Compensation type multi-purpose annular blowout preventer

An annular blowout preventer, multi-purpose technology, applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problem of not being able to adapt to multiple specifications and different shapes at the same time, the oil pipe cannot be lifted and lowered, and the three gates The plate blowout preventer is complex and other problems, to achieve the effect of improving blowout prevention accidents, good sealing effect under pressure, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

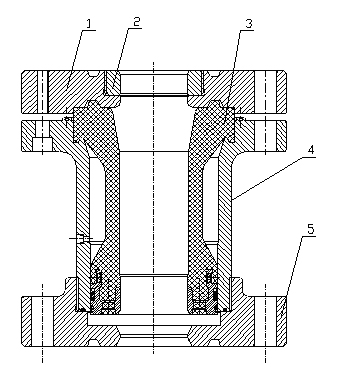

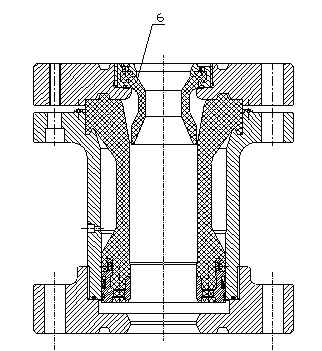

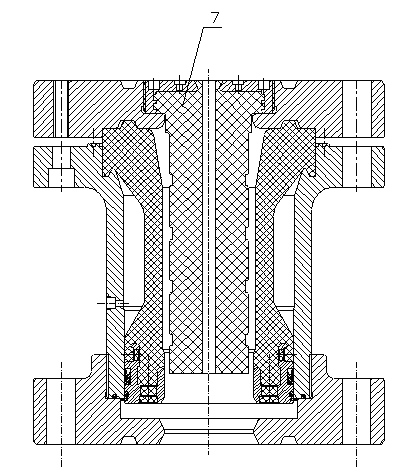

[0033] The structural diagram of the compensation type multi-purpose annular blowout preventer is as follows: figure 1 As shown, it at least includes an upper flange 1, a lower flange 5, and a sealing cylinder body. The sealing cylinder body is composed of an inner sealing body 3 and an outer sealing body 4. A space is formed between the outer sealing body 4 and the inner sealing body 3. Cavity structure, the upper end of the outer sealing body 4 is connected with the upper flange 1 with bolts, the lower end of the outer sealing body 4 is connected with the lower flange 5 with threads, and the flange hole of the upper flange 1 communicates with the flange hole of the lower flange 5 up and down ; When the fluid medium is injected into the cavity between the outer sealing body 4 and the inner sealing body 3, the inner sealing body 3 shrinks inward, so that the inner sealing body 3 hugs the oil pipe or cable or closes the empty well, so that the oil pipe fixed by the sealing body ...

Embodiment 2

[0035] The upper flange 1 in embodiment 1 is as Figure 4 As shown, the upper flange 1 is circular, and the outer circle size of the upper flange 1 is consistent with the matching wellhead flange. The thickness of the outer edge of the upper flange 1 is 40 mm to 70 mm. The hole 9, the inner through hole 9 is the through hole of the oil pipe or the tool, and the upper end side wall of the inner through hole 9 has a first internal thread 8.

[0036] The upper surface of the upper flange 1 has a steel ring groove 10, which can cooperate with the steel ring of the matching wellhead upper flange to play a sealing role. There is an annular groove in the middle of the lower part of the upper flange. There is a sealing groove 12 on the upper plane of the annular groove. The annular groove is used to fix the outer edge of the upper part of the inner sealing body 3 and seal the connection position through the sealing groove 12. The upper end of the flange 1 has upper flange bolt holes ...

Embodiment 3

[0040] Inner sealing body 3 in embodiment 1 is as Figure 7 As shown, the inner sealing body 3 is also called the anti-spray rubber sleeve. The inner sealing body 3 is a hollow cylinder. The diameter of the inner hole 16 in the inner sealing body is different. 15. The diameter of the inner hole 16 of the inner seal is the same as that of the remaining sections; the inner seal body 3 has a falling sealing edge 17 on the outer circle of the upper part, and the upper surface of the falling sealing edge 17 has a sealing boss 14, and the inner sealing body 3 is connected to the upper flange 1 at the upper end When the sealing boss 14 cooperates with the sealing groove 12 of the upper flange 1, the sealing is realized; the falling end of the falling sealing edge 17 is the falling sealing ring 18, and the falling sealing ring 18 and the outer circle of the main body of the inner sealing body 3 middle rings 19 has a certain gap, so that the inner sealing body 3 plays a sealing role when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com