug can be smashed through thegear feeding device, and then the materials can be uniformly, accurately and efficiently fed. According to the multi-section spiral sealing feeding device for the particle materials, the materials canbe continuously fed into a sealed continuous cracking reactor, and the purposes that safe production is achieved, continuous feeding is achieved, the production efficiency is improved, and energy sources are saved are achieved.

Owner:BEIJING UNIV OF CHEM TECH

Incoming and outgoing sand roasting device

PendingCN109434015AAvoid getting lostAchieving tightnessMould handling/dressing devicesMaterials science

The invention belongs to the technical field of casting material treatment equipment and particularly discloses an incoming and outgoing sand roasting device which comprises a furnace body and is characterized by further comprising a sand inlet and outlet structure; the sand inlet and outlet structure comprises a sealed tank, a sand level control portion and a discharge portion and is arranged onthe side wall of the furnace body; the upper part of the sealed tank is provided with a sand inlet; the lower part of the sealed tank is provided with a sand outlet; the sealed tank is communicated with the furnace body through the sand inlet; the sand outlet is communicated with the discharge portion; and the sand level control portion can control discharge of the discharge portion. The device can realize sealing and automatic sand incoming and outgoing while sands go in and out.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Zinc-aluminum-magnesium rare earth corrosion-resistant coating

InactiveCN102534305AImprove the effect of cathodic protectionReduce porosityMolten spray coatingRare earthZinc

The invention discloses a zinc-aluminum-magnesium rare earth corrosion-resistant coating, which contains the following components in percentage by weight: 5-23 percent of Al, 0.05-0.1 percent of Mg, 0.05-1 percent of rare earth metal RE and the balance of Zn. In the zinc-aluminum-magnesium rare earth corrosion-resistant coating, the rare earth metal RE is at least one of La and Ce. The zinc-aluminum-magnesium rare earth corrosion-resistant coating in accordance with the invention has wide application range, and meets the steel and iron corrosion resistance requirements under different environments; and brine corrosion resistance performance is over 2 times that of a pure zinc layer.

Owner:STATE GRID CORP OF CHINA +1

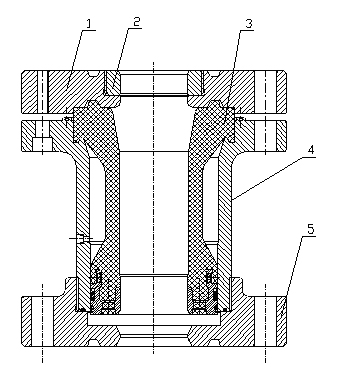

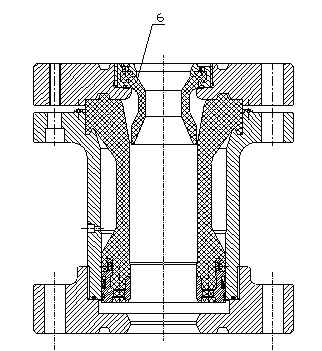

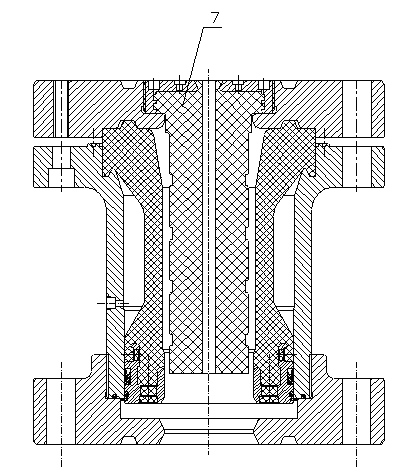

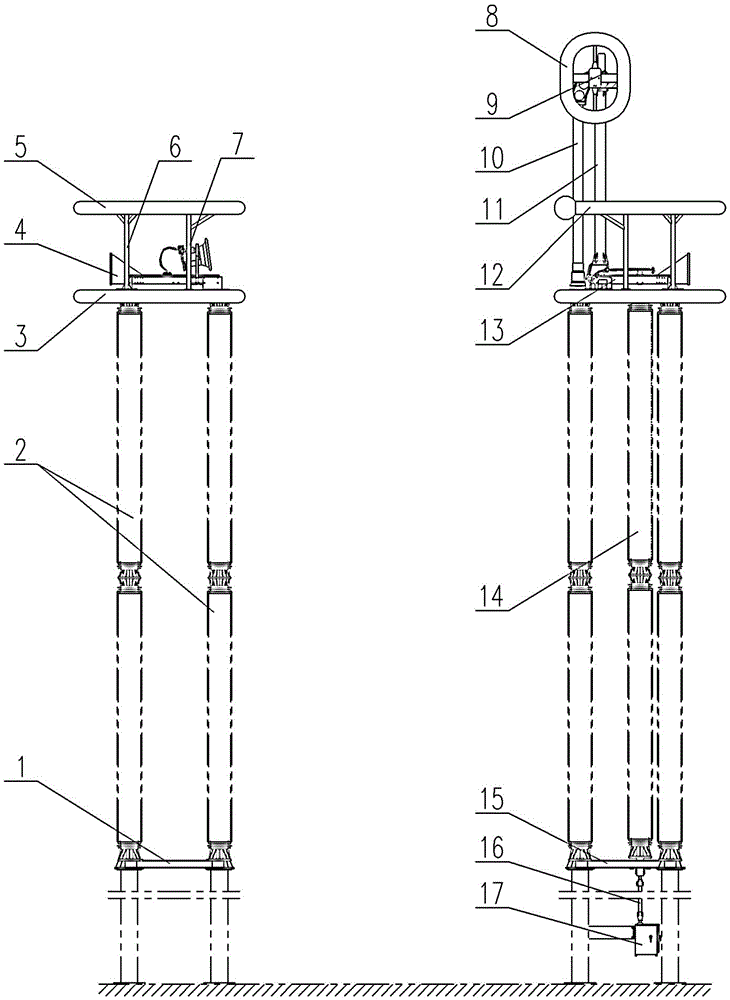

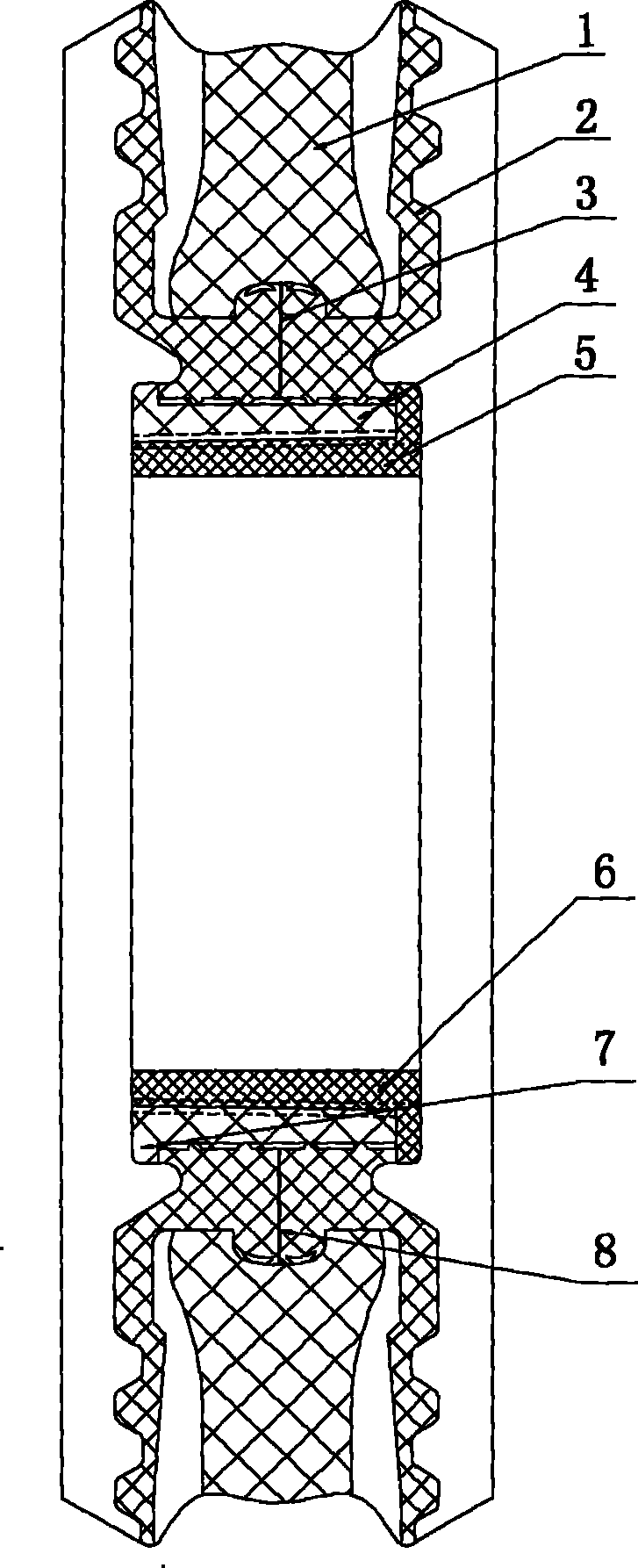

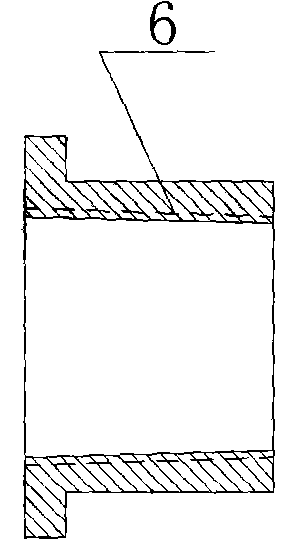

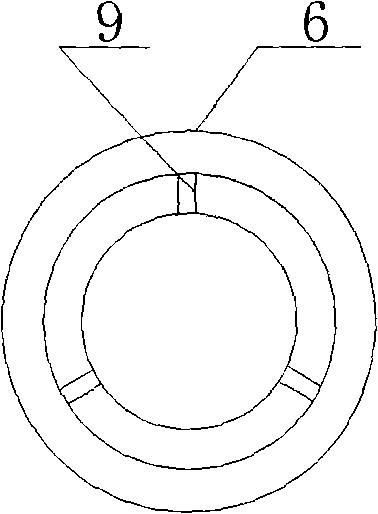

Compensation type multi-purpose annular blowout preventer

The invention relates to a blowout preventer of oilfield well mouth seal, in particular to a compensation type multi-purpose annular blowout preventer special for annular sealing and blowout prevention of wellhead oil pipes and bushings during abrasive cleaning operation of running and pulling oil pipes and sleeves of oil and water wells and oil and gas wells. The compensation type multi-purpose annular blowout preventer comprises an upper flange, a lower flange and a sealing cylinder body, wherein the sealing cylinder body is formed by an inner sealing body and an outer sealing body. The compensation type multi-purpose annular blowout preventer is characterized in that a cavity structure is formed between the outer sealing body and the inner sealing body, the upper end of the outer sealing body is connected with the upper flange, and the lower end of the outer sealing body is connected with the lower flange. When a fluid medium is injected into the cavity between the outer sealing body and the inner sealing body, the inner sealing body shrinks inwards, thereby enabling the inner sealing body to tightly hold an oil pipe or a cable or close an empty well and sealing and isolating the upper end and the lower end of the oil pipeline fixed by the sealing body. The invention provides the compensation type multi-purpose annular blowout preventer which has the advantages of light weight, convenience for installation and operation, oil pipe running and pulling operation under pressure, wide pipe well range and good on-line leak sealing effect.

Owner:雷宽成

Self-closing quick connection plug

The invention relates to the technical field of pipe fittings, in particular to a self-closing quick connection plug. The self-closing quick connecting plug comprises a male connector and a female connector. The male connector is arranged in the female connector in a pluggable mode. The female connector comprises a valve cavity, a liquid inlet and a liquid outlet, wherein the liquid inlet and the liquid outlet are communicated with the valve cavity. A self-closing device used for closing the liquid inlet or the liquid outlet is arranged in the female connector, the self-closing device comprises a valve body used for sealing the liquid inlet or the liquid outlet, an elastic element is arranged on one side of the valve body and a connecting rod is arranged on the other side of the valve body. The valve body is arranged in the valve cavity, at least a part of the connecting rod is located in the liquid inlet or the liquid outlet, one end of the elastic element is connected with the valve cavity and the other end of the elastic element is connected with the valve body. The quick connection plug is simple in structure and can realize automatic closing after a pipeline is disconnected.

Owner:梅晓萌

Mining explosion-proof variable-frequency speed regulation device convenient to maintain

InactiveCN102437715ASelf-sealingFix the leakCouplingsPower conversion systemsFrequency changerCapacitance

The invention discloses a mining explosion-proof variable-frequency speed regulation device convenient to maintain, comprising a shell and a transducer, wherein a guide rail and a supporting rack which is slidably matched with the guide rail are arranged in the shell; the transducer is a voltage type transducer; a filtering capacitor in a flat wave loop of the transducer is fixedly mounted in the shell; and other circuit elements of the transducer are mounted on the supporting frame; the transducer and the circuit part which is fixedly mounted inside the shell are in the circuit connection through a plug connector; a water cooling device is arranged on the supporting frame; a cooling water pipe is arranged in the shell; and the cooling water pipe and a water pipeline in the water cooling device are plugged to form a water cooling loop. With the adoption of the mining explosion-proof variable-frequency speed regulation device convenient to maintain, a modularized movement is formed by the transducer, the supporting frame and the cooling device, and the circuit and the cooling water pipe inside the shell are rapidly connected with each other in a plugging and matching manner, thereby improving the maintenance efficiency.

Owner:TIANJIN HUANING ELECTRONICS

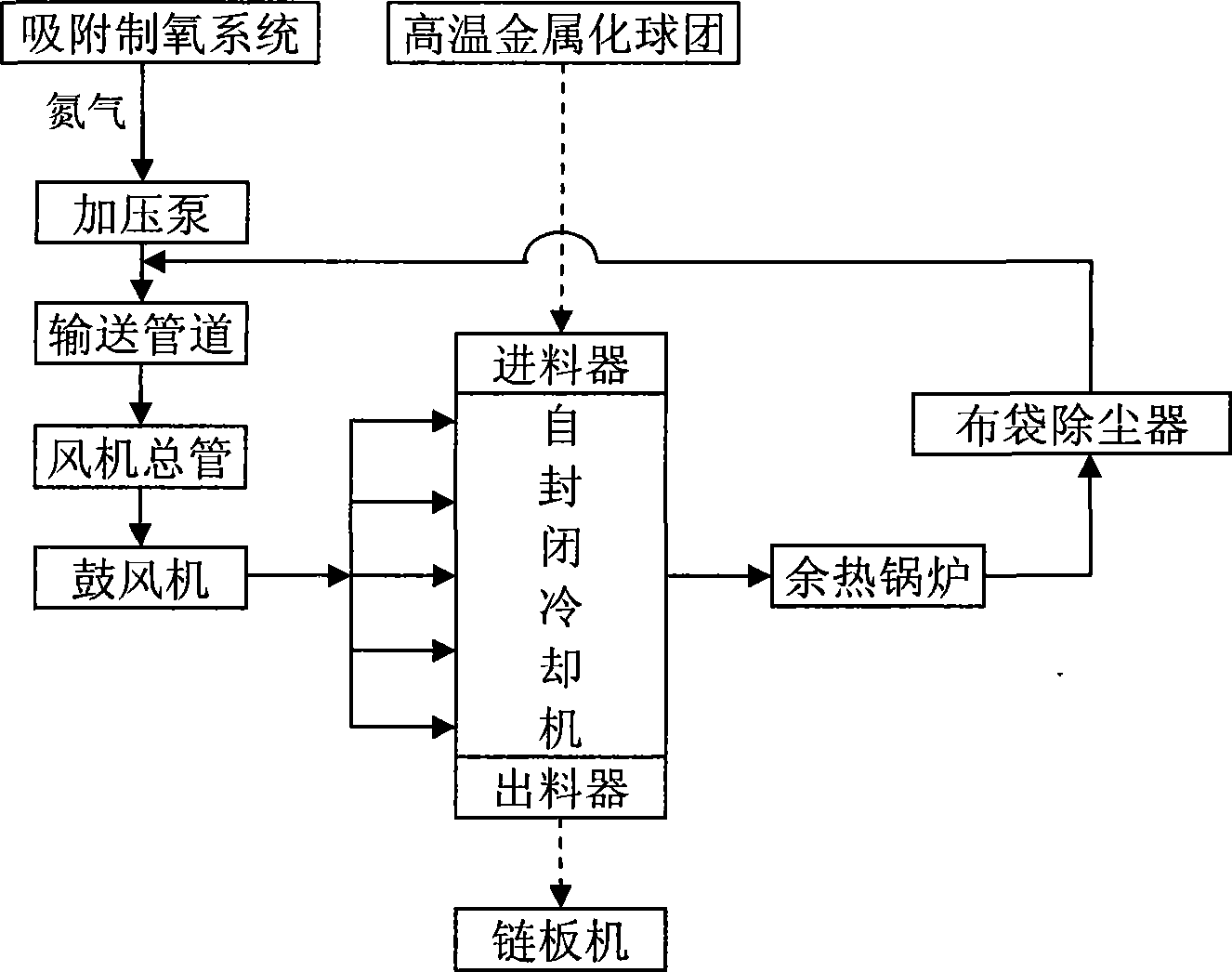

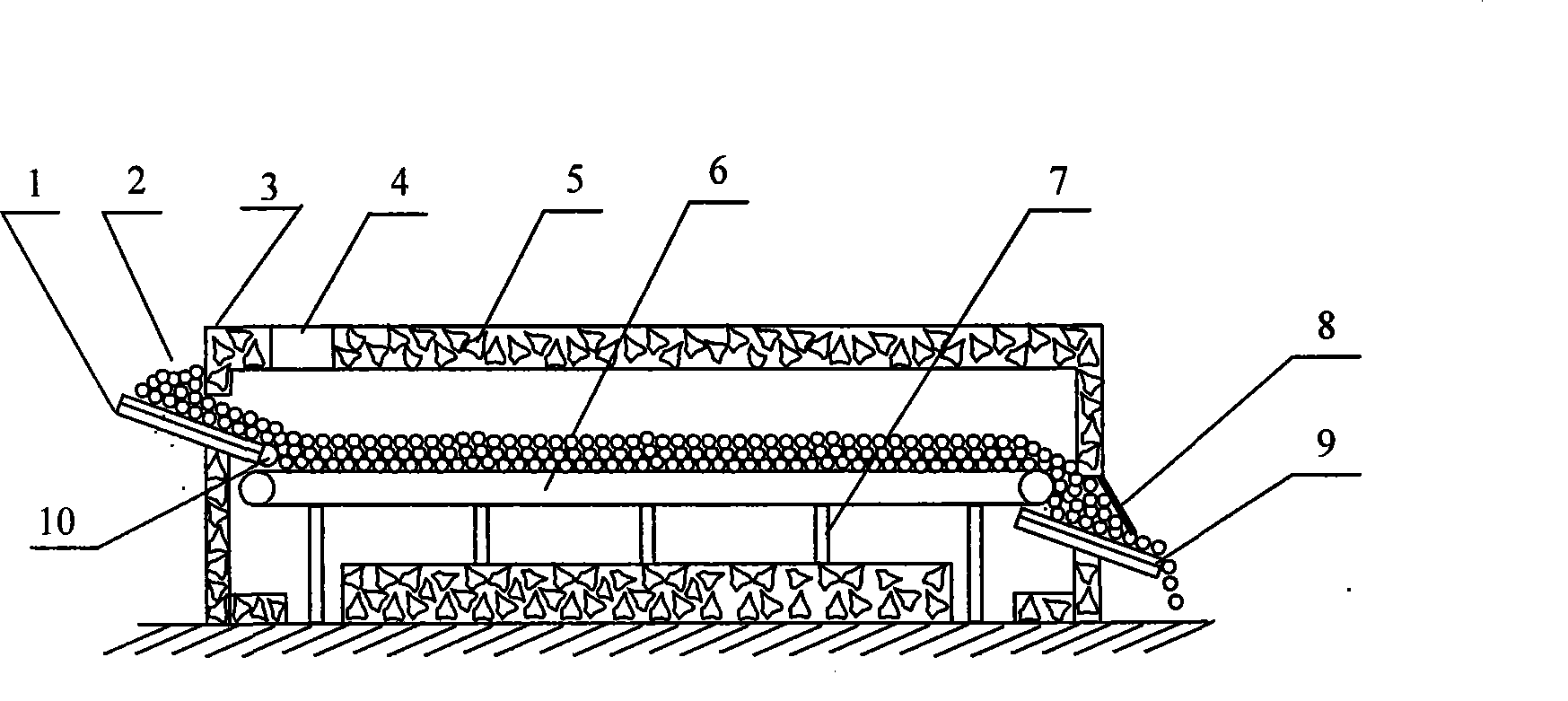

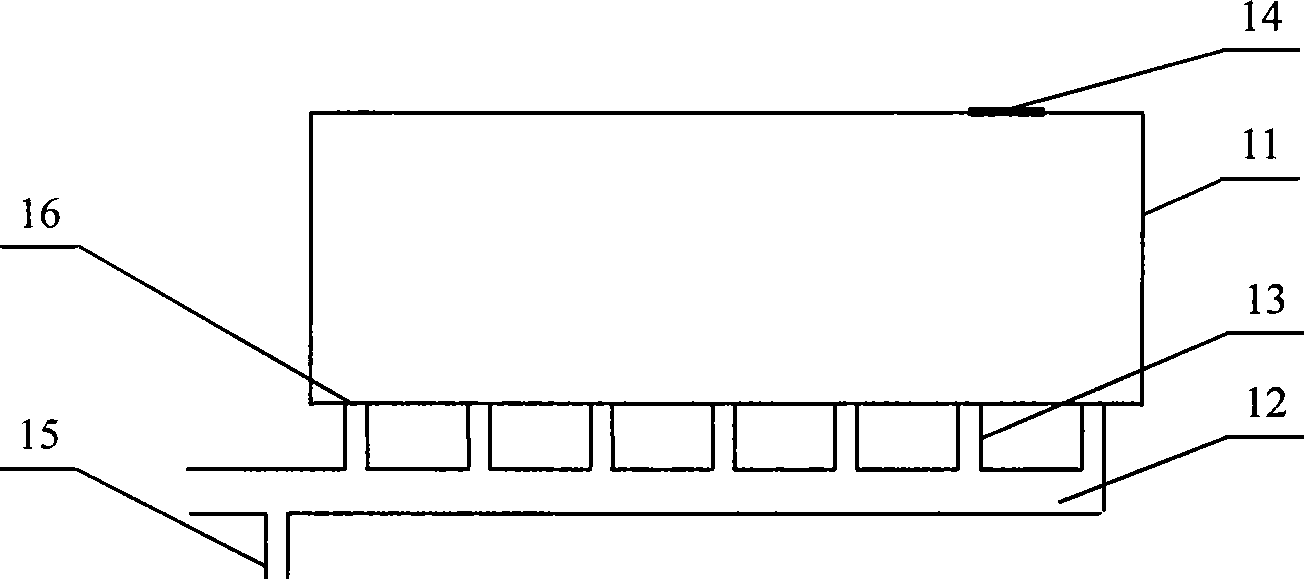

Self-sealing nitrogen circulating cooling method and apparatus

The invention provides a self-sealing nitrogen circulating cooling method which comprises the following steps: a. nitrogen discharged after oxygen generation through the absorption oxygen-generation technology in a steel plant is delivered to a blower header pipe through a pressure pump and a delivery pipeline, and the nitrogen in the blower header pipe is mixed with a recycle gas after recovery of heat; b. after pressure is applied to the mixed gas by a blast blower, the mixed gas is delivered to an air inlet pipe of a cooler, enters a material layer zone of a self-cooler through the air inlet pipe, and then is output through a large flue after heat exchange with a high temperature mass at the temperature of 1000 DEGC; and c. the temperature of waste gas in the large flue reaches up to 500-600 DEG C, and then is reduced to 180-230 DEG C after recovery of heat, and the waste gas is again led to the blower header pipe as a recycle gas for mixed cycle utilization with supplementary nitrogen. The technology can realize continuity, stability, recovery of high temperature waste gas and metallization rate of products in production, meet the national policy requirements for energy conservation, emission reduction and cyclic economy, and provide space for reducing production cost.

Owner:LAIWU IRON & STEEL GRP

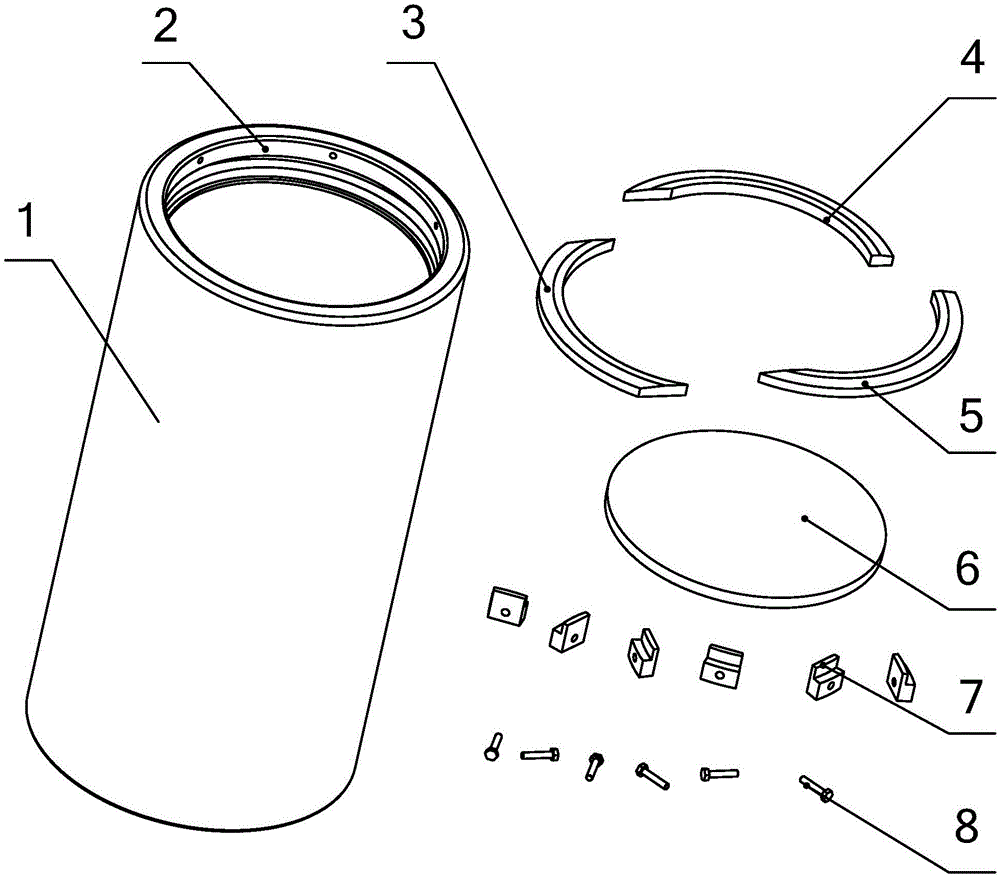

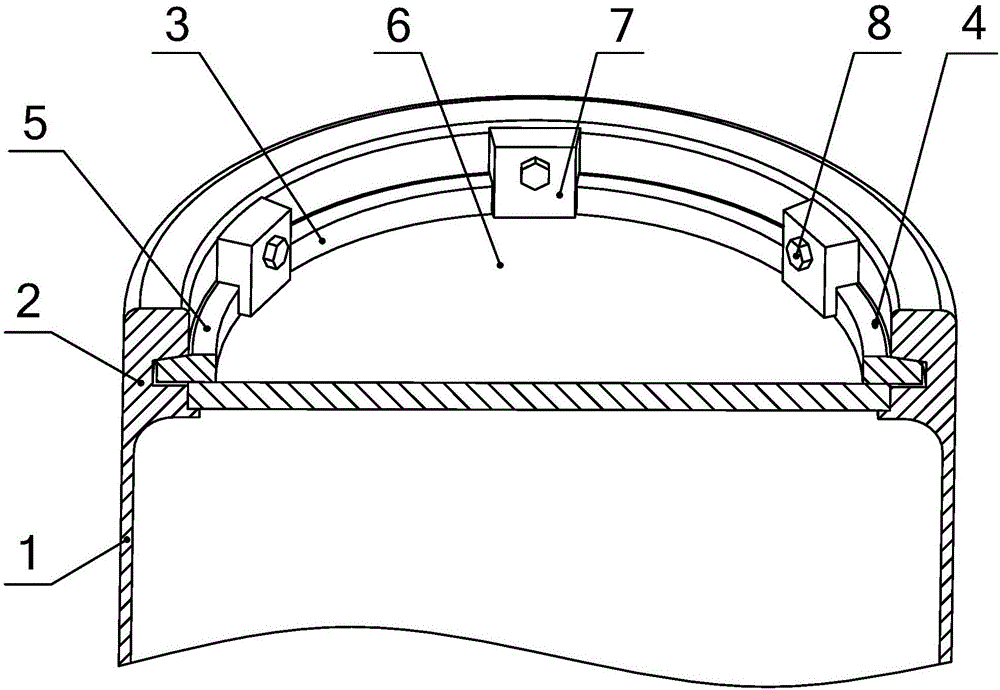

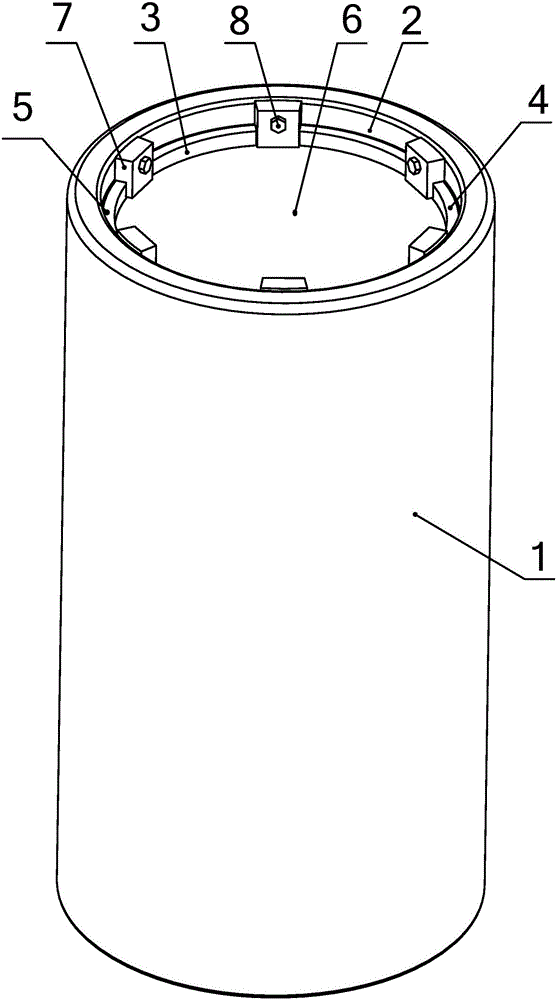

Full-wedge structure anti-explosion container

The invention discloses a full-wedge structure anti-explosion container which comprises a barrel and a flange arranged at the top of the barrel; a check ring in a circular shape is formed at the lower part of the internal wall of the flange in bulged manner; a wedge clamping groove in a circular shape is formed in the middle of the internal wall of the flange in hollowed manner; a cover plate is placed horizontally on the upper surface of the check ring of the flange; a first wedge strip, a second wedge strip and a third wedge strip are arranged at the edge of the upper surface of the cover plate; the first wedge strip, the second wedge strip and the third wedge strip are sequentially connected end to end to form a zero-clearance wedge ring; the first wedge strip, the second wedge strip and the third wedge strip are each provided with a wedge clamping block; the zero-clearance wedge ring is externally matched with a plurality of pressing blocks; the pressing blocks are fixed to the internal wall of the upper part of the flange through screws; and all the pressing blocks, under the pressing force of the screws provide the wedge matching pressing force to the various wedge clamping blocks of the zero-clearance wedge ring. Under the action of the pressing force, self sealing of the zero-clearance wedge ring can be realized, and the full-wedge structure anti-explosion container especially has good effects on limiting the leakage of an explosion product and protecting explosion shock.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

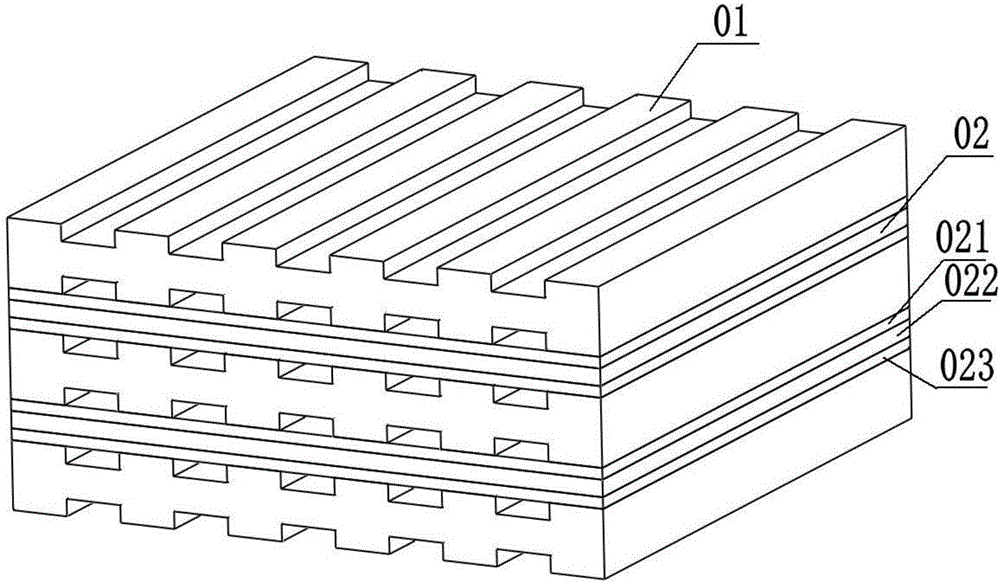

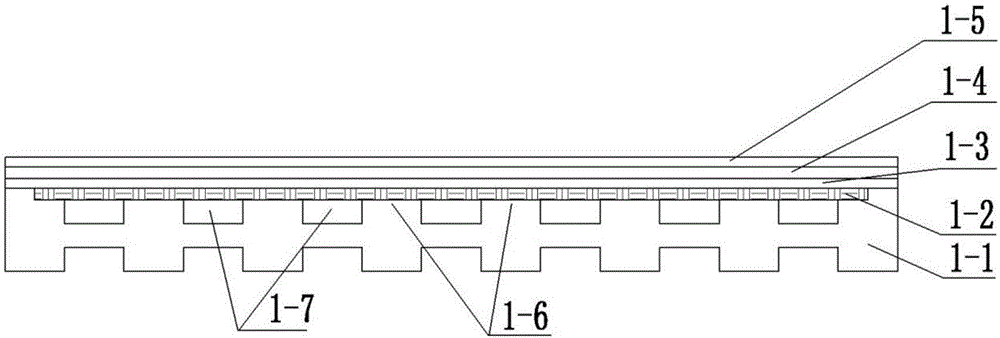

Connector of self-sealing flat plate type solid oxygenated fuel cell and preparation method

ActiveCN106549172ASelf-sealingReduce manufacturing costFinal product manufactureSealing/support meansFuel cellsBiochemical engineering

The invention discloses a connector of a self-sealing flat plate type solid oxygenated fuel cell and a preparation method. The connector comprises a metal connecting pole and a porous metal layer, wherein a gas passage is arranged on one side of the metal connecting pole; a groove is formed in the side, provided with the gas passage, of the metal connecting pole, and the porous metal layer is arranged in the groove. A connector and supporting metal integrated structure of the self-sealing flat plate type solid oxygenated fuel cell is prepared through a method that a shelter is finally removed through sheltering and powder metallurgy on one side of the interior of the connecting pole. A cell functional layer is prepared on the integrated structure, self-sealing of the cell can be realized, the manufacturing technique of a cell stack can be greatly simplified, the cell stack does not need the introduction of any additional sealing structure, the problem that the flat plate type solid oxygenated fuel cell is sealed is overcome, the manufacturing cost of the cell is reduced, and the commercial popularization of the cell is facilitated.

Owner:浩燃科技(中山)有限公司

Isolation switch

ActiveCN104319157BSelf-sealingReduce erosionHigh-tension/heavy-dress switchesAir-break switchesEngineeringMechanical engineering

Owner:HENAN PINGGAO ELECTRIC +1

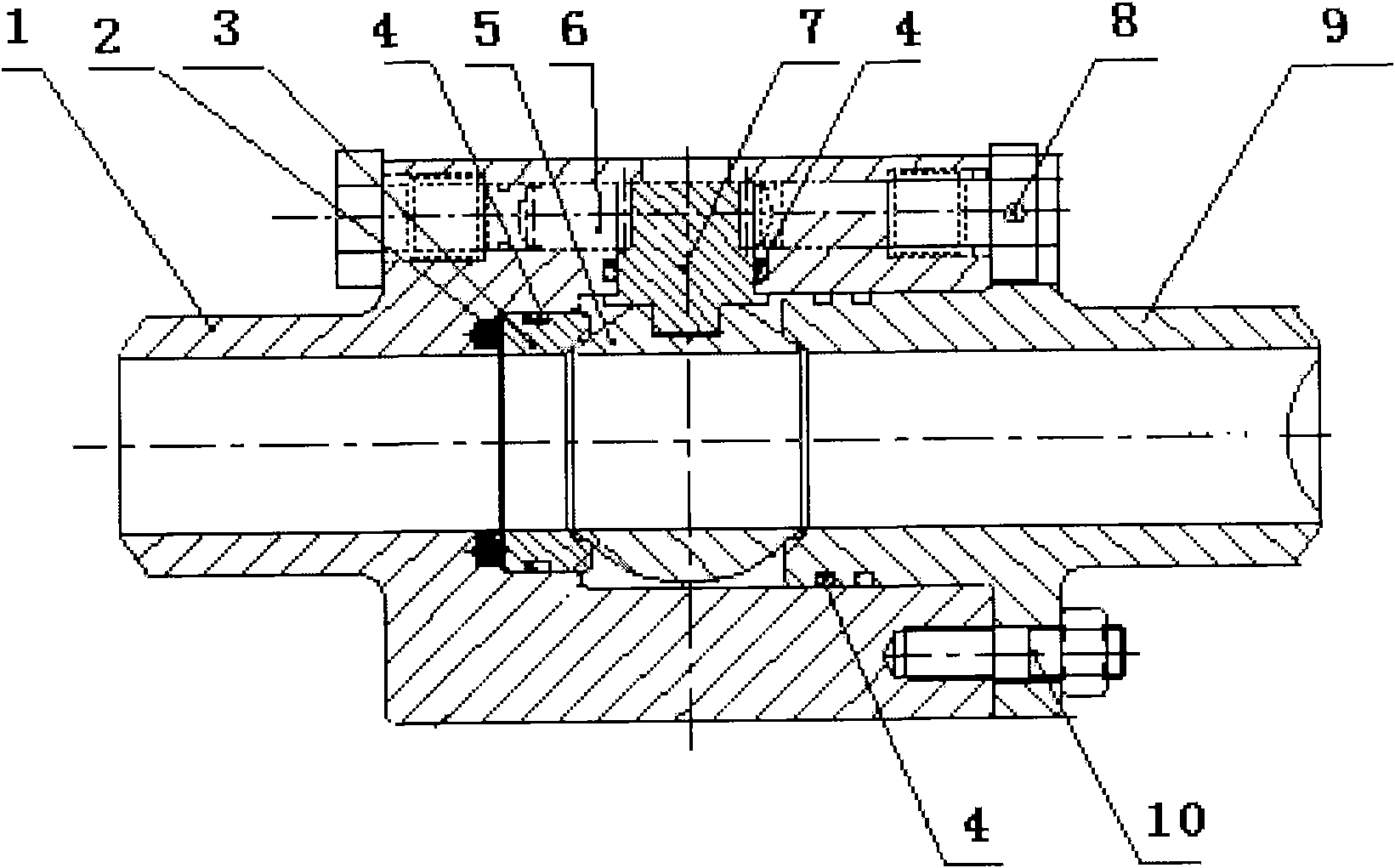

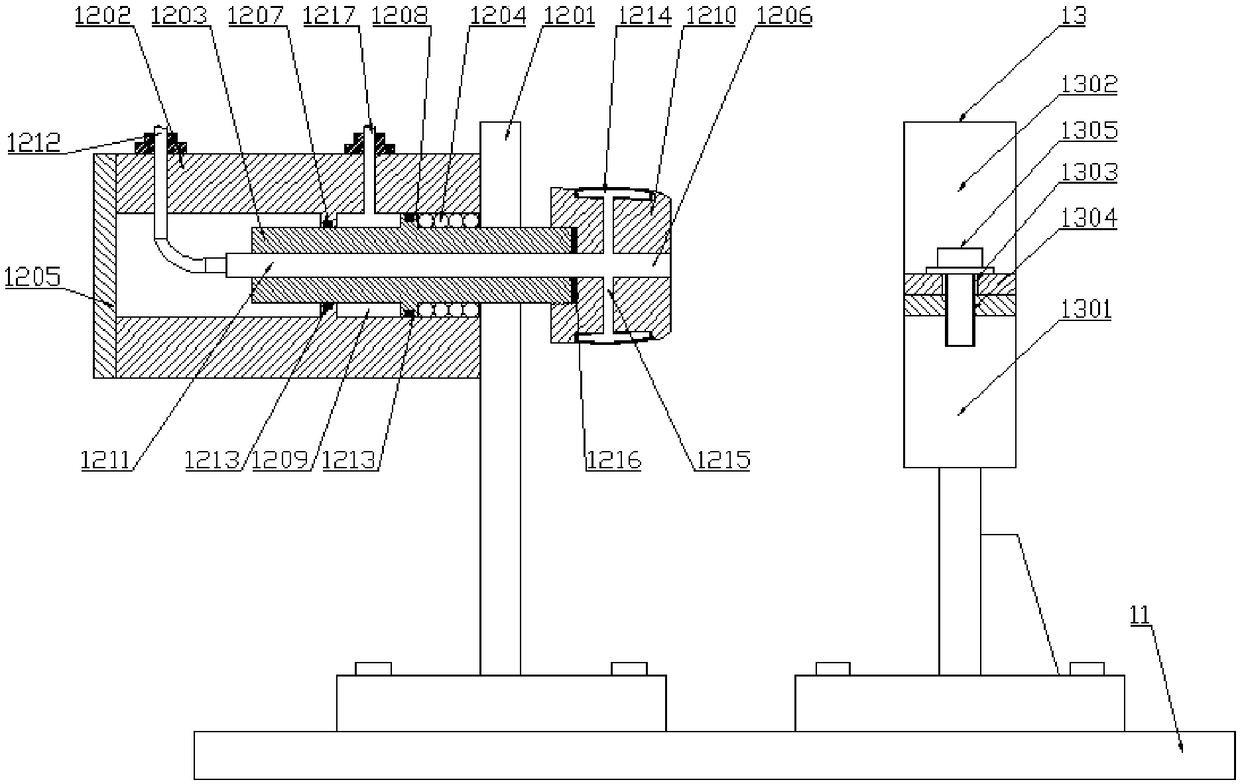

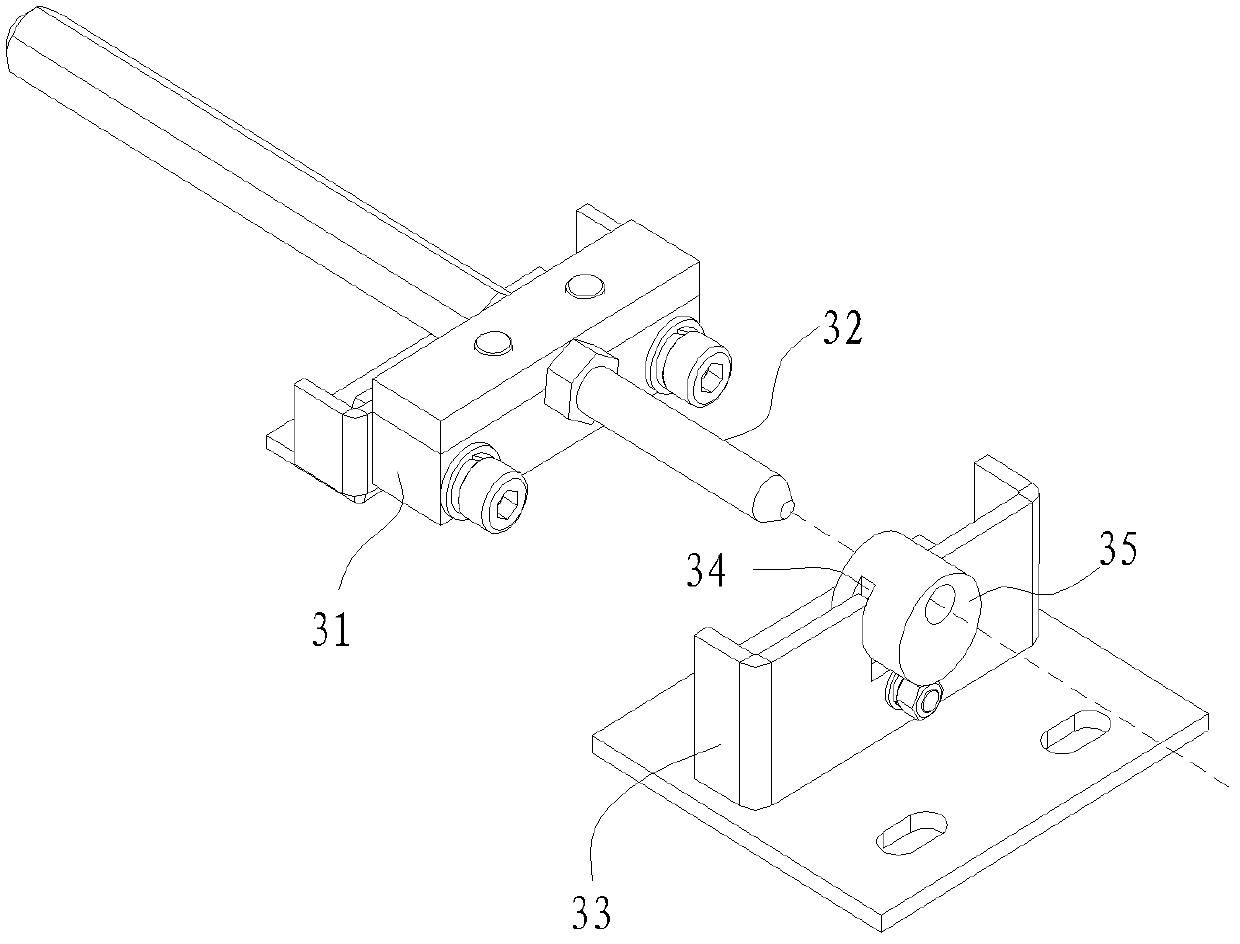

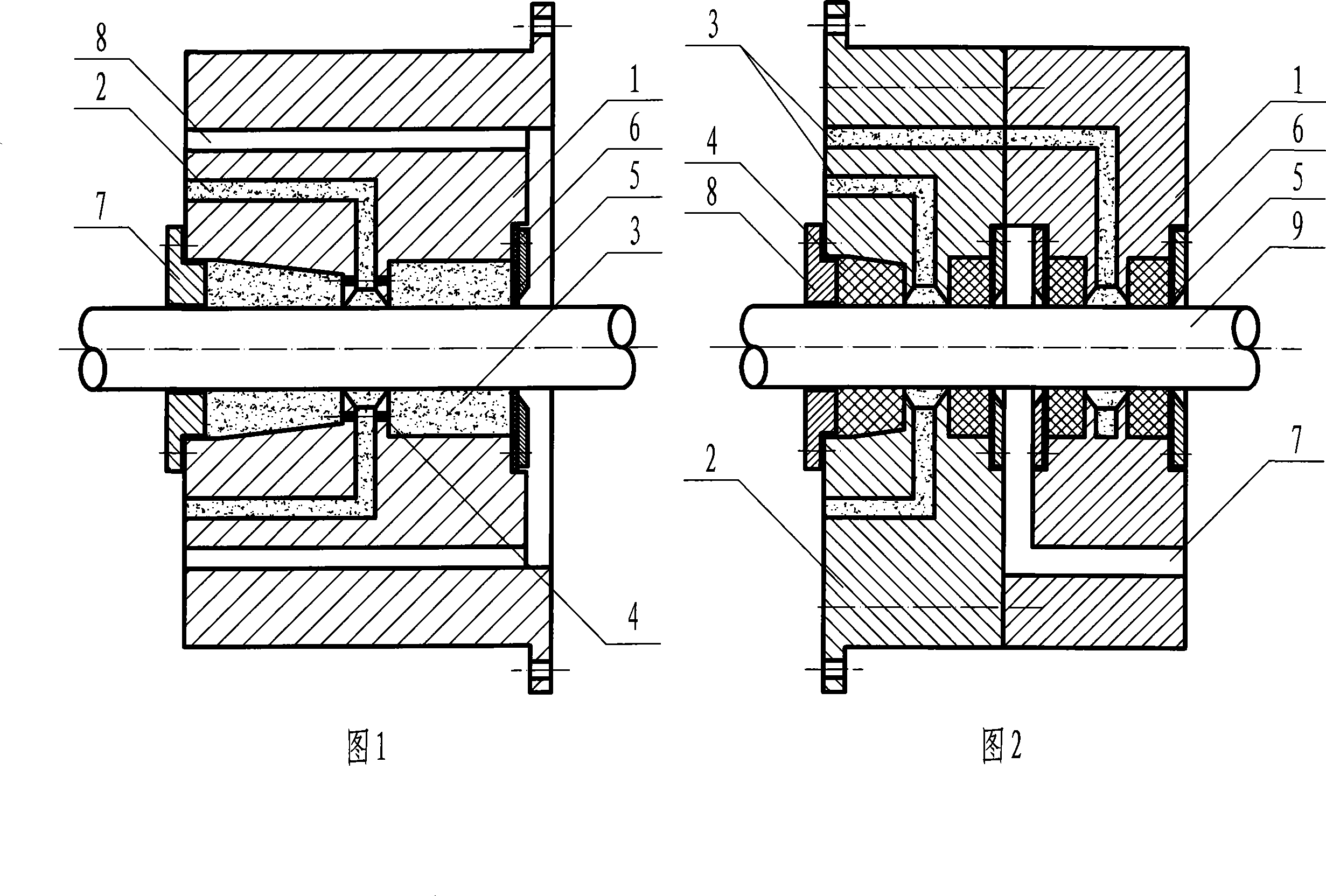

Rapid changing and feeding joint mechanism of fluid medium

ActiveCN102788215AFast and smooth exchangeRealize automatic dockingPipe elementsCouplingsButt jointEngineering

The invention belongs to changing and feeding joint devices of a fluid medium and specifically relates to a rapid changing and feeding joint mechanism of the fluid medium between two separation parts when gas and liquid fluid media are in a butt joint state. The rapid changing and feeding joint mechanism is characterized in that a plurality of joints combined by male and female joints are distributed in a butt connection surface between a part A and a part B, each joint combined by the male and female joints is a seal joint which is automatically and integrally formed by pushing each self-sealing male joint into each self-sealing female joint, each self-sealing male joint is composed of a male casing, a guide ring, a guide sleeve, a piston, a thread blocking sleeve, a spring A, a seal ring and a blocking ring, and each self-sealing female joint is composed of a female casing, a sleeve, an ejector rod, a spring B and a seal ring. The rapid changing and feeding joint mechanism has the advantages that the design is reasonable, the structure is compact, besides, the mechanism is self-sealing, free of leakage and convenient to manufacture and install, the operation is safe and reliable, and the like.

Owner:KEDE NUMERICAL CONTROL CO LTD

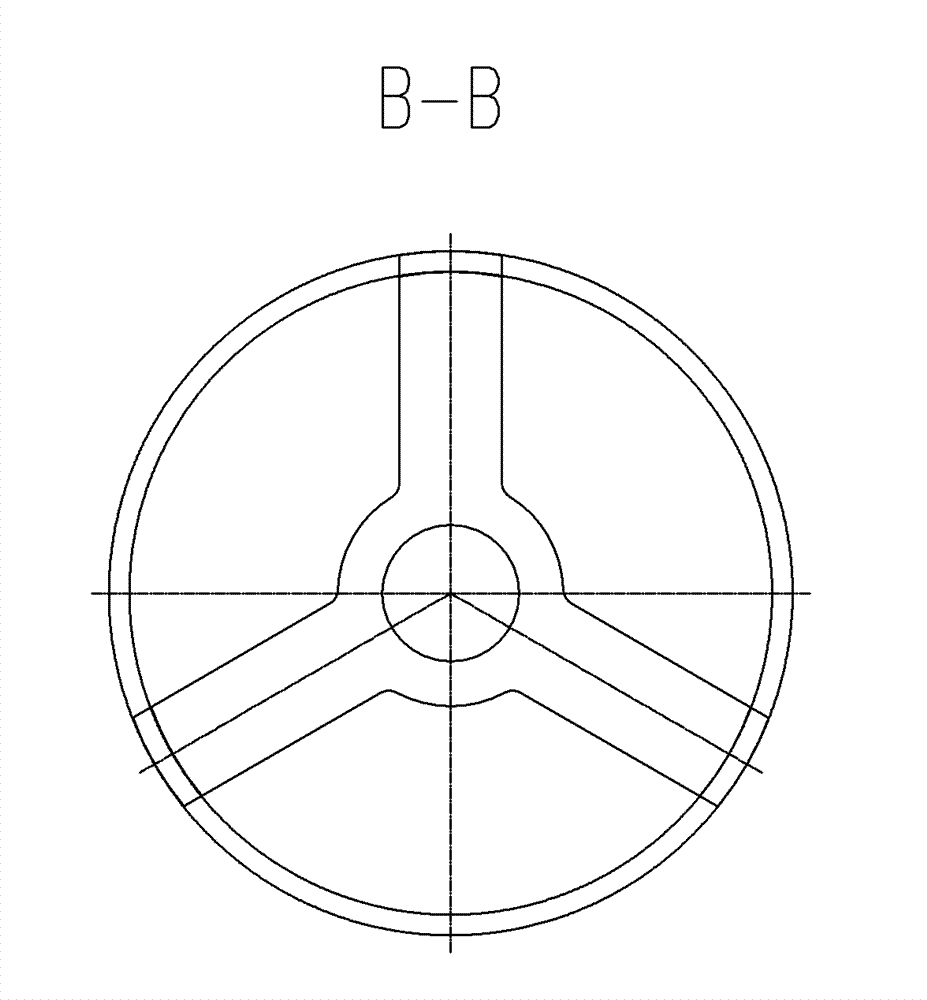

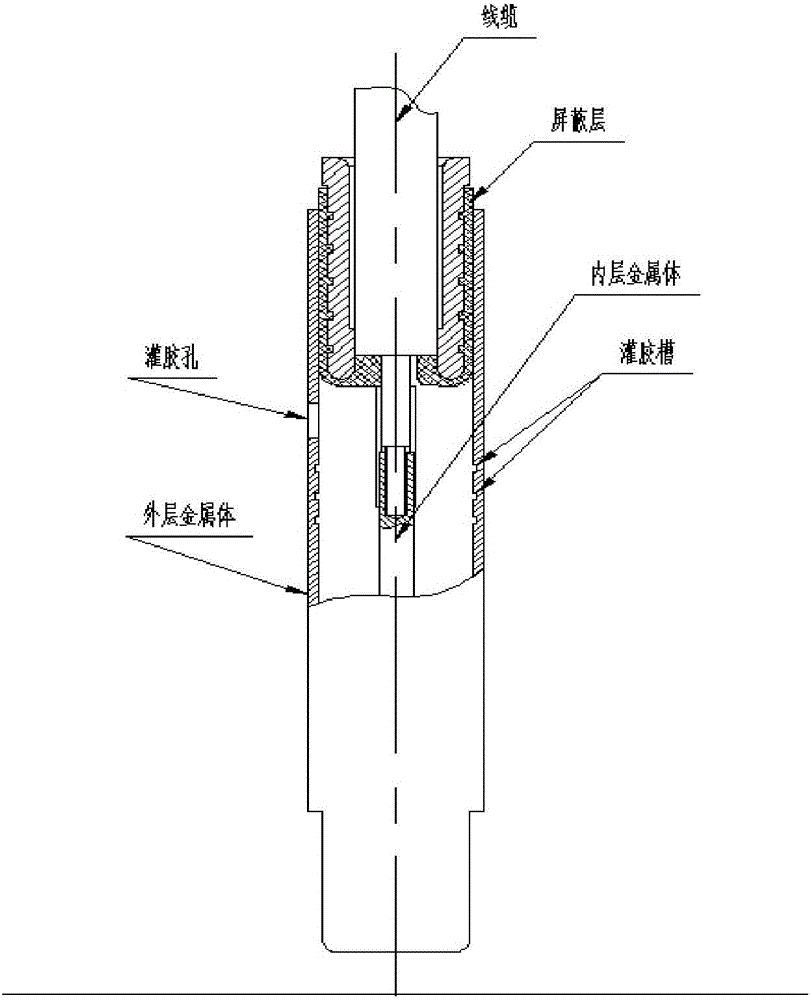

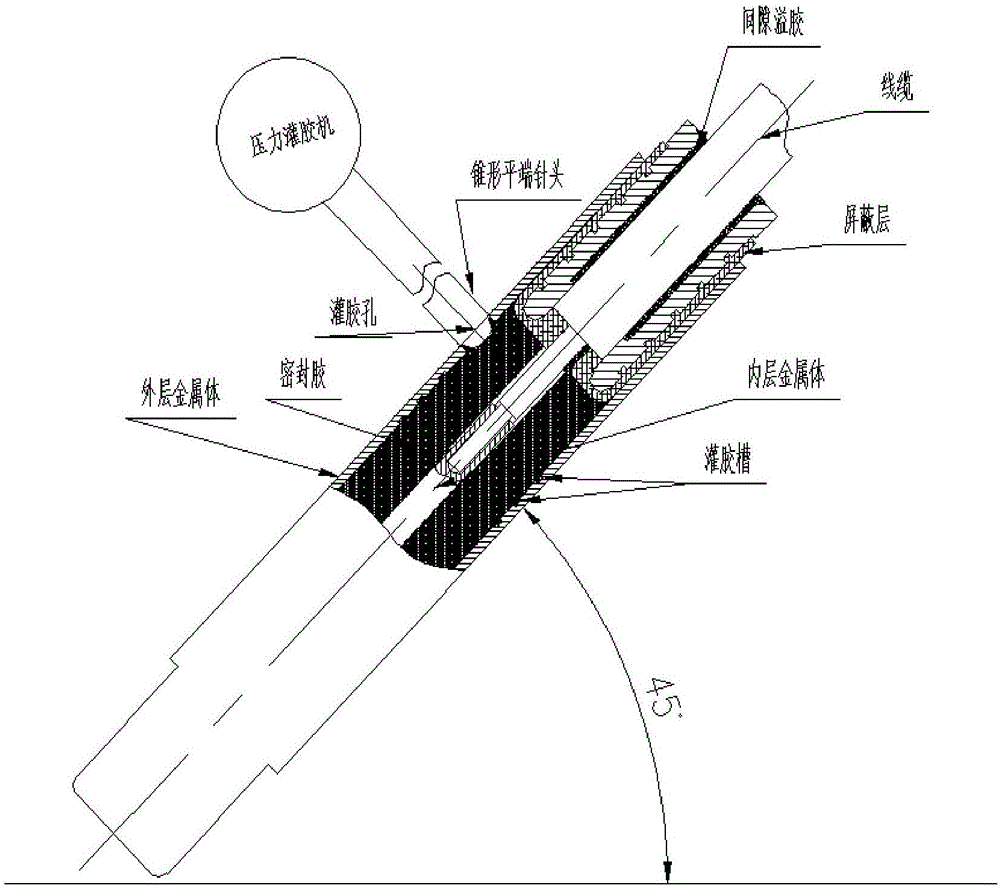

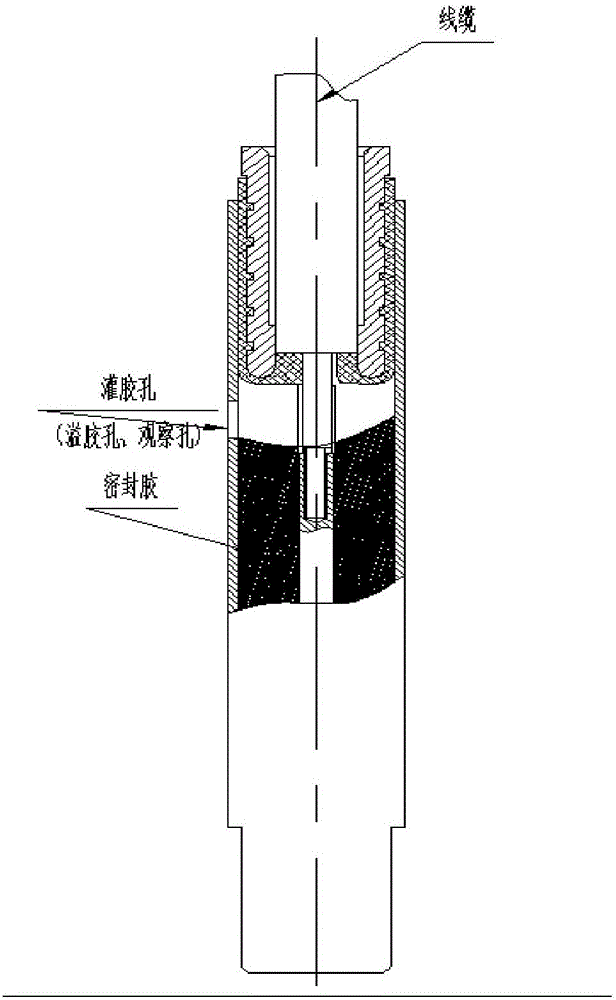

Assembly and encapsulation method of high-frequency elongate contact piece with cable

ActiveCN106785792AReliable pottingSelf-sealingContact member cases/bases manufactureElectrical performanceElectrical connector

The invention relates to an assembly and encapsulation method of a high-frequency elongate contact piece with a cable. The assembly and encapsulation method comprises the following steps of opening an encapsulation hole with a diameter slightly smaller than the maximum diameter of an encapsulation needle head in an outer-layer metal body above a part needed to be encapsulated of an electrical connector by 1-2 millimeters; assembling the cable and the electrical connector to form a high-frequency contact piece which is not sealed; inclining the high-frequency contact piece at an angle of 45 degrees, hermetically connecting the encapsulation needle head and the encapsulation hole of the electrical connector, and performing pressurization and encapsulation until an adhesive liquid overflows out of a tail press part of the high-frequency contact piece; and vertically placing and curing the high-frequency contact piece, wherein a part of adhesive liquid overflows out of the encapsulation hole. The technical operation and method is practical, and reliable encapsulation of the elongate contact piece which is automatically sealed, has high reliable electrical performance and is provided with the cable is achieved.

Owner:杭州航天电子技术有限公司

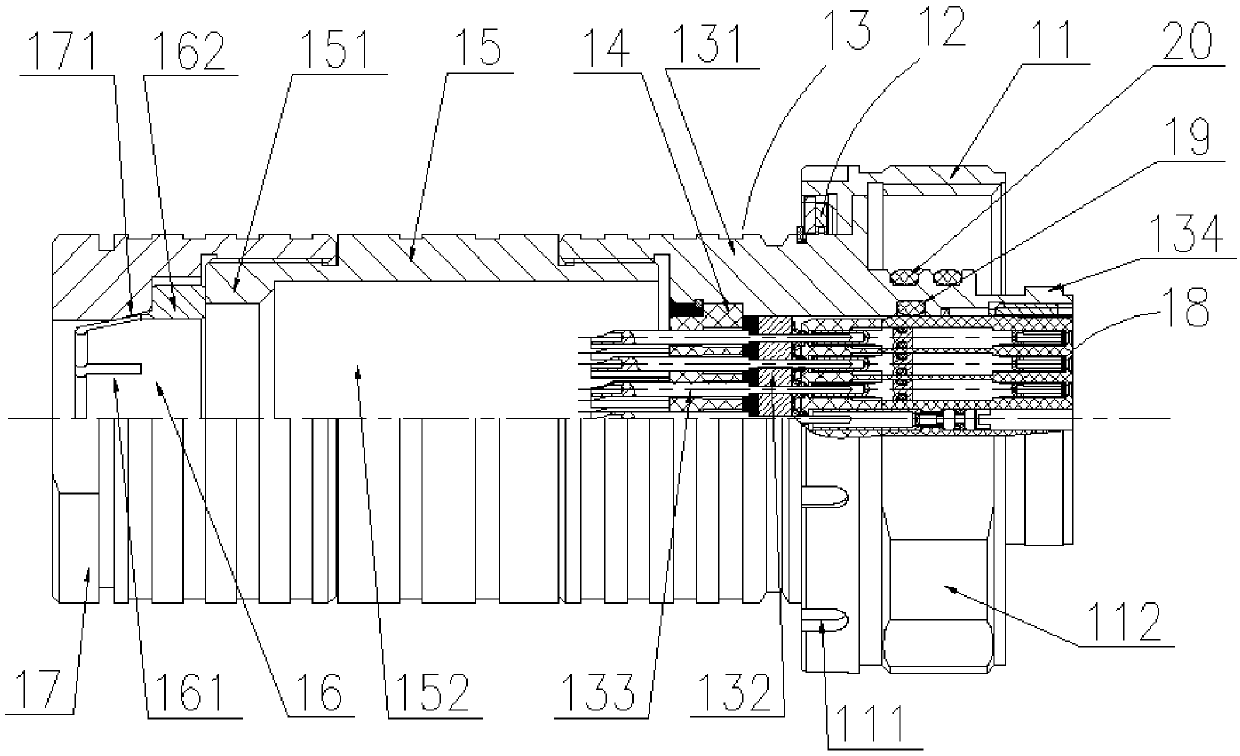

Flexible self-sealed anti-humeral-protrusion compression packer

InactiveCN105114027AReliable anti-shoulder designPrevent tamperingSealing/packingEngineeringJoint action

The invention discloses a flexible self-sealed anti-humeral-protrusion compression packer and solves the problem that existing packers are low in pressure resistance. The packer specifically comprises a central pipe, a transmission cylinder, a piston sleeve and a compression plug, a plurality of clamping claws are uniformly arranged at the lower end of the transmission cylinder circumferentially, a boss is arranged on the central pipe below the transmission cylinder, a spring is arranged between the transmission cylinder and the boss of the central pipe, a pressure-carrying rubber sleeve, a middle rubber sleeve and a pressure-applying rubber sleeve sequentially sleeve the central pipe below the boss, a shoulder is arranged outside the boss of the central pipe, a protecting cover is placed between the shoulder and the pressure-carrying rubber sleeve, the piston sleeve sleeves outside the central pipe below the pressure-applying rubber sleeve, and an annular cavity along the circumferential direction of a base of the middle rubber sleeve is arranged in the middle rubber sleeve and filled with liquid, a conical portion of the compression plug is inserted into a lower port of the pressure-applying rubber sleeve, and a plurality of annular runners and longitudinal runners are arranged on the surface of a base of the compression plug. Due to joint action of the above structure, pressure resistance of the packer is improved, and needs of deep-well fracturing and large-scale joint net fracturing are met.

Owner:NORTHEAST GASOLINEEUM UNIV

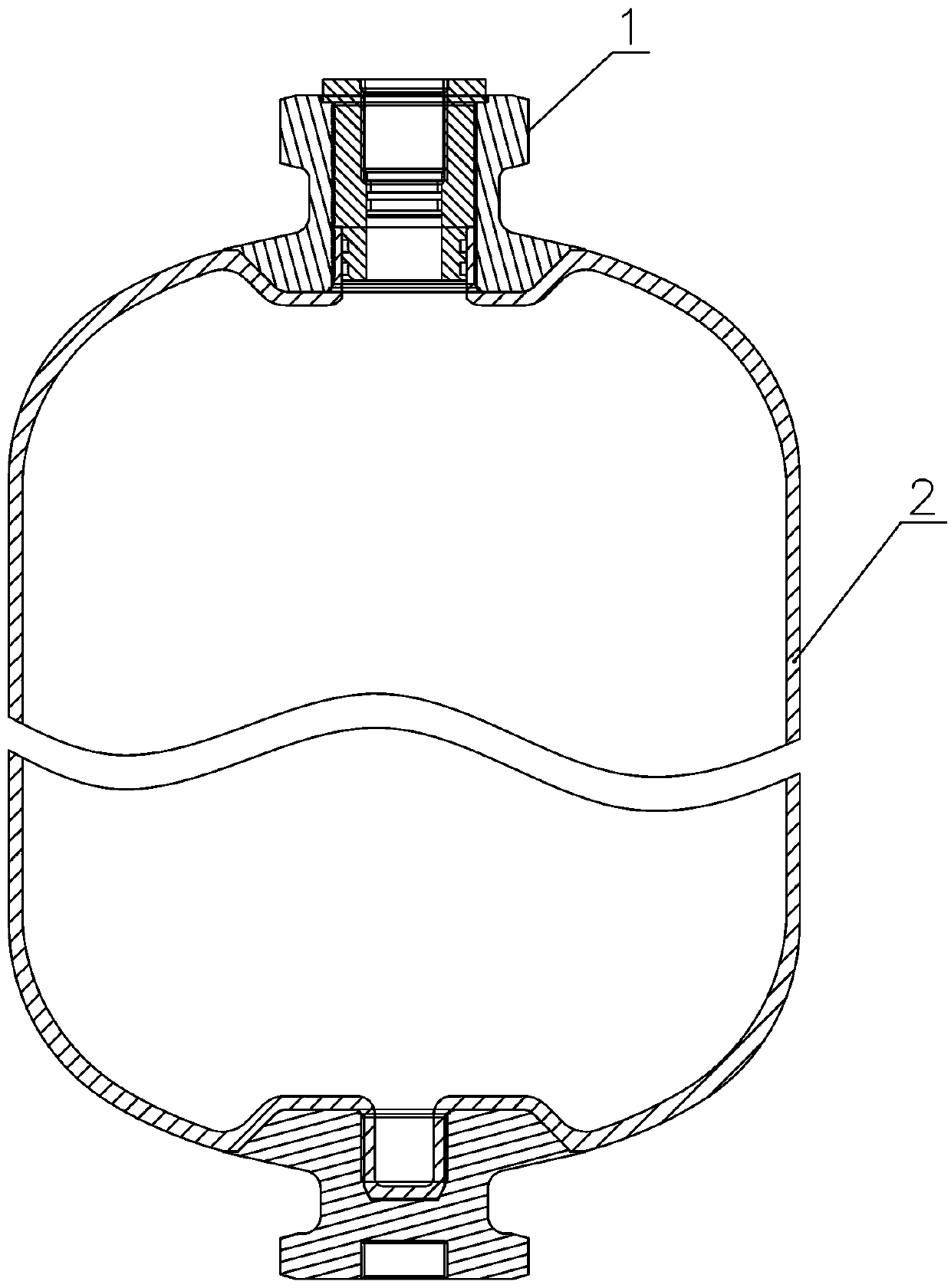

Plastic liner fiber fully-wound gas bottle mouth structure

PendingCN110848558AEasy to installFirmly connectedVessel mounting detailsVessel geometry/arrangement/sizeFiberGas cylinder

The invention discloses a plastic liner fiber fully-wound gas bottle mouth structure. The plastic liner fiber fully-wound gas bottle bottle mouth structure comprises a metal bottle mouth and a plasticliner; the top of an upper sealing head of the plastic liner is recessed inwards to form an embedded groove; a connecting pipe with a first external connecting thread section is arranged in the embedded groove; the metal bottle mouth is composed of an outer joint and an inner joint; an embedded block matched with the embedded groove is arranged at the bottom of the outer joint; a joint internal thread hole in the outer joint penetrates downwards; the embedded block is fixed in the embedded groove and the contour of the embedded block and the outer contour of the upper sealing head are splicedinto a spherical surface; a mounting hole is formed in the inner joint; an inner thread section is formed in the upper section of the mounting hole; the inner joint is composed of an upper cylinder body and a lower cylinder body which are with a second external connecting thread section; the inner joint is screwed in the outer joint through the second external connecting thread section; the lowercylinder body clamps the connecting pipe between the lower cylinder body and the joint inner thread hole; and a first sealing structure is further arranged between the lower cylinder body and an inner hole of the connecting pipe. The structure is convenient to install and good in sealing performance.

Owner:ZHANGJIAGANG FURUI HYDROGEN ENERGY EQUIP CO LTD

Preparation method of self-sealing planar solid oxide fuel cell

ActiveCN106571475AAchieve self-sealing effectOvercoming Sealing DifficultiesSemiconductor lasersSealing/support meansFuel cellsNanotechnology

The invention discloses a preparation method of a self-sealing planar solid oxide fuel cell, wherein the preparation method comprises the following steps: (1) processing a metal connecting pole having a gas passageway structure; (2) allowing a porous metal layer and the metal connection pole to form a whole; (3) trimming the upper surface of the whole formed by the porous metal layer and the metal connection pole, to obtain a surface for spraying; (4) preparing an anode layer on the surface of the porous metal layer by a spraying method; (5) preparing an electrolyte layer on the surface of the anode layer by a spraying method; and (6) preparing a cathode layer on the surface of the electrolyte layer by a spraying method. Because the battery connecting pole and the porous stainless steel substrate are subjected to edge sealing treatment in advance, the self-sealing effect is realized after preparation of a battery is completed, and the problem of the sealing of the battery is effectively overcome.

Owner:浩燃科技(中山)有限公司

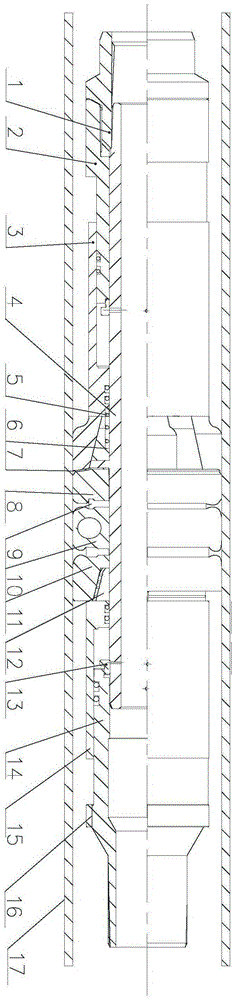

Self-sealing type low-rank coal and coal slime negative pressure drying device

InactiveCN104596233AAchieving a self-sealing stateSelf-sealingDrying solid materials without heatHeating arrangementDischargerWater vapor

The invention discloses a self-sealing type low-rank coal and coal slime negative pressure drying device. The self-sealing type low-rank coal and coal slime negative pressure drying device comprises a spiral feeder, a drying barrel and a spiral discharger which are connected in sequence in a matched manner, wherein the spiral feeder is provided with a feeding opening; the spiral discharger is provided with a material outlet; spiral blades in the spiral feeder and the spiral discharger are fixedly connected with a central hot air pipe; coal scrapers achieving stirring and loosening effects are uniformly arranged around the inner wall of the drying barrel at equal intervals; heat exchange pipes for supplying heat needed by coal drying are arranged in the drying barrel; the spiral discharger is provided with a vapor discharging opening; the vapor discharging opening is connected with a dust collection device through a vacuum pump. The negative pressure drying device is ingenious in structural design; by the use of a spiral extruder type structure, continuous feeding and continuous discharging of coal are realized, and a self-sealing state of the drying device is achieved; due to the adoption of an indirect heating mode, the device has the advantages of preventing high-temperature spontaneous combustion and avoiding explosion; furthermore, water in a coal material can be further removed efficiently and quickly.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Dissepiment strainer plate inlet orifice clamping head

The invention relates to a membrane filter plate feed inlet clamp and a membrane filter plate feed inlet which is composed of the membrane filter plate feed inlet clamp, the wall of a plate core feed inlet is provided with an annular groove, the membrane feed inlet is a turning edge structure, the back part annular shape of the turning edge is provided with a boss, the bottom part of the boss is provided with one, two or more circles of lip edges, the membrane part which is adjacent to one, two or more circles of lip edges and one, two or more circles of lip edges constitute an open damping cavity respectively, the open damping cavity and the groove in the plate core are combined by sealed extrusion, the surface of the membrane feed inlet is a concave-convex point distributing surface, the wall of the hollow core clamp part is provided with an expansion line slot, the hollow core clamp is positioned in the membrane feed inlet, a flange clamp is screwed in the hollow core clamp and expands the wall of the hollow core clamp, and the membrane is radially sealed and tightened in the groove of the plate core by the hollow core clamp wall.

Owner:杭州兴源环保设备有限公司

Break-free machine injection and plastic type multipurpose shaft gland

The invention provides an injection and molding typed multipurpose shaft seal without shutdown, belonging to the shaft end sealing technical field. The structure of the invention comprises a sealing body in first grade or higher than the first grade; the sealing body in each grade is internally provided with an injection molding hole; the end of the injection molding hole is communicated with the a cirque sealing chamber which is enclosed by the sealing body and a rotation shaft; the two sides of the cirque sealing chamber are provided with a packing chamber; corresponding sealing grease, sealing paste, sealing liquid or solid sealing material can be selectively injected into the injection molding hole according to different sealing parts, pressure and medium, thus preventing the internal and external leakage of the shaft seal. Compared with the prior art, the injection and molding typed multipurpose shaft seal without shutdown of the invention can be widely applied to the shaft end sealing of various rotation equipments in positive pressure and negative pressure, such as steam turbine, generator, water pump, fan, gearbox, etc., and can also be combined with the traditional seals, such as labyrinth seal, packing seal, mechanical seal, magnetic seal, etc. The invention can realize the overall sealing between the sealing body and the shaft, between the sealing body and a sealing sleeve, and between the sealing sleeve and the equipment. The invention can be suitable for the shaft seal of the equipment which is not concentric with the shaft. The sealing body and the sealing sleeve can be made into taper, thus realizing self sealing.

Owner:潘健

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com