Gas fuel constant volume combustion chamber capable of being internally installed with diaphragm plate

A gas fuel and combustion chamber technology, applied in combustion engines, internal combustion piston engines, machines/engines, etc., can solve the problem that constant volume combustion chambers cannot be used for compression ignition combustion and center ignition combustion at the same time, to achieve increased use, mixing even air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

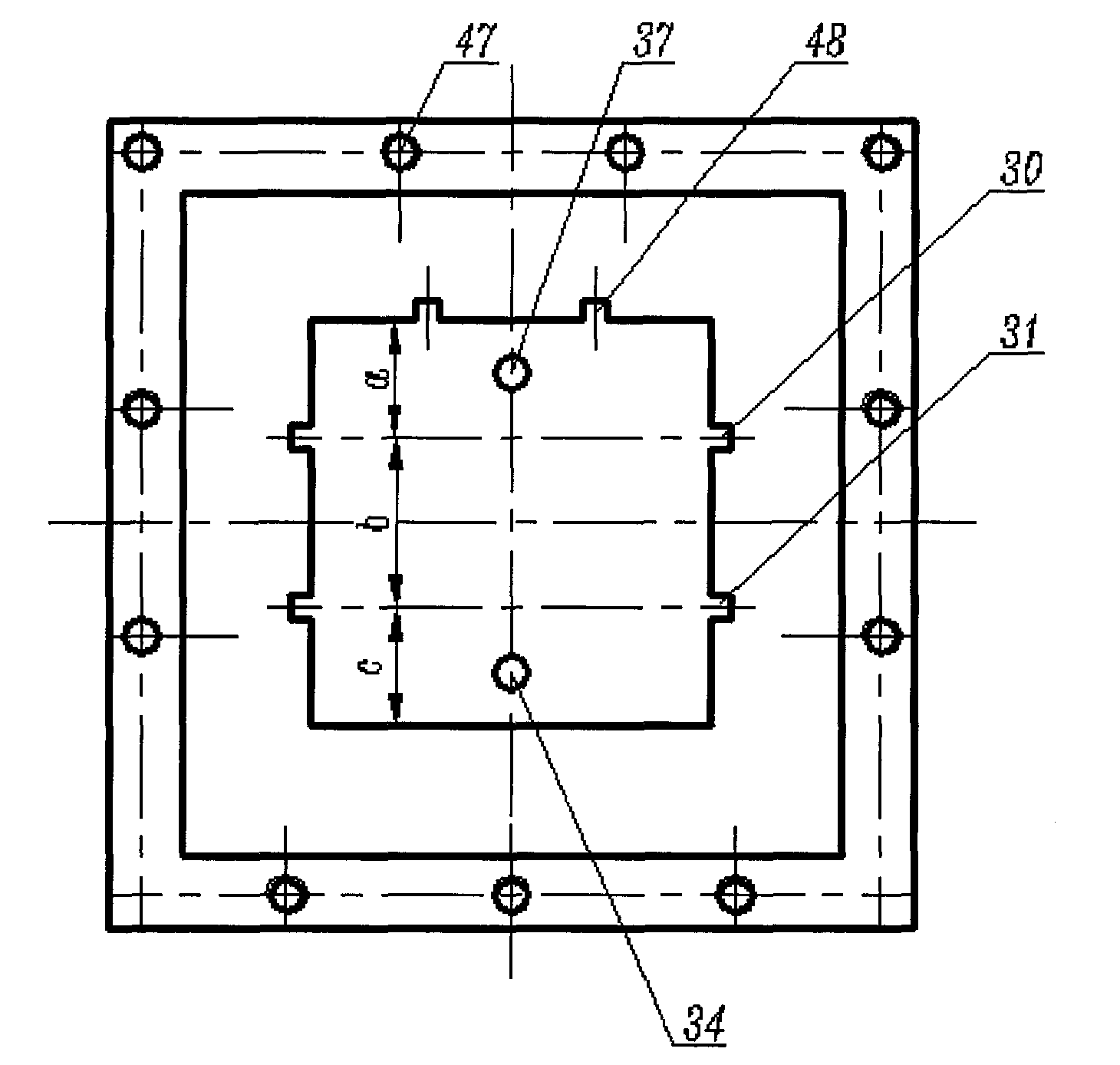

[0033] Based on the characteristics of this patent, there are mainly three implementation modes. First, the central ignition pin is ignited when there is no partition, which is used for the test of the laminar combustion characteristics of gas fuel; second, when the partition with small holes is added, the spark plug at the top of the combustion chamber is ignited or the top and bottom are ignited according to a certain timing, using It is used to study the compression ignition (natural) or ignition phenomenon of gas fuel and the EGR effect; thirdly, when the slit partition is added, the top of the spark plug in the combustion chamber is ignited, and it is used to study the slit quenching effect of gas fuel.

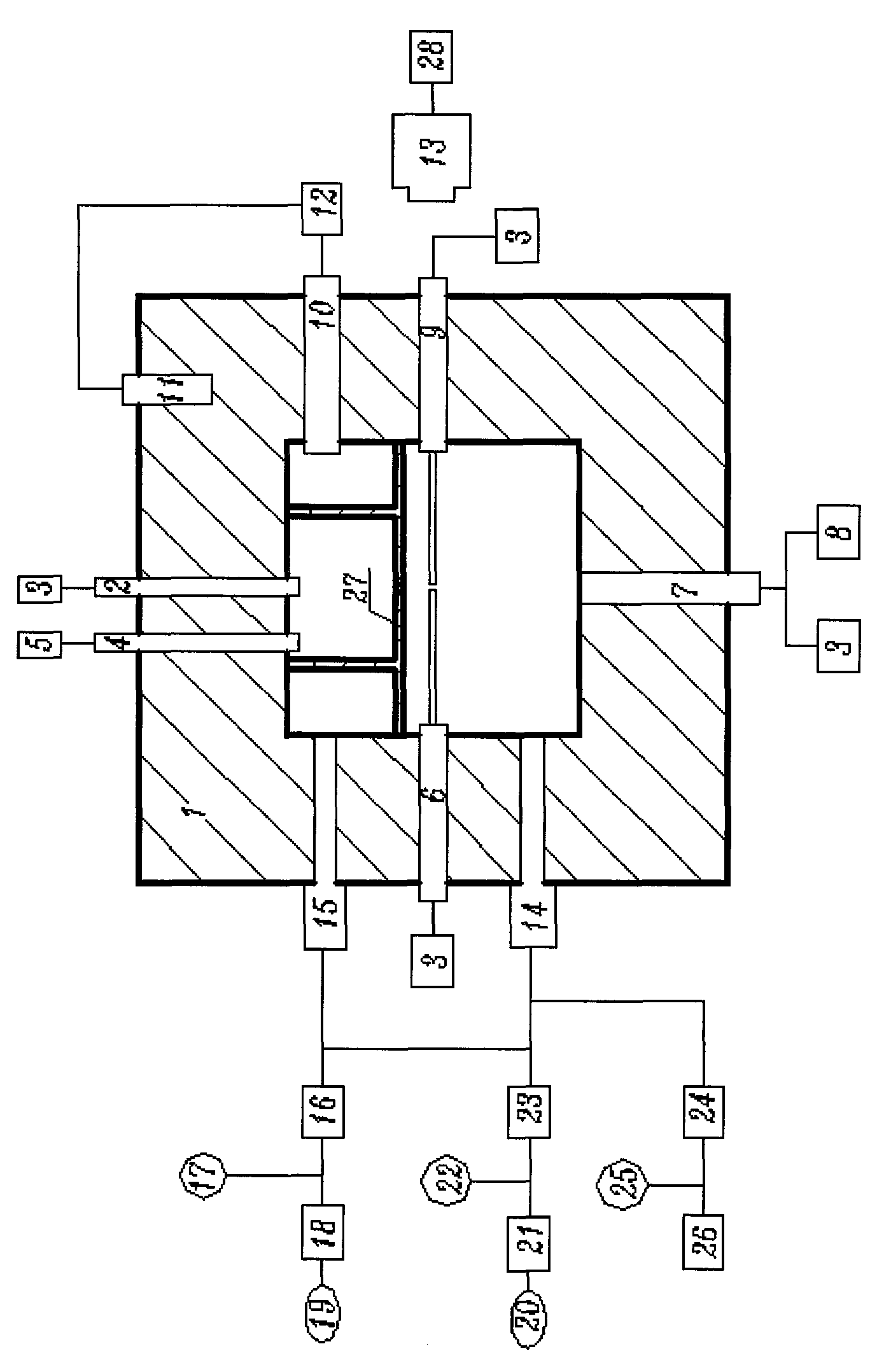

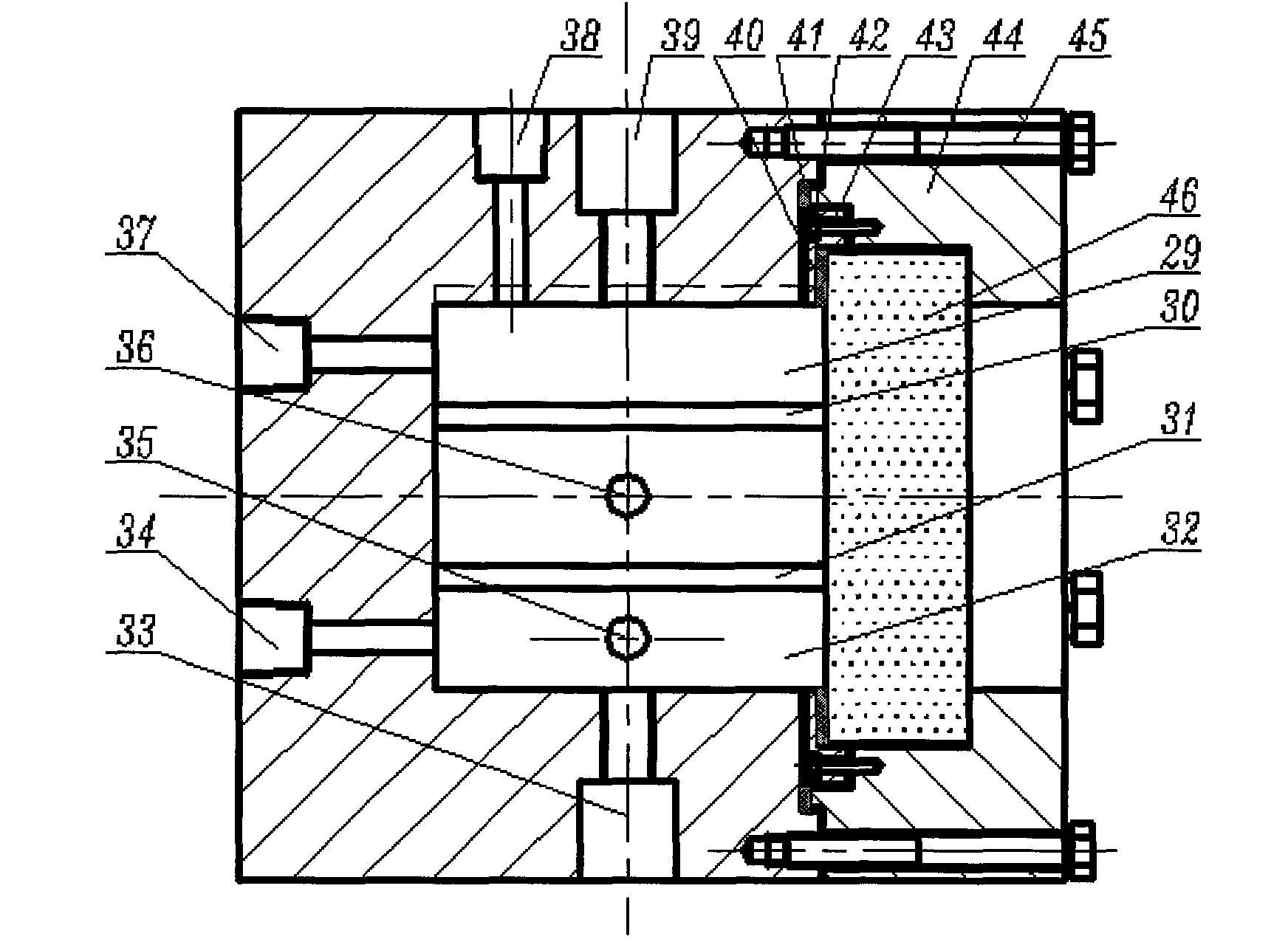

[0034] Combine below Figure 1 to Figure 21 The embodiment when the partition board with small holes and the slit partition is added in the combustion chamber will be described in detail.

[0035]This embodiment is mainly composed of a main body 1, a built-in diaphragm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com