Multi-section spiral continuous feeding device for particle materials

A kind of feeding device, technology of granular material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

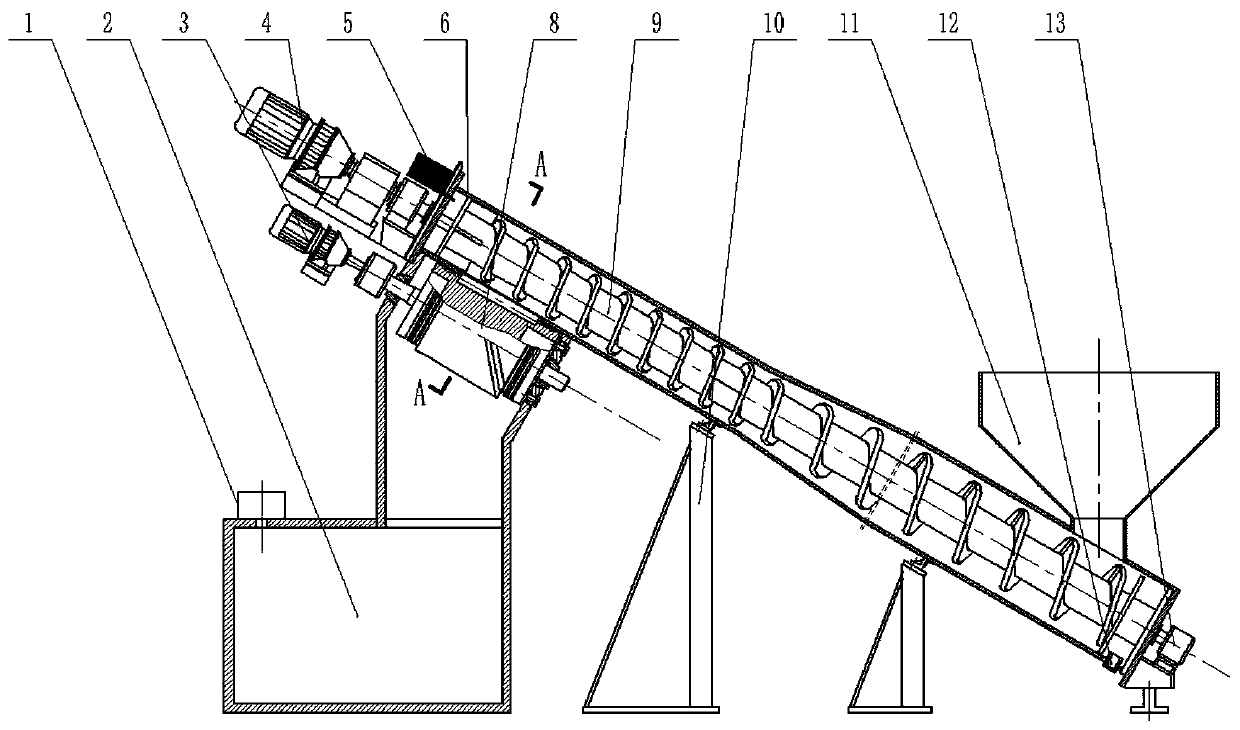

[0022] Waste tire rubber granules are an embodiment of the present invention. Waste tire rubber granules enter the screw conveying device from the feed port (11) (13), and use the propulsion of the screw blade to make the raw material form a material plug during operation to achieve material self-sealing. , the material enters between the tooth grooves of the feed gear (8), falls evenly into the feed bin (21) as the feed gear (8) rotates, and falls into the reactor (2).

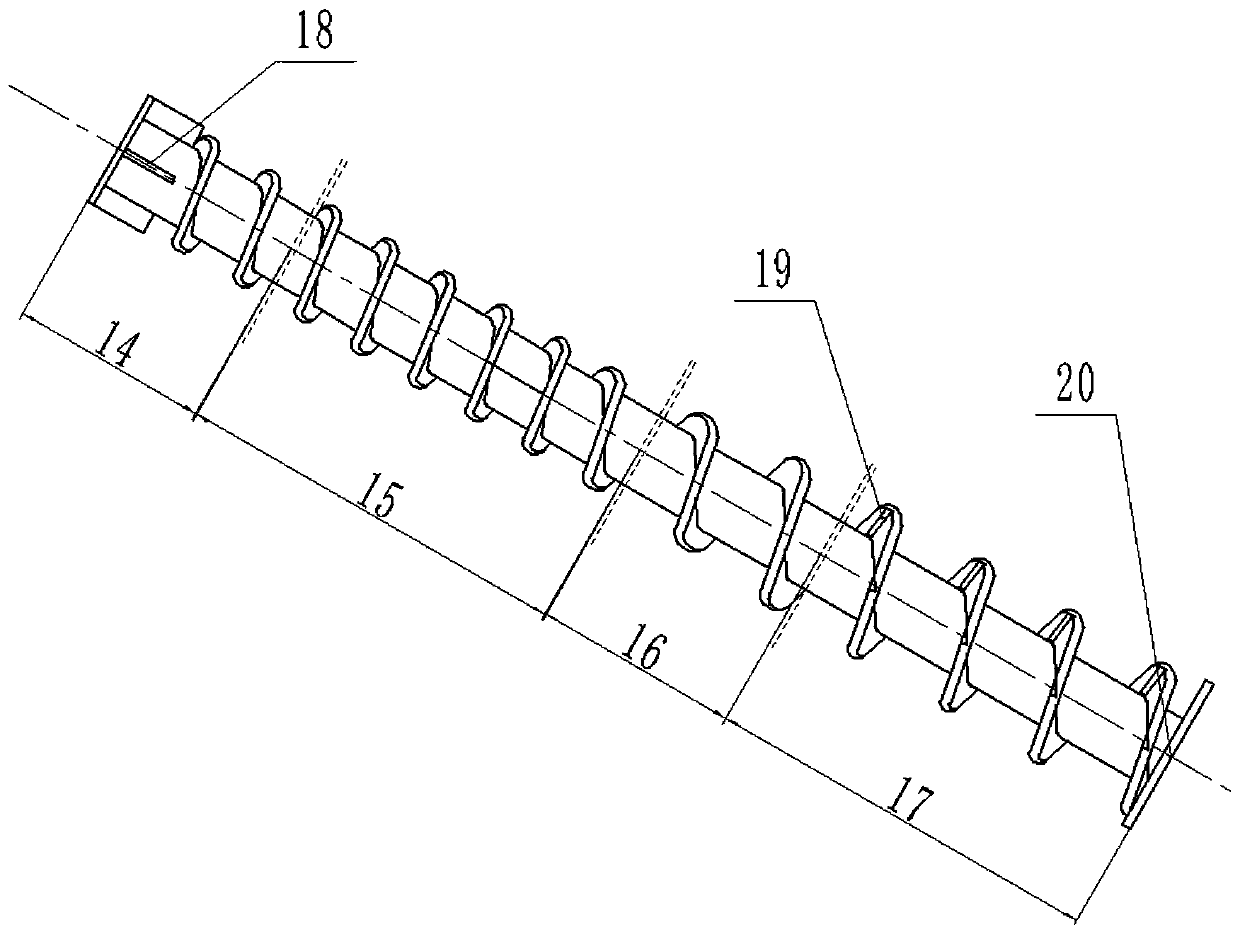

[0023] First turn on the motor, the screw conveying device and the feed gear (8) are running and do not open the reactor temporarily, the feed port (11) is filled with materials, and the materials are compressed through the variable diameter extrusion section (16), and are conveyed in the small diameter and small pitch conveying section ( 15) The inside is compacted, the material moves to the discharge port (24), the feed gear (8) scrapes the material into the tooth groove and takes it out of the screw conveyo...

Embodiment 2

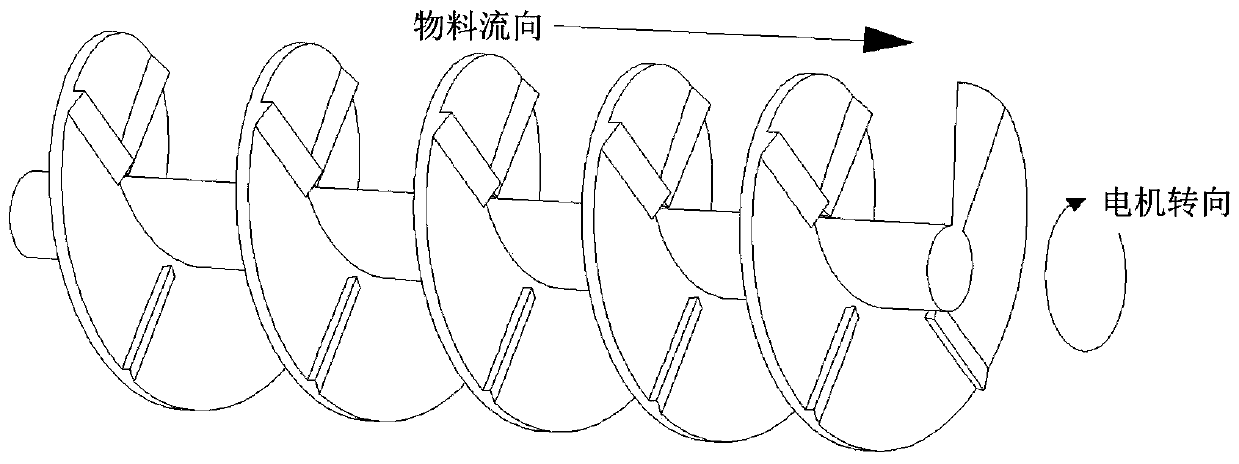

[0027] In another technical scheme, the feed gear (8) is a left-handed gear (28), such as Figure 5b , Figure 6b As shown, when the feed gear (8) and the screw conveyor (9) rotate in opposite directions, the material flow direction near the discharge port (24) is the same as the gear tooth movement direction, and when the feed gear (8) and the screw conveyor (9) Rotate in the same direction, the direction of material flow near the discharge port (24) is opposite to the direction of gear tooth movement, but because the inclined direction of gear teeth is opposite to the direction of material flow, the scraping effect is weak, which is suitable for strong fluidity , Materials with poor toughness, such as PVC.

Embodiment 3

[0029] In another technical scheme, the feed gear (8) is a spur gear (29), such as Figure 5c , Figure 6c Shown, feeding gear (8) and screw conveyor (9) rotation direction all have scraping effect preferably, but scope of application is not as good as right-handed gear (27), is not as good as left-handed gear to harder material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com