Automatic wall building machine

A wall-laying machine and automatic technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of low labor efficiency, manpower and material resources, and complex machines, so as to improve the level of automation, speed up plastering, The effect of improving the efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

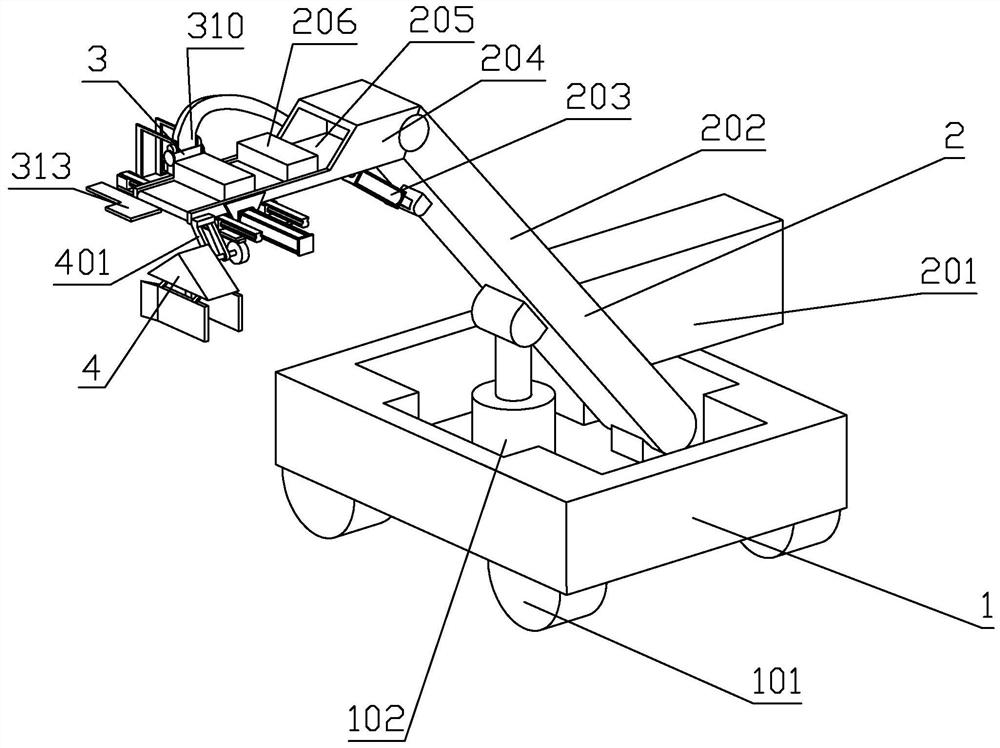

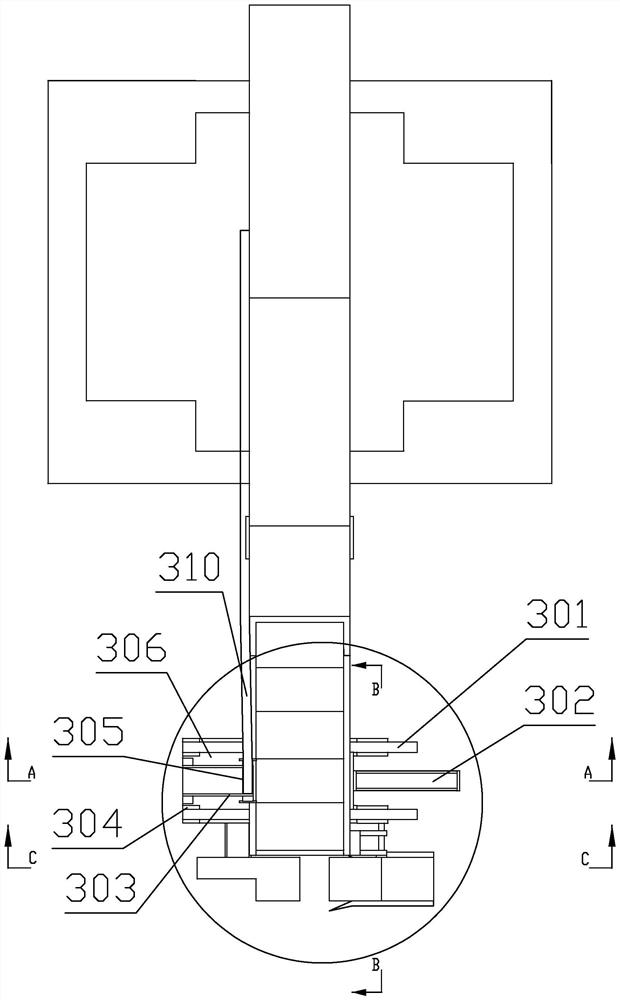

[0027] combine Figure 1-5 , an automatic wall-laying machine, comprising a chassis 1, a plurality of wheels 101 are provided on the side of the chassis 1 close to the ground, a main hydraulic cylinder 102 is provided on the side of the chassis 1 away from the ground, and the output end of the main hydraulic cylinder 102 rotates with the brick feeding part 2 Socketing, the end of the brick feeding part 2 close to the chassis 1 is rotatably socketed with the chassis 1.

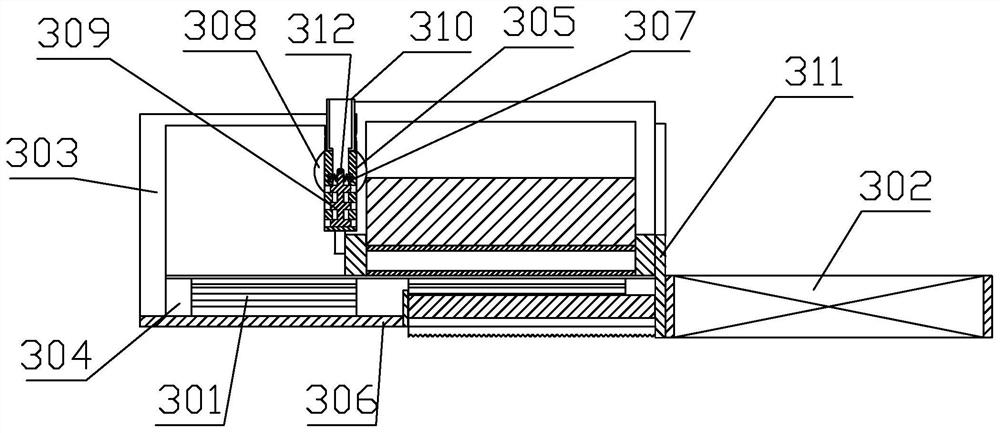

[0028] Plastering part 3, the plastering part 3 is arranged on the end of the brick feeding part 2 away from the chassis 1, and is responsible for evenly applying cement ash on the surface of the brick;

[0029] The adjusting part 4 is arranged on the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com