Patents

Literature

31results about How to "Prevent dust leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

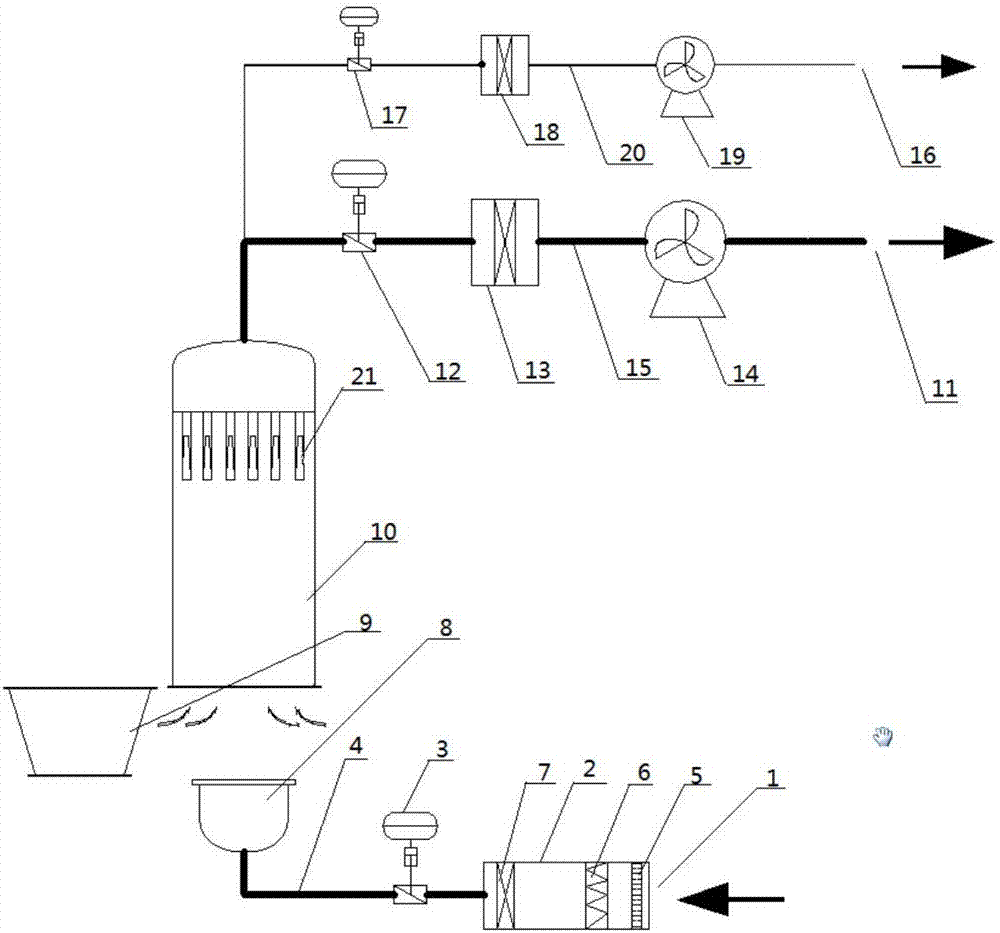

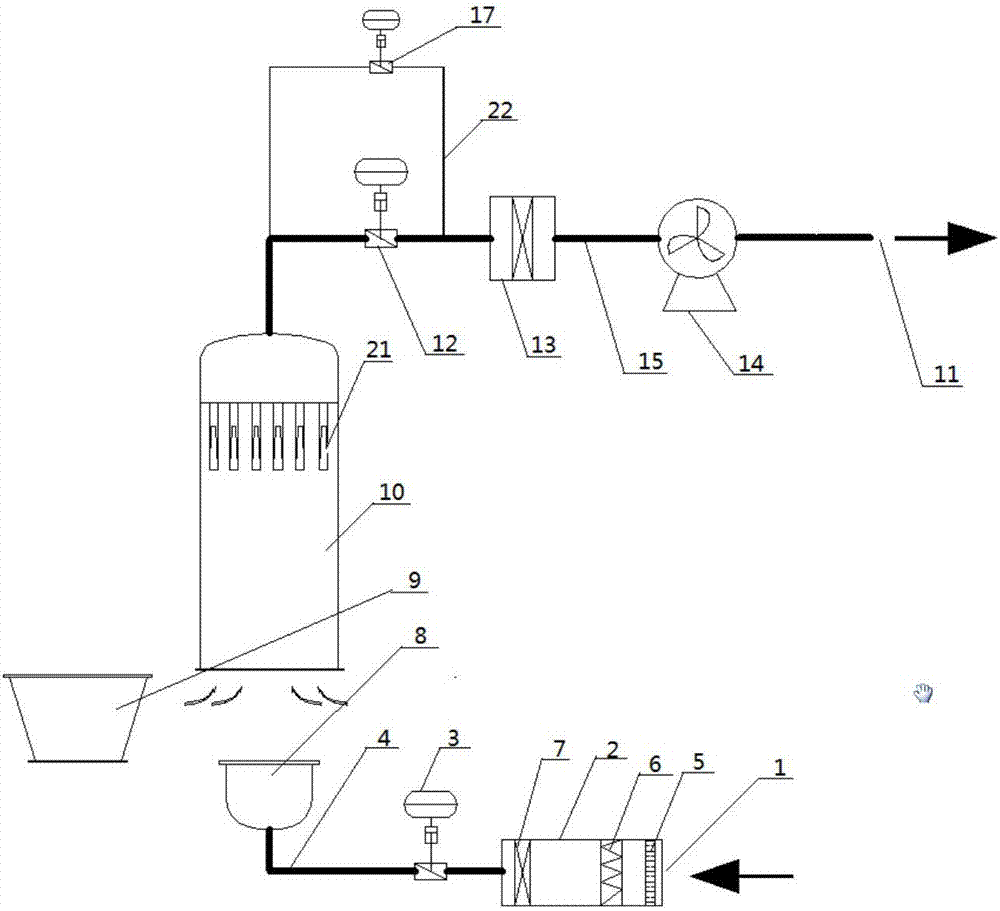

Waste recycling and regenerating device used in flue gas purification method

ActiveCN104399363APrevent dust leakageReduce dosageDispersed particle separationAlkali metal nitrate preparationAtmospheric pollutantsFlue gas

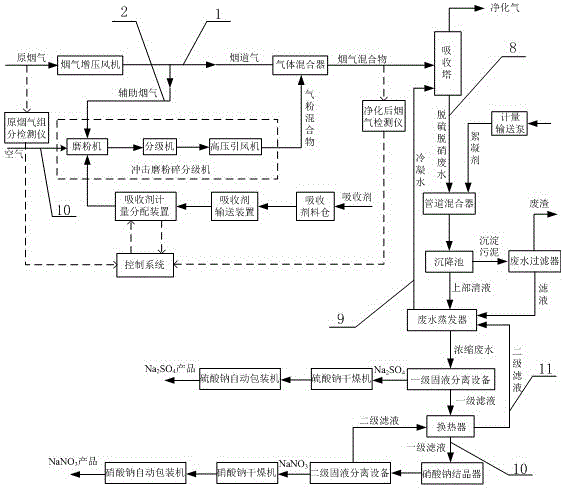

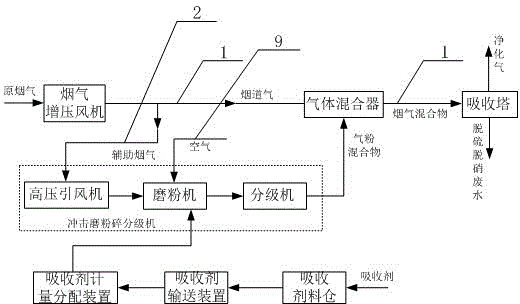

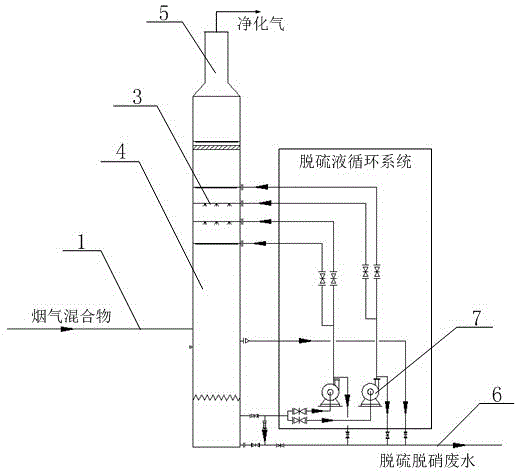

The invention discloses a waste recycling and regenerating device used in a flue gas purification method. The waste recycling and regenerating device comprises a wastewater regeneration system which is connected with flue gas purification equipment, wherein the flue gas purification equipment is a treatment unit for achieving desulfurization and denitrification of original flue gas; the wastewater regeneration system is a reuse unit which is used for separating the wastewater generated from desulfurization and denitrification by the flue gas purification unit and used for respectively preparing products of Na2SO4 and NaNO3. The waste recycling and regenerating device is simple to operate, pollutants in original flue gas are removed, and environment pollution is reduced, products of Na2SO4 and NaNO3 can be produced, the cost of atmospheric pollutant treatment is greatly lowered, the secondary pollution is avoided, and good social benefits and economic values are achieved.

Owner:CHENGDU HUAXITANG INVESTMENT

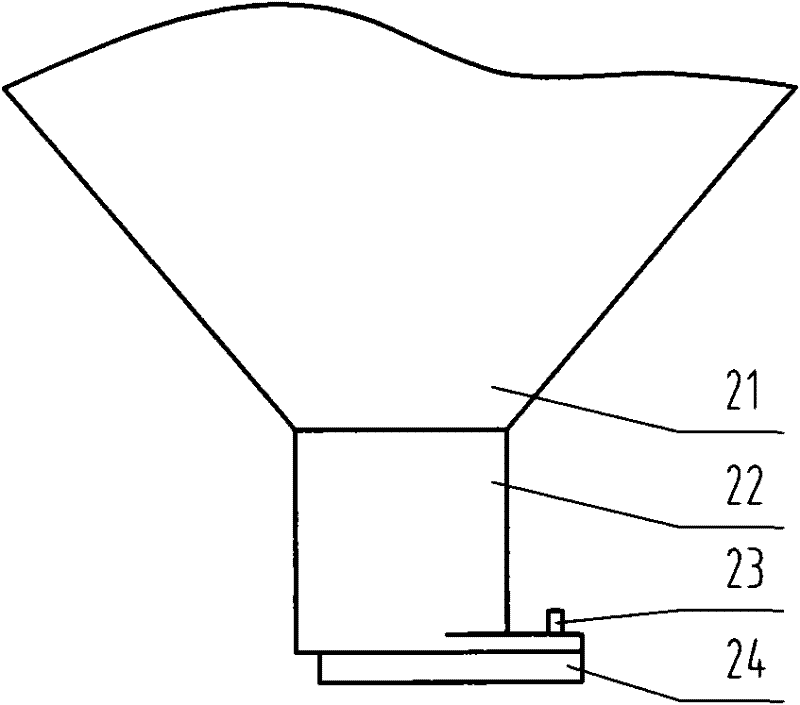

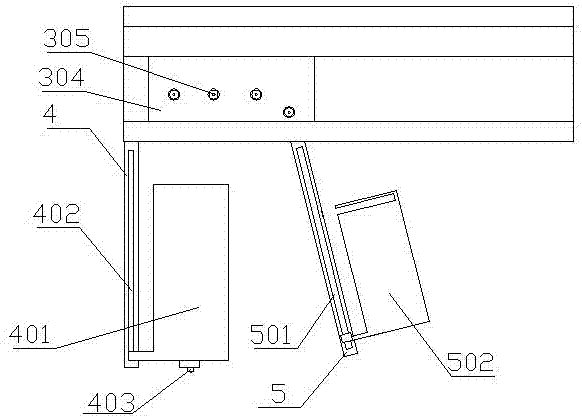

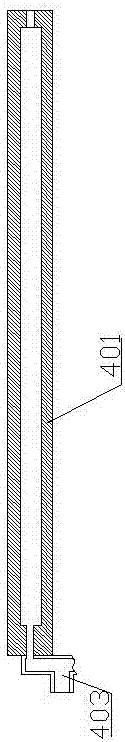

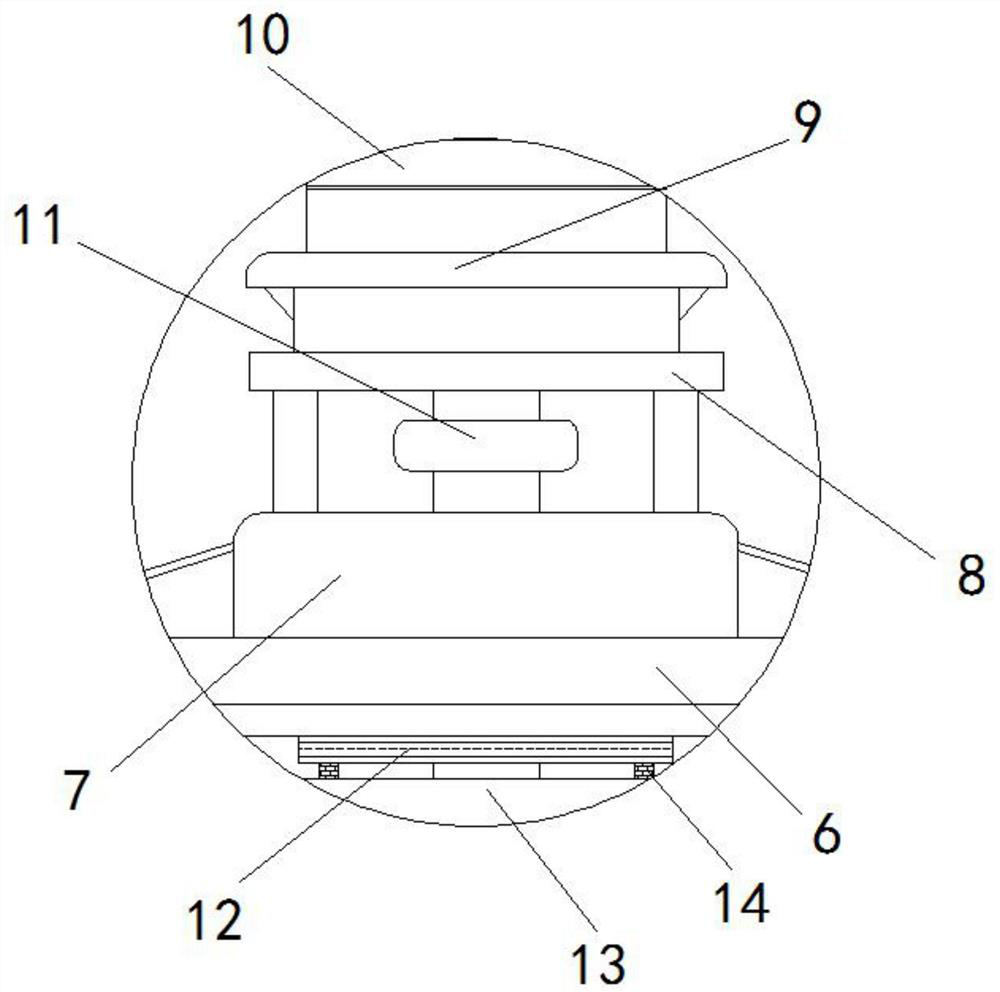

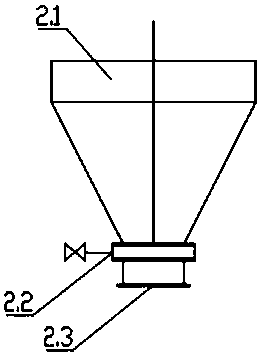

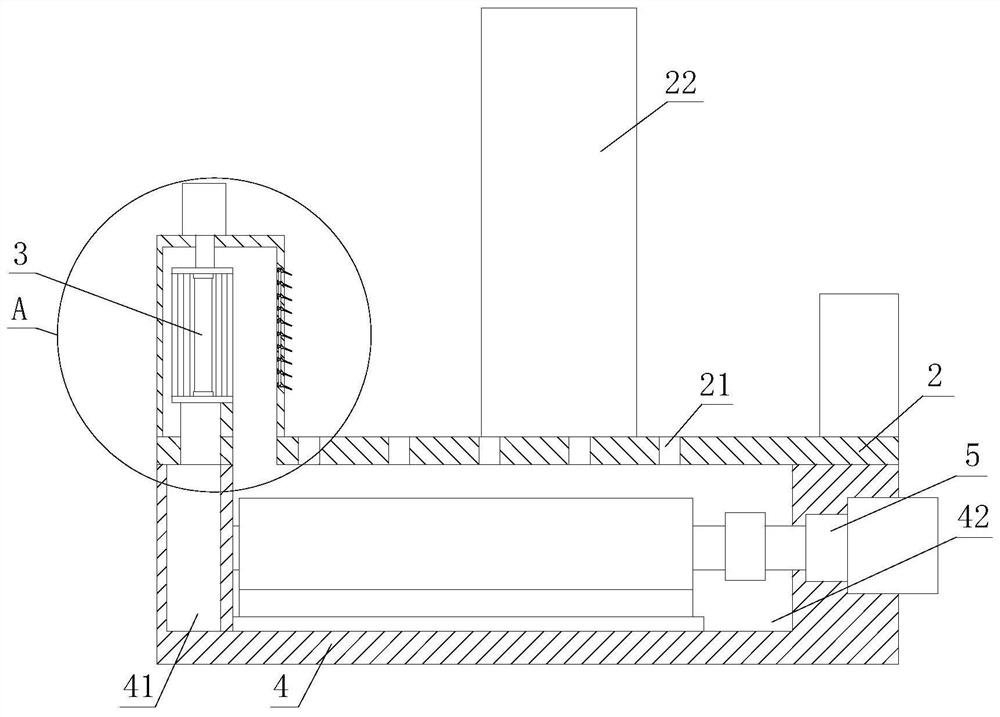

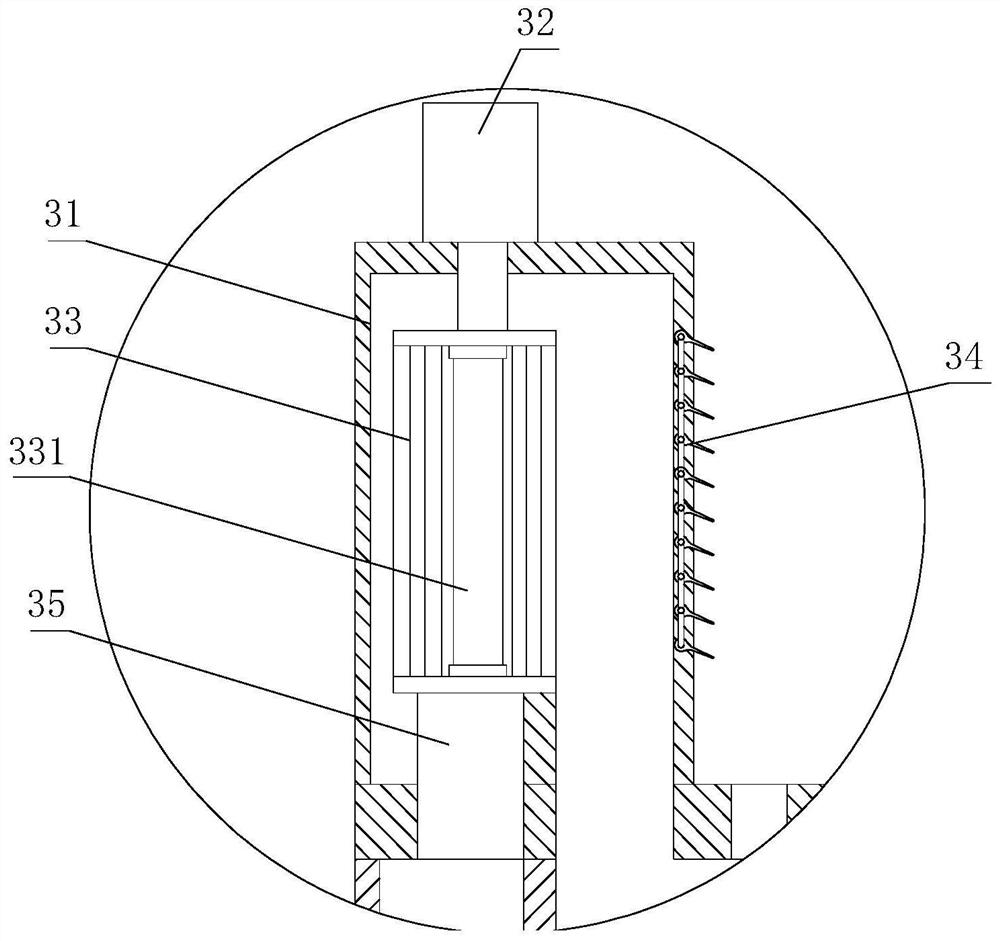

Seal charging valve

ActiveCN104648855APrevent dust leakageEnsure stable air pressureLarge containersSlide valveAutomatic controlSluice gate

The invention relates to a seal charging valve and relates to the field of hoppers. The seal charging valve comprises a hopper; the lower end of the hopper is provided with a discharge hole; the upper end of the hopper is provided with a charging plane sluice gate; the charging plane sluice gate is provided with a bell sealing structure; the discharge hole of the hopper is provided with an automatically controlled seal sluice gate. According to the seal charging valve, a charging hole is provided with the charging plane sluice gate and the discharge hole is provided with the bell; during charging, the charging plane sluice gate is opened, the bell is closed, and materials enter the hopper from a raw material cabin; during discharging, the charging plane sluice gate is closed, the bell is opened, the seal charging valve operates in a recycle mode as above, and the charging plane sluice gate and the bell alternately operate in a combination mode; meanwhile the charging plane sluice gate and the bell are provided with seal structures, dust is prevented from escaping, air flows are effectively prevented from flowing reversibly, and accordingly stabilization of air pressure inside a system and normal discharging of materials are guaranteed.

Owner:扬州炳星机械有限公司

Architectural decoration engineering type wall drilling electric drill anti-dust device

InactiveCN108748718AEffective dust prevention and dust collectionPrevent dust leakageCleaning using toolsWorking accessoriesCrushed stoneEngineering

The invention discloses an architectural decoration engineering type wall drilling electric drill anti-dust device and relates to the technical field of architectural decoration engineering equipment.The device comprises a dust cover. A first connecting sleeve is fixedly connected to the narrow-opening end of the dust cover. A fixed connection barrel is arranged at the end, away from the dust cover, of the inner surface of the first connecting sleeve in an inserted manner. A fixing device is connected to the end, away from the first connecting sleeve, of the fixed connection barrel. A secondconnecting sleeve is fixedly connected to the end, away from the first connecting sleeve, of the dust cover. The architectural decoration engineering type wall drilling electric drill anti-dust devicecomprises the dust cover, and the purpose that dust is effectively prevented and collected in the drilling process is achieved; the device is low in application cost and convenient to use; in the drilling process, by means of the dust cover, the problem that the dust and rock fragments spatter to hurt workers can be effectively prevented, and in addition, relative personnel can be effectively prevented from inhaling much dust; the dust generated in the drilling process can be collected and disposed; the indoor environment can be maintained to be clean conveniently, and cleaning can be conducted conveniently.

Owner:李树勤

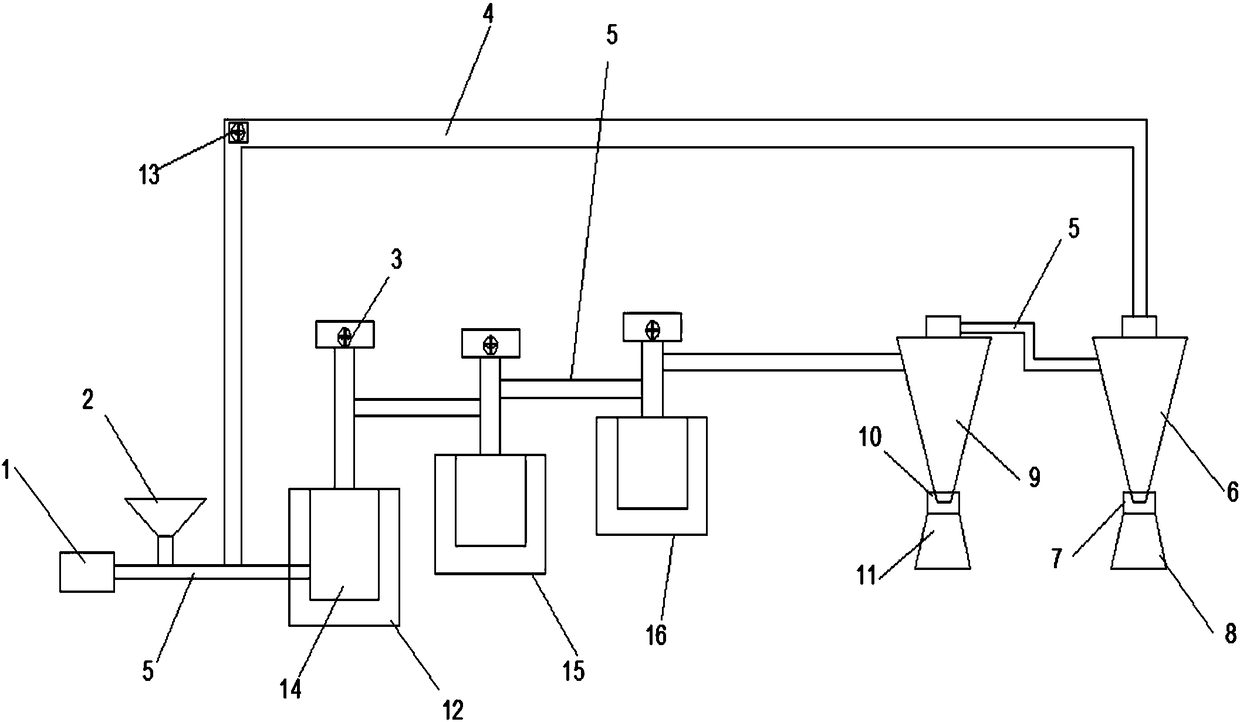

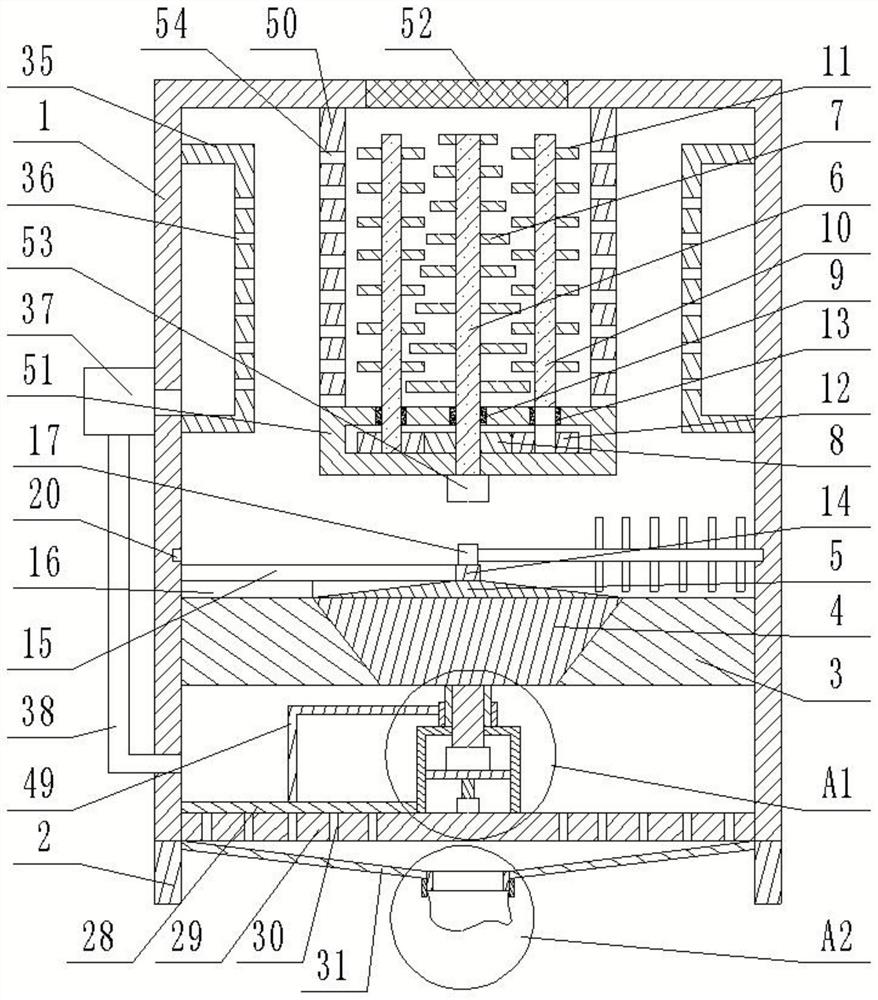

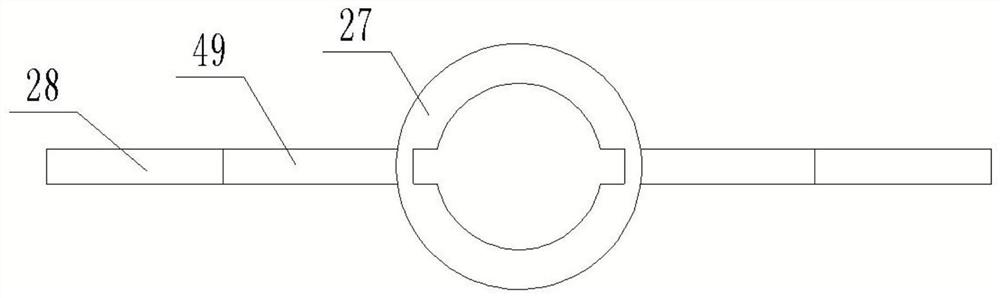

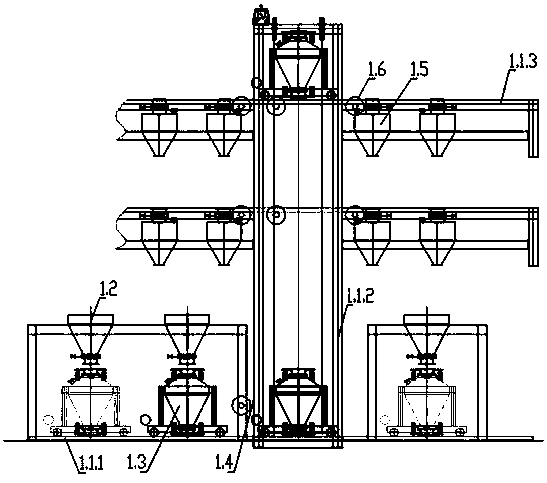

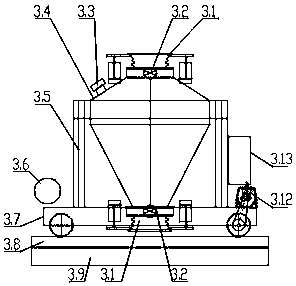

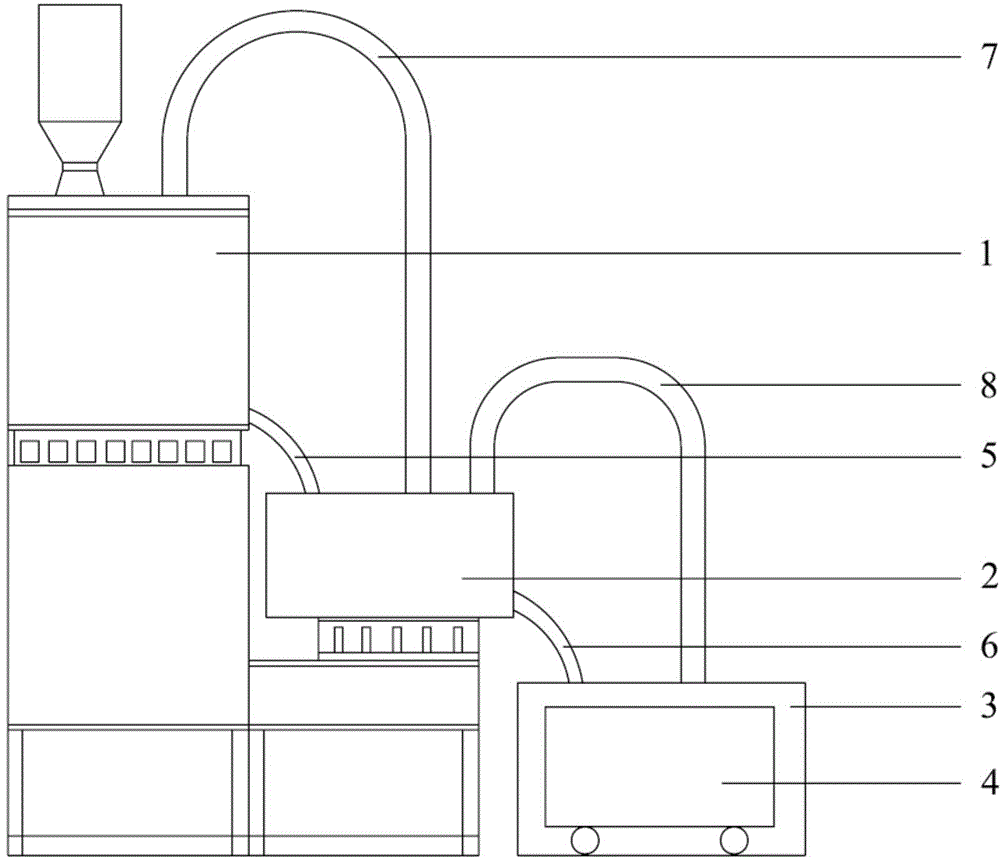

Automatic dust-free batching scale

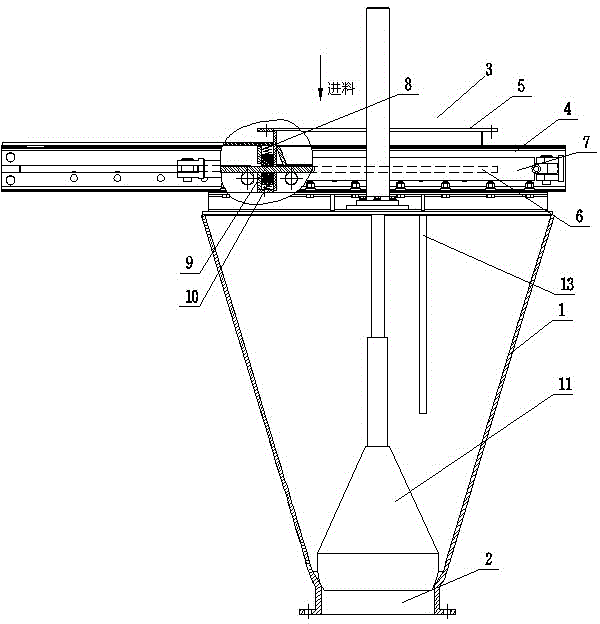

InactiveCN102192776AEasy to pushEasy alignmentSpecial purpose weighing apparatusControl systemEngineering

The invention relates to an automatic dust-free batching scale, which comprises a support, a stock bin, a feeding device, a guide rail, a horizontal movement framework, an elevating framework, a weighing sensor, a batching bucket and a control system. During an operation, the large-volume batching bucket is pushed into a first feeding station, and the feeding process of multiple materials can be automatically completed according to a formula by the system; and dust leakage is prevented by adopting a hermetic sealing technology. The automatic dust-free batching scale disclosed by the invention has the advantages of high measuring accuracy, high automation degree and avoidance of human errors.

Owner:BEIJING GOLDENTEAM TECH

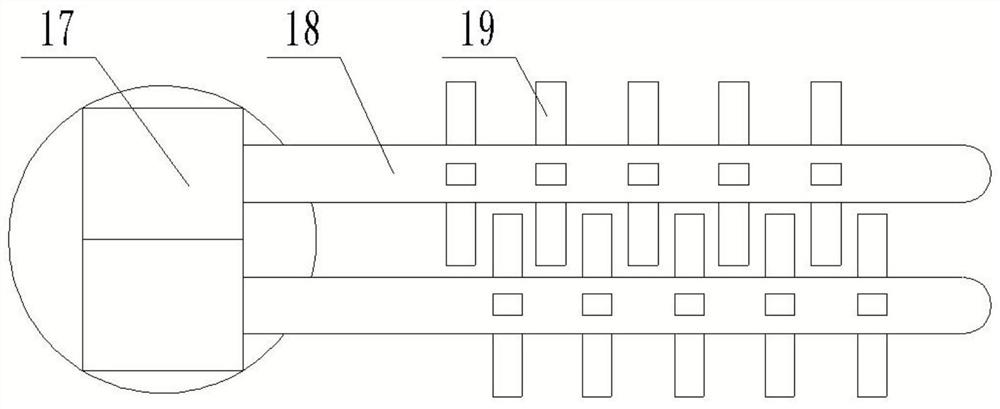

Method for preventing cement bag from leaking ash, and cement bag sealing device

ActiveCN107140263AImprove tensile propertiesPrevent dust leakageWrapper twisting/gatheringAir pumpEngineering

The invention provides a method for preventing a cement bag from leaking ash, and a cement bag sealing device. The cement bag sealing device comprises a stand, and an ash blocking gasket positioning mechanism, a filling port forming mechanism, a bag pressing mechanism, an edge rolling mechanism and a bag sewing mechanism which are fixed on the stand; the ash blocking gasket positioning mechanism comprises a positioning push block, a positioning cylinder, an air pipe and an air pump; the interior of the positioning push block is of a hollow structure; multiple exhaust holes are formed in one side of the positioning push block; an intake port protruding from the surface of the positioning push block is welded to the part, at the side opposite to the exhaust holes, of the positioning push block; the intake port is connected with the air pump through the air pipe; and the edge rolling mechanism comprises a double-layer edge rolling former and a pressing piece which are positioned on the head and tail sides of a bag body. By tailoring the cement bag, precisely positioning an ash blocking gasket, performing double-layer edge rolling and sewing the cement bag with a line of threads, the ash blocking gasket is provided with an enough large blocking face for blocking pinholes during filling of cement, so that the ash leakage phenomenon is effectively prevented, the pollution and the waste are reduced, and the consumption of sewing threads is reduced.

Owner:湖南安福环保科技股份有限公司

Wine bottle surface dust removing device

InactiveCN107350247AReduce manual operationsRealize automatic purge functionHollow article cleaningElectrostatic chargesArchitectural engineeringWine bottle

The invention discloses a dust removal device on the surface of a wine bottle, which comprises a bottom plate, a groove is opened in the middle of the bottom plate, a feeding plate is clamped in the groove, a bolt is threadedly connected to the bottom of the feeding plate, and the bottom of the bolt extends to the bottom of the bottom plate Outside the bottom, a bracket is installed on the top of the bottom plate, and fixed blocks are welded on the inside of the bracket, and the fixed blocks are connected to each other through cross bars. In the present invention, by setting a cover plate, a telescopic spring, a storage box, a cavity, a limit plate and a fixing nut, the electrostatic precipitator can remove dust, blow air and release the tempered glass on the feeding plate through the static eliminator arranged on the bracket. Positive and negative ions, and by turning on the motor, the wire rope is pulled, thereby driving the cover plate to slide back and forth on the cross bar, realizing the automatic purge function, greatly reducing the sundries and static electricity attached to the wine bottle, and eliminating the need for employees to manually operate blowing The procedure of sweeping the glass effectively reduces the labor intensity, avoids the phenomenon of leakage and dust removal, and improves the work efficiency.

Owner:新皇冠(大冶)包装有限公司

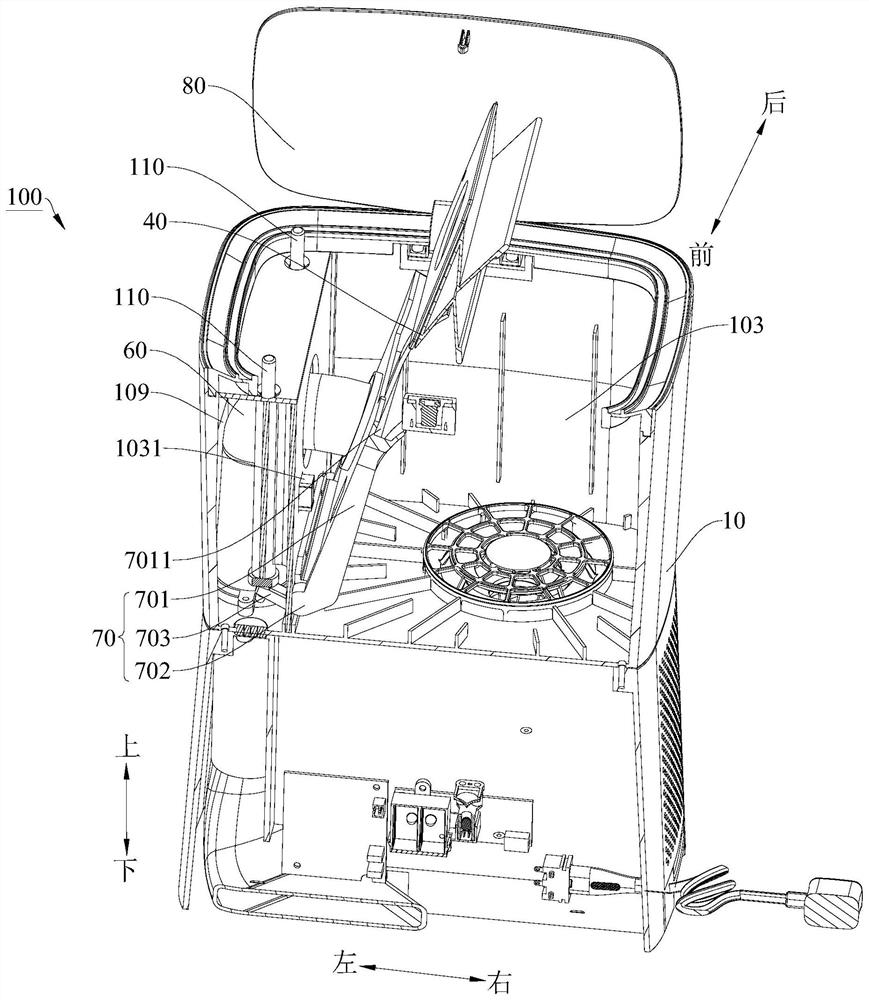

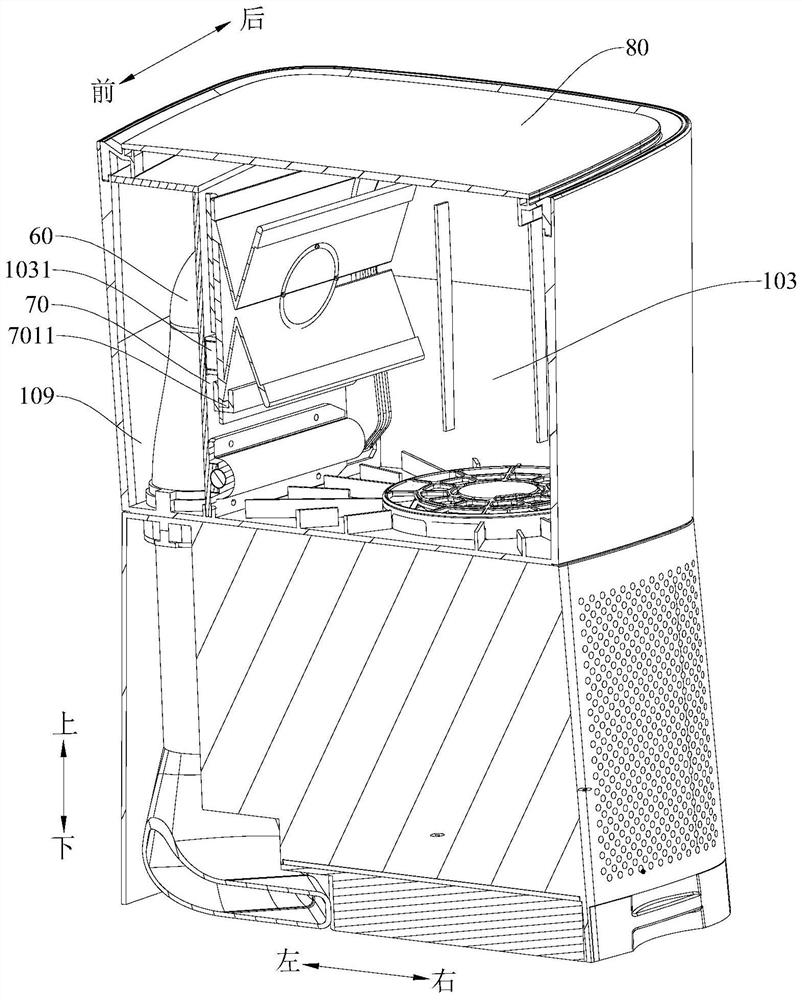

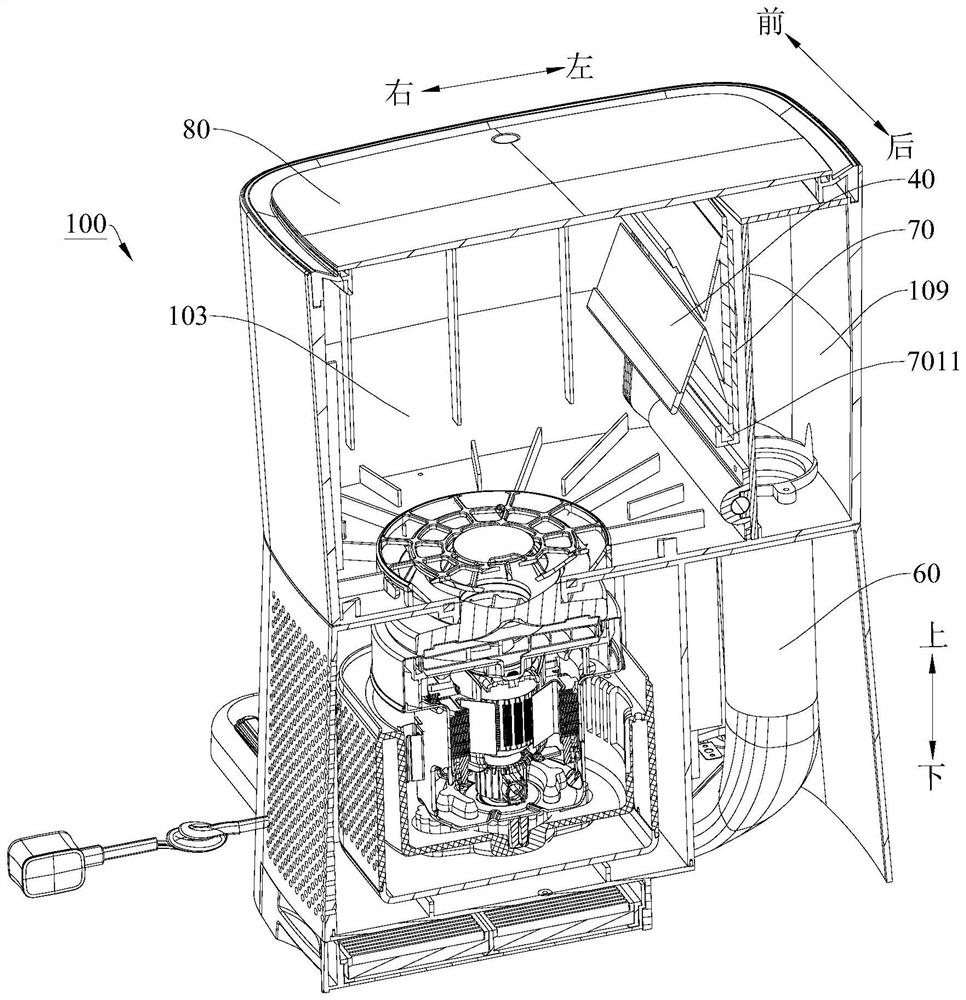

Dust collection station of dust collection equipment and dust collection equipment

PendingCN111603109AEasy to take outEasy to operateCarpet cleanersFloor cleanersMechanical engineeringWaste management

The invention discloses a dust collection station of dust collection equipment and the dust collection equipment, the dust collection station comprises a main body, an air pipe and a movable frame. The main body is provided with a dust collection cavity, and the main body is provided with a dust collection port; one end of the air pipe is communicated with the dust collection port, and the other end extends into the dust collection cavity; the movable frame is movably arranged in the dust collection cavity, and a dust collection container is detachably arranged on the movable frame; when the movable frame moves to a preset position, the other end of the air pipe can extend into the dust collection container; when the movable frame deviates from the preset position, the end of the air pipeextends out of the dust collection container. The movable frame is arranged in the dust collection cavity and the dust collection container is detachably arranged on the movable frame, the movable frame moves to enable the air pipe to extend into or out of the dust collection container, the dust collection container is more convenient to take out, the operation is easy, time and labor are saved, the air pipe extends into the dust collection container to be matched, the sealing reliability of the dust collection container can be improved in this way, and dust leakage is effectively prevented.

Owner:MIDEA ROBOZONE TECH CO LTD

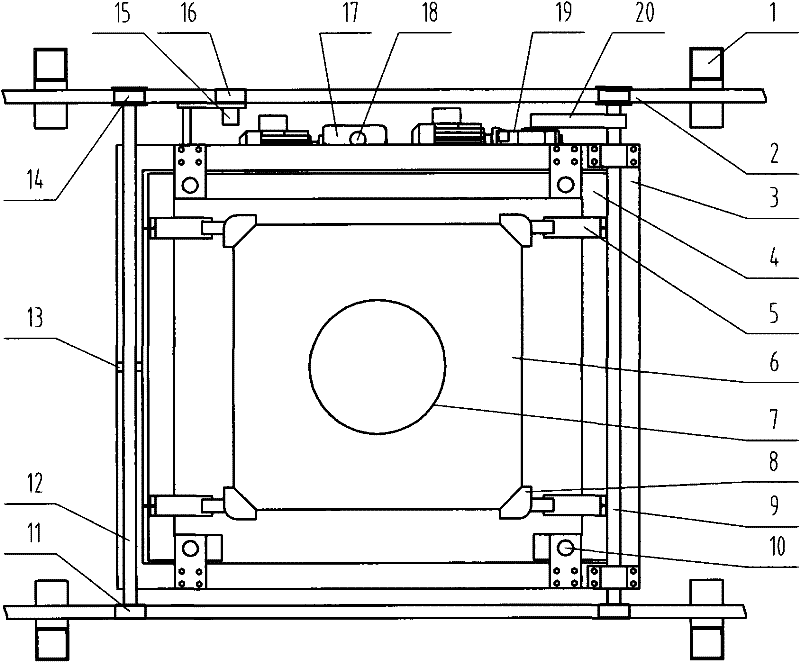

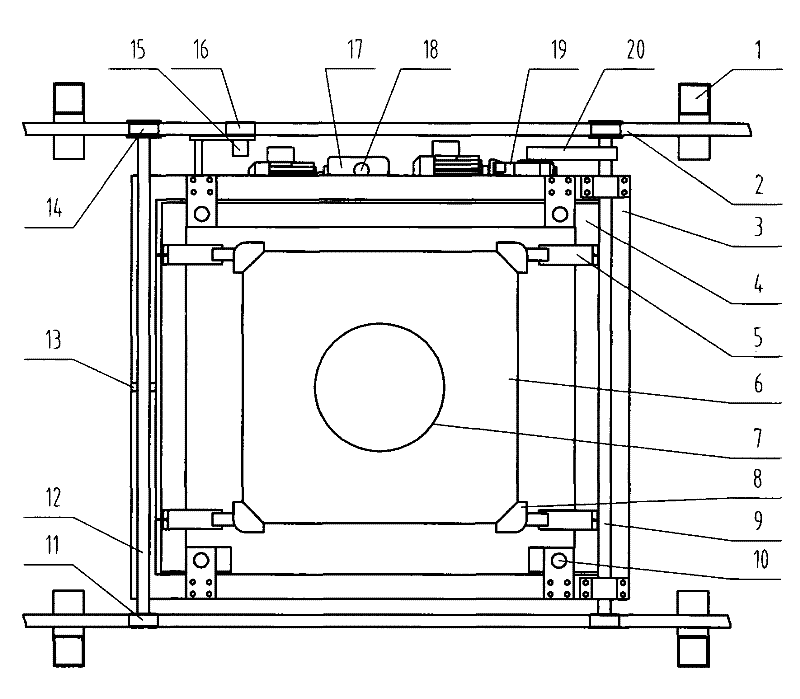

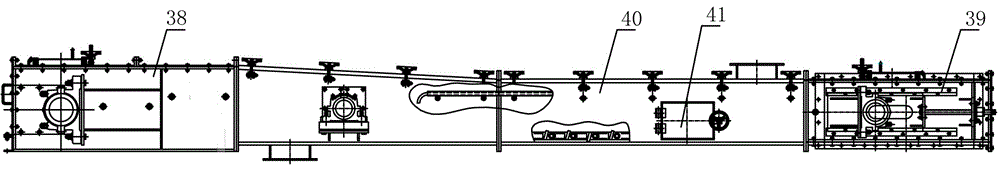

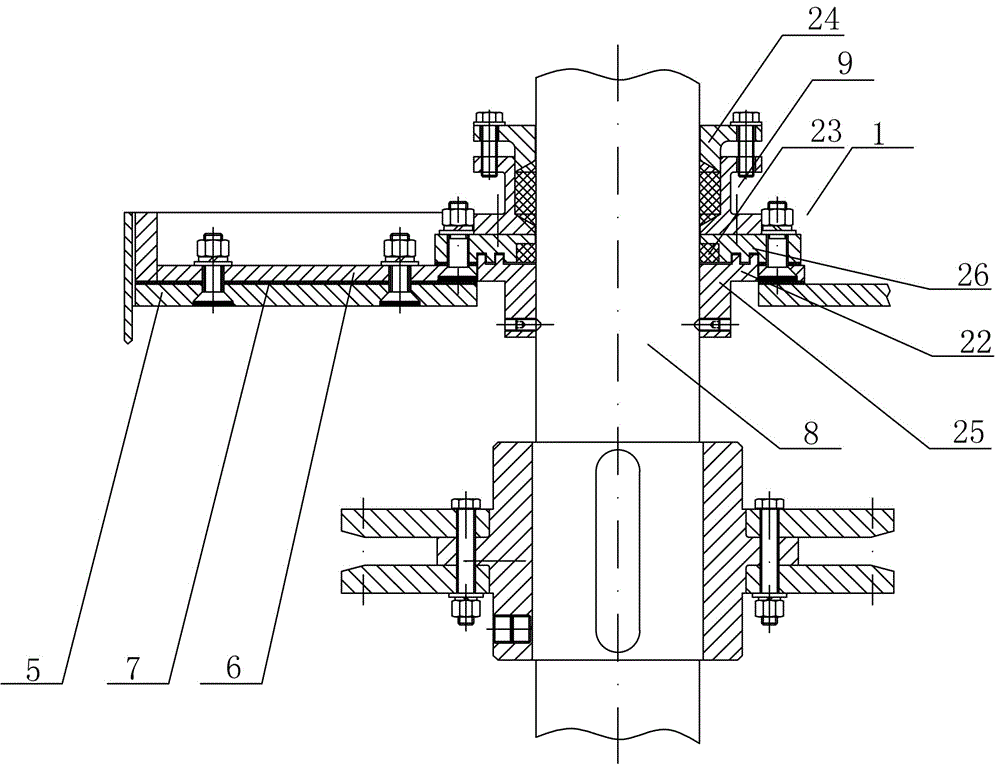

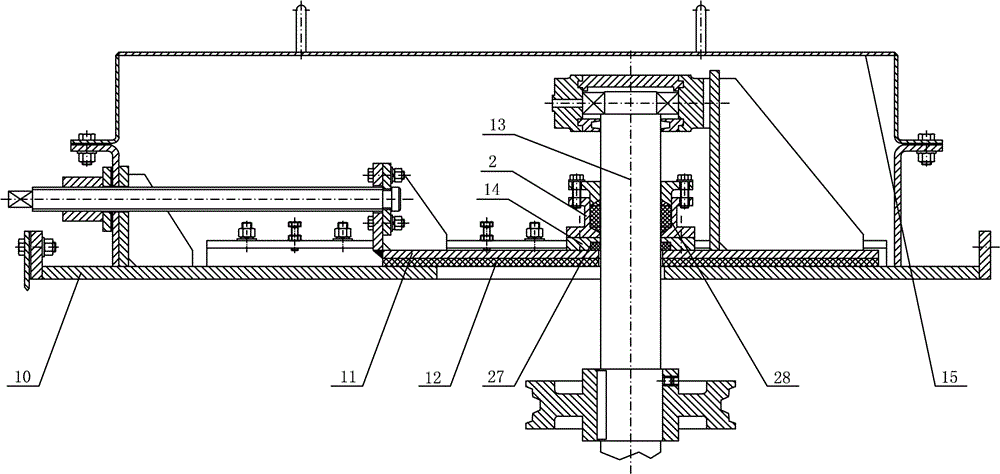

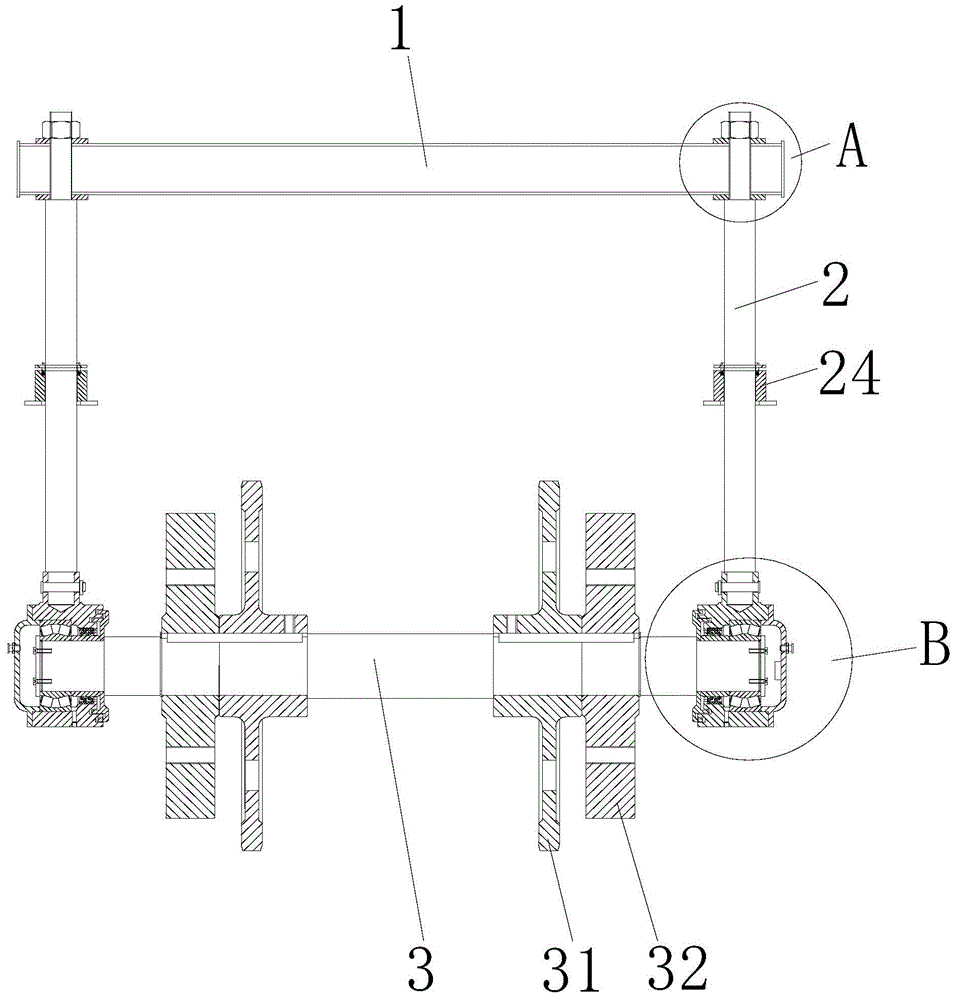

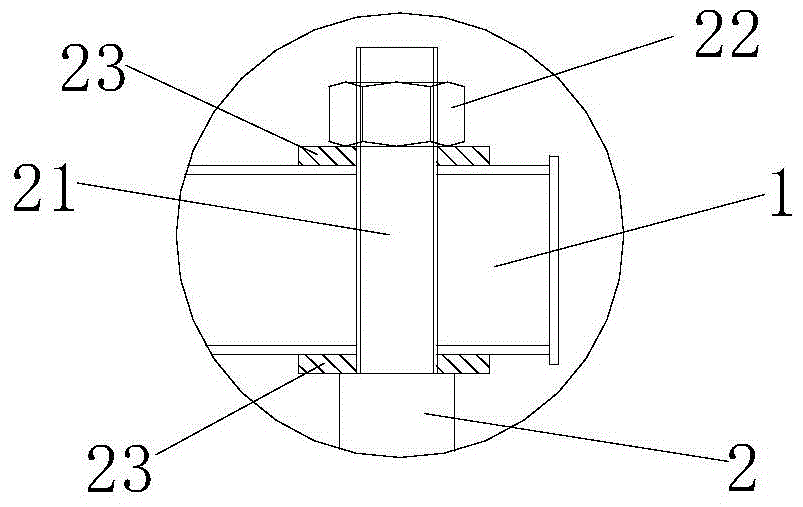

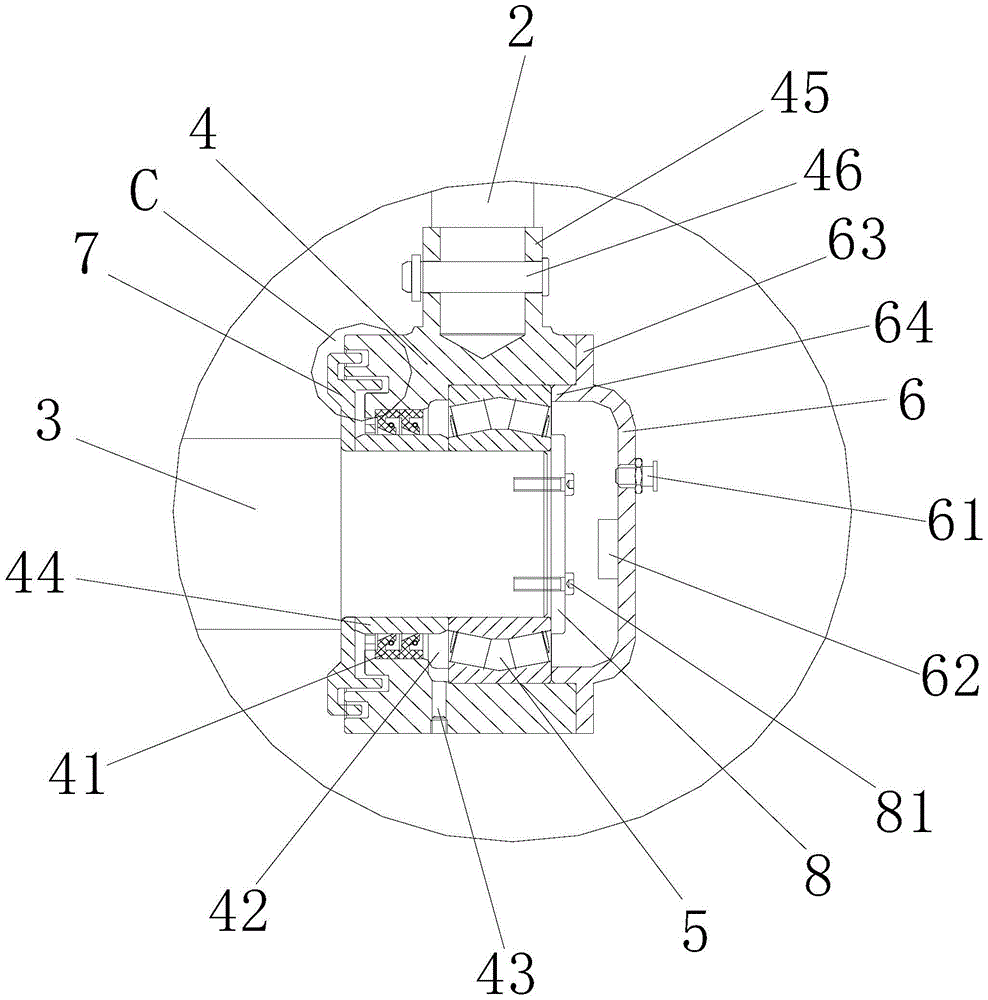

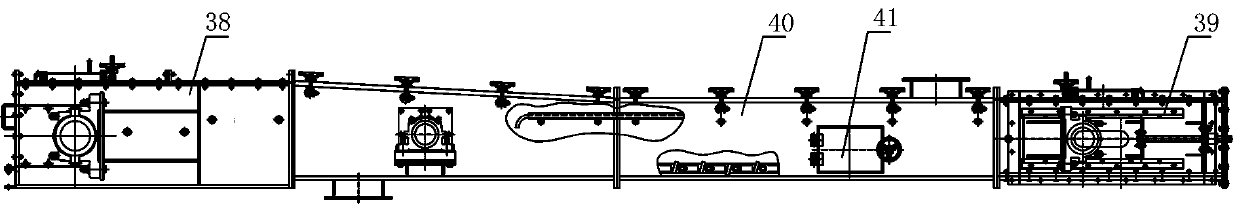

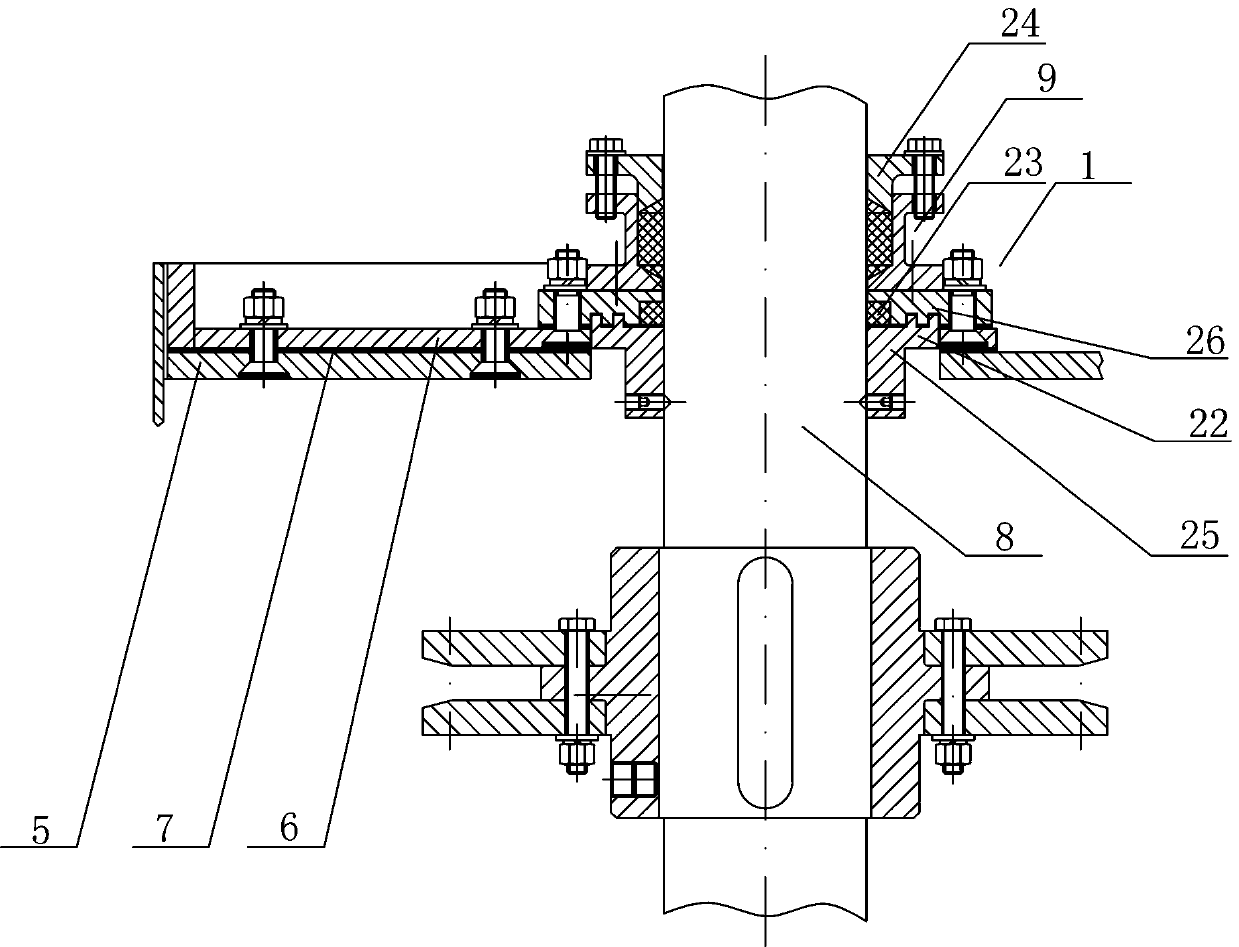

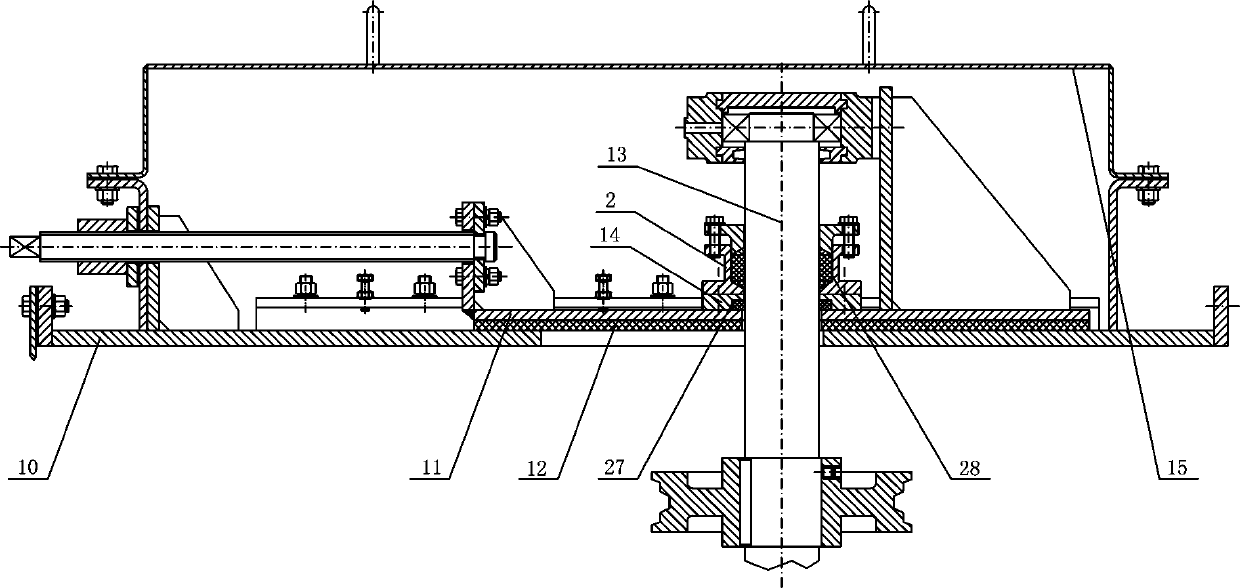

Positive-pressure sealing and rapid cover plate opening embedded scraper transporter

ActiveCN106379693AReduce dust leakageReduce dust rateConveyorsPackagingLocking mechanismPositive pressure

A positive-pressure sealing and rapid cover plate opening embedded scraper transporter comprises a head part, a tail part and an intermediate section, all of which are provided with access doors. The head part is provided with a head sealing mechanism, and the tail part is provided with a tail sealing mechanism. The intermediate section is provided with a sealing and rapid upper cover opening mechanism, and the access doors are provided with sealing and rapid viewing door opening mechanisms. According to the positive-pressure sealing and rapid cover plate opening embedded scraper transporter, through well sealing on the shaft stretching-out end of the embedded scraper transporter, the access doors, an upper cover and other places where dust is possibly generated, environment pollution is reduced; and through the improvement on the access doors and an upper cover locking mechanism, rapid cover opening is convenient, and time is saved.

Owner:HUBEI YIDU YIYUN ELECTROMECHANICAL ENG CO LTD

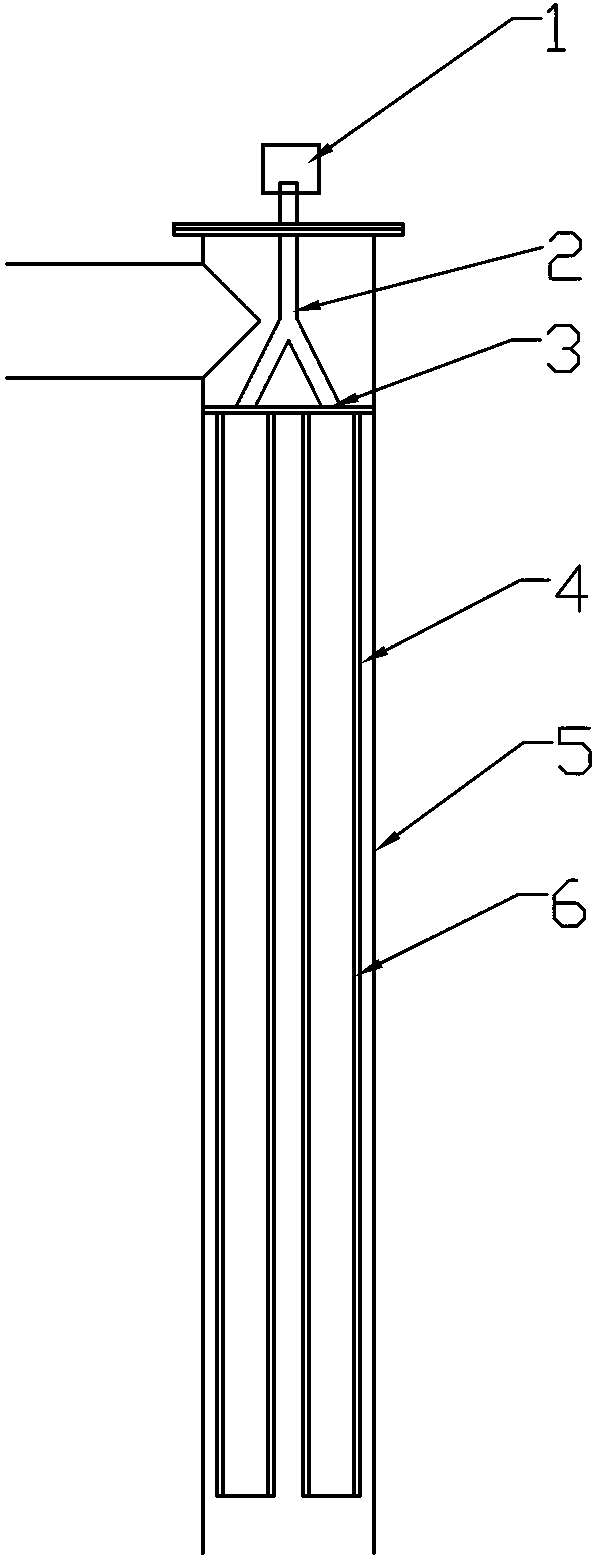

Bell-jar funnel cap for fluidized bed

InactiveCN1877196ALarge flow areaAvoid differential pressureFluidized bed combustionApparatus for fluidised bed combustionFluidized bedLow load

The invention relates to a bell cover wind cap used in fluid bed, belonging to the boiler wind distributor of cycle fluid bed. Wherein, it comprises a ventilate tube, an outer frame at the outer part of ventilate tube, wind distribute holes uniformly arranged at the lower part of outer frame, a taper air channel inside the ventilate tube, and a float inside the taper air channel. The invention can avoid pressure impulse caused by the foam breakage to cause ash leakage, when in low load; and in high load, its total resistance of wind cap and wind distribute plate will not increase along the load increase to reduce the generate efficiency.

Owner:TSINGHUA UNIV

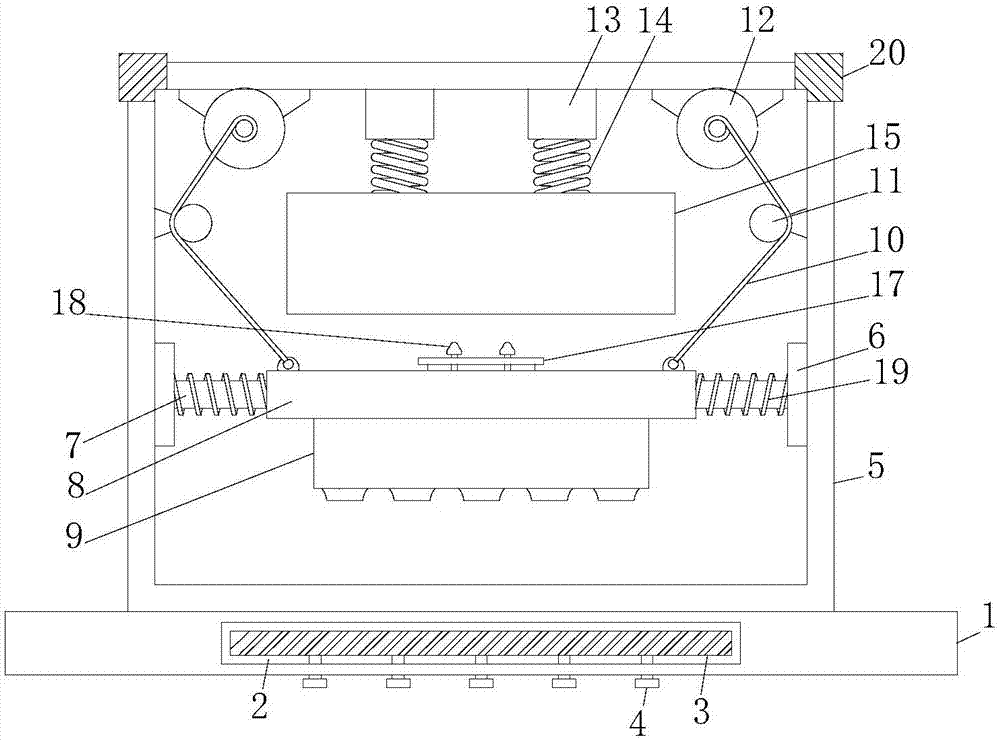

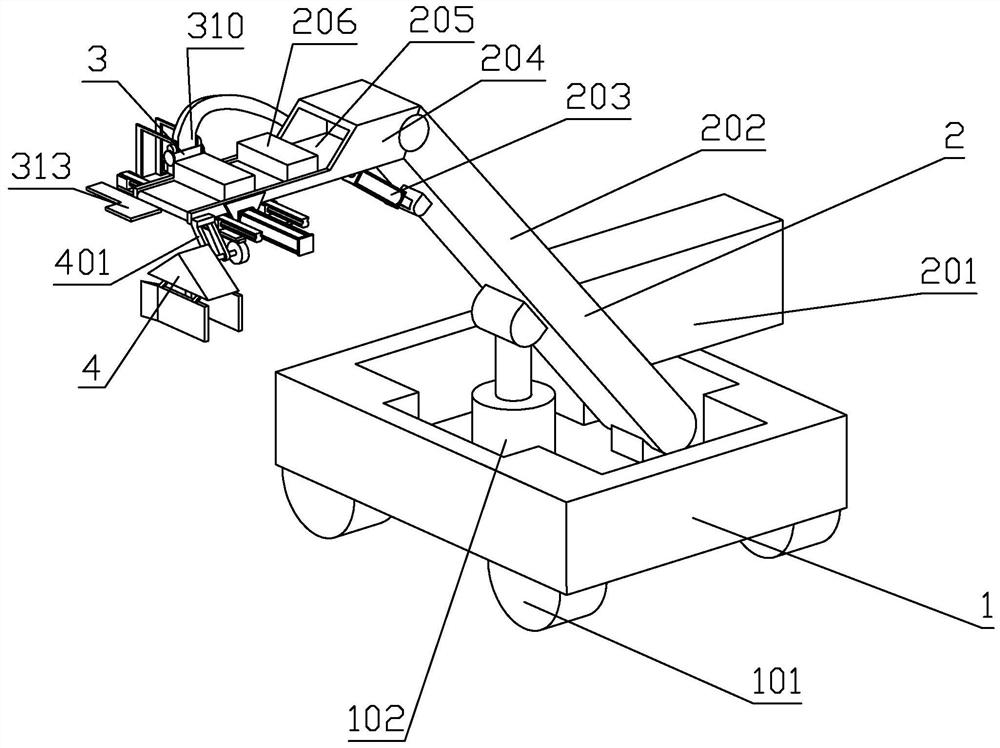

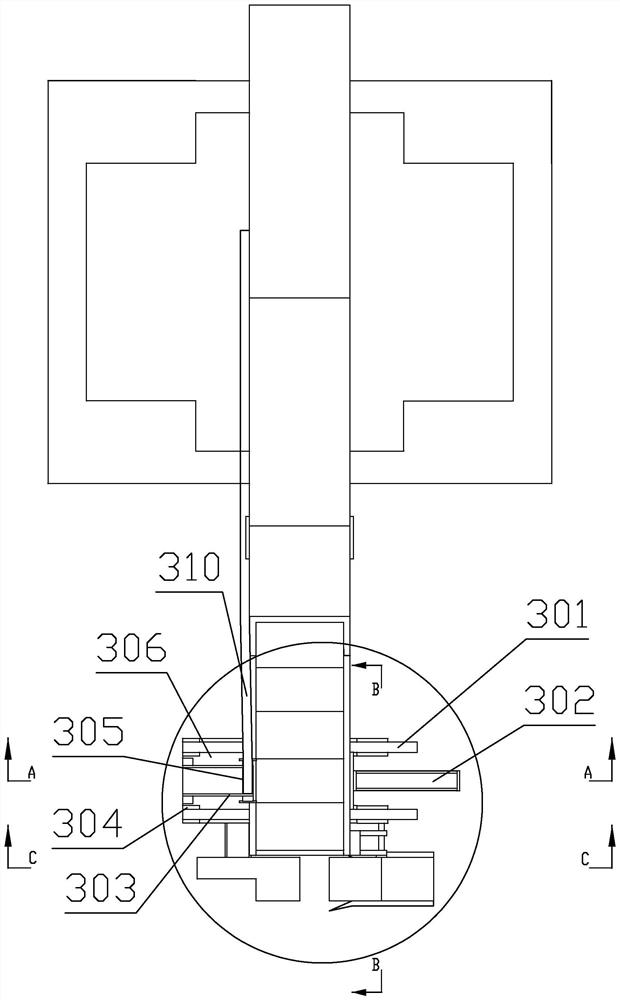

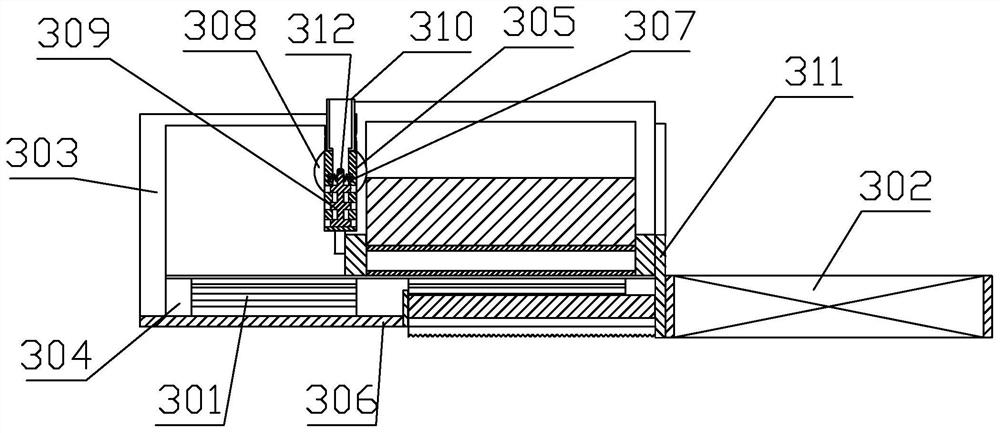

Automatic wall building machine

ActiveCN113550611ASpeed up plasteringImprove machine efficiencyBuilding material handlingHydraulic cylinderBrick

The invention belongs to the field of building robots, and particularly relates to an automatic wall building machine. The automatic wall building machine comprises a chassis, a plurality of wheels are arranged on the side, close to the ground, of the chassis, a main hydraulic cylinder is arranged on the side, away from the ground, of the chassis, the output end of the main hydraulic cylinder is rotationally sleeved with a brick conveying component, and the end, close to the chassis, of the brick conveying component is rotationally sleeved with the chassis. A plastering component is arranged at one end, far away from the chassis, of the brick conveying component and is responsible for uniformly smearing cement ash on the surfaces of bricks; an adjusting component is arranged at one end, far away from the chassis, of the brick conveying component and is responsible for adjusting the bricks to meet the vertical precision of a wall body and a set brick layer height. According to the automatic wall building machine, the plastering speed can be effectively increased, ash falling is avoided, and automatic wall building is stably and efficiently conducted.

Owner:中交一公局第七工程有限公司

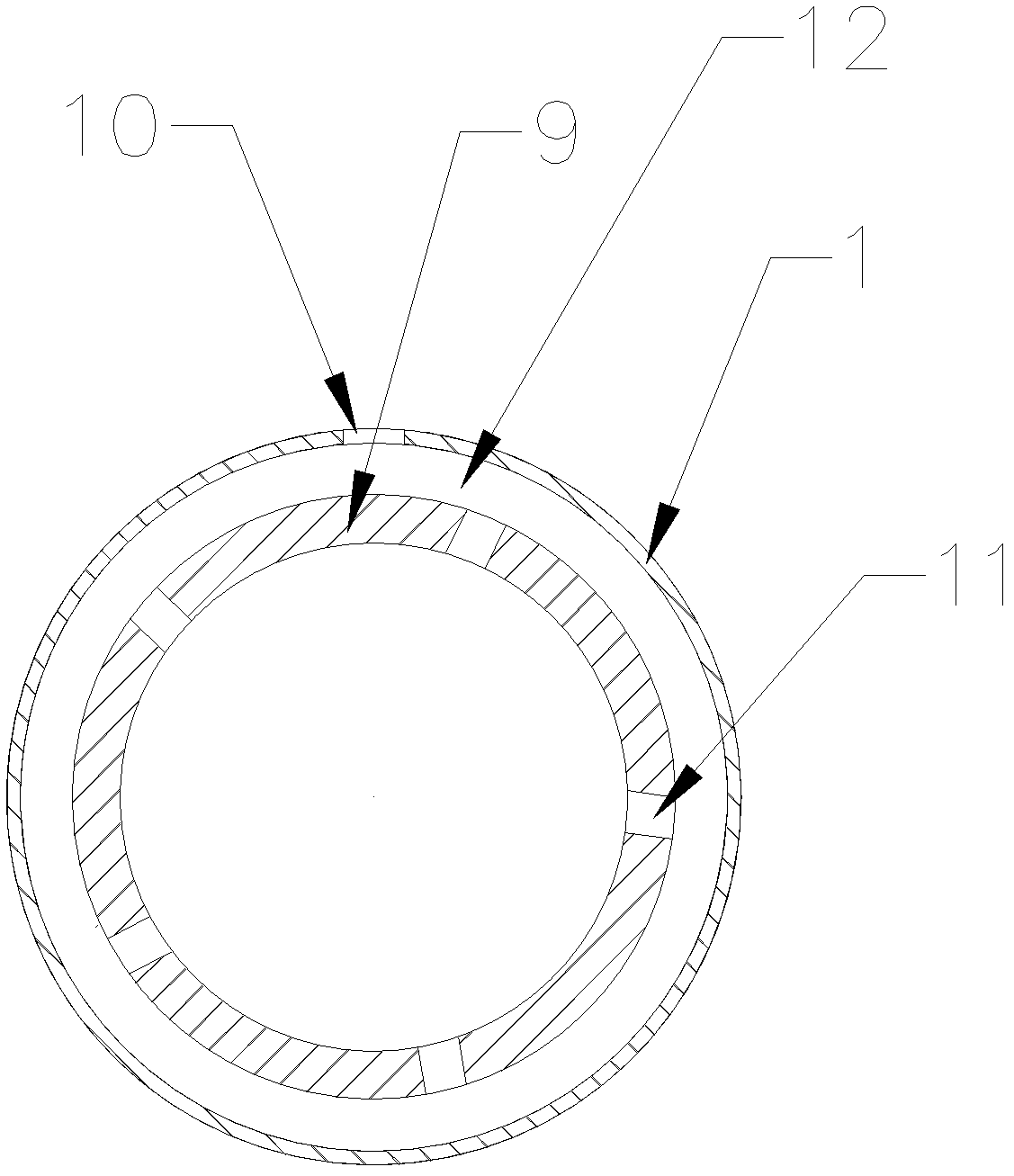

Dust collection pipeline of dust collector

PendingCN111000490ACracks or even fracturesExtended service lifeSuction hosesThermodynamicsThreaded pipe

The invention discloses a dust collection pipeline of a dust collector. The dust collection pipeline includes a metal telescopic pipe; a first telescopic rubber pipe is fixedly arranged on the inner surface of the metal telescopic pipe; a plurality of electric heating wires are fixedly arranged in the first telescopic rubber pipe; second telescopic rubber pipes are arranged in the electric heatingwires; a storage battery is fixedly arranged on one side of the outer surface of the metal telescopic pipe; and the output end of the storage battery is electrically connected with the input ends ofthe electric heating wires, a first connecting mechanism is arranged at the end, away from the middle of the metal telescopic pipe, of the storage battery, the first connecting mechanism is arranged on the metal telescopic pipe, and the first connecting mechanism is composed of a first half-threaded pipe, a second half-threaded pipe, a first adjusting nut and a first rubber pipe. The dust collection pipeline is simple in structure and reasonable in design, and is convenient to assemble, disassemble and clean, and meanwhile the phenomenon that the pipeline is hardened under the condition of lowtemperature, and consequently breakage occurs is prevented.

Owner:江苏乾诚环境科技有限公司

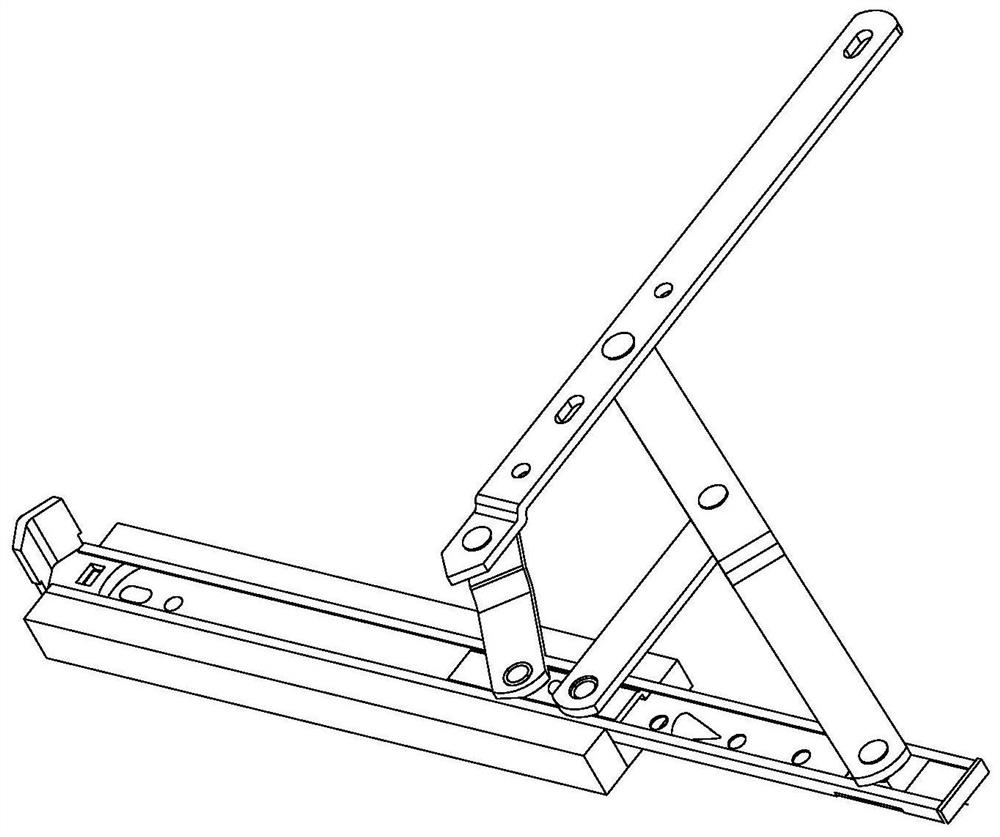

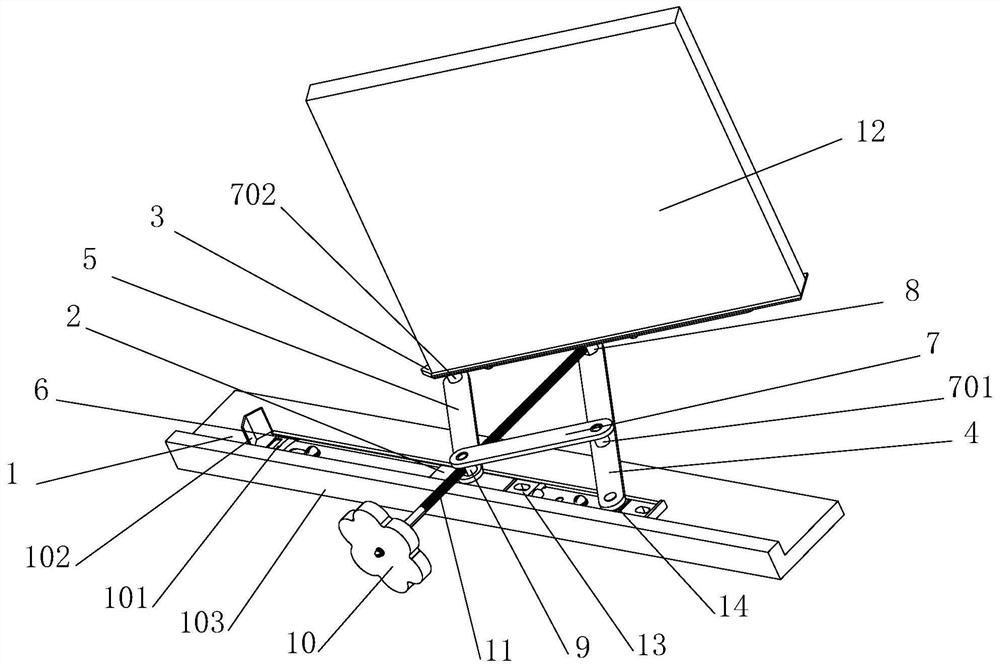

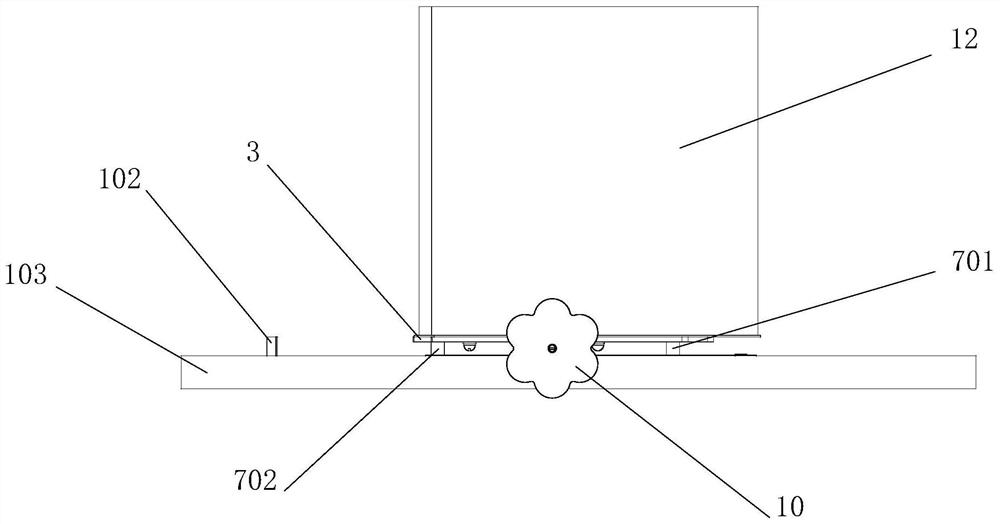

Window hinge capable of automatically adjusting angle according to wind direction and control method of window hinge

ActiveCN113605797AAvoid damageExtended service lifeWing fastenersWindows/door improvementControl theoryScrew thread

The invention relates to a window hinge capable of automatically adjusting the angle according to the wind direction and a control method thereof. The window hinge capable of automatically adjusting the angle according to the wind direction comprises a supporting frame, a sliding block, a bottom rod, a long rod, a short rod, a connecting rod, a screw hole shaft A, a screw hole shaft B, a rotary knob and a screw rod, a sliding rail is arranged on the supporting frame, the sliding block is arranged in the sliding rail, one end of the long rod is hinged to one end of the sliding rail, the other end of the long rod is hinged to the middle of the bottom rod, the lower side of one end of the short rod is hinged to the sliding block, the other end of the short rod is hinged to one end of the bottom rod, one end of the connecting rod is hinged to the upper side of one end of the short rod through a screw hole shaft B, the other end of the connecting rod is hinged to the middle of the long rod, the long rod is hinged to the bottom rod through a screw hole shaft A, one end of the screw rod is movably connected with the screw hole shaft A, and the other end of the screw rod is fixedly connected with the knob and penetrates through the screw hole shaft B. According to the window hinge, a window can be fixed at a certain angle to be normally opened after being opened through a threaded screw, the window can be automatically adjusted along with the wind direction through ae controller, and the maximum air inlet angle is kept all the time.

Owner:肇庆市创威精密五金制品有限公司

Woven bag coating, preparation method, coating method and woven bag

ActiveCN111472175AIncrease exhaustMeet the requirements of moisture resistanceTextile/flexible product manufactureTextiles and paperLow-density polyethyleneMasterbatch

The invention provides a woven bag coating, a preparation method, a coating method and a woven bag, and solves the problems that in the prior art, when the cement laminating plastic woven bag is prepared, the problem of air exhaust needs to be solved by punching on plastic woven cloth coated with a coating film, but the phenomena of running, overflowing and ash leakage exist during filling when punching is carried out, and damping is prone to being caused in the later period. The woven bag coating is prepared from the following raw materials including, by weight, 2%-15% of low-density polyethylene, 40%-70% of special grade polypropylene, 30%-60% of first-grade polypropylene, 0.3%-0.5% of a whitening agent, 2%-10% of a master batch, 0.2%-0.5% of an anti-reflection master batch, 0.05%-0.1% of a cooling master batch and 0.5%-1% of paraffin, wherein the sum of the weight percentages of the raw materials is 100%. The preparation method is used for preparing the cement woven bag, and the woven bag is good in exhaust effect, high in tensile strength and good in moisture resistance.

Owner:宜良县日发塑业有限公司

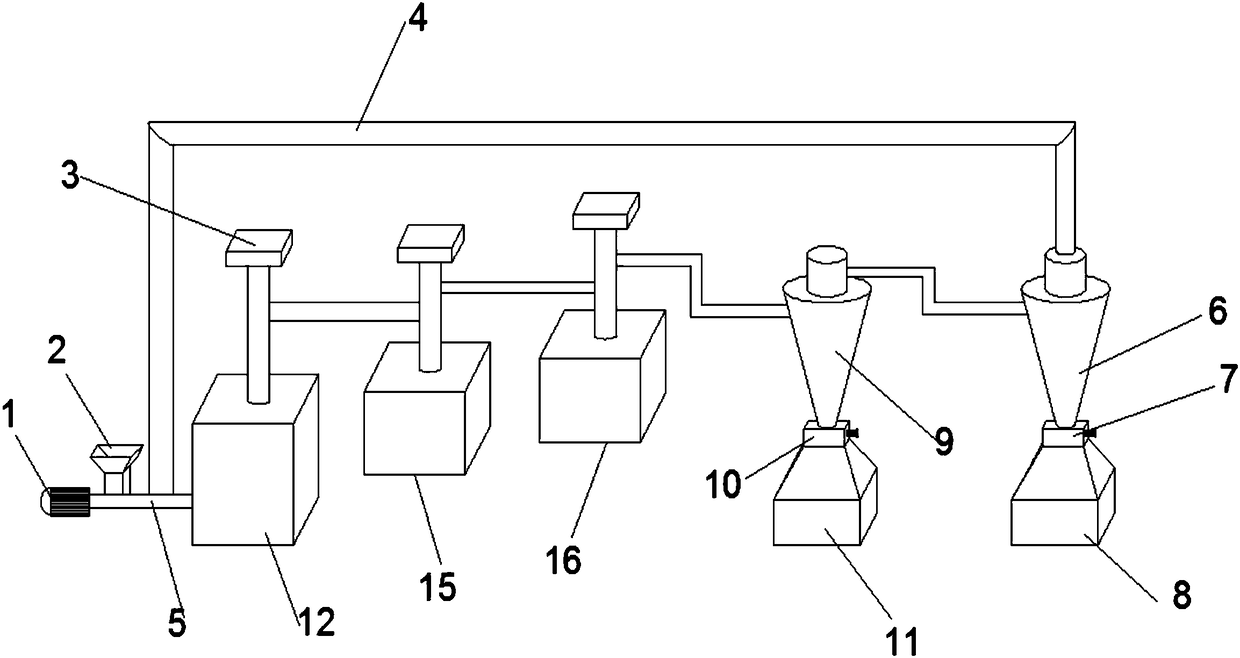

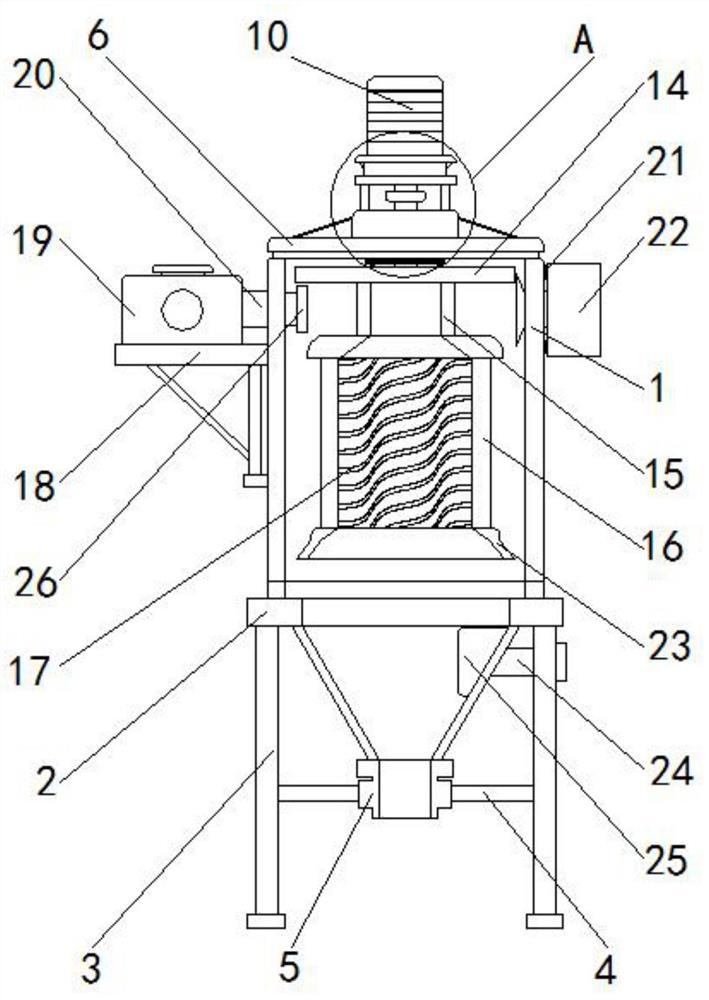

Closed superfine grinding device

PendingCN108311263AReasonable designPrevent dust leakageGrain treatmentsElectric machineryPulverizer

The invention discloses a closed superfine grinding device, comprising a material storage bin, a first crushing box, a conveying pipeline, a cyclone separator and a fine powder collector, wherein thematerial storage bin is welded on the conveying pipeline; a conveying motor is communicated with the conveying pipeline; the conveying pipeline passes through the first crushing box and is communicated with a crusher; a cavity arranged between the first crushing box and the crusher is internally filled with cooling water; the crusher is communicated with a first induced draft fan by means of a pipeline; one end of the conveying pipeline is communicated with a pipeline of the first induced draft fan, and the other end of the conveying pipeline is communicated with the cyclone separator; a second material receiving barrel is arranged at the bottom of the cyclone separator; the cyclone separator is communicated with the fine powder collector by means of the conveying pipeline; the bottom of the fine powder collector is provided with a first material receiving barrel; the top of the fine powder collector is communicated with an air return duct, and the other end of the air return duct is communicated with the conveying pipeline at the position close to the material storage bin; the air return duct is internally provided with a second induced draft fan. The closed superfine grinding device is reasonable in design and avoids dust leakage for a closed design.

Owner:高维科

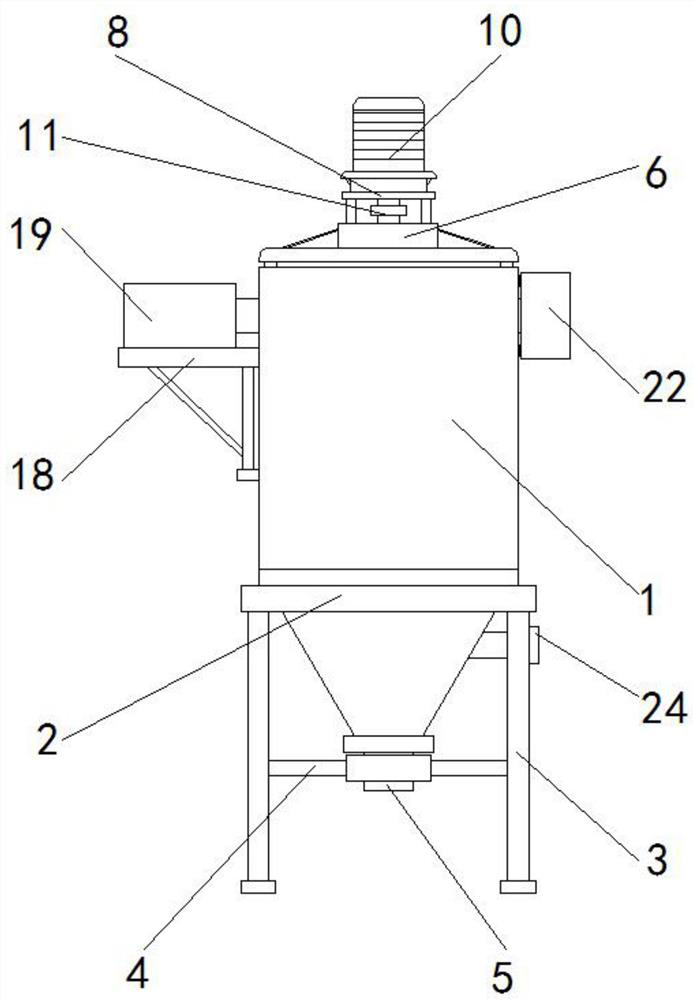

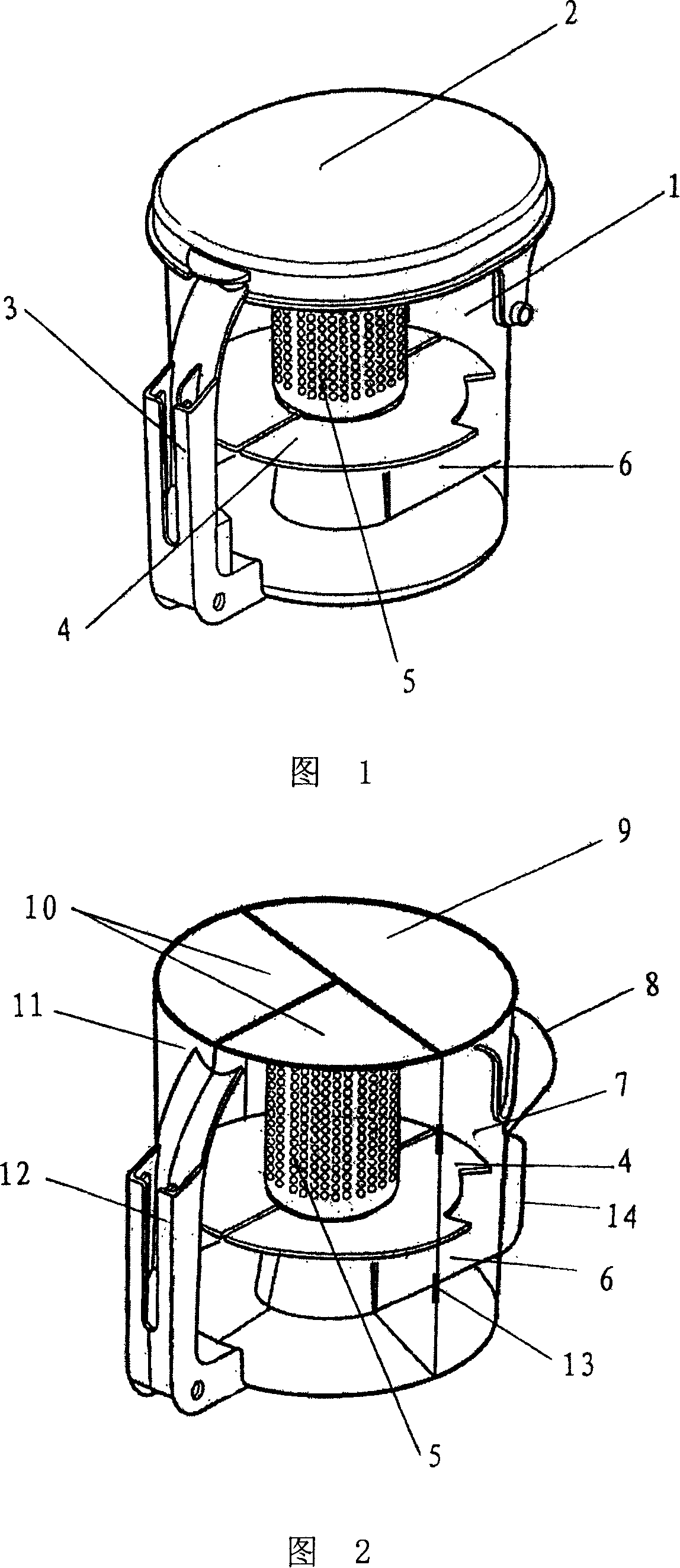

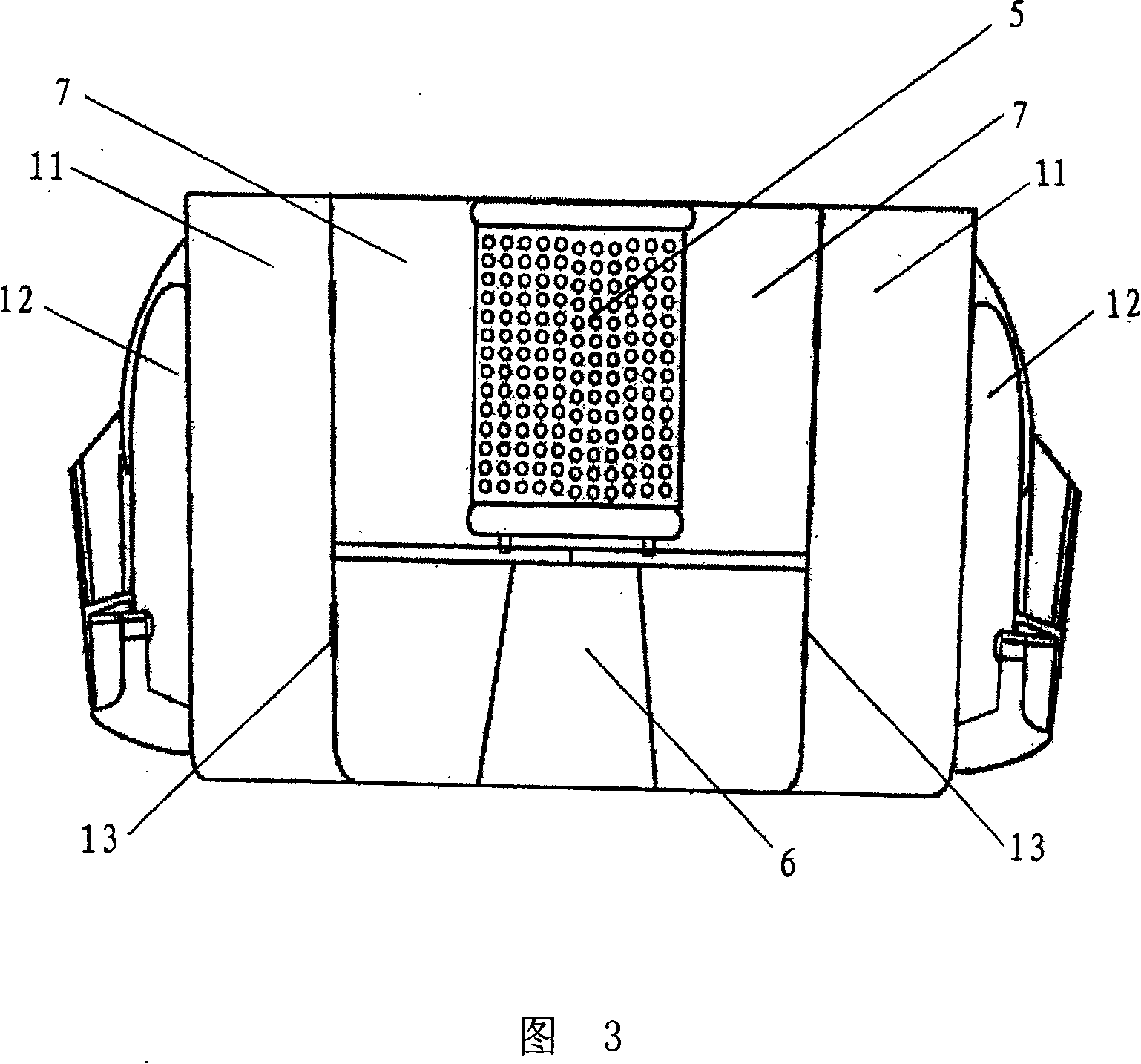

Built-in cyclone type bag-type dust collector

InactiveCN113398704APrevent dust leakageEasy to useCombination devicesMechanical engineeringMechanics

The invention relates to a built-in cyclone type bag-type dust collector. The bag-type dust collector comprises a reaction box, a discharging bottom box and a stable supporting rod, the top of the reaction box is provided with a rotating air duct mechanism which penetrates through the reaction box and controls rotation, and the side edge of the stable supporting rod is provided with a circulation mechanism which controls circulation. The discharging bottom box is located at the bottom of the reaction box and fixedly connected with the reaction box, and four stable supporting rods are fixedly connected to the bottom of the discharging bottom box. According to the built-in cyclone type bag-type dust collector, feeding of materials can be controlled through a feeding connecting block connected to the side edge of the discharging bottom box and a feeding stabilizing block in the discharging bottom box, blowing of an air blowing opening is controlled by arranging a conveying fan, and therefore air can be controlled to conveniently enter an air bag connecting block; and an air bag is connected outside the air bag connecting block, so that air can be controlled to enter the air bag connecting block, dust leakage is prevented, and convenience is brought to use of a user.

Owner:盐城优源环保科技有限公司

Composite hot melting filter bag and preparation process thereof

ActiveCN113769490ADoes not take lengthIncrease the proportionDispersed particle filtrationMechanical engineeringComposite material

Owner:JIANGSU DINGSHENG FILTER BAG CO LTD

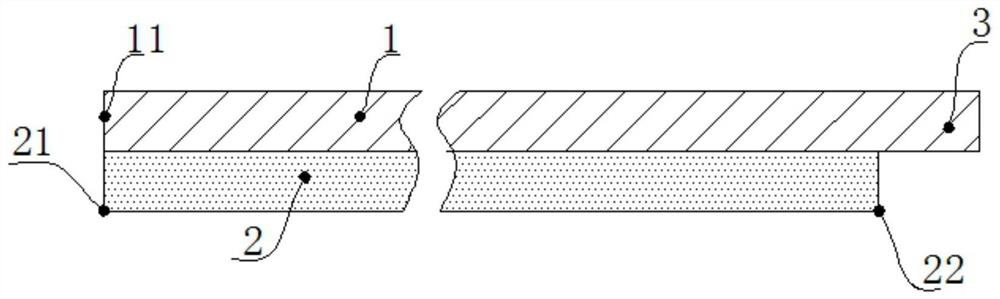

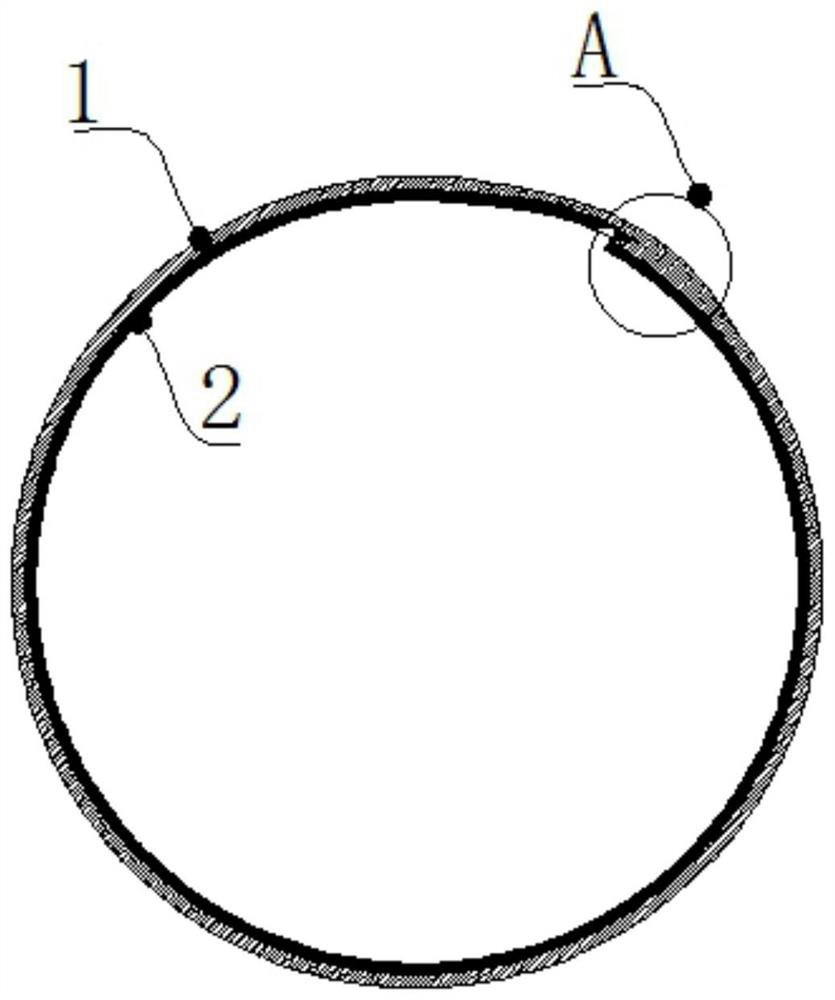

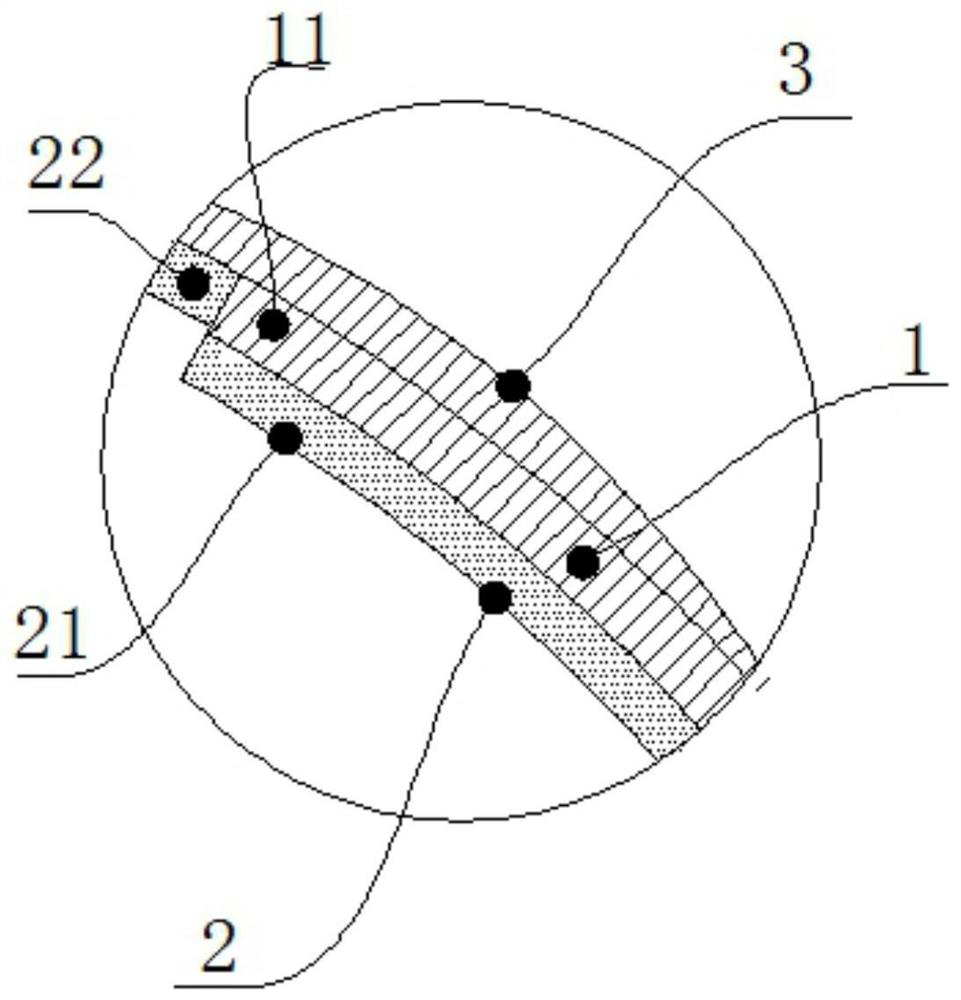

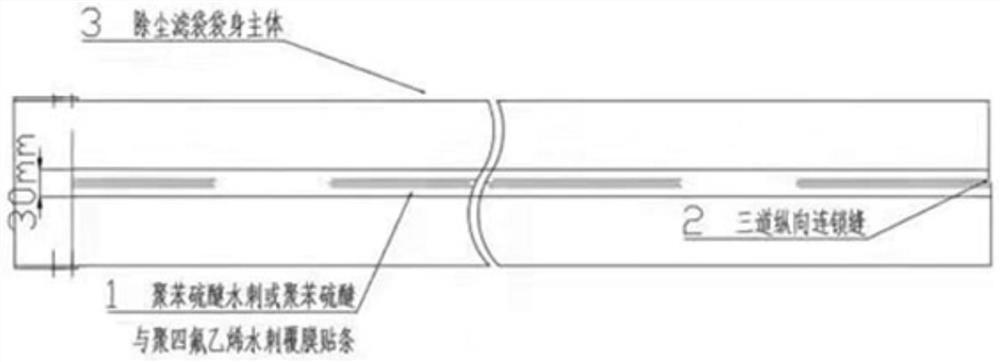

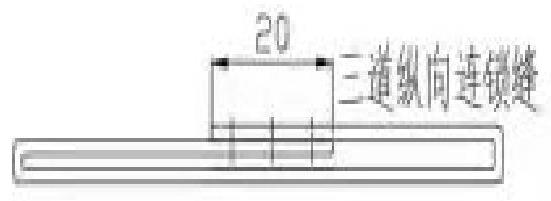

Spunlace laminating joint strip and ultra-low emission dust removal filter bag

ActiveCN114247212APrevent dust leakageHigh filtration precisionHuman health protectionDispersed particle filtrationDust controlFilter material

The invention relates to a preparation method of a spunlace film-coated joint strip, the spunlace film-coated joint strip and an ultralow-emission dust removal filter bag. The preparation method of the spunlace laminating joint strip comprises the steps that polyphenylene sulfide or polyphenylene sulfide mixed polytetrafluoroethylene fibers are subjected to opening, mixing, carding, lapping and drafting and then fed into a spunlace entanglement reinforcing system, pre-wetting spunlace is carried out, then second spunlace is carried out, and after spunlace, a fiber web becomes spunlace non-woven fabric with certain mechanical performance and appearance. According to the spunlace laminating joint strip and the ultralow-emission dust removal filter bag adhered with the spunlace laminating joint strip, the polyphenylene sulfide or polyphenylene sulfide spunlace laminating non-woven joint strip can be well adhered with filter material sewing needle holes and gaps generated by lap joint of the dust removal filter bag, and the spunlace laminating joint strip and the ultralow-emission dust removal filter bag have the advantages of attractive weld seam, firm adhesion, high dust removal efficiency and the like. Dust leakage of sewing needle holes of the dust removal filter bag is prevented, and the filtering precision of the needle seams of the filter bag is improved; and the existing gluing or PTFE sealing film and dust removal filter bag sewing combination mode can be effectively replaced.

Owner:SHANGHAI BG INDAL FABRIC

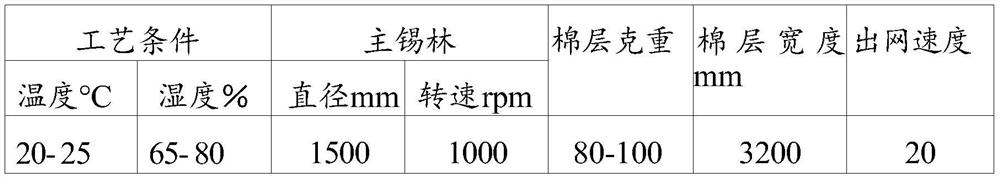

Novel fluid bed drier

InactiveCN107014153APrevent dust leakageProtect the production environmentDrying solid materials with heatGranular material dryingWaste managementProduction area

The invention provides a novel fluid bed drier which comprises an air inlet system, a drying machine body and exhaust systems. The novel fluid bed drier is characterized in that the exhaust systems comprise a drying exhaust system and a dust removing exhaust system, and in addition, the drying exhaust system and the dust removing exhaust system run asynchronously in the working state of a dryer. By means of the novel fluid bed drier, the different exhaust systems are used in drying and discharging correspondingly, outer leakage of dust in a boiling bin is effectively prevented in the discharging process, the production environment is protected, the cleanliness requirement of a production area is ensured, the phenomena that outer leakage of dust exists, boiling exhaust is started, and consequently air balance is affected, and damage is caused to room roofs and walls are avoided, burdens of a system purification air conditioner are reduced, the cleaning and replacing times of an air return filtering net and a system filter are reduced, and economic efficiency and environment friendliness are achieved.

Owner:BEIJING SHOUER PHARMA FACTORY

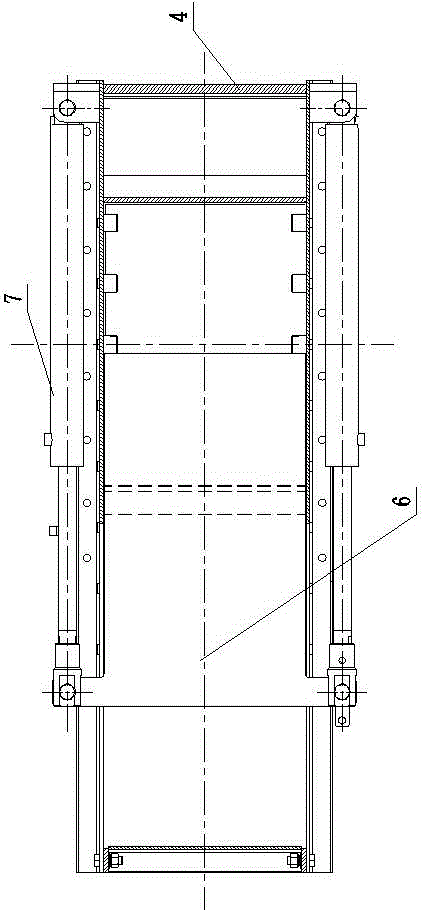

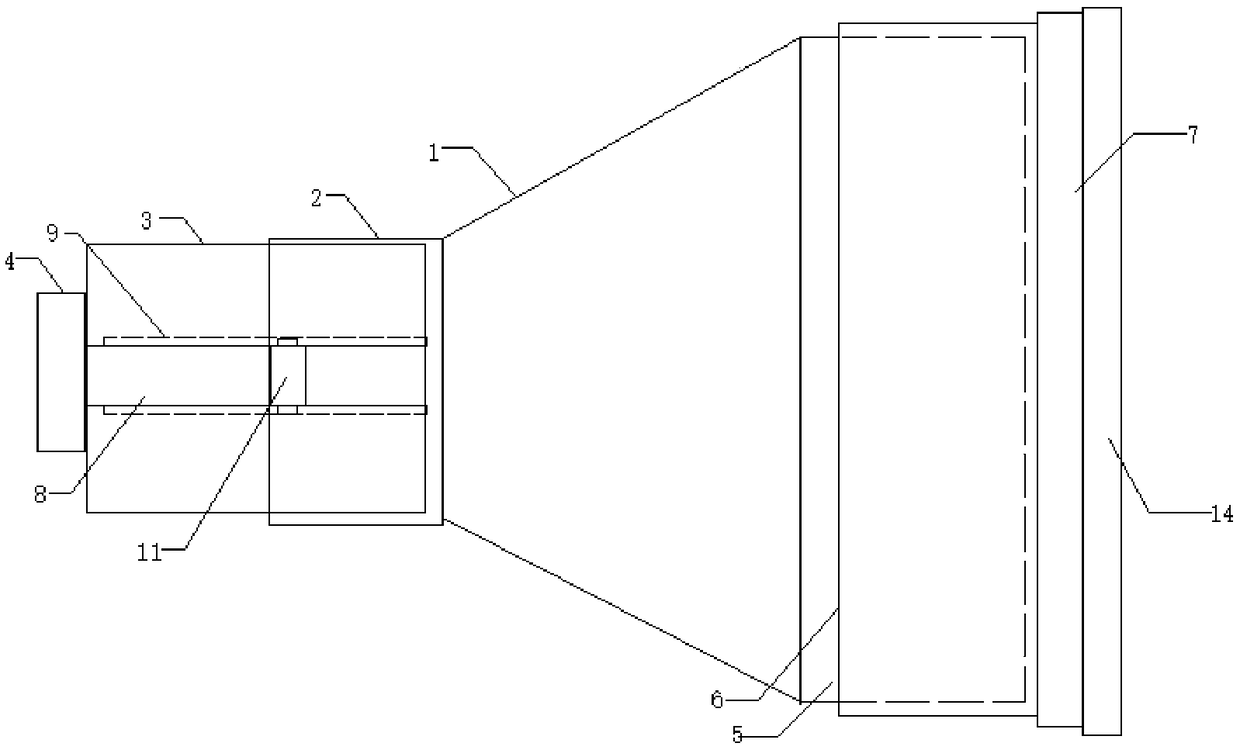

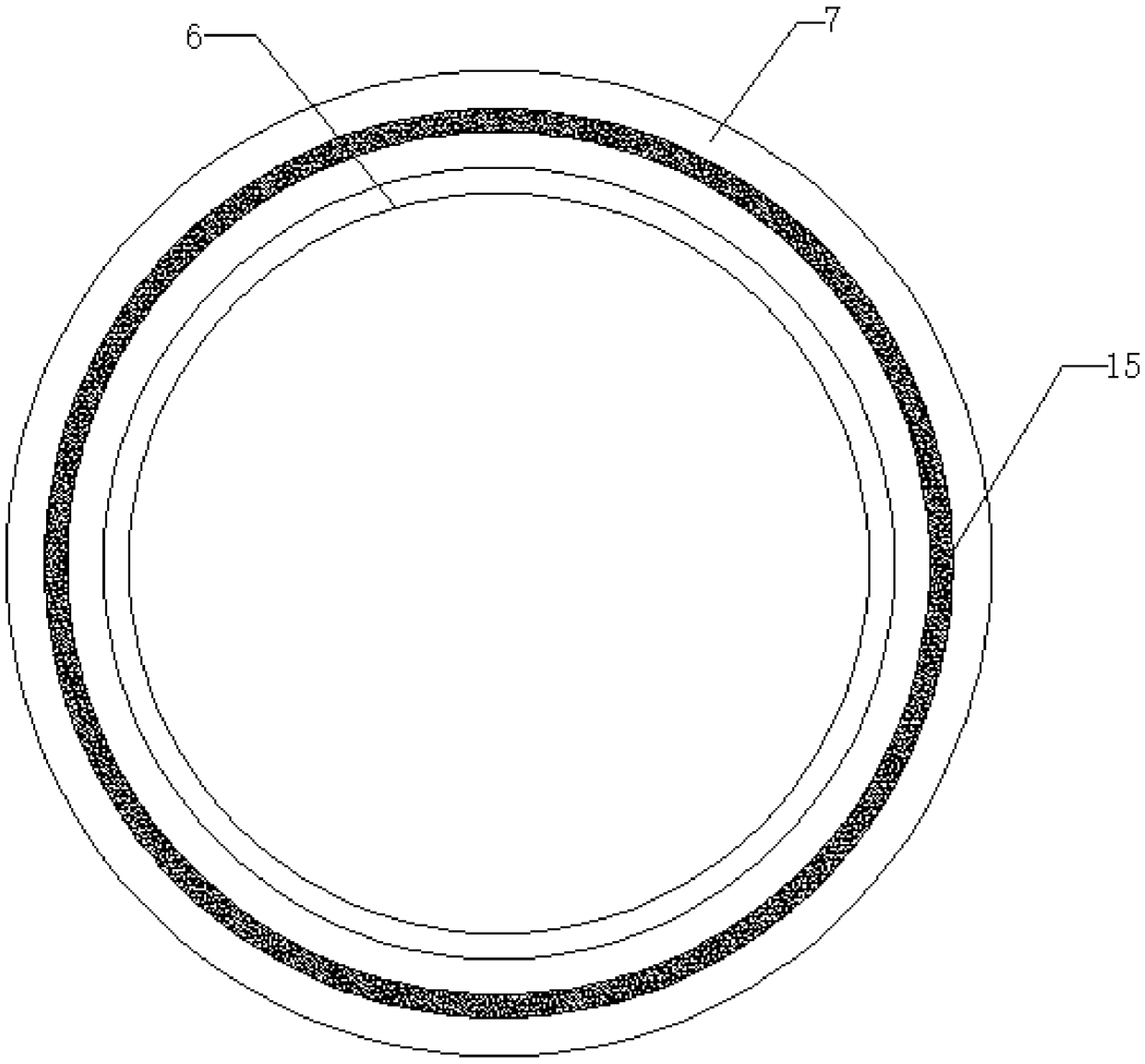

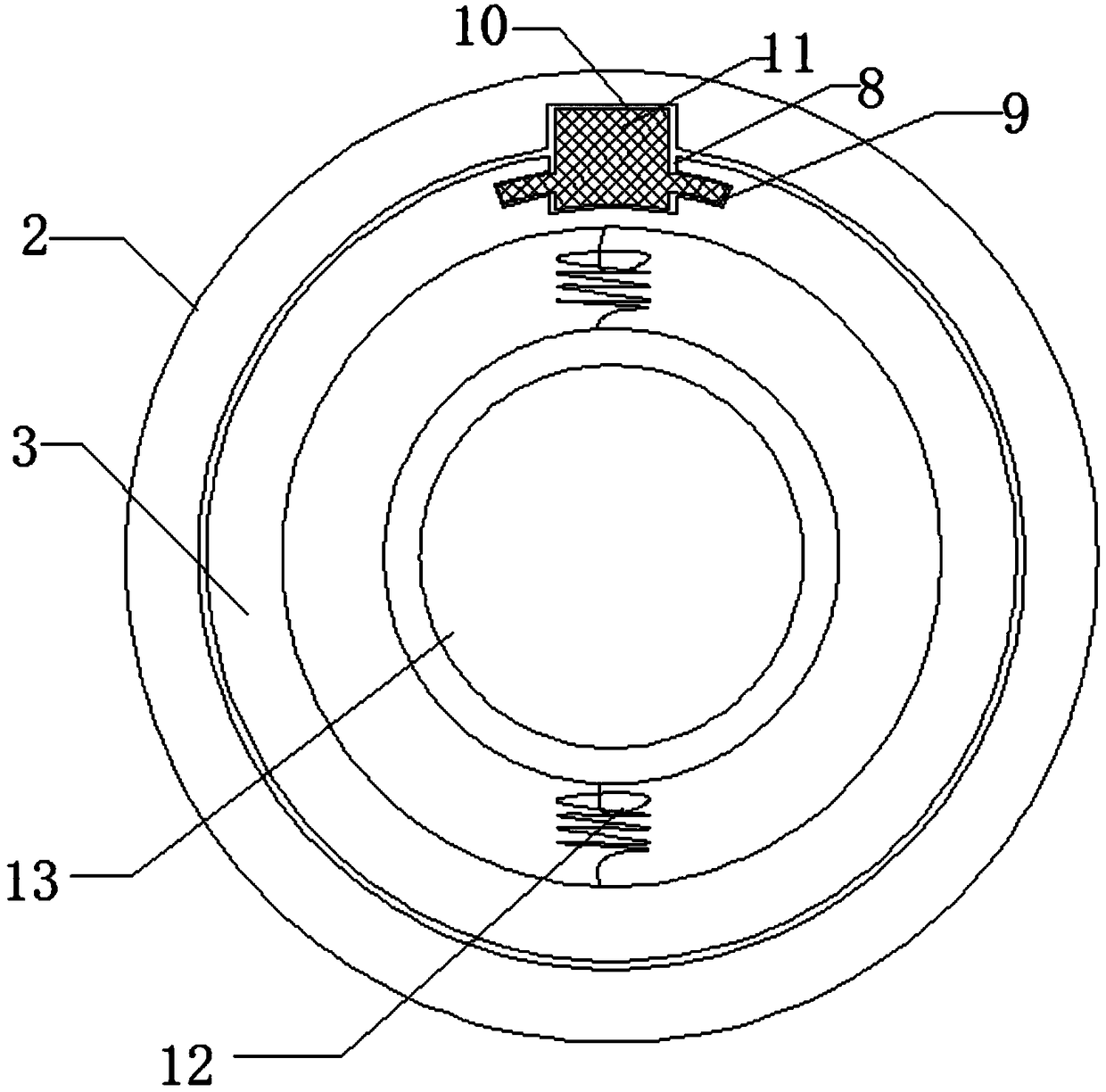

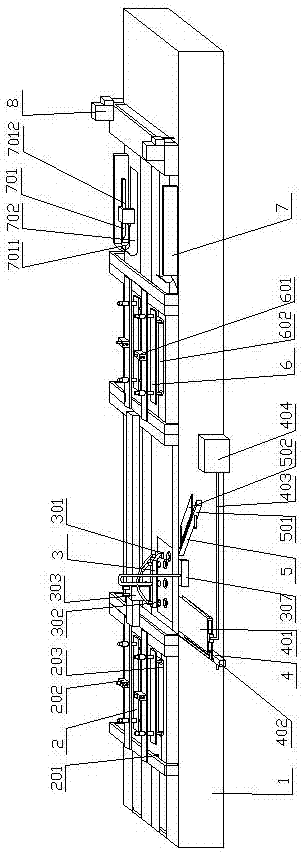

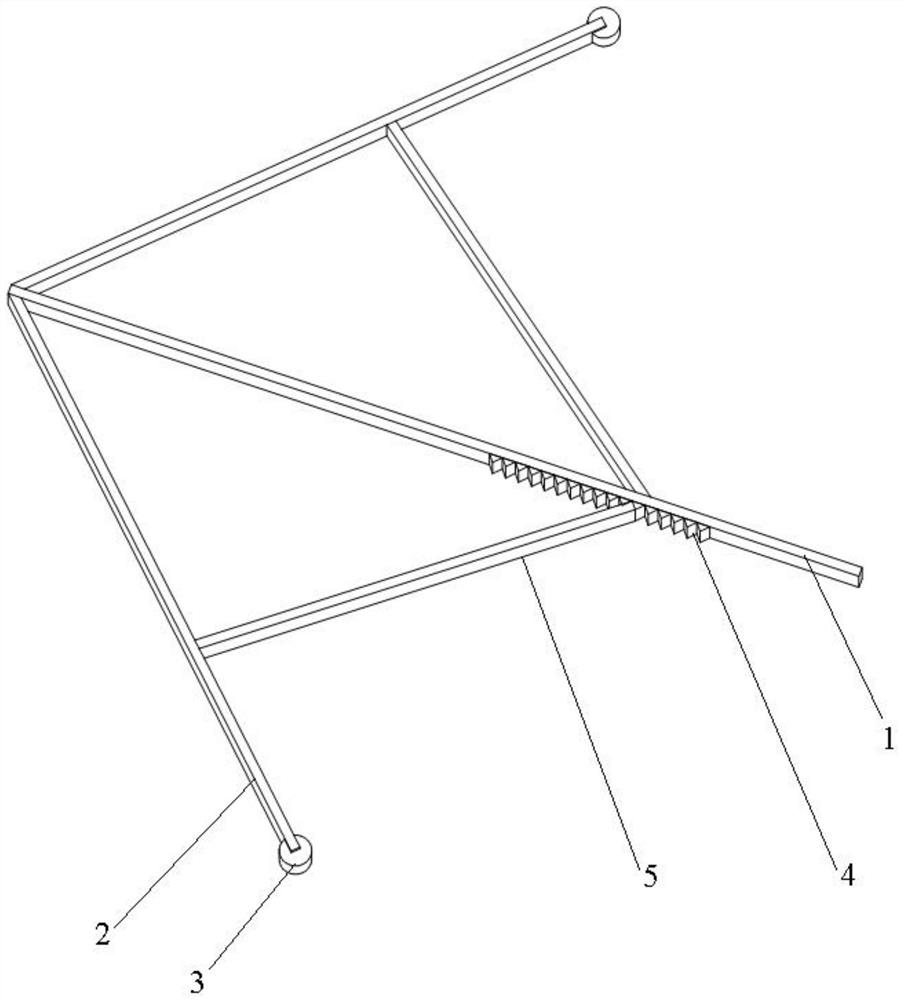

A frame structure of inner tension tail of plate chain bucket elevator

Owner:杭州和泰机电股份有限公司

A kind of positive pressure sealing quick opening cover buried scraper conveyor

ActiveCN106379693BReduce dust leakageReduce dust rateConveyorsPackagingLocking mechanismPositive pressure

A positive-pressure sealing and rapid cover plate opening embedded scraper transporter comprises a head part, a tail part and an intermediate section, all of which are provided with access doors. The head part is provided with a head sealing mechanism, and the tail part is provided with a tail sealing mechanism. The intermediate section is provided with a sealing and rapid upper cover opening mechanism, and the access doors are provided with sealing and rapid viewing door opening mechanisms. According to the positive-pressure sealing and rapid cover plate opening embedded scraper transporter, through well sealing on the shaft stretching-out end of the embedded scraper transporter, the access doors, an upper cover and other places where dust is possibly generated, environment pollution is reduced; and through the improvement on the access doors and an upper cover locking mechanism, rapid cover opening is convenient, and time is saved.

Owner:HUBEI YIDU YIYUN ELECTROMECHANICAL ENG CO LTD

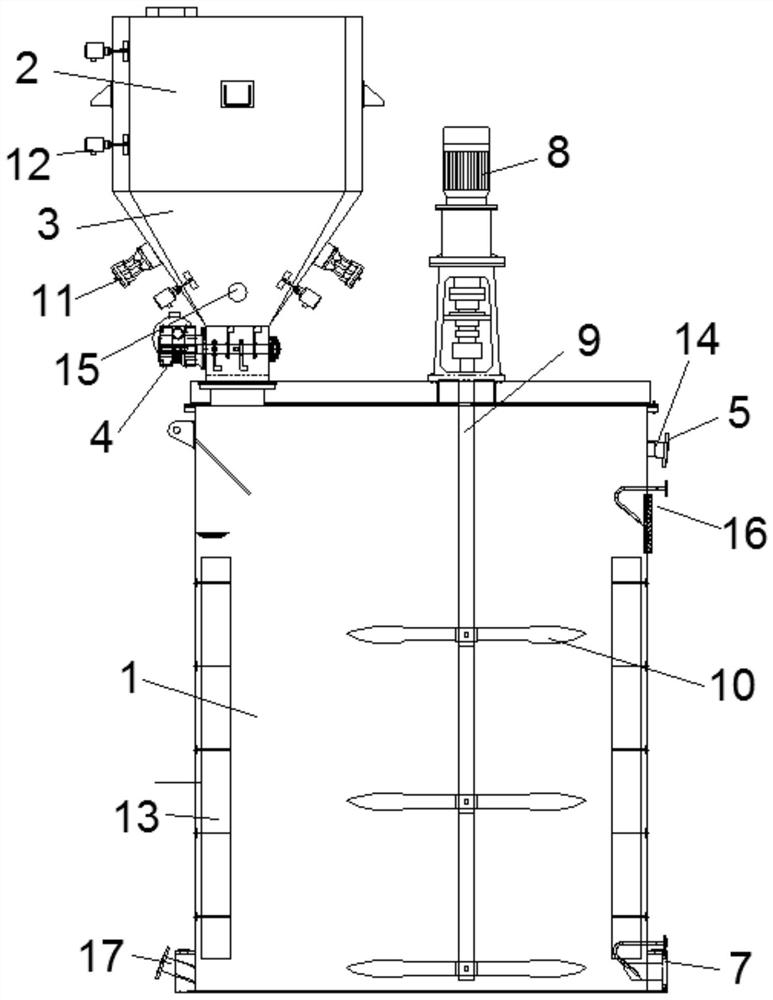

Novel closed salt dissolving device

PendingCN113413795APrevent dust leakageDissolution is achieved quicklyRotary stirring mixersMixer accessoriesElectric machineryFunnel shape

The invention discloses a novel closed salt dissolving device comprising a dissolving tank and a stirring device; a stock bin tank is arranged on the dissolving tank, the stock bin tank comprises a storage bin and a discharging bin which are sequentially arranged from top to bottom, the discharging bin is in a funnel shape, an overflow opening is formed in the top end of the side wall of the dissolving tank, and a discharging opening is formed in the bottom end of the side wall of the dissolving tank; and the stirring device comprises a motor arranged on the outer side of the dissolving tank and a stirring shaft arranged in the dissolving tank, the stirring shaft is connected with the motor, and a stirring paddle is arranged on the stirring shaft. The amount of added crystalline salt can be controlled, a quantitative dissolution mode is adopted, meanwhile, dust leakage during dissolution can be avoided through micro negative pressure in the dissolution tank, the dissolution effect is good, and the efficiency is high.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

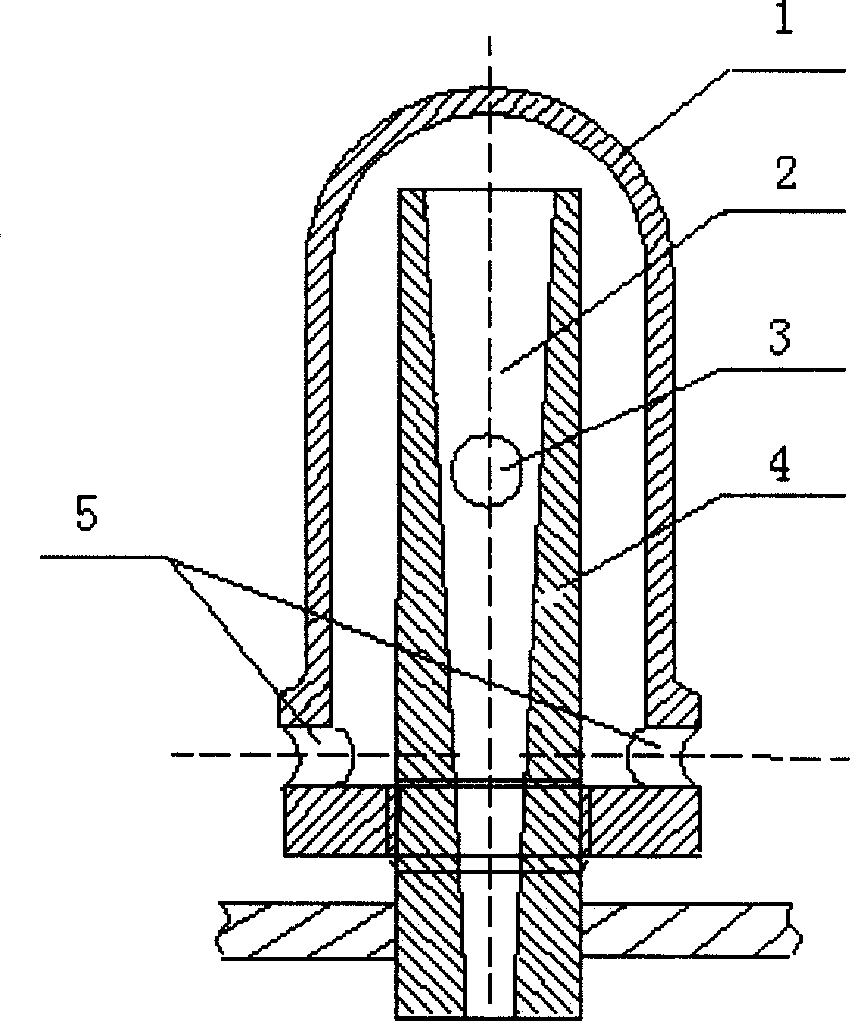

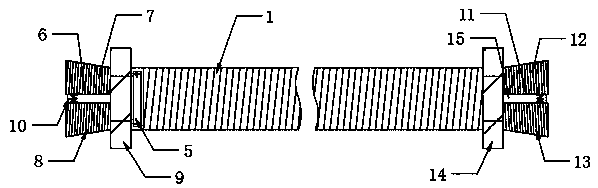

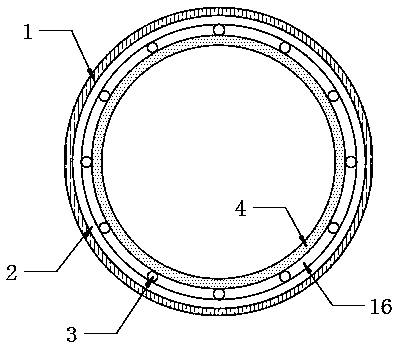

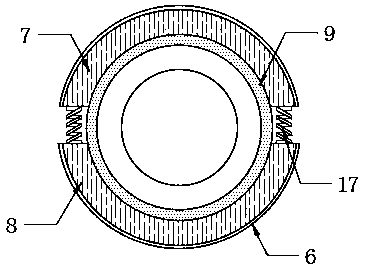

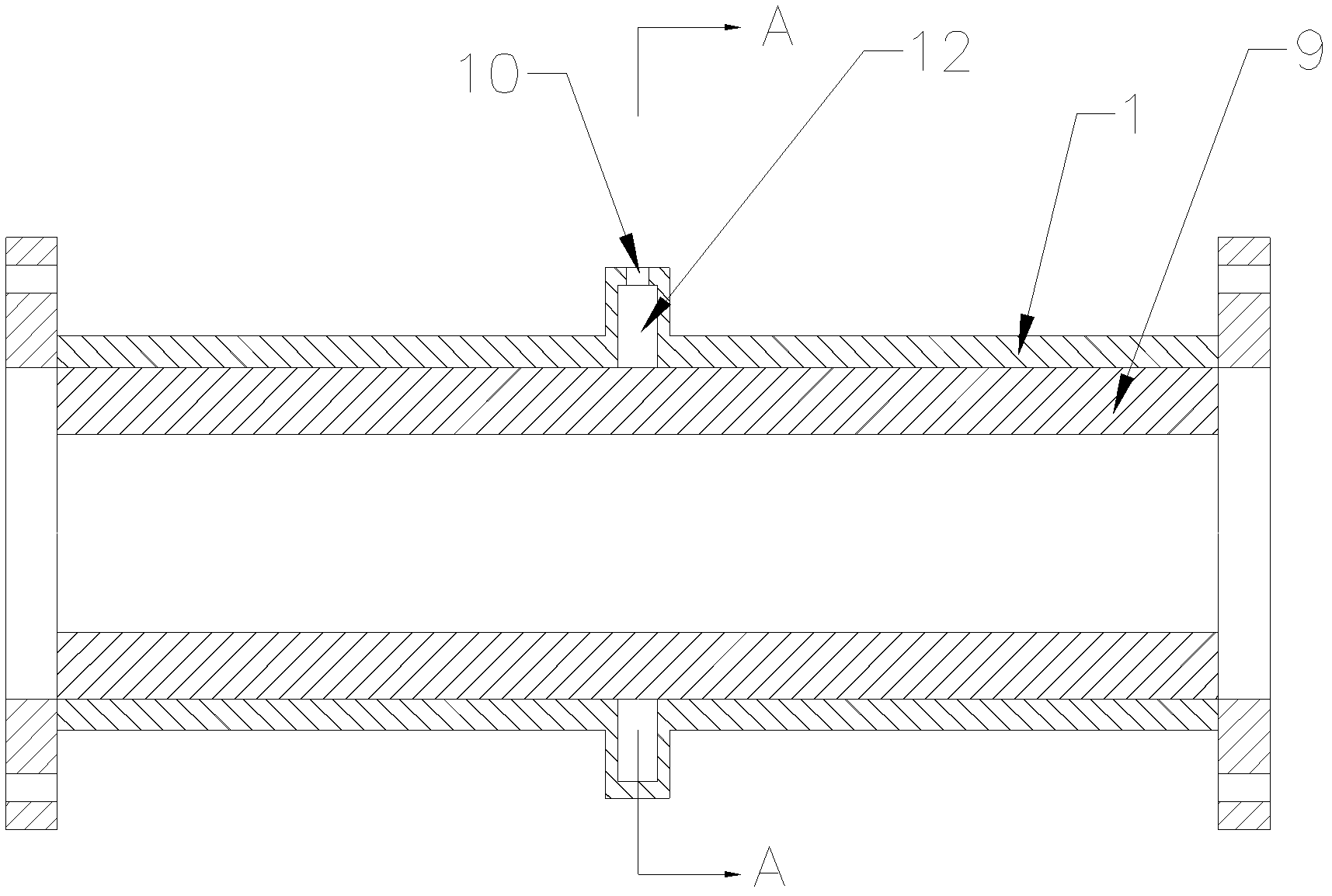

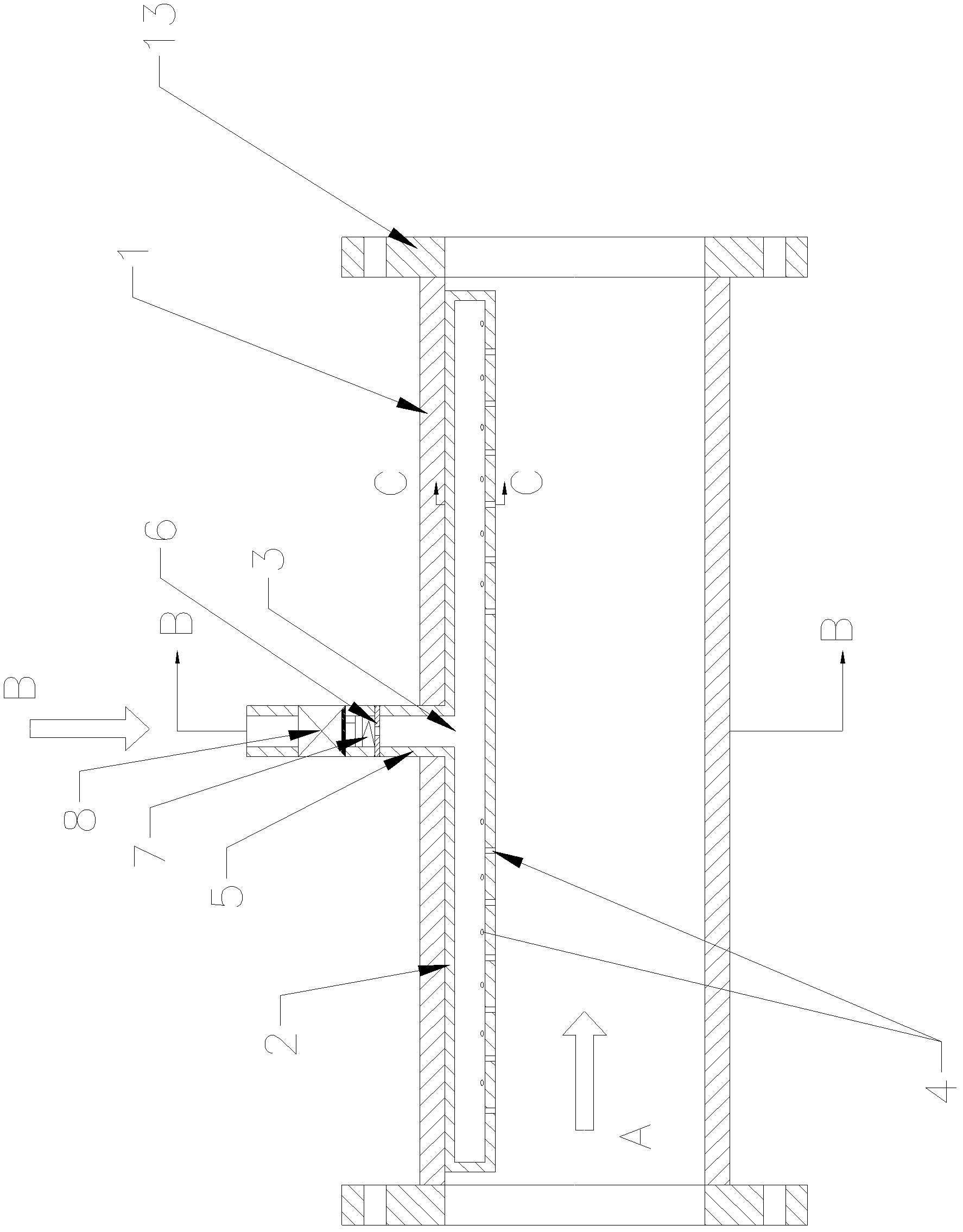

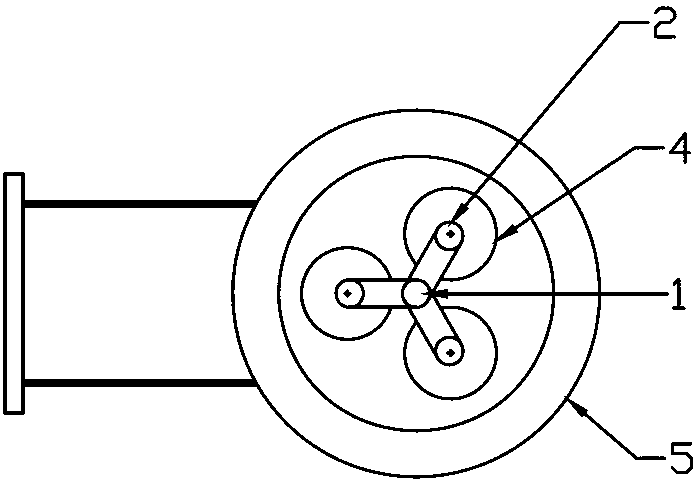

Gas supplementing device and ash removing system comprising same

ActiveCN102380268BUniform pressureReduce wearDispersed particle filtrationProcess engineeringEngineering

The invention provides a gas supplementing device which comprises a gas supplementing pipe (1) and a gas source distribution pipe (2), wherein the gas source distribution pipe (2) is arranged in the gas supplementing pipe (1), and the two ends of the gas source distribution pipe (2) are closed; the two opposite sides of the gas source distribution pipe (2) are provided with a gas inlet (3) and multiple gas source distribution holes (4) respectively; the gas inlet (3) is communicated with the outer part of the gas supplementing pipe (1); the multiple gas source distribution holes (4) are distributed along the axial direction of the gas source distribution pipe (2); and the axes of at least some of the gas source distribution holes (4) are parallel to the axis of the gas inlet (3). In addition, the invention also provides an ash removing system comprising the gas supplementing device. As the gas source distribution holes are distributed along the axial direction of the gas source distribution pipe, annular vortex is not generated, pressure of the gas injected from the gas source distribution holes is relatively uniform, and abrasion of the gas supplementing pipe is reduced, thus the ash leakage of the gas supplementing device is prevented.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Environment-friendly machine for crushing and recycling glass

PendingCN113351312AImprove applicabilityPrevent dust leakageDirt cleaningCleaning using toolsGrindingEngineering

The invention discloses an environment-friendly machine for crushing and recycling glass. The environment-friendly machine comprises a crushing shell, a crushing device, a grinding device, a dust adsorption device and a discharging device, the bottom of the crushing shell is fixedly connected with a supporting seat, the crushing device is arranged at the top of an inner cavity of the crushing shell and fixedly connected with the top surface of the inner cavity of the crushing shell, the grinding device is arranged in the middle of the inner cavity of the crushing shell, the dust adsorption device is arranged at the top of the inner wall of the crushing shell, and the discharging device is arranged at the bottom of the inner cavity of the crushing shell; the outer wall of a grinding ring is fixedly connected with the middle part of the inner wall of the crushing shell, the outer wall of a grinding cone is slidably connected with the inner wall of the grinding ring, the bottom face of the grinding cone is in transmission connection with a driving mechanism, the driving mechanism is arranged on the top face of the discharging device, a conical table is fixedly connected to the top face of the grinding cone, and a material sweeping mechanism is fixedly connected with the top face of the conical table; and the bottom of the material sweeping mechanism is slidably connected with the top face of the grinding ring, and two secondary material crushing mechanisms are arranged side by side and fixedly connected with the top of the material sweeping mechanism.

Owner:KAIFENG UNIV

Fully-sealed environment-friendly bulk material transfer device and method thereof

PendingCN110498177APrevent dust leakageRealize dust-free workStorage devicesMaterial transferMaterial storage

The invention relates to a fully-sealed environment-friendly bulk material transfer device and a method thereof. The device comprises a base, an elevator bracket, a material temporary storage bin bracket and a transfer vehicle, wherein the elevator bracket and the material temporary storage bin bracket are arranged on the base, the material temporary storage bin bracket is arranged on the side part of the elevator bracket, an elevator is arranged on the elevator bracket, at least one material temporary storage bin is arranged on the material temporary storage bin bracket, a plurality of parallel horizontal unloading machine frames are also sequentially arranged on the elevator bracket along the vertical direction, at least one material storage bin is arranged on each horizontal unloading machine frame, and the transfer vehicle reciprocates between the material storage bins and the material temporary storage bin. The fully-sealed environment-friendly bulk material transfer device and the method thereof have the advantages that: the structure is simple and the use is convenient, discharging and receiving devices can be designed into multiple types such as top-down arrangement, bottom-up arrangement and horizontal arrangement according to the process, and the requirements of different working conditions can be met.

Owner:青岛迪凯自动化设备有限公司

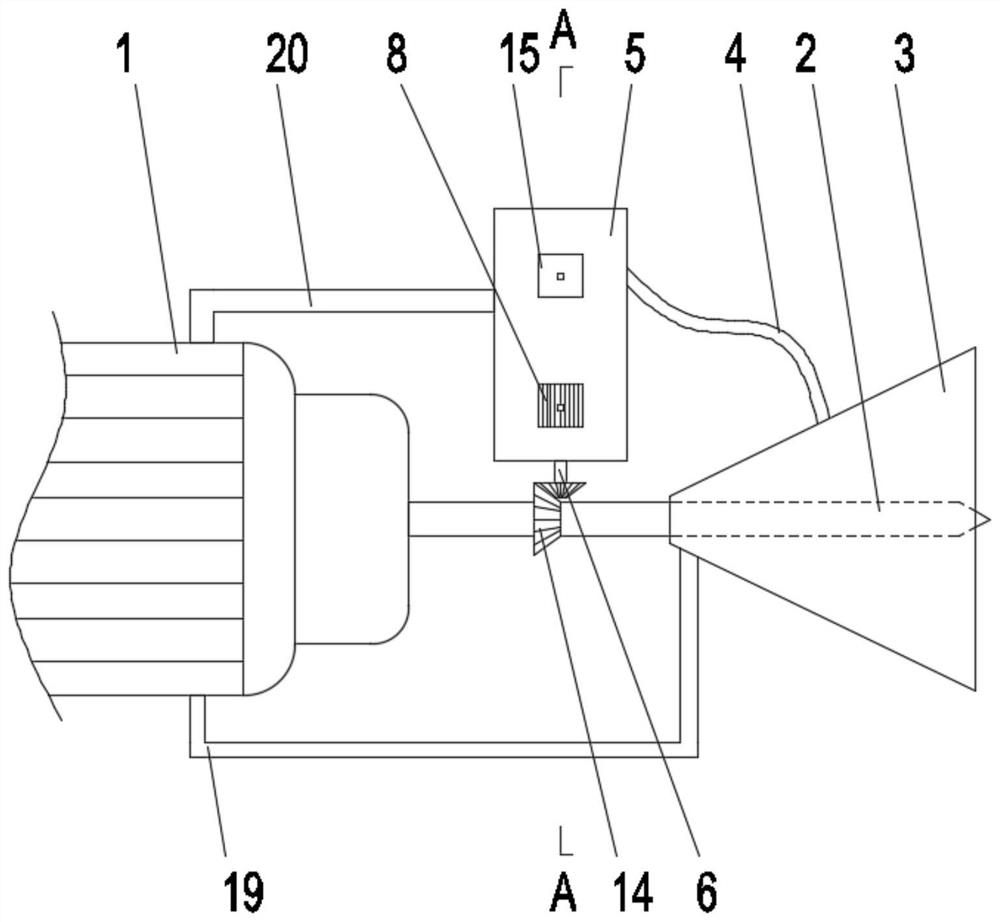

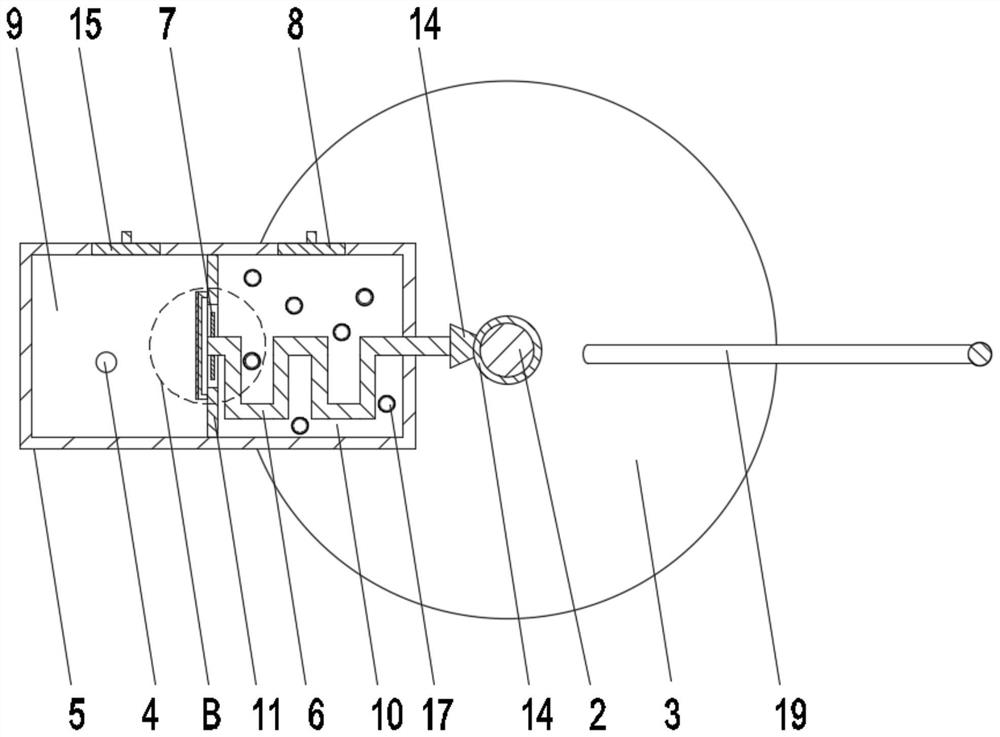

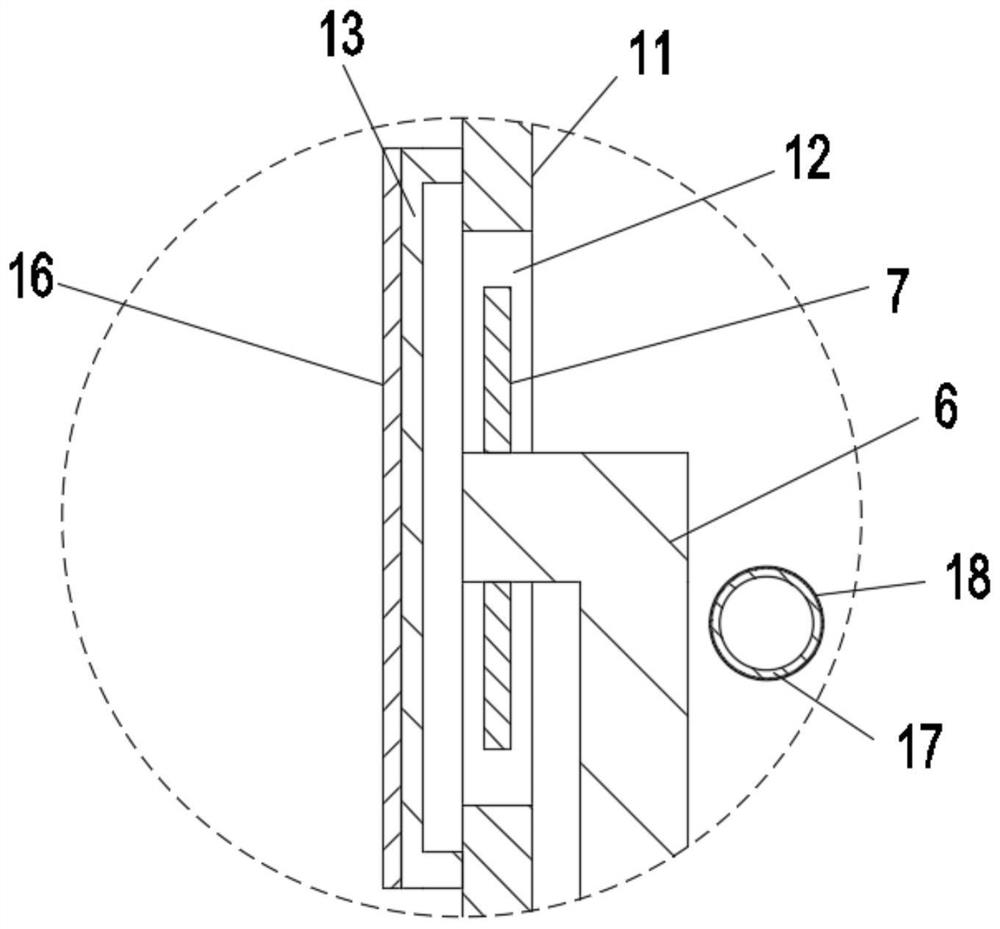

Chain mounting device and method for embedded scraper conveyor

Owner:CHINA FIRST METALLURGICAL GROUP

Handheld electric drill

PendingCN114055637APrevent dust leakagePrevent leakageWorking accessoriesStone-like material working toolsDrill holeMining engineering

A handheld electric drill is used for solving the technical problems that in the background technology, dust is generated in the process that constructors drill holes through a handheld electric drill, the health of the constructors is harmed, and the construction environment is harmed. The handheld electric drill comprises an electric drill body, a dust removal cover and a dust removal assembly, wherein a drill rod is arranged on the electric drill body, the dust removal cover is of an elastic horn-shaped structure, the dust removal cover is fixedly connected with the electric drill body, and the drill rod penetrates through the dust removal cover from the necking end of the dust removal cover and can rotate relative to the dust removal cover; and the dust removal assembly is connected with the dust removal cover through a connecting pipe in a communicating mode, the dust removal assembly is connected with the drill rod through a connecting assembly, and the dust removal assembly is used for sucking and filtering dust along with rotation of the drill rod. The handheld electric drill is simple in structure and mainly used for drilling.

Owner:SICHUAN TAILONG CONSTR GRP CO LTD

PVC powder mixing device and PVC powder mixing method

The invention discloses a PVC powder mixing device and a PVC powder mixing method. The mixing device comprises a high-speed mixing mechanism, a low-speed cooling mechanism, a discharging mechanism and a first communicating channel which are arranged from top to bottom in a stepped mode, whereinthe first communicating channel communicates thehigh-speed mixing mechanism with the low-speed cooling mechanism. The PVC powder mixing method comprises the following steps of conveying powder into the high-speed mixing mechanism for mixing powder at high speed; conveying the mixed powder rapidly into the low-speed cooling mechanism via a first conveying channel, and releasing air intensity generated by the powder entering the low-speed cooling mechanism instantly through the first communicating channel communicated with the high-speed mixing mechanism; and conveying powder cooled by thelow-speed cooling mechanism to the discharging mechanism via a second conveying channel. According to the invention, the mechanism is simple; the production cost is low; a dedusting device is not required to be arranged additionally; the dedusting effect is good; environment pollution is prevented; the working environment and the air quality are improved.

Owner:龙国才

Vacuum cleaner dust-gathering cartridge

The vacuum cleaner dust-collecting barrel related by the present invention is formed from a cylindrical barrel body whose front end is opened and a barrel top set on the barrel body, said barrel body is formed from rear fixed barrel body and front barrel body whose front portion two sides are opened. The described barrel top is composed of rear fixed barrel top and front opened barrel top, and combined together with the correspondent fixed barrel body and front portion two-side opened barrel body respectively. One-edge of every side opened barrel body is hinged with one edge of said fixed barrel body is equipped with an air inlet and an air outlet, said air inlet is positioned in the upper portion of said fixed barrel body, and the air outlet is positioned in the lower portion of said fixed barrel body. Said invention can greatly raise its cdust-collecting efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

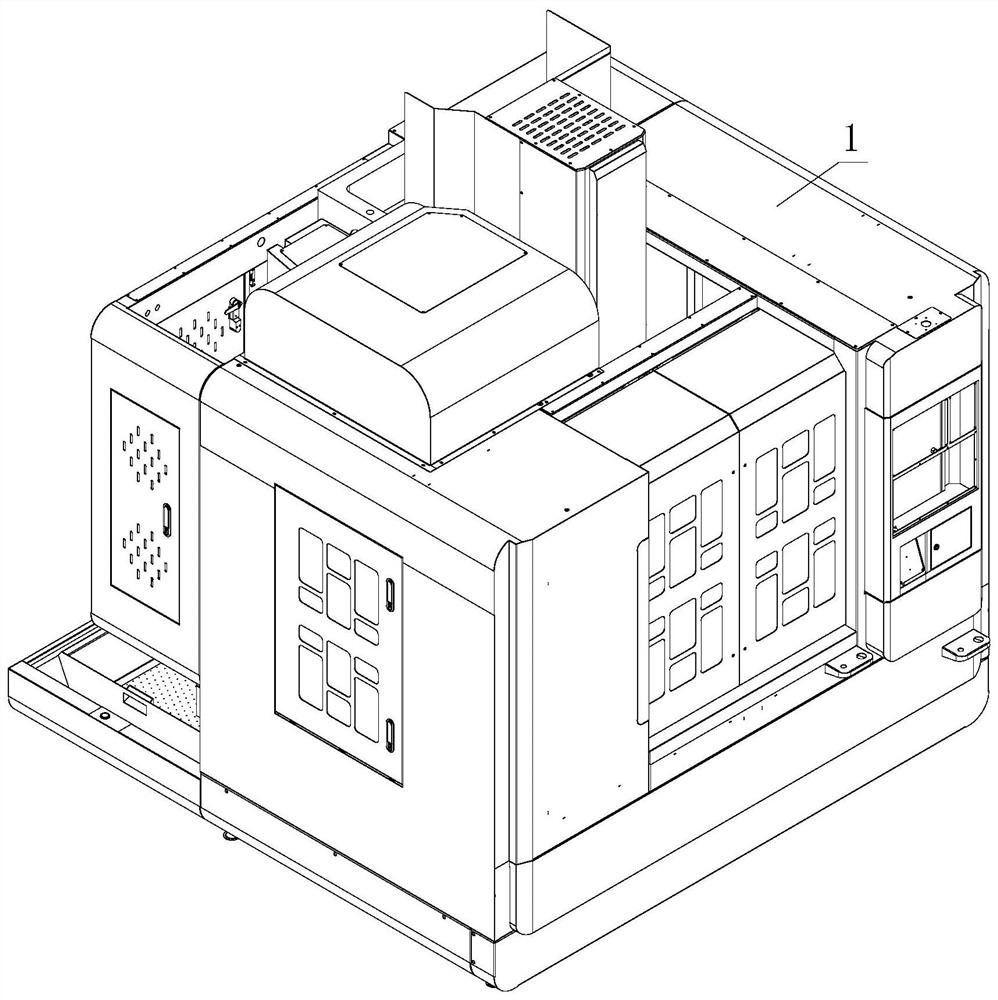

Convenient-to-clean machining platform for vertical machining center

PendingCN111890114AImprove filtration efficiencyPrevent dust leakageCombination devicesMaintainance and safety accessoriesScrapProcess engineering

The invention discloses a convenient-to-clean machining platform for a vertical machining center. The machining platform comprises an outer cover, wherein an outer cover is arranged outside a lathe ina sleeving mode; a machining platform body located in the outer cover is arranged on the lathe, a machined part is arranged on the machining platform body, and cleaning devices are arranged at the side ends of the machining platform body; and the cleaning devices comprise cleaning shells, centrifugal exhaust fans, dust removal purifiers, shutter dust suction ports and dust conveying ports, and the centrifugal exhaust fans are arranged on the cleaning shells. According to the convenient-to-clean machining platform for the vertical machining center, dust is filtered through dust removing and purifying filter elements and then discharged through the centrifugal exhaust fans, and air and the dust are separated, so that dusty gas is purified, and the filtering efficiency is improved; and an iron removing device is arranged in a scrap collecting groove, scrap particles falling from scrap discharging holes are filtered through filtering magnetic rollers, and iron scraps are adsorbed, so thatthe scrap particles are removed and filtered, and the dust clearing and collecting efficiency is improved.

Owner:重庆乔柏智能科技有限公司

Bag isolator for producing carbon

The invention discloses a bag isolator for producing carbon, comprising a pulse electromagnetic valve, a blow-sweep pipe, a fixed frame, a plurality of fitter bags and a guide cylinder, wherein the guide cylinder is a circular tube which is provided with an opening at the lower end and fixedly provided with a branch opening in the side wall of the upper end; the upper end of the guide cylinder is provided with an end cover; the guide cylinder is internally provided with the blow-sweep pipe, the fixed frame and a plurality of filter bags in sequence from top to bottom; the upper end of the blow-sweep pipe is connected with the pulse electromagnetic valve arranged on the guide cylinder after passing through the bottom of the upper end of the guide cylinder, and the lower end of the blow-sweep pipe is provided with openings which are same as the filter bags in number and are communicated with the filter bags; the fixed frame is located below the branch opening of the guide cylinder; and the openings at the upper ends of the filter bags are connected to the fixed frame. The bag isolator is not only simple in structure, convenient to use, low in cost, capable of ensuring sufficient backflow utilization of carbon powder to further ensure the precision of material proportion and very suitable for carbon production enterprises and scientific research institutions for carbon proportioning and material conveying links.

Owner:JINAN WANFANG CARBON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com