Preparation method of self-sealing planar solid oxide fuel cell

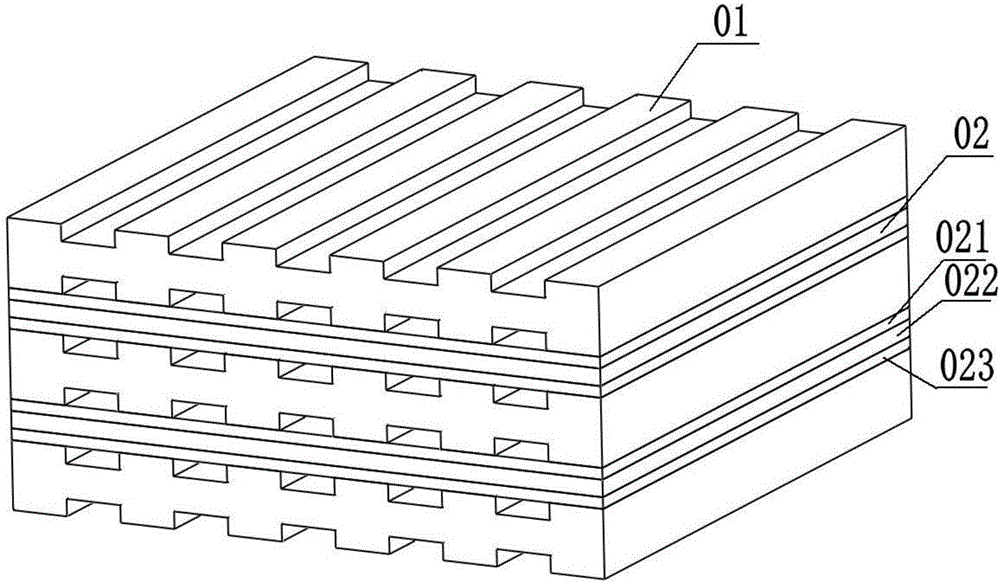

A solid oxide and fuel cell technology, which is applied to fuel cell components, fuel cells, sealing/supporting devices, etc., to achieve the effect of solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

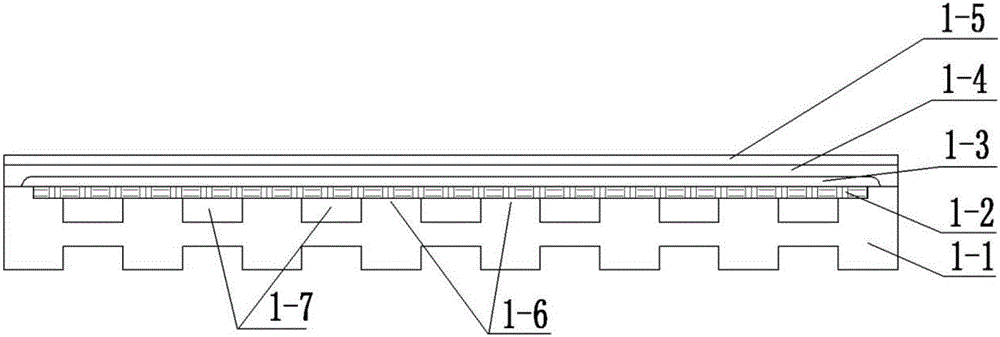

[0032] A method for preparing a self-sealing flat solid oxide fuel cell of the present invention comprises the following steps:

[0033] (1) Process the metal connection electrode 1-1 with a gas channel structure;

[0034] (2) forming a whole with the porous metal layer 1-2 and the technical connecting pole 1-1;

[0035] (3) Trimming the overall upper surface of the porous metal layer 1-2 and the metal connecting body 1-1 to form a surface available for spraying;

[0036] (4) Prepare a layer of anode layer 1-3 on the porous metal surface by thermal spraying;

[0037] (5) Prepare a layer of electrolyte layer 1-4 on the surface of the anode layer by thermal spraying;

[0038] (6) A cathode layer 1-5 is prepared on the surface of the electrolyte layer by thermal spraying.

Embodiment 1

[0040] in a 10×10cm 2 Process an outer bevel on the metal connecting pole 1-1 with a size of 9.1×9.1cm 2 , the inner groove size is 9×9cm 2 , a slope-like groove whose depth is equal to the thickness of the porous metal layer 1-2 (stainless steel), is placed in a 9×9cm 2 After the porous stainless steel, the porous metal layer 1-2 is connected to the metal connection electrode 1-1 by brazing, and the connection part includes the edge and the support surface 1 where the porous metal layer 1-2 contacts the metal connection electrode 1-1 -6. Then the surface of the porous metal layer 1-2 is ground, and the Ni / YSZ anode 1-3 (9.2×9.2cm 2 ), YSZ electrolyte layer 1-4 (10×10cm 2 ) and LSCF cathodes 1-5 (10×10cm 2 ), the single cell exhibited good voltage and power output.

Embodiment 2

[0042] in a 20×20cm 2 An outer bevel is processed on the metal connecting pole 1-1 with a size of 18.2×18.2cm 2 , the inner groove size is 18×18cm 2 , a slope-like groove with a depth equal to the thickness of the porous metal layer 1-2 (stainless steel), placed in a 18×18cm 2 After the porous stainless steel, the porous metal layer 1-2 is connected to the metal connecting electrode 1-1 by laser welding. Then the surface of the porous stainless steel is ground, and the Ni / ScSZ anode 1-3 (20×20cm 2 ), the ScSZ electrolyte layer 1-4 (20×20cm 2 ), the LSCF cathode 1-5 (20×20cm 2 ), thus completing the preparation of the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com