In-furnace heat adjusting system for horizontal high-temperature kiln

A high temperature, kiln technology, applied in the field of casting material processing equipment, can solve the problems of low energy utilization rate and high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

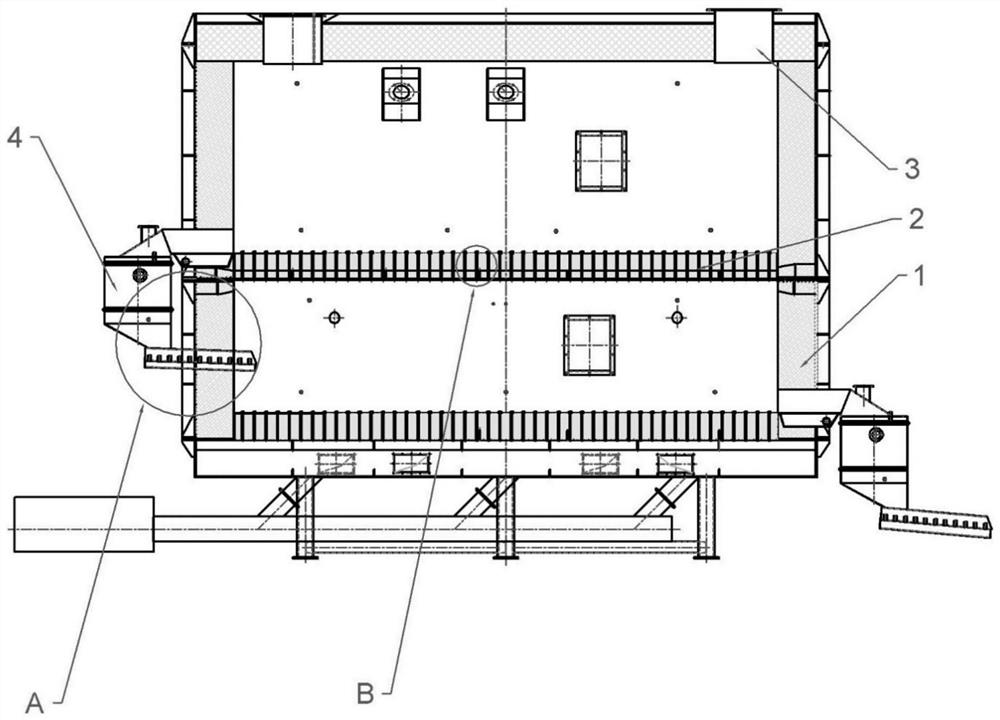

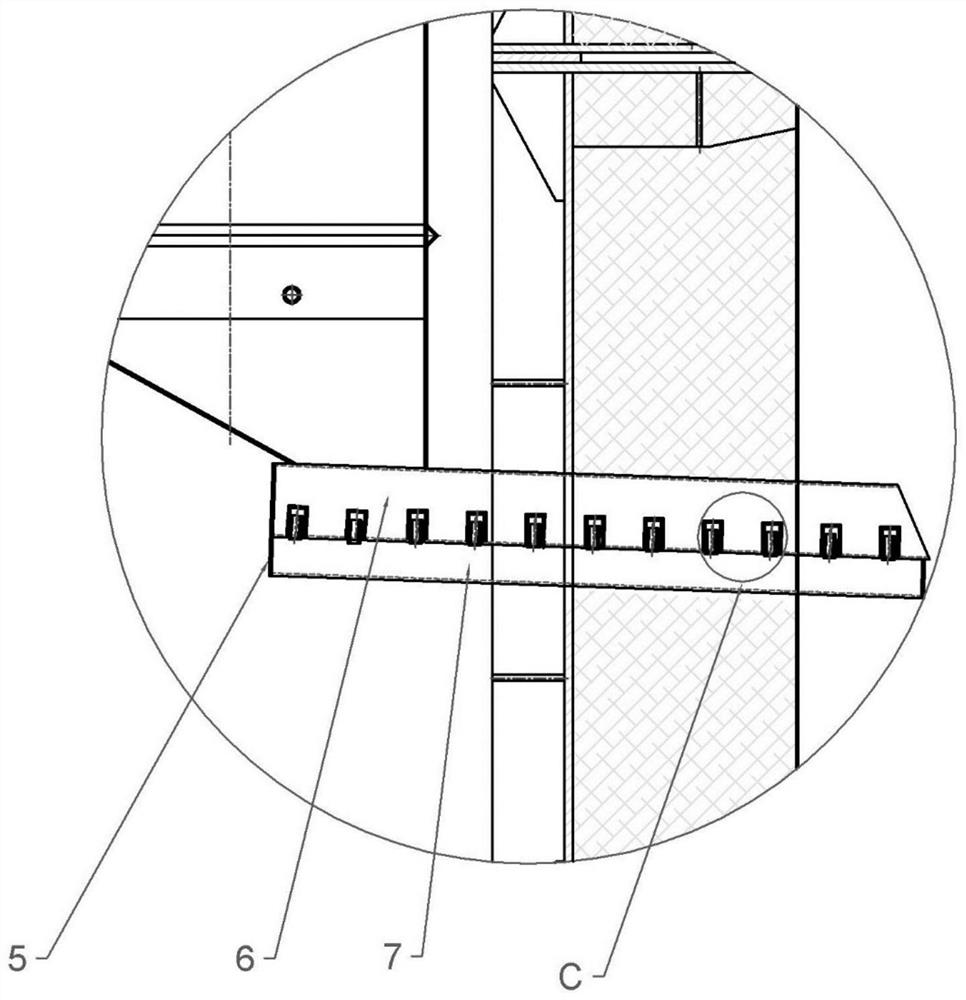

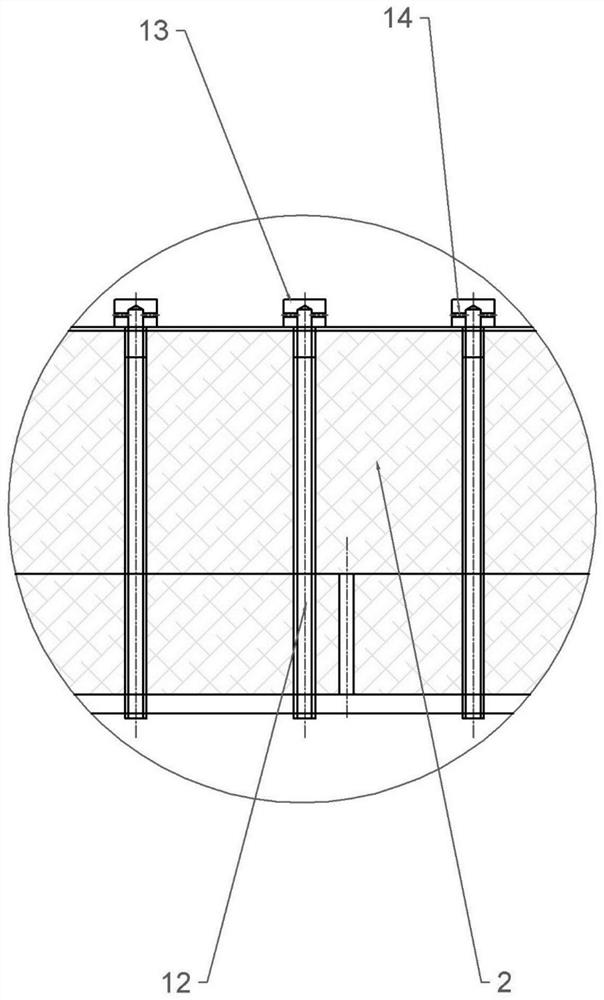

[0024] This embodiment is basically as attached figure 1 , figure 2 , image 3 with Figure 4 Shown: a furnace heat regulating system for a horizontal high-temperature kiln, including a furnace body 1, and a horizontal sealing plate 2 is arranged in the furnace body 1, and the sealing plate 2 divides the furnace body 1 into a first chamber and a second chamber chamber, the sealing plate 2 is evenly provided with a plurality of connecting pieces, the connecting piece includes a connecting pipe 12 and a wind cap 13, the connecting pipe 12 passes through the sealing plate and its lower end communicates with the second chamber, the upper end of the connecting pipe communicates with the wind cap 13, and the side of the wind cap Multiple air outlets 14 are provided. A connecting portion is provided on the side of the furnace body 1, and the connecting portion communicates with the first furnace body 1 and the second furnace body 1; the connecting portion includes a closed box 4 ...

Embodiment 2

[0029] Such as Figure 5 with Image 6 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a sand separation structure. The sand distribution structure includes a first sand distribution part and a second sand distribution part (not shown in the figure), the second sand distribution part includes a connecting plate and a plurality of sand distribution rods, and a plurality of sand distribution rods are arranged side by side and their ends are connected to The connecting plates are connected, and gaps are provided between adjacent sand-distributing rods. The first sand dividing part includes two connecting rods 25 and a plurality of struts 26 , the two connecting rods 25 are hinged and each connecting rod 25 is connected with a plurality of struts 26 . In this embodiment, a first connecting rod 23 and a second connecting rod 24 are also included. The other ends of the first connecting rod 23 and the second connecting rod 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com