Liquid storage device and storage cover of dosing machine

A stocker and batching machine technology, which is applied in the field of liquid stocker and stocker cover, can solve the problems of increasing operation requirements and operating time, inconvenient disassembly and assembly of liquid stocker, and the need for translation or forceful pulling and pressing, etc. It achieves the effect of simple and convenient disassembly and assembly, stable and reliable sealing effect and ingenious principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail through the following embodiments. However, those skilled in the art should understand that the following embodiments do not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

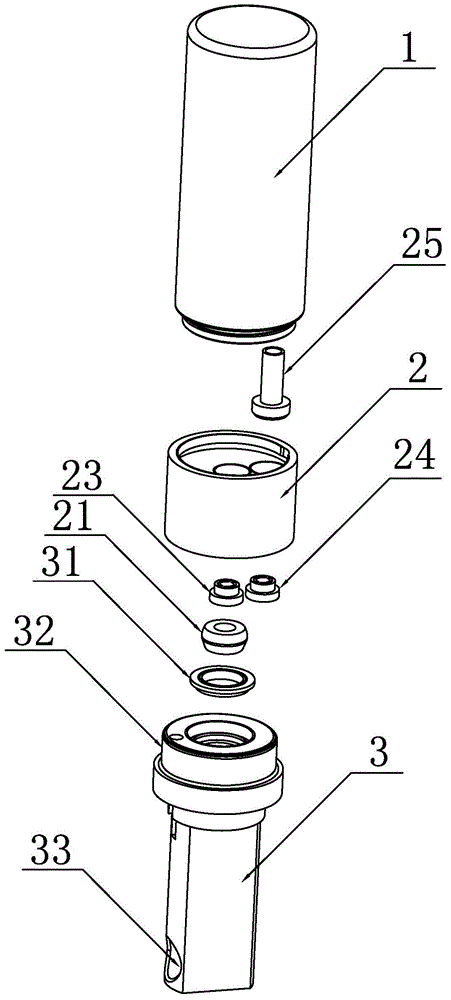

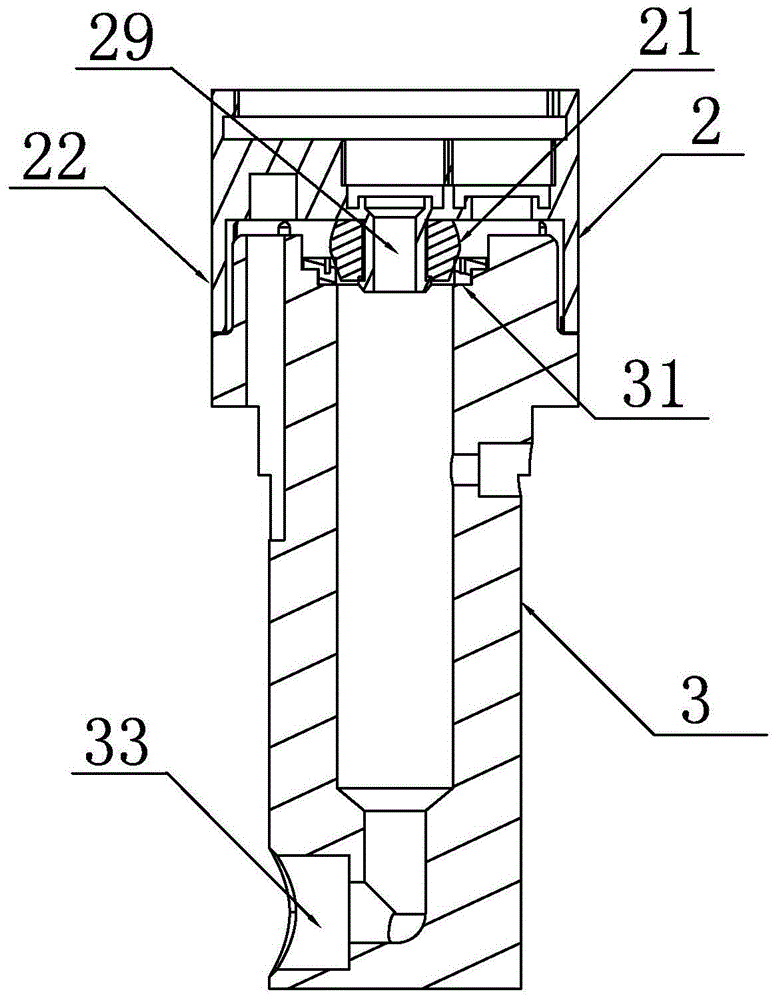

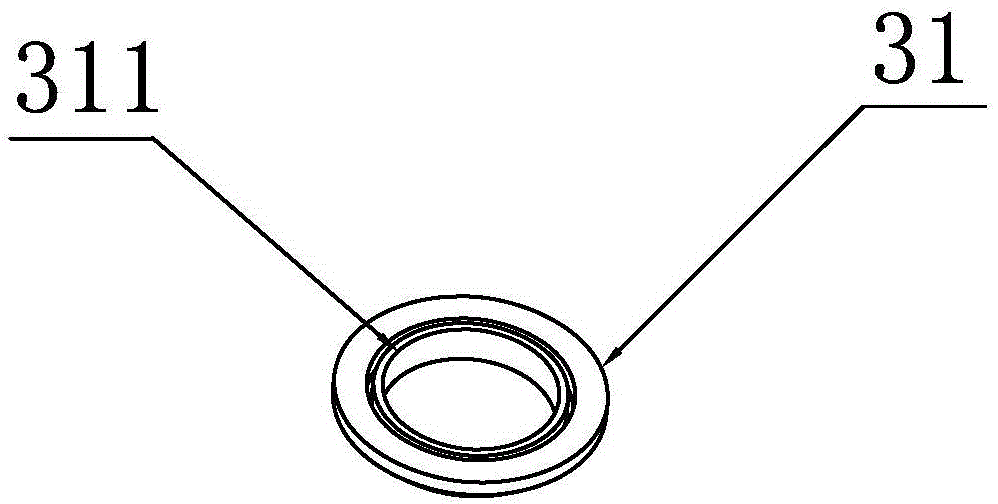

[0038] Refer to attached figure 1 As shown, the liquid storage device of the batching machine of the present invention is mainly composed of a liquid storage cavity 1 , a storage cover 2 and a storage seat 3 . Wherein, the bottom end of the liquid material storage chamber 1 is connected with the top end of the material storage cover 2, the bottom end of the material storage cover 2 is provided with a first sealing structure 21, and the top of the hollow material storage seat 3 is provided with a second sealing structure 31. After the material cover 2 is placed on the material storage seat 3 , the liquid storage conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com