Cord thread integral winding reinforced rubber air spring

A rubber air spring, winding enhancement technology, used in springs, springs/shock absorbers, gas shock absorbers, etc., can solve problems such as high sealing requirements and large flange openings, and improve overall connectivity and space. The effect of small size and strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

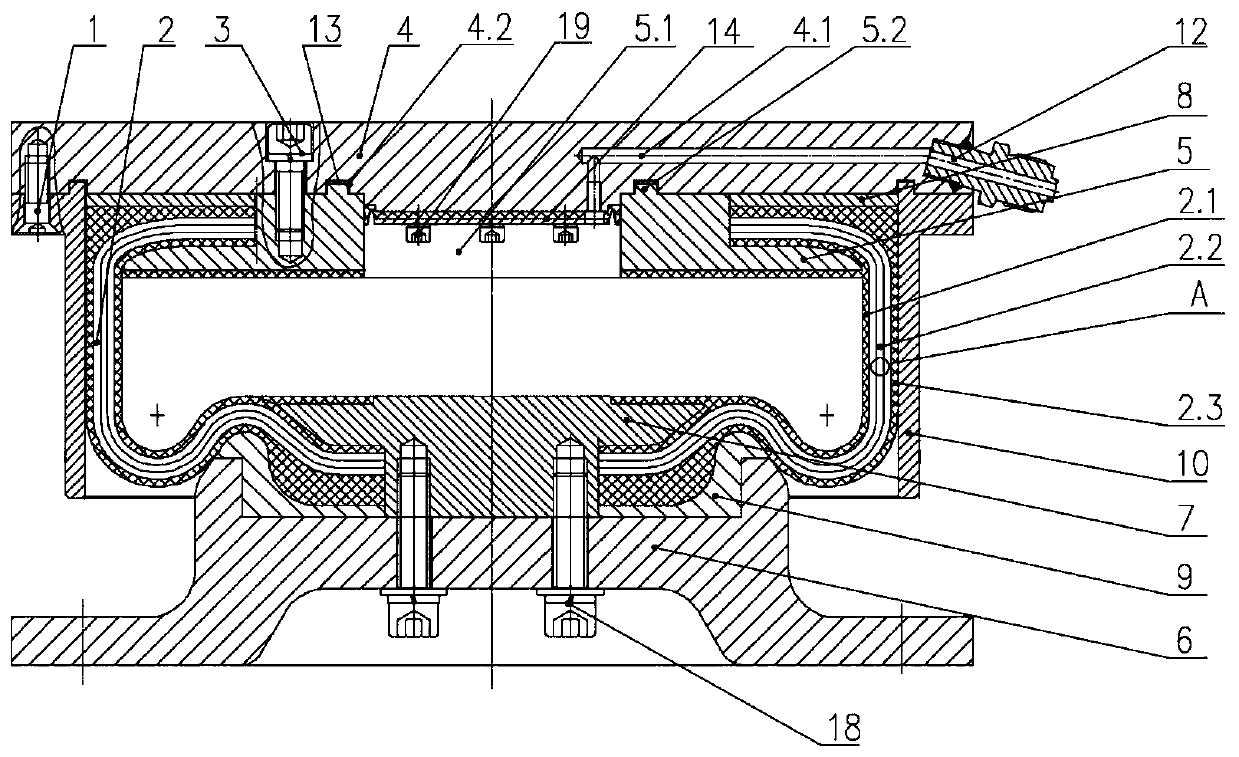

[0033] Below in conjunction with accompanying drawing, the present invention will be further explained:

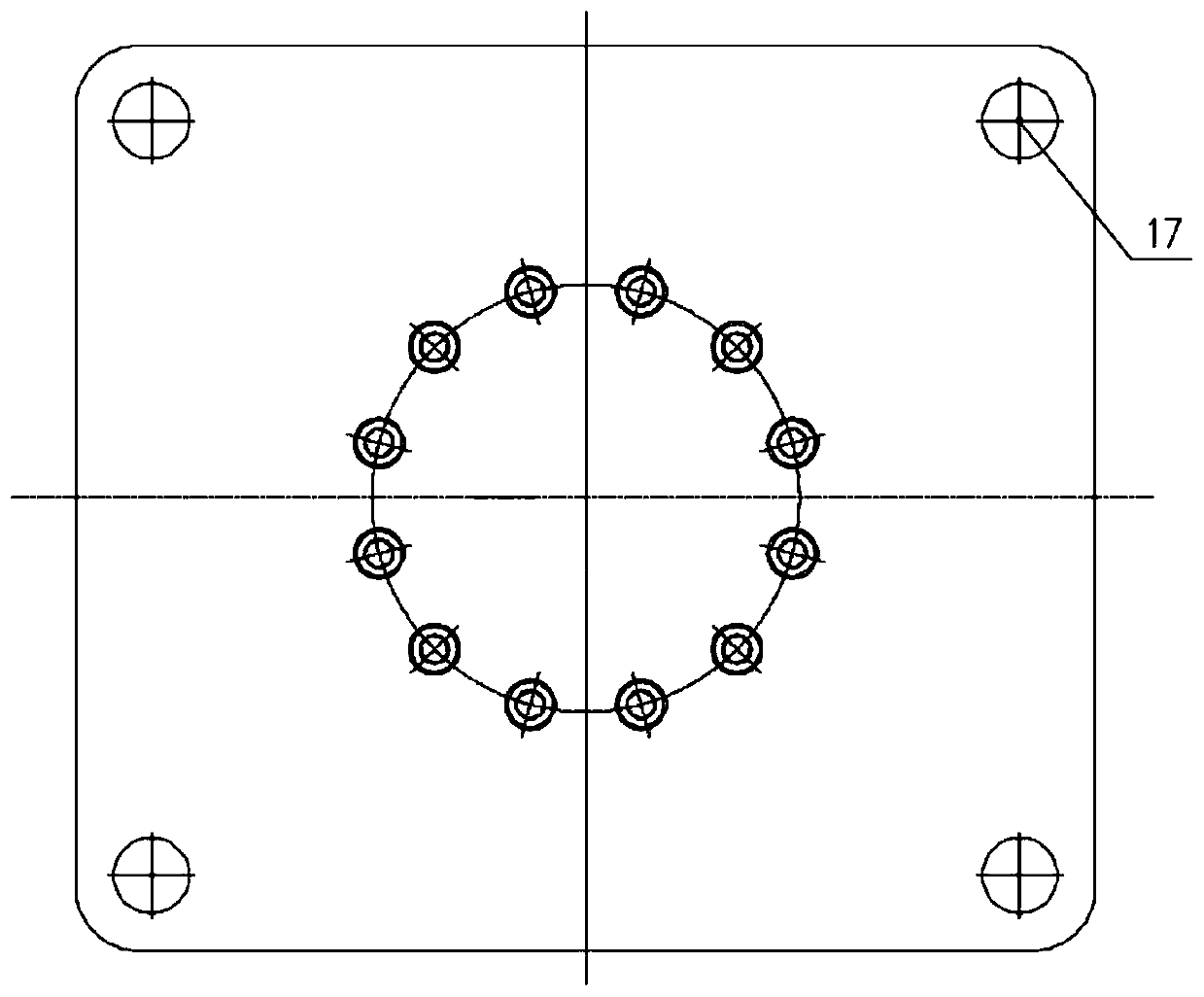

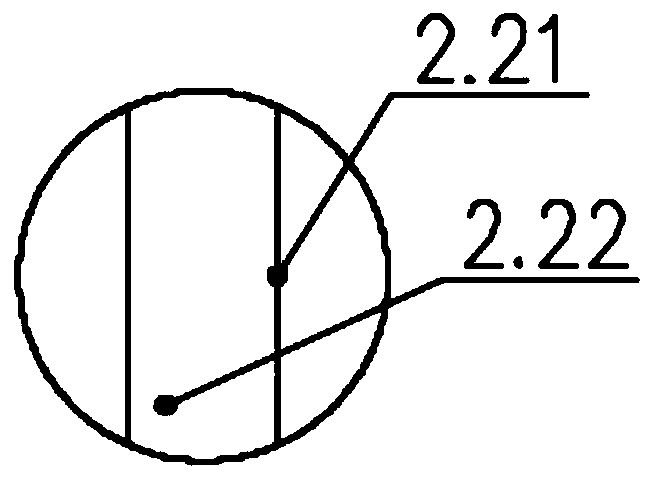

[0034] see figure 1 and figure 2 In the present invention, the upper cover plate 4 and the lower cover plate 6 all reserve a plurality of mounting holes 17 for installing corresponding upper damping equipment and bottom base; the capsule body 2 is connected with the upper and lower flanges 5, 7 and The upper flange 5 is connected with the upper cover plate 4 through the second bolt 3, the lower flange 7 is connected with the lower cover plate 6 through the third bolt 18, and the capsule body 2 is connected with the upper cover plate 4 and the lower cover 6 are respectively provided with upper and lower compression rings 8, 9, the capsule body 2 is covered with a constraining flange 10, and the constraining flange 10 is fixed on the upper cover 4 via the first bolt 1 Above all, the static and dynamic stiffness and other mechanical properties of the air spring can be adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com