Deep excavated soil cutting slope protection structure and construction method

A technology for slope protection and soil quality, which is applied in infrastructure engineering, excavation, construction, etc., can solve problems such as difficult to cover soil quality, difficulty in interaction between anchor rods and soil, increase of slope runoff distance and time, etc., to increase engineering The effect of aesthetics, reducing rainwater infiltration into embankment, and improving pull-out performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

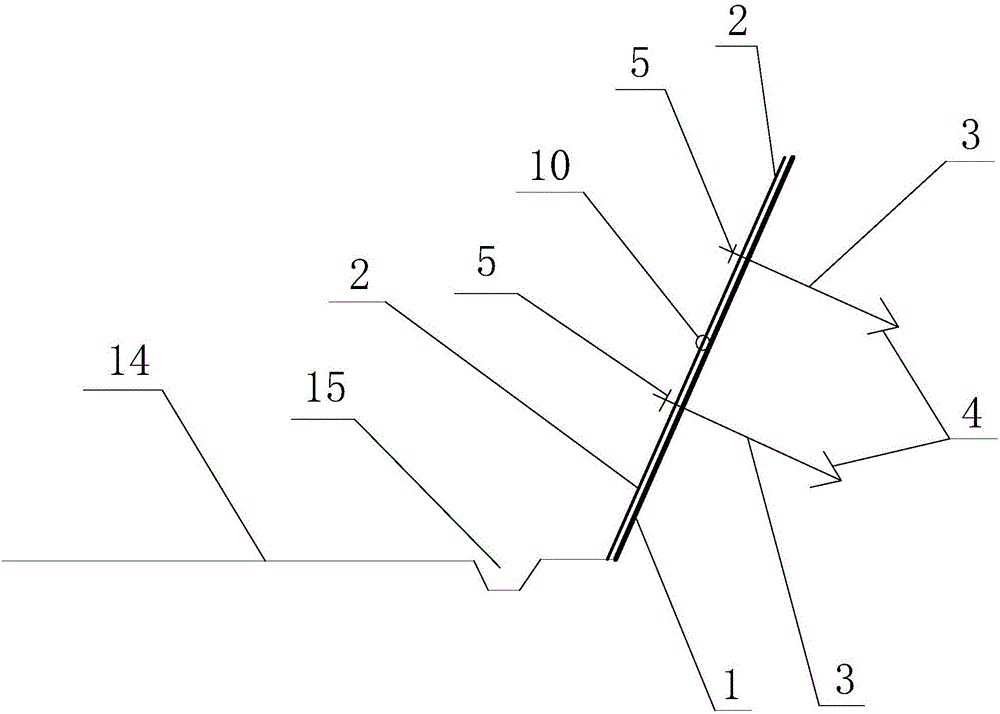

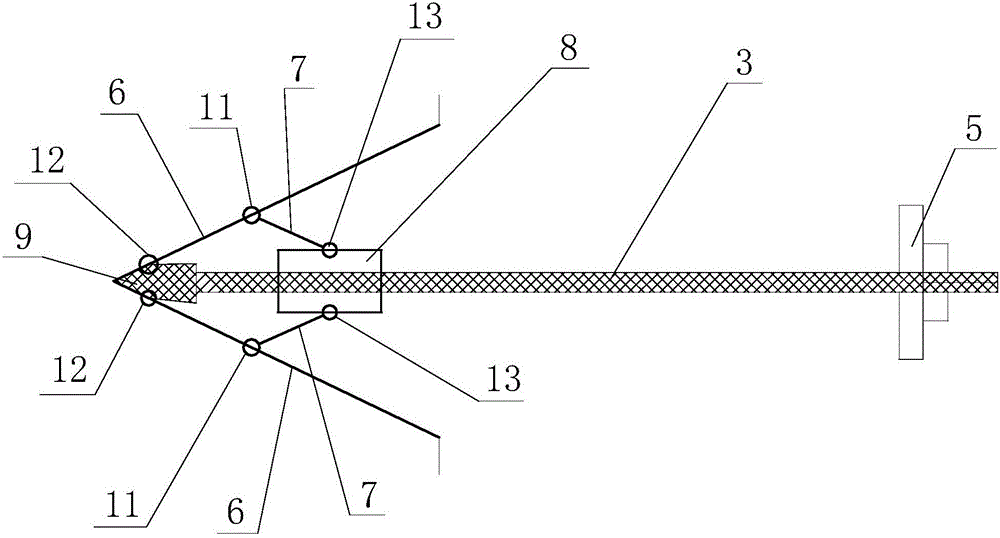

[0029] Such as figure 1 , figure 2 As shown, a deep excavation soil cutting slope protection structure includes a slope 1, a road surface 14, a protective plate 2 and several protective components, the side slope 1 is located at the side edge of the road surface 14, and the protective component consists of a pull rod 3 and an expansion The mouth 4 is fixedly connected. The slope 1 is covered with several protective plates 2. The protective component passes through the side slope 1 and is placed inside the slope 1. The end of the protective component close to the side slope 1 is fixedly connected with the protective plate 2. The preferred expansion nozzle 4 of the present invention comprises an expansion leaf 6, a power transmission leaf 7 and a slide tube 8, one end of the pull rod 3 is an expansion end 9, the other end of the pull rod 3 is a protective plate connection end, and the expansion end of the pull rod 3 9. An expansion leaf 6 is connected to the movable hinge, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com