Pipe airtightness detecting worktable,

An air tightness detection and workbench technology, which is used in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, and testing of machine/structural components, etc. , qualitative can not be quantitative and other problems, to reduce the detection time, enhance the degree of automation, improve labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

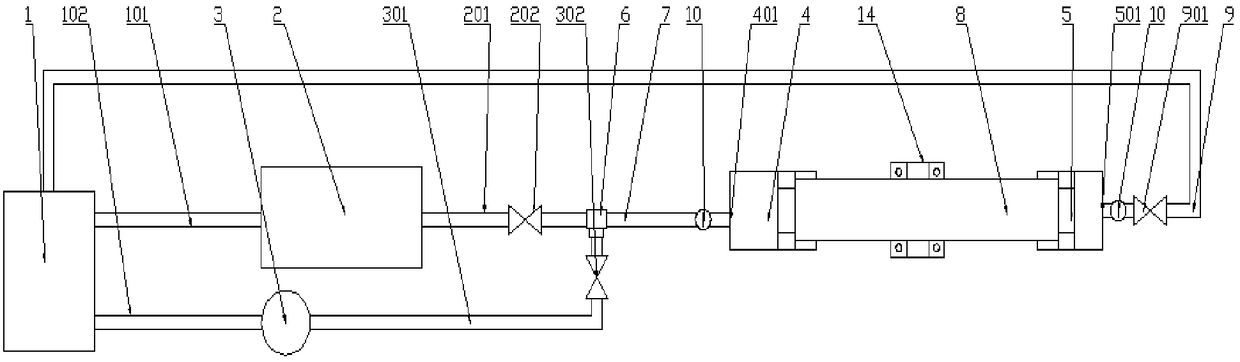

[0035] like Figure 1-2 As shown, a pipe fittings airtightness detection workbench includes an inflation device 1, a high-pressure auxiliary tank 2, a detection device 3, a first pipe fittings airtight pressurization positioning device 4, a second pipe fittings airtight pressurization positioning device 5; The inflation device 1 is connected to the detection device 3 through the first air inlet pipe 101, and the detection device 3 is also provided with a first air outlet pipe 301; the high-pressure auxiliary tank 2 is connected to the inflation device through the second inlet pipe 102. 1 connection; the high-pressure auxiliary tank 2 is also provided with a second air outlet pipe 201, and the first air outlet pipe 301 and the second air outlet pipe 201 communicate with the main air intake pipe 7 through a tee 6; The trachea 7 is connected to the first pipe airtight pressure positioning device 4, the other end of the first pipe airtight pressure positioning device 4 is connecte...

Embodiment 2

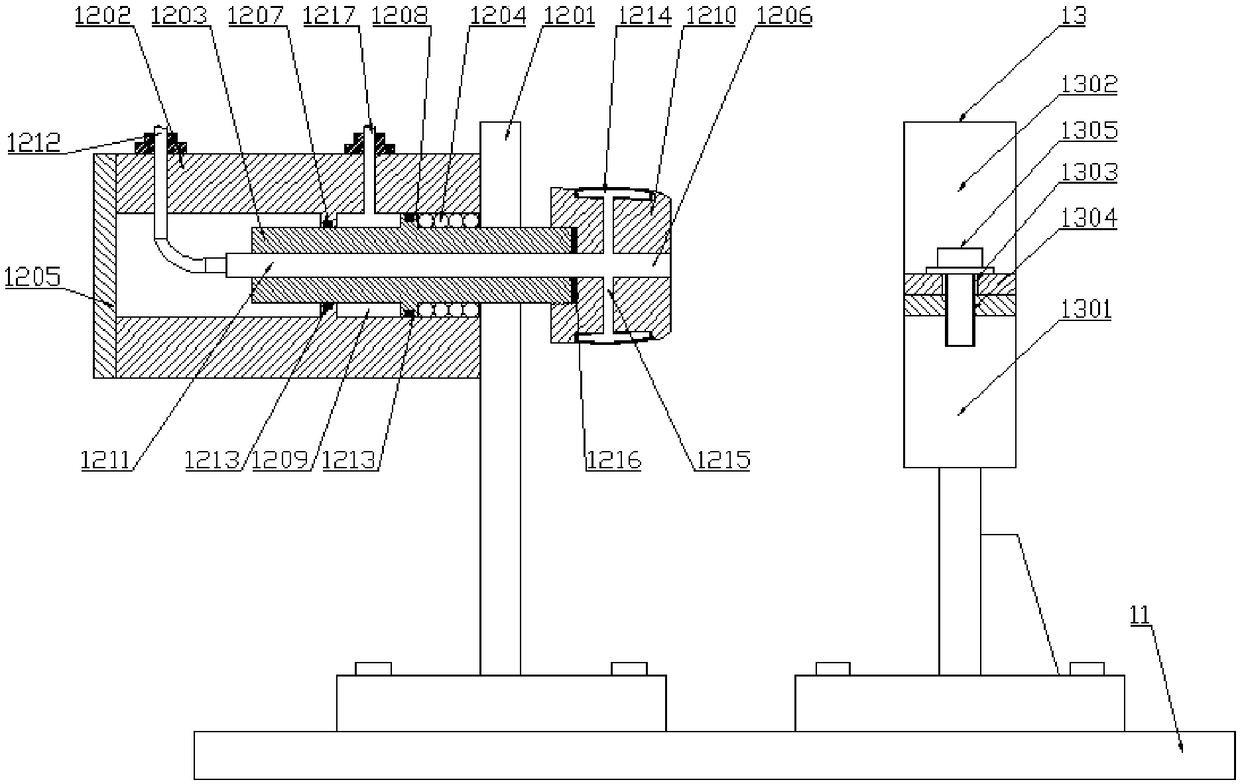

[0039] like image 3 As shown, a pipe fittings airtightness detection workbench, this embodiment is similar to the structure principle of the embodiment, and the difference from Embodiment 1 is that the first pipe fittings airtight pressurization positioning device 4 and the second The airtight pressurization and positioning devices 5 of the two pipe fittings all include a base 11 and a pneumatic pressurization mechanism 12 fixedly installed on the base 11. The pneumatic pressurization mechanism 12 includes a bracket 1201, a cylinder liner 1202, a push rod 1203, and a spring 1204. And the rear cover plate 1205, the cylinder liner 1202 is installed on the bracket 1201; the cylinder liner 1202 is a through-hole structure, and the inner cavity of the through hole is provided with a sealing guide ring 1207; the inner sleeve of the cylinder liner 1202 There is a push rod 1203, the push rod 1203 is provided with a sealing shoulder 1208, the sealing guide ring 1207 and the sealing sh...

Embodiment 3

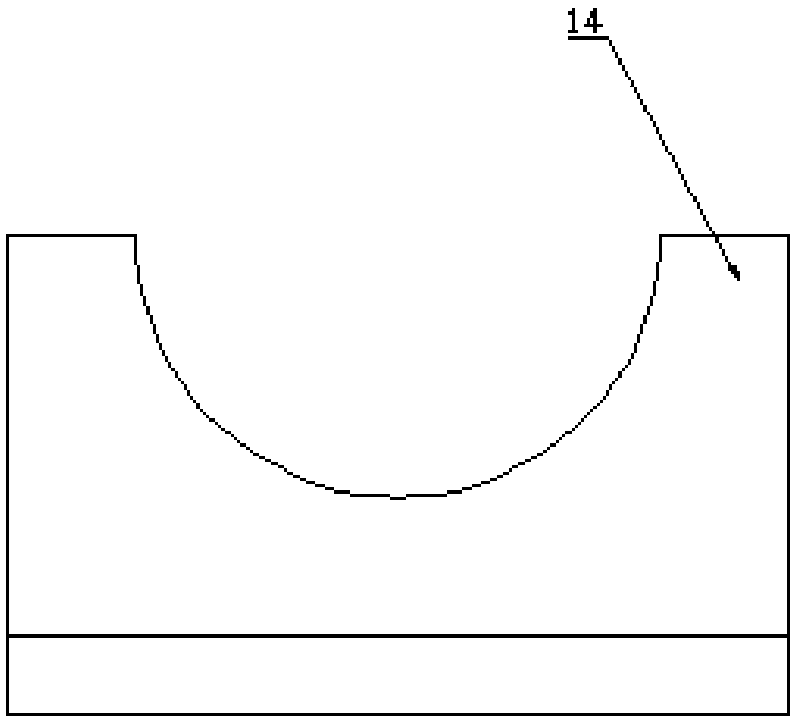

[0046] like Figure 4 As shown, a pipe fittings air tightness detection workbench, this embodiment is similar to the structure principle of embodiment 1 and embodiment 2, the difference between this embodiment and embodiment 1 and embodiment 2 is that the base 11 is also A pipe fitting fixing seat 13 is provided, and the pipe fitting fixing seat 13 includes a U-shaped base 1301 and a U-shaped cover 1302, the U-shaped cover 1302 is hinged and fixed on the U-shaped base 1301, and the U-shaped cover 1302 A through hole 1303 is provided on the movable end of the U-shaped base 1301, and a threaded hole 1304 matching the through hole 1303 is correspondingly provided on the U-shaped base 1301, and the U-shaped cover plate 1302 is fixed on the On the U-shaped base 1301 ; the U-shaped bottom of the U-shaped base 1301 and the U-shaped cover 1302 are respectively provided with anti-slip pads 1306 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com